3D printer prezzo

Carbon 3D Printer Pricing - Carbon

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert to help you select the right printer and tailor pricing based on your needs.

Get a Quote Now

Carbon product offerings and pricing vary by country and region. Please contact a Carbon expert for a quote.

Discover the right Carbon 3D printer for your production needs and budget

Carbon printers come in a variety of models with build volumes and price points to suit your specific needs.

M1 | M2 | M3 | M3 Max | L1 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5. | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 307 x 163 x 326 mm 12.1 x 6.4 x 12.8 in | 400 x 250 x 460 mm 15.7 x 9.8 x 18.1 in | |

|---|---|---|---|---|---|---|

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 160 µm; 25, 50, or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 µm+ 1 µm per mm dimension size Up to ±0.  0026 in + 0.001 in per in dimension size 0026 in + 0.001 in per in dimension size | Coming Soon | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.002 in | Coming Soon | Up to ±40 μm Up to ±0.002 in | |

| Explore M1 | Explore M2 | Explore M3 | Explore M3 Max | Explore L1 | ||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

Need Pricing for Your Part?

Not in the market for a printer but want to understand pricing for your part? Get a quote from a certified Carbon production partner. These manufacturers are certified experts in the Carbon DLS 3D printing process––from design to production.

Get Part Pricing

Carbon 3D Printer Pricing FAQs

How much does a Carbon 3D printer cost?

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert now to help you select the right printer and tailor pricing based on your needs.

Contact a Carbon Expert

“The subscription model is beneficial as we are able to make payments over time versus one large capital investment. This enables us to keep costs down and allows for the flexibility to add more printers as the division grows.” Nick Windlow Smile Shapers, Director of Business Development

Why are Carbon 3D printers offered as a subscription?

We focus on helping you succeed in delivering better products in less time–not on selling you equipment. We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

Advantages of the Carbon subscription

-

A partner committed to your long-term success instead of a one-time printer sale.

Paying upfront for a printer puts all the performance risk on you as the customer for your success. We believe in our technology and approach enough to share the risk to ensure you are successful. Instead of paying us upfront for equipment, you pay us as you use it. If we don’t deliver exceptional value, you won’t renew your subscription.

-

Flexibility in your capital equipment investments.

Carbon subscriptions can vary in length depending on your needs.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer. -

Updates, maintenance, and support are included.

Owning a printer means you own maintenance and upkeep. With Carbon, we handle maintenance and we routinely upgrade printers with new software to improve your printers’ performance. Carbon printers have a track record of consistent, reliable and accurate production over time. We maintain them and ensure excellent uptime so that you can focus on developing and producing great products.

The value of a subscription model for connected 3D printers

| Traditional Ownership of Non-Connected 3D Printer | Subscription Model for Connected 3D Printer | |||||||

|---|---|---|---|---|---|---|---|---|

| Continual platform improvement | Gradually becomes obsolete after date of purchase | Improves over time with over the air updates every few weeks | ||||||

| Immediate support for new materials | Purchase separately or available on new version | Included* | ||||||

| Integrated technical support | Purchase service package separately | Included | ||||||

| Minimal unplanned downtime | Not connected, resulting in slower response time | Real-time customer support | ||||||

| Predictive maintenance to optimize machine uptime | Lagged service response time halts production efforts | Preemptive troubleshooting by Carbon keeps machines running | ||||||

* Exceptions include additional hardware costs for specific materials, e. g., RPU 130 and EPU 41 Black. g., RPU 130 and EPU 41 Black.Learn more about our subscription pricing model. | ||||||||

What happens after my subscription term is finished?

Once your subscription has finished, you have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Can I upgrade my printer during my subscription term?

Yes, you can upgrade your 3D printer during your Carbon subscription term.

What types of platform improvements can be expected?

Gain access to the latest software tools and support for new materials

Improvements to the Carbon platform add new features and capabilities in design and automation, fleet and factory management, and printing and post-processing. These updates can instantaneously deliver improved print outcomes, better workflow management, new design capabilities, and seamless support for new resins. See our recent platform improvements here.

What makes Carbon technical support so great?

Real-time customer support with predictive maintenance

Our connected 3D printers offer streamlined, remote troubleshooting and accelerated customer support. By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

Ready to Get Started?

Speak with an expert to learn more about how Carbon can support your product development process at every step, from concept to mass production.

Contact a Carbon Expert

Get a Free Sample Part

There’s no substitute for holding a 3D printed part in your hand. Experience the quality of Carbon DLS-printed parts by requesting a free sample part below.

Request a Free Sample Part

Get Your Parts Made

Not in the market for a printer but still want Carbon DLS-printed parts? Find a certified Carbon production partner to get your parts made. These manufacturers are certified experts in the Carbon DLS 3D printing process—from design to production.

Find a Carbon Production Partner

Find a Carbon Dental Outsource Partner

Carbon 3D Printers

The L and M Series printers and Smart Part Washer offer versatility and enable scalable manufacturing.

Learn More

Materials

Find the right material for your project, from consumer product elastomers to high-temperature automotive materials.

Learn More

Carbon Design Engine

Design high-performance conformal lattices to improve product performance and speed up print time.

Learn More

Eazao - Ceramic 3D Printing

Matirx ——This is our third generation ceramic 3D printer project.

out-of-the-box

Eazao Zero is ready to use out-of-the-box, the whole machine arrives fully assembled. That means you don’t have to waste time reading manuals and putting parts together.

No Air Compressor Needed

To make it more user-friendly for beginners, we developed electric putter instead of compressed air to guarantee outstanding printing quality and stability for prints.

Eco-friendly Printing Material

Eazao can print a variety of materials such as pottery clay and porcelain clay, which is much more Earth-friendly than traditional plastic FDM printing materials.

Print up to 28” in height, multi-materials and air chamber extruder. Matrix is the ultimate next-generation 3D printer for pottery, creative construction and education.

Buy Now

Now we present a truly next-generation ceramic printer, the Eazao Zero has arrived. Eazao Zero is easy to use, produces brilliant ceramics, and features all the upgrades that our community asked for. Get ready for an incredible ceramic 3D printing experience that turns your home into a custom pottery studio.

Buy Now

Eazao Bio is a machine for micro-fluid 3D printing in the laboratory. It is equipped with a 30ml standard material tube, and 3D printing experiments can be carried out with a minimum of 5ml material. And the direct extrusion methodhas better compatibility with materials.

Buy Now

The Eazao Mega 5 is our largest 3d Clay printer with a 32bit operating system, full-color touch screen, dust resistance module, and a massive build volume of 370 x 390 x 470mm.

Learn More

More affordable, you can upgrade your FDM printer to a ceramic 3D printer using this Air kit.

Buy Now

Using this kit, you can upgrade your FDM printer to a ceramic 3D printer.

This kit is suitable for all FDM open-source 3D printers.

Buy Now

Compare with othersThis is the most recent addition to my equipment, sent by the Chinese company for me to have a look at. Much the same size as my original JK Delta this has a screw/auger printhead and clay delivery is via compressed air or mechanical ram. I have used it for doing a bunch of tests and it works well.

Jonathan Keep

Artist potter

The Eazao is a kickstarter, so do your own research before giving money. I personally wanted to play with ceramics enough that I backed their first kickstarter and I was happy to see this one appear. The Cerambot Eazao is a new 3d printer specifically for ceramics. For more information: https://youtu.be/56Cv3HEnIvQ

For more information: https://youtu.be/56Cv3HEnIvQ

Caleb Kraft

Maker

Backers ReviewLatest Release

If you encounter any problems during use, you can find answers in FAQ and BLOG.

Our blog

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited quantities. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

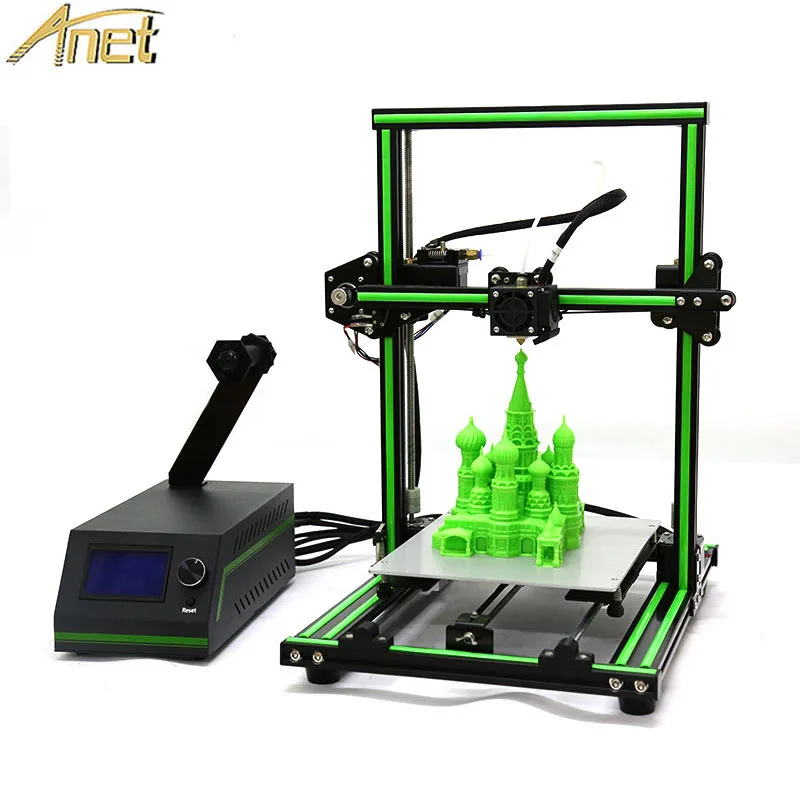

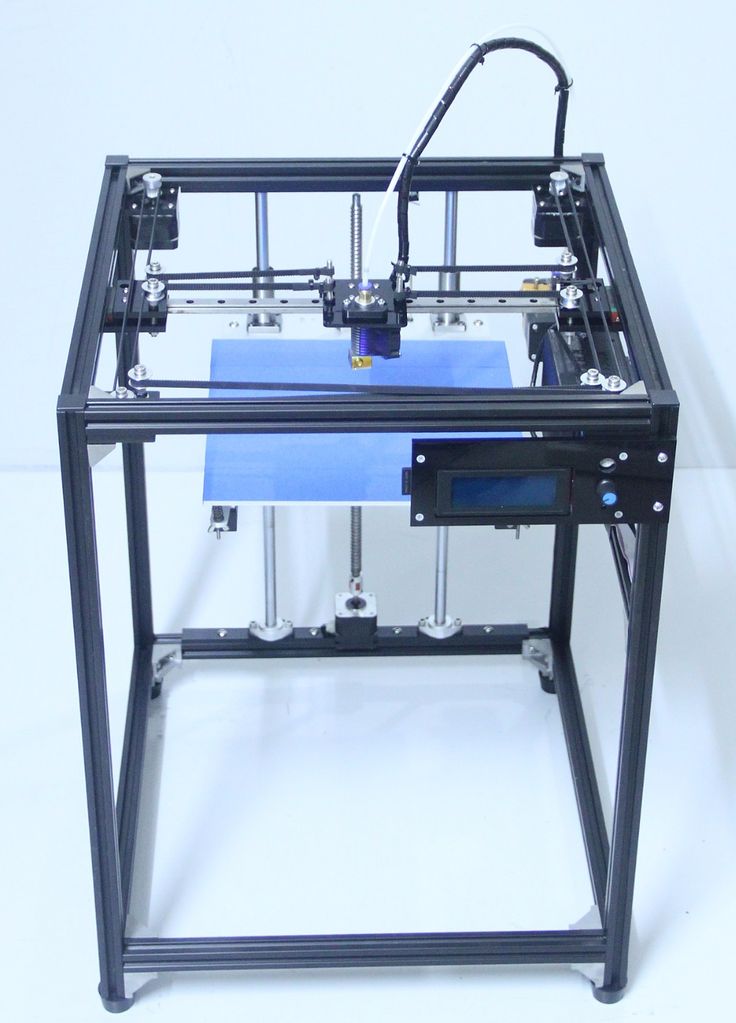

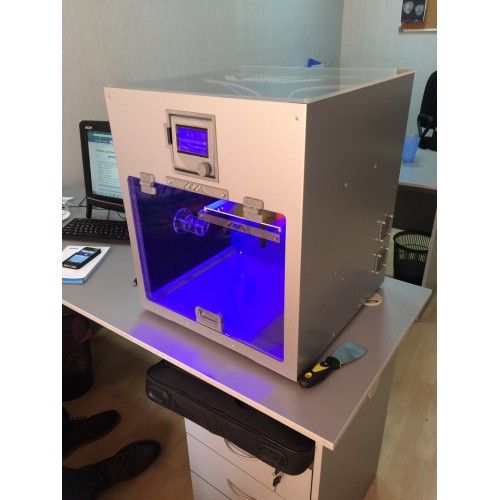

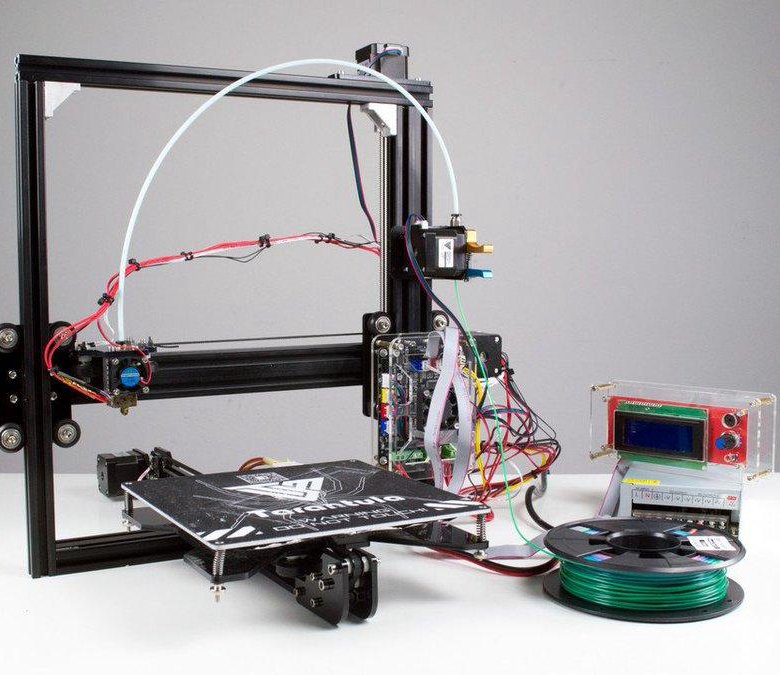

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

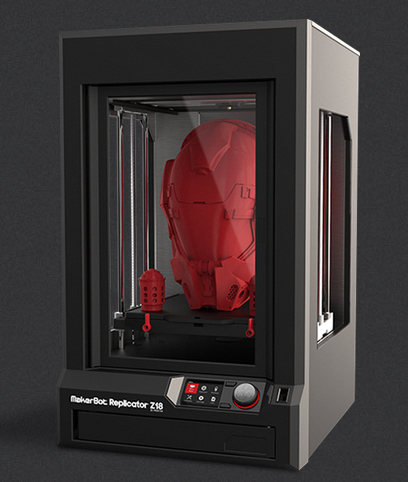

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

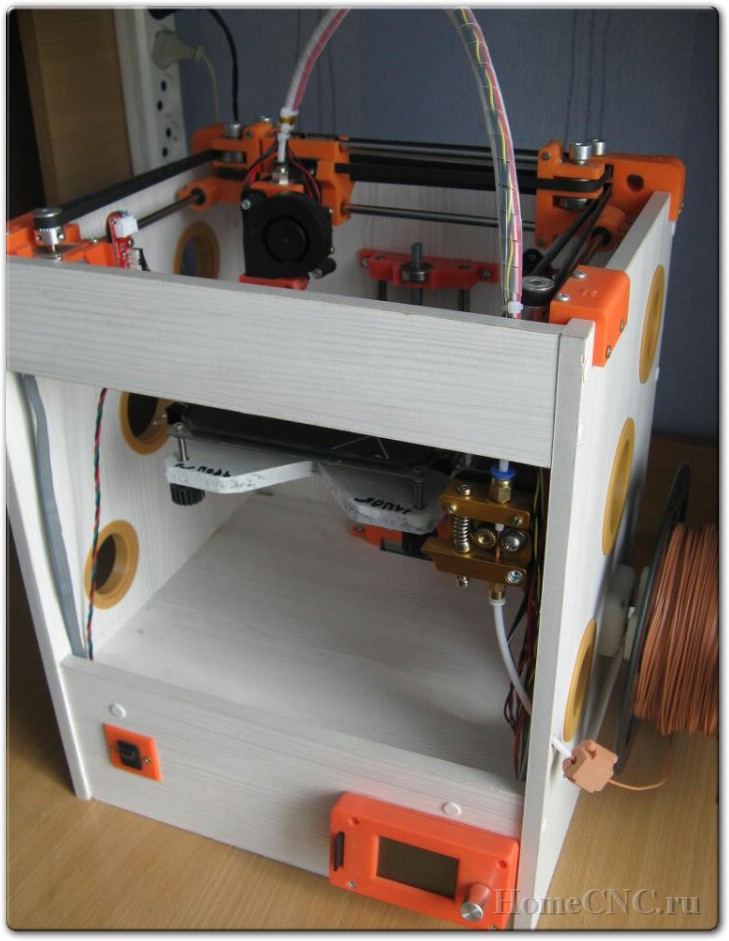

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

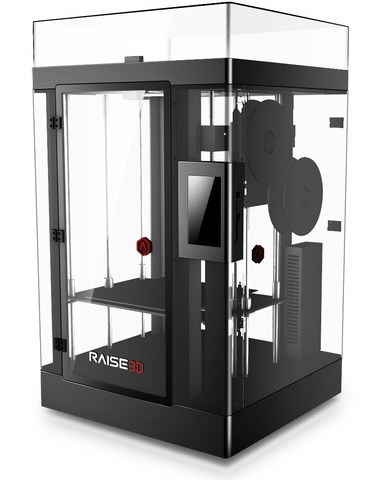

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

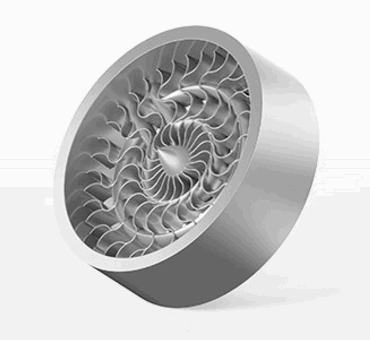

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Direct Metal Sintering (19008) 9008 | |

|---|---|---|---|---|---|

| Permission | ★☆ | ★ opa ★ ution | ★ opa | ★cle | ★cle ★ MyQUTION | SUMPLE | 1112 HICE | ★ opa ☆ | 1111111 ☆☆☆ | 1 ☆ | ★ opa |

| Ease of use | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | US$100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one particular model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to 3rd party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes.

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.

Usually, calculating cost per part, lead time, and comparing alternatives to see if a solution is right for your business is a tedious task of creating a complex spreadsheet in an attempt to collect all of the often hidden information from a manufacturer.

Use our simple online tool to calculate cost per model and order lead time when printing with a Formlabs stereolithographic 3D printer and compare time and cost savings with other manufacturing methods.

Calculate the cost and time

How much does a 3D printed house cost?

3DPrintStory News How much does a 3D printed house cost?

Every new innovation comes to market with a price. For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices.

Since there are a number of 3D printed building projects around the world, it is impossible to give an exact price for a 3D printed house. Instead, we'll take a look at some of the most recent and promising projects and their prices.

However, in general, jumping ahead a bit, you'll see that a 3D printed house can cost as little as $10,000, sometimes less. Let's take a look!

Example 1. House Apis Cor

One rather promising project from Russia. Apis Cor is a Russian company that specializes in the development of a mobile 3D construction printer capable of printing entire buildings on the spot.

Apis Cor built a 410 square foot home to showcase the potential and capabilities of its mobile 3D construction printer. The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house.

The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house.

Here is a more detailed list of costs, according to the company's website:

- Foundation: $277

- Walls: $1624

- Floor and roof: $2434

- Electrical installations: $242

- Windows and doors: 242 $

- Exterior: $831

- Interior (including stretch ceiling): $1,178.

The company even decorated the house both inside and out. The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like.

Example 2. ICON - house for less than $4,000?

Look at the picture above. This house was 3D printed by Texas-based ICON.

ICON specializes in low cost building solutions, so their main project is a 3D printed house.

In partnership with the non-profit organization New Story, ICON plans to build an entire block of these affordable 3D printed homes in El Salvador. The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions.

A prototype 3D printed house cost about $10,000, but the company claims it can bring that down to $4,000, which is amazing and impressive news. The approximate assembly time for such a house from ICON is approximately 24 hours.

Example 3 Winsum - 10 houses in one day

Winsun from Shanghai became famous in 2014 by reaching the 3D printing milestone of 10 houses in just one day!

Winsun used large concrete 3D printers, 10 meters wide and 6.6 meters high. The company said that each 3D printed house costs $4,800, which is surprisingly low for 2014!

Although Winsun's 3D houses are not so exquisite, they have generated a lot of public interest. This project has definitely contributed to the increase in the number of houses made with 3D printers and the development of 3D printers themselves for their production.

Winsun is also known for producing one of the most advanced 3D printed buildings to date, which we will discuss in the next section...

Example 4 Office Building in Dubai in the world, printed on a 3D printer. What it is? Beautiful and futuristic office building in Dubai.

The entire 3D printing process took Winsun only 17 days. Up to this point, we have mentioned fairly cheap 3D printed houses, but this building was clearly more expensive - around $140,000. However, compared to what it would have cost had it not been 3D printed, the final price is impressively low.

Conclusions

As we mentioned above, it is difficult to give an exact price for 3D printing at home, since the price depends on the size and complexity of the design.

But keep in mind that these days you can 3D print a house for as little as $4,000. This price covers the frame of the house (base, walls, roof) and, in some cases, wiring.

As you may have noticed, the cost of an office building in Dubai is quite high compared to cheaper and smaller 3D printed houses.