Louis vuitton 3d printing

Case Study: How Louis Vuitton Uses 3D Printing

Explore how fashion authority Louis Vuitton uses 3D printing to increase productivity and expand their creative process.

Posted on October 6, 2017

by

Scott Cahoon

Recently, manufacturing has experienced a radical transformation. Large, capital-intensive production lines fabricating thousands of the same parts or components have evolved to smaller, nimbler facilities fabricating small batch, customizable products and assemblies. The “go to” product for these newer facilities is the desktop 3D printer. To see this process in action, look no further than Louis Vuitton and the production of consumer products. Join us to discover how products that we use on a daily basis are being impacted by this new paradigm.

Abstract

The method of transforming raw materials into finished products has been part of civilization since man first began wielding tools. It is only in recent history when machines and processes came to bear that modern industrial production began to take root. When one thinks today of manufacturing, large footprint, open factories with robotics and huge production machinery come to mind. It is only within the last couple of decades that a fundamental shift and a new way of thinking has taken root that is set to transform how modern products are made.

Much of this change has been driven by the insertion of technology. However, another driving force is the consumer’s desire for unique, customizable products. In the eyes of the consumer, average, run of the mill products do not always make the grade. The consumer now desires a more intimate connection and experience with the product and this is a result that most mass production runs are not able to provide.

To address this need, companies such as Louis Vuitton have implemented modular techniques where production is organized around customizable batch processes to take advantage of new technologies and deliver products on an as-needed basis. Many of these technologies such as milling machines and 3D printers are now able to fit comfortably on desktops and can be easily configured onto moveable workstations to insert along flexible production lines. This provides a broad menu of capabilities set on an otherwise small physical footprint.

Many of these technologies such as milling machines and 3D printers are now able to fit comfortably on desktops and can be easily configured onto moveable workstations to insert along flexible production lines. This provides a broad menu of capabilities set on an otherwise small physical footprint.

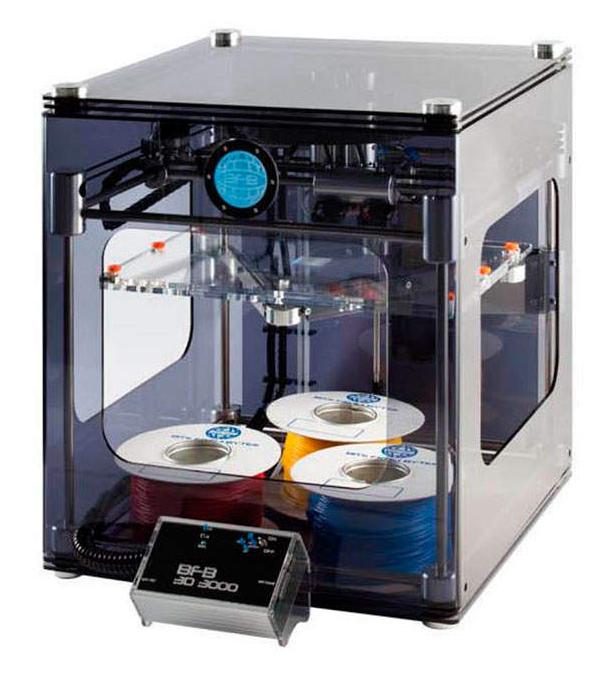

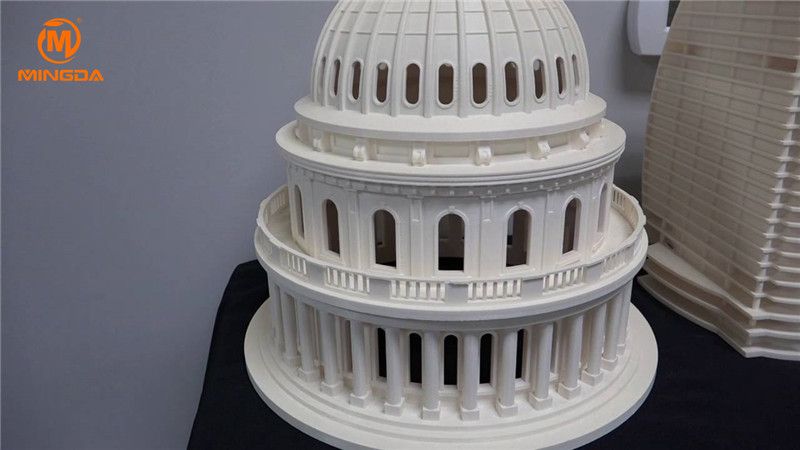

One capability in modular production that cannot be understated is the use of desktop 3D printing (see Figure 1). Desktop 3D printing is a mainstay on the product design, iteration and prototyping side of the business. Now, this capability is slowly making inroads downstream to include the fabrication of jigs, fixtures, molds and end components. Previously jigs, fixtures and molds could only be produced by tooling and injection molding before implementation. This process was not only time inefficient, but added additional cost to the production line. Now, these components may be easily designed, produced and placed on the production line, often in less than 24 hours. This not only increases efficiency and flexibility, but lowers unit costs.

Figure 1: The BCN3D Sigma R17 desktop 3D printer

Louis Vuitton is now able to leverage the use of 3D printing technology worldwide. Desktop 3D printing allows engineers and manufacturers at each location to explore and to be creative in designing new and/or improved production processes. New production techniques utilizing 3D printing are easily researched, implemented or discarded at minimal additional cost. This information is then shared and collaborated on with all manufacturing personnel worldwide. This allows for smooth transitions in new set-ups and modifications of production lines going into each new season.

Louis Vuitton has always been the leader in producing quality, luxury products that consumers regularly patronize. To continue this long-standing tradition, Louis Vuitton personnel are constantly searching for new and improved ways of delivering these products to the consumer. The use of new technologies, to include desktop 3D printing, will continue to be an indispensable tool in its quest to remain one of the world’s iconic brands.

Introduction

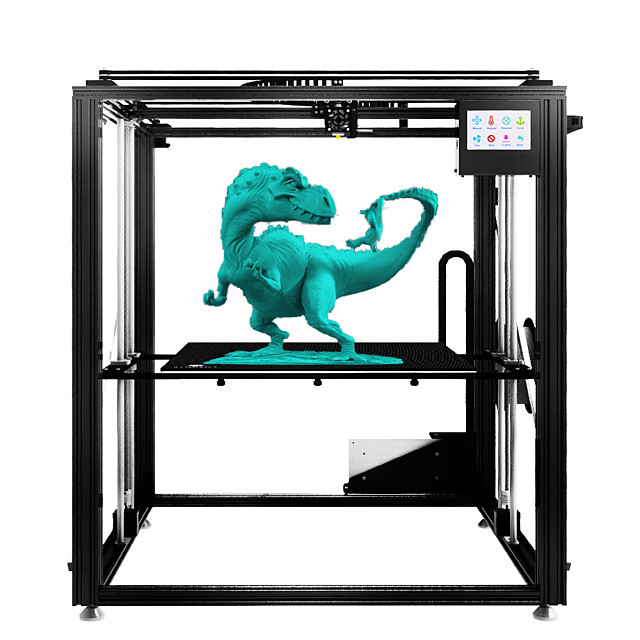

There has been much speculation about the future of desktop 3D printing and if the technology will change the way products and parts are produced. The hype phase has passed and has given way to uncertainty among many users and those peering in from the outside. While many are focusing on home use and the hobbyist market, others are concentrating on how desktop 3D printing will be used in manufacturing. Now, with many manufacturers transitioning to the modular production paradigm, desktop 3D printing has found a home and is an integral technology in the modular production process.

Modular production has been in existence for decades but is only recently gaining traction in the way consumer products are being produced. Much of this traction is a result of the introduction and miniaturization of new and existing technologies. Small milling machines, laser cutters and 3D printers are now commonplace in modular configurations which provide tremendous flexibility in setting up lines and fabrication processes.

One consumer products manufacturer where modular production techniques and desktop 3D printing have had a significant impact is Louis Vuitton. Louis Vuitton is well known for its iconic, quality, handmade products, and this tradition has carried through from its origin in 1854. What has changed are the tools and processes that go into fabricating the handmade products. Now, tools such as jigs, fixtures, and molds that were once made through injection molding are now 3D printed. Also, 3D printers provide component parts that assist in the setup of the production lines for each product. Now lines can be configured and tested in real time without having to wait for all the final component parts.

Louis Vuitton takes all the results and best practices of their production processes and freely shares this information corporate-wide. These best practices and results using 3D printing do not necessarily have to be “invented” locally for all facilities to take advantage. In the end, the use of desktop 3D printing has had a dramatic impact on the company’s bottom line.

In the end, the use of desktop 3D printing has had a dramatic impact on the company’s bottom line.

Problem Definition

The overarching goal is for product manufacturers to determine the techniques and scenarios in which the introduction and use of desktop technologies can optimize time and minimize costs in product production.

High-Level Solution

The foundation of Louis Vuitton’s reputation for producing high quality, luxury products lies in the quality of sourced materials to include leather, suede and gold-plated hardware and the repetitive precision of its fabrication processes. Even with the insertion of technology, Louis Vuitton still fabricates every product by hand. The key is to ensure that the process yields the same quality product during each iteration.

To compound the challenge, every change of season introduces an entirely new product line from original designs that have never been produced and will be retired at the end of that season. This timeline provides little room for error and the fabrication process for each product needs to be finalized before full production begins. This configuration of product lines is replicated world wide where approximately 250 seasonal product lines are established across 17 different facilities. With some facilities fabricating the same product in parallel, this translates into approximately 25 product lines that will have to be set up and vetted at each location.

This timeline provides little room for error and the fabrication process for each product needs to be finalized before full production begins. This configuration of product lines is replicated world wide where approximately 250 seasonal product lines are established across 17 different facilities. With some facilities fabricating the same product in parallel, this translates into approximately 25 product lines that will have to be set up and vetted at each location.

To meet this seasonal demand, Louis Vuitton has established a modular production scheme that provides versatility, flexibility and decreases the amount of setup time. The scheme centers around small physical footprints where machines and equipment on mobile desktops/platforms are easily moved and configured depending on the desired workflow or function of the individual module. Often times, part design and prototyping are conducted on the same production floor so engineers and designers can participate in the process. An example of a modular configuration may be seen in Figure 2. (Note: This figure is only a modular representation and in no way represents an actual physical configuration at any known facility or location.)

An example of a modular configuration may be seen in Figure 2. (Note: This figure is only a modular representation and in no way represents an actual physical configuration at any known facility or location.)

Figure 2: Modular Configuration for Louis Vuitton's workflow

Notice the placement of the 3D printer in Figure 2. Due to its modularity, the printer can be a station on the production line or in a more centralized location in the modular cell to provide 3D printing capabilities where needed. For example, jigs and fixtures were previously designed, tooled and fabricated off site or at a different location on site and then delivered to the production line. Often times this process could take days and even longer than a week before the correct jig or fixture was delivered and inserted in the production line. Now this process can be accomplished in less than 24 hours or even overnight while the production line is not in operation. As a result, changes to jigs and fixtures may be iterated on the fly to guarantee the best solution with no down time.

One of the more interesting uses of 3D printing has been in the production of components as hardware stand-ins during the initial production line setup and test (see Figure 3). The lead time for gold-plating of hardware components can be anywhere from two to three weeks. With 3D printed components, Louis Vuitton is able to do complete production runs to ensure that all components fit well together and have proper clearances in final assembly. This entire process may proceed before any hardware is delivered. This ensures that the use of materials and fabrication time is optimized across the facility.

Figure 3: Hardware stand-ins during the initial production line setup

Solution Details

With each new season, Louis Vuitton factories transform. The fabrication modules of previous product lines are reconfigured to prepare for the new seasonal designs that will be introduced to customers in coming months. There is no time to waste as the new product lines and processes need to be vetted before actual production begins. Desktop 3D printers step to the front in the process of configuring and proofing the lines.

Desktop 3D printers step to the front in the process of configuring and proofing the lines.

Engineers on the production floor review product designs and begin conceptual design and prototyping of the tools that will be needed to fabricate each new product. Each product line is unique, so unique jigs, fixtures and molds will be iterated and deployed over the coming days (see Figure 4). Previously, these items were supplied by out of pocket injection molders and tooling for the molds was required. This was a process that would take from several days to two weeks and add cost to the setup process. Now these items can be iterated on site and fabricated at night while the facility is closed and be ready the following day.

Figure 4: Unique jigs, fixtures and molds

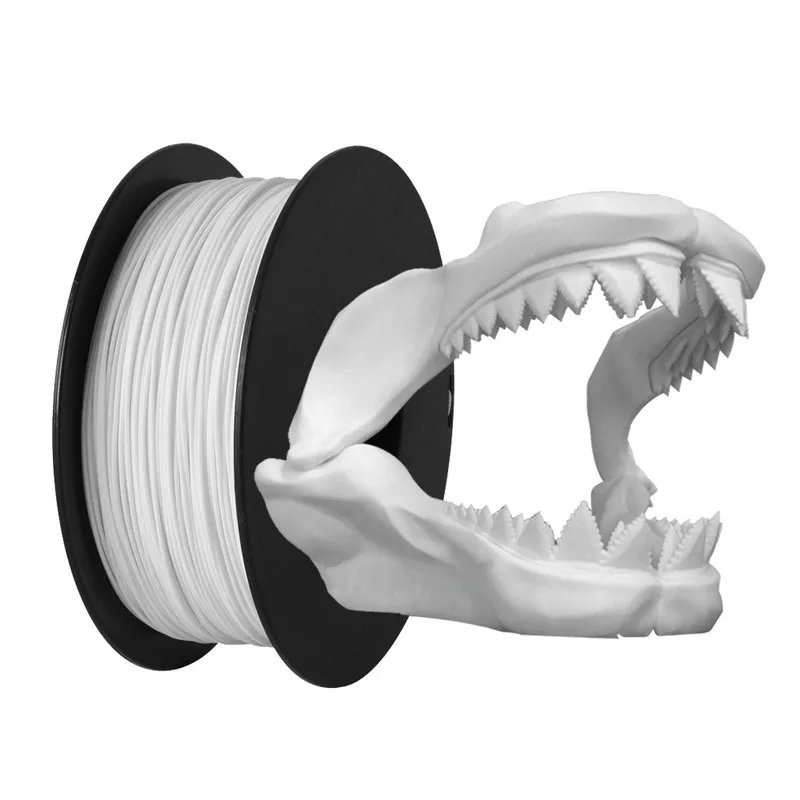

With the introduction of materials such as PETG Filament, molds are 3D printed that can withstand heat and are able to shape products where leather and suede are routinely used. (Figure 5 shows the bottom of a bag that was shaped with a 3D printed mold. ) This process of mold fabrication preempts the need for cast metals and molds made from injection molding and saves on product line setup time and costs.

) This process of mold fabrication preempts the need for cast metals and molds made from injection molding and saves on product line setup time and costs.

Figure 5: Bag shaped using a 3D printed mold

Once the production lines are set, sample runs are initiated to determine the feasibility, stability and reproducibility of the process. At this time, all component parts are available for assembly minus hardware. The hardware is gold-plated and has a lead time of two to three weeks. In order to conduct the sample runs and to ensure clearances and the stability of the process, 3D printed parts are used as a proxy in place of the hardware. This allows for real time tests and initial production of the product without any delays.

The modular production process is a collaborative process that requires active participation and feedback from all involved. Information about best practices and new techniques are shared locally as well as internationally. This provides the opportunity for creativity and the freedom to try different approaches to improve the process. The key to producing quality products is the use of the best materials and the ability to repeat sound processes.

This provides the opportunity for creativity and the freedom to try different approaches to improve the process. The key to producing quality products is the use of the best materials and the ability to repeat sound processes.

Business Benefits

For Louis Vuitton, the introduction of desktop 3D printing into the process of fabricating quality, high-end products has been nothing but positive. Desktop 3D printing saves time in setup and initial runs, but also reduces production costs. More importantly, process quality is improved which translates in additional costs savings from a reduction in the failure rate. All of these positive develops are traced back to 3D printing.

Summary

Going forward, modular production techniques will continue to influence how consumer products are made and delivered to the consumer. The combination of additive fabrication technologies with subtractive processes achieves a variety of fully integrated, compact manufacturing systems. These systems may then be integrated into one facility and be located nearer to the consumer.

These systems may then be integrated into one facility and be located nearer to the consumer.

Low-cost desktop 3D printers are now indispensable in the manufacture of quality, high-end products. They lower the costs associated with tooling for injection molding and are able to produce components overnight while the facility is closed. They also provide a tremendous amount of flexibility essential in today’s manufacturing environment. Those that delay in the adoption of modular techniques and 3D printing will be at a major disadvantage. Now is the time to upgrade.

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related products3D Printing and Luxury Brands

3D printing has been around since the 80s but it is only in recent times that this technology has slowly become more commonly used in the luxury sector. Should these luxury brands be fearful of 3D printing or should they embrace it and create a new form of partnership?

Should these luxury brands be fearful of 3D printing or should they embrace it and create a new form of partnership?

Our society’s ability for mass production started in the 1800s after undergoing various industrial revolutions. This has opened up society to a myriad of manufacturing capabilities, such as using steam engines to power textile machinery. While this is a giant leap in terms of technological advancement with innovation at its nucleus, there is also the untimely demise of traditional craftsmanship as it slowly becomes economically unviable for the mass.

However, this creates another opportunity whereby these ateliers pride themselves in producing extremely high-quality handcrafted products that cater to a niche group of people who have the eye and money to make these purchases. Hence, this allowed for the advent of luxury brands such as Louis Vuitton, Hermes, Chanel, Prada and others. But as society continues to innovate, new forms of production will undoubtedly emerge and cause a ripple effect on the luxury sector.

- READ MORE: Best Looks From Spring 2022 Haute Couture

By the 21st century, society has progressed by leaps and bounds and now we are in the age of 3D printing. While this new technology hasn’t been widely adopted for commercial purposes, 3D printing is slowly but surely trickling down more widely across the population.

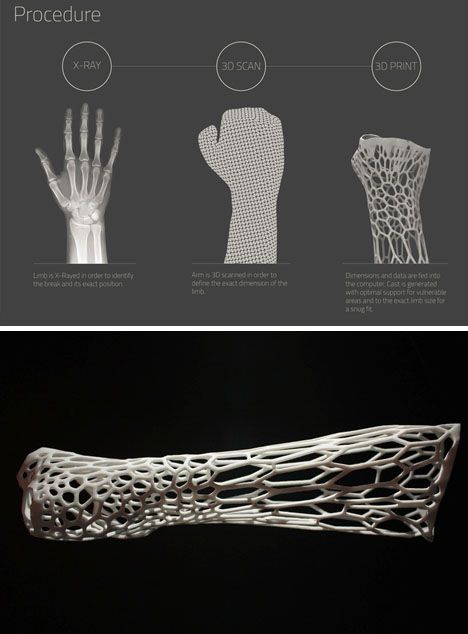

If you are new to the game of 3D printing, simply put, it works similarly to how a regular printer would function. But unlike traditional printing, where you can only have the product in 2D, 3D printing uses additive manufacturing to realise your dream creation. Layers of molecules fuse and build up to form a three-dimensional shape. Using 3D printing requires no special tools like cutting tools or moulds. The precise addition process helps create complex structures; hence, the possibilities are limitless.

In the realm of luxury fashion, brands have started to incorporate 3D printing into their design process. Take a look at Balenciaga’s Autumn Winter 2018 collection. You will be surprised to know that the clothes consisted of 3D printed pieces. Each model’s exact measurements were recorded and input into the computer to be printed as per the fitting requirements. We can derive another strong case for 3D printing, which is sustainability, an issue pertinent to the fashion industry.

Take a look at Balenciaga’s Autumn Winter 2018 collection. You will be surprised to know that the clothes consisted of 3D printed pieces. Each model’s exact measurements were recorded and input into the computer to be printed as per the fitting requirements. We can derive another strong case for 3D printing, which is sustainability, an issue pertinent to the fashion industry.

Using 3D printing produces almost no waste — a standard that many fashion houses strive for these days. Brands under LVMH have employed 3D printing to make prototypes of their products, as with Adidas and its footwear. More prominently, in the making of the accessories such as sunglasses and jewellery, 3D printing help to create a customised mould that is unique to the customer, elevating the luxurious experience.

- READ MORE: Luxury Sneakers 2022: Louis Vuitton, Dior & More

Taking a look at the current trend within the fashion industry, one would observe that personalisation ranks at the top of the list. In the past, owning a luxury product was the ultimate aim. Now with the ubiquity of luxury brands, the exclusivity often associated with luxury has been diluted. That is not to say these luxury brands are not desirable anymore. In fact, there is a growing appetite for them amongst the burgeoning younger generation.

In the past, owning a luxury product was the ultimate aim. Now with the ubiquity of luxury brands, the exclusivity often associated with luxury has been diluted. That is not to say these luxury brands are not desirable anymore. In fact, there is a growing appetite for them amongst the burgeoning younger generation.

3D printing makes it even easier for brands to produce their products in a shorter time to make up for the increased demand for their products. This increases access to luxury goods. How then can top brands continue to justify their price points? If one could simply 3D print out luxury goods that look virtually the same, then it makes sense that luxury brands should lower its prices.

To justify the prices, one has to look at the heritage, craftsmanship and material used to make these luxury goods. Brands like Chanel, Louis Vuitton, Prada have a storied history where its artisans have spent almost their entire lifetime perfecting their skills. When you purchase a product, you are essentially buying their time in producing that item. And while some parts of a product could be 3D printed out, the technology cannot replicate the natural drape of a fabric or stitch up a piece of clothing. Luxury buyers are appreciative of the artisans spending utmost attention on the details. For them, it justifies the exorbitant prices that tag along with the products.

And while some parts of a product could be 3D printed out, the technology cannot replicate the natural drape of a fabric or stitch up a piece of clothing. Luxury buyers are appreciative of the artisans spending utmost attention on the details. For them, it justifies the exorbitant prices that tag along with the products.

3D printing cannot recreate the experience of buying a luxury product in a store along with the opportunity to be part of the brand’s philosophy. Still, it can complement the process of perpetuating these brands’ legacies to a broader audience. Moving forward, 3D printing will only become more entrenched, so rather than shun its presence, a synergy should be encouraged.

For more fashion reads, click here.

STL File Louis Vuitton Logo・3D Printed Model Download・Cults

Flower butterfly (pack of 1)

0.63 €

Hollowed Easter egg Voronoi (Osterei)

0,63 €

Key ring with new Kia logo (Schlüsselanhänger)

0. 69 €

69 €

Vase with anatomical heart

1.99 €

Flower butterfly (pack of 2)

0.99 €

Rabbit Hollow Out Voronoi

0,99 €

Cat (pack)

0.99 €

4 Easter eggs (Ostereier)

1.25 €

Best 3D Printer Files in the Fashion Category

Melon Shades

Free

Cat Skull Mask

Free

Heart band

Free

Deactivated

Deactivated

Bowtie (with Wroclaw Skyline)

Free

3d printable Glasses

Free

Sunglasses Case

2,50 €

Bestsellers in the Fashion category

Kento Nanami Glasses - Jujutsu Kaisen

1,50 €

CyberCat - cosplay mask

23. 91 €

91 €

WOTP mask from MUSE - mask "The will of the people"

5 € -fifty% 2.50 €

Dragon claws

3,80 €

BATCAT HELMET

3.72 €

12 in 1 Storage Cube for Game Cartridges and MicroSD Cards for Nintendo Switch

1.99 €

Articulated skull mask

4,80 €

Cadena cubana print in place of Cuban chain

1.45 €

Gyro Motor Factory / Watch Factory

2.50 €

Croc nuts

0.97 €

Cigarette Holder Ring Joint Holder device free hands sh-02 3d print ana cnc

0,85 €

Aizawa Shouta "Eraser Head" Goggles

4,80 €

SPRIGATITO_ POKEMON

0,74 €

Slim - smart wallet

2. 19 €

19 €

Figure box Qatar 2022

1.74 €

NIKE AIR JORDAN 1 FINGER

2,18 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Implementation of blockchain technology - 3D printing from General Electric, bonds and other initiatives

05/18/2019 Alex Kondratyuk

#blockchain for corporations

In the new issue of the “Blockchain for corporations” rubric, the Orbita Center for the Practical Application of Blockchain Technologies has compiled an overview of the latest initiatives to introduce distributed ledger technology in various fields especially for ForkLog.

Top Stories:

- General Electric Demonstrates Blockchain 3D Printing Solution to track shipments of critical items (equipment, metal powders, 3D models, etc.) to create high-value aircraft and power engineering parts;

- New blockchain cases: The World Bank announced the launch of a secondary market for blockchain bonds; consortiums using Corda technology continue to expand; Bosch and Pfizer are positive about the development of services based on distributed ledger technology; blockchain for luxury brands Louis Vuitton and Alyx, for European car carriers, as well as for a document management system;

- In Russia: The Ministry of Telecom and Mass Communications plans to create an intellectual property center on the IPChain platform. [simple_tooltip content=' Additive manufacturing, the name 3D printing is also common - a group of technological methods for the production of products and prototypes, based on the gradual addition of material to the base in the form of a flat platform or axial workpiece.

- Bradesco, one of the largest Brazilian banks, has joined the trade finance blockchain platform Marco Polo. In the past few months, a significant number of financial companies have joined Marco Polo: Austrian Raiffeisen, German BayernLB, Helaba, S-Servicepartner, Commerzbank and LBBW, Russian Alfa-Bank.

- Three large French banks - BNP Paribas, Natixis and Societe Generale have joined the Fusion LenderComm blockchain platform, created to increase the efficiency of syndicated lending. Earlier, the British bank NatWest joined the platform, developed by one of the largest technology companies in the financial sector, Finastra.

Why is it important?

Why is it important? - The head of Bosch, one of the world leaders in the supply of components for the development of the Internet of Things, at the Bosch ConnectedWorld 2019 conference announced the beginning of the transition in the development of the company from the concept of "Internet of Things" to the concept of "Economy of Things" (Economy of Things). Distributed registry technologies were named as one of the central technologies for such a transition, allowing machines not only to exchange information with each other, but also to conduct business operations. As examples, cases of automatic payment by electric vehicles for refueling with electricity, payment for toll roads, etc. are given.

- Ken Nessel, senior director of business technology at pharmaceutical giant Pfizer, said that in his experience, the main barrier to the development of blockchain projects is not the technological shortcomings of blockchain technologies, but the difficulties with the formation of business consortiums - reaching agreements on a common blockchain governance model.

infrastructure, common standards, etc.

infrastructure, common standards, etc. - Blockchain company ConsenSys announces launch in partnership with [simple_tooltip content='French multinational company that owns Louis Vuitton and Dior']LVMH[/simple_tooltip ] and Microsoft's AURA platform for tracking luxury products on the Quorum blockchain. With AURA, buyers can trace the history of a product, from the manufacturer and materials used, to the point of sale, thus confirming its authenticity.

Pilot brands on the platform will be Louis Vuitton and Dior. Further expansion of luxury brands is under discussion as well as the addition of new companies from the luxury product industry.

Pilot brands on the platform will be Louis Vuitton and Dior. Further expansion of luxury brands is under discussion as well as the addition of new companies from the luxury product industry. - Blockchain company IOTA has partnered with Avery Dennison to launch a blockchain solution to track the supply chain of luxury brand ALYX. Consumers will be able to find out information about the product of this brand and check its authenticity using a QR code. Why is this important?

']additive manufacturing[/simple_tooltip].

']additive manufacturing[/simple_tooltip]. It is noted that the production of expensive parts using 3D printing (for example, for aviation or power engineering) requires a new level of supply chain control. In particular, the network controls the supply of equipment, the origin of digital 3D models, materials and components.

The blockchain network was developed in the General Electric innovation laboratory - Forge Lab. It has a high level of data transmission protection using quantum technologies. It is planned that this development will be applied not only to the additive manufacturing industry, but also to industry, energy, healthcare and defense industries.

Why it matters: General Electric is a global leader in many high-tech markets. The company's development of a blockchain network to track the supply of critical components could set a new standard for supply chain security in high-tech industries.

The World Bank announced the launch of a secondary market for blockchain bonds

In August 2018, the World Bank, together with the Australian Commonwealth Bank, issued the world's first bonds (bond-i), whose issue and sale were recorded on the blockchain. The volume of the issue amounted to $76 million. May 15, 2019year, the World Bank announced the launch of a secondary market for the purchase and sale of bonds-i.

The volume of the issue amounted to $76 million. May 15, 2019year, the World Bank announced the launch of a secondary market for the purchase and sale of bonds-i.

Why is this important: the bond-i project is one of the world's foremost in the use of blockchain for the bond market. Most likely, his success will positively influence the pilot projects of other market participants.

Blockchain consortiums on the Corda platform continue to expand

Bosch and Pfizer positively assess the opportunities for the development of blockchain services

Why this is important: both companies have been developing blockchain projects for a long time and are members of various blockchain consortiums. Bosch’s global positive outlook on the role of blockchain in the development of the digital economy and Pfizer’s more down-to-earth assessment, which emphasizes that the difficulties in the development of blockchain projects are not related to technology, but to agreements between participants, speak of the gradual adoption of blockchain technologies by large corporations.

Luxury brands Louis Vuitton and Alyx launch blockchain services to track their products

The European Consortium of Car Transporters announced the development of a blockchain platform

Vinturas, a consortium of leading European automotive logistics companies, announced plans to launch a supply chain blockchain platform in September 2019.

The main goals of creating a blockchain platform are to increase the transparency of car logistics (which will allow dealers to better plan their deliveries and shipments), as well as to combat fraud related to used car mileage twisting.

Vinturas includes logistics companies from Sweden - Axess Logistics, the Netherlands - Koopman Logistics, Ireland - NVD, Norway - Autolink. A major maritime carrier, EML, will also participate in the work of the consortium. A wide geographical coverage will allow to offer the consortium's customers the possibility of tracking vehicle deliveries in most European countries. The technology partner is IBM.

Vinturas is announced as an open ecosystem that other companies from both the logistics industry and the IT and other sectors can join.

Why is this important? In this case, we see that competing companies were able to overcome differences and agree on cooperation to improve the efficiency of their business processes.Billon received 2 million euros from the EU to improve the blockchain solution for a document management system . The grant was received for the development and commercialization of the Blockchain for Trusted Document Management (B4TDM) blockchain solution.

B4TDM will allow storing, signing and sending electronic documents using a high-performance (up to 5 million documents per day) blockchain network that allows you to control access to the document. It is noted that the Polish Credit Bureau has already begun to use the initial version of the product in 2018. B4TDM is expected to comply with regulatory requirements related to the protection of personal data, in particular - GDPR.

Why it's important: is gaining attention because it has a commercial partner, won the European Commission competition, and in 2018 also won the European Hottest Corporate Blockchain Project competition. Despite the fact that many companies are engaged in the topic of using the blockchain to control access to documents, Billon seems to have groundwork for advancing development in this direction.

In Russia

The Ministry of Telecom and Mass Communications plans to create an intellectual property center on the IPChain platform

According to the draft decree of the President of the Russian Federation, published by the Ministry of Telecom and Mass Communications on May 6, 2019, the Government of the Russian Federation and the IPChain association will act as founders of the Russian Center for Intellectual Property (RCIP).