3D printer patent

3D Printing Patents landscape » 3D Printing Media Network

The scenario for 3D printing patents is as complex as one can imagine. Not only is 3D printing the most horizontal technology that exists, with specific patentable applications in just about every segment of manufacturing, but it also spans across multiple technology areas including mechanical (hardware), IT (software and automation) and material science. In addition, not only can 3D printing technologies be patented but also anything made with a 3D printer that was not made before (and most things have never been made before with a 3D printer). Finally, 3D printing can be used to easily copy patented (and copyrighted) products, adding more complexity to the legal landscape.

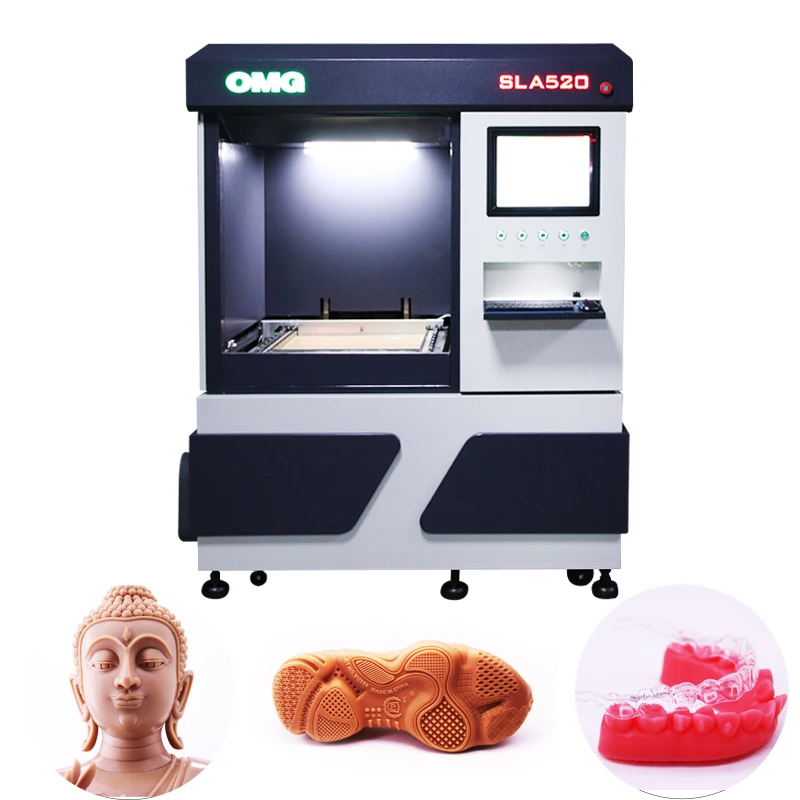

We all know that the success story of 3D printing officially began in 1984 when Charles W Hull applied for a patent for stereolithography. In 1989 S Scott Crump of Stratasys invented fused deposition modeling, which fuses material layer by layer until a 3D object is created. This style of additive manufacturing is what most people associate with 3D printing today. In 2009 the patent for fused deposition modeling expired and companies started to take a different approach by trying to sell to consumers instead of business to business. Together with the rise of Kickstarter, a perfect storm formed and hype around 3D printing in the early 2010s was born.

Top 3 owners of 3D printing patents. Please consult the IPlytics report for the full list of the top 10 companies. Source credit: IPlytics.

Several patent experts have undertaken the challenge of trying to clarify the 3D printing patent landscape and how it is evolving. SmarTech Analysis just released a fully comprehensive interactive report that will enable companies to easily search for and identify previously released metal AM patents. The report is going to be released shortly so stay tuned. In the meantime, a great resource to start learning about 3D printing patents is this free report from Tech Insights. It dates back to 2013 – which is an eternity in 3D printing – but it will give you a very detailed and full overview of everything that happened until then. More recently, German company IPlytics published a free report on the evolution of 3D printing patents and relative litigation.

It dates back to 2013 – which is an eternity in 3D printing – but it will give you a very detailed and full overview of everything that happened until then. More recently, German company IPlytics published a free report on the evolution of 3D printing patents and relative litigation.

This IPlytics report looks at additive manufacturing and 3D printing from an IP perspective, again demonstrating that 3D printing patents are on the rise. In order to identify 3D print-related patents, the IPlytics platform database performed an extensive keyword search of worldwide filed patents in the 3D-print technology field. The search was based on the patent’s content, making use of state-of-the-art stemming and semantic indexing methods. Between 2007 and 2019 the analysis identifies 95,302 patents and 43,718 patent families (unique patents in the INPADOC database) relevant for 3D printing. The report then goes on to identify the largest patent holders (spoiler: GE has the most, HP a close second) and the countries where the most 3D printing patents have been filed (spoiler: the US is first).

The number of 3D printing patent applications filed per year (source credit: IPlytics)

One very interesting chart is the one that concerns litigation cases: between 2000 and 2018 there have been 155 litigation cases in the United States in the 3D printing field. IPlytics found that from the 155 litigated patents in 3D printing a total of 71 (45%) have been transferred (reassigned) at some point in time. By comparing the date of the first transfer with the date of the first litigation the IPlytics platform was used to assess the transfer timing before or after the litigation took place. It turned out that 80% of all patents that have been both litigated and transferred have changed owners before the litigation, with 22.5% doing so within the same year.

3D printing patent litigation cases in the US (source credit: IPlytics)

Patenting is increasing sharply for 3D printing technologies. Further, 3D printing patents are increasingly transferred and litigated. Senior patent managers and patent directors involved in industries where 3D printing has an impact should constantly monitor this evolving situation. 3dpbm‘s AM Focus Patents intends to provide an updated patent landscape and an access point to the tools to help you do just that.

3dpbm‘s AM Focus Patents intends to provide an updated patent landscape and an access point to the tools to help you do just that.

-

Desktop Metal has completed the qualification of Grade 420 stainless steel (420 SS) for use on the Production System platform, which leverages patent-pending Single Pass JettingTM (SPJ) technology for high throughput AM production. Manufacturers can now leverage SPJ technology for the mass production of high-strength, end-use parts in 420 SS…

Read More -

Tethon Corporation Inc. (Tethon 3D) announces issuance and publication of the company’s U.S. patent number 11,126,088 “Photopolymer Development Resin Base for Use with Three-dimensional Printer” on September 21, 2021.

Read More Genesis resins are used as a composite matrix to create materials for ceramic AM via stereolithographic processes. The patented product line…

Genesis resins are used as a composite matrix to create materials for ceramic AM via stereolithographic processes. The patented product line… -

The Australian Patent Office has examined the Australian member of AML3D‘s International Patent Portfolio and has now granted the company an Australian patent for its Wire Additive Manufacturing (WAM) process. AML3D’s Australian patent provides coverage over the method and apparatus for manufacturing 3D metal parts. Key coverage items include the…

Read More -

Desktop Health, a service recently launched by Desktop Metal, received the Conformité Européenne (CE) Mark certification for its Flexcera resin, a proprietary technology for use in 3D fabrication of high-quality dental prosthetics. The CE Mark affirms that Flexcera resins meet the requirements of the European Medical Devices Directive, paving the…

Read More -

Global materials company Tethon Corporation (dba Tethon 3D), of Omaha Nebraska USA, received the US patent “Three-Dimensional Printed Objects with Optimized Particles for Sintering and Controlled Porosity”, for optimally sintering parts that 3D printed via photopolymerization processes of bound metal and bound ceramic slurries.

Read More The patent covers objects made from…

The patent covers objects made from… -

NUBURU, a leader in high power blue laser technology, today announced that it has been awarded seven new blue laser IP patents, further demonstrating its dominant intellectual property portfolio in visible laser technology and its applications across 3D printing and material processing. NUBURU was awarded US Patent No. 10,562,132, No.…

Read More -

PostProcess Technologies Inc. has been granted another U.S. patent for its automated 3D printing post-processing solutions. This patent, U.S. Patent No. 10,737,440, pertains to the company’s support removal process, specifically its Submersed Vortex Cavitation (SVC) technology. The company’s SVC technology is one of its polymer support removal and resin removal…

Read More -

AM quality assurance software developer Sigma Labs has been granted two U.S. patents for its PrintRite3D software platform. The recently obtained patents expand the company’s intellectual property portfolio, making for a total of 11 issued patents and 24 pending patents.

Read More Sigma Labs’ PrintRite3D software enables manufacturers to detect defects that…

Sigma Labs’ PrintRite3D software enables manufacturers to detect defects that… -

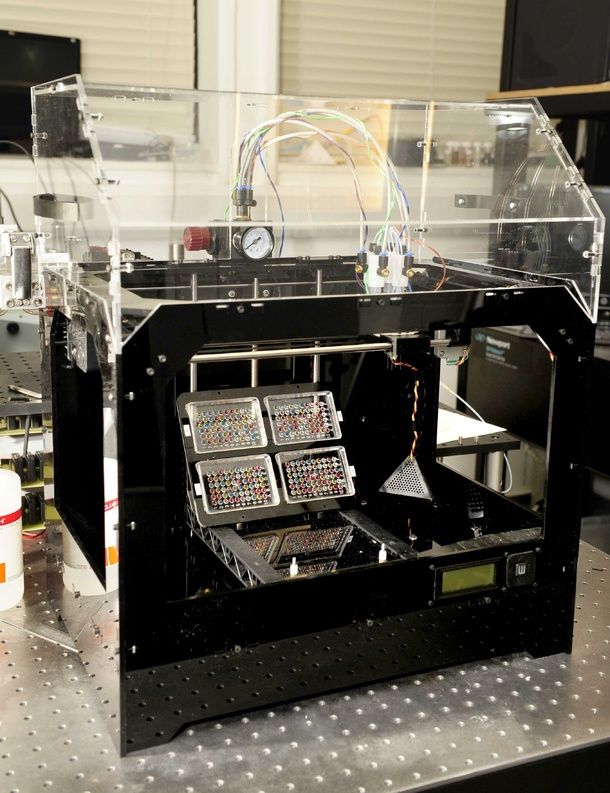

Chicago-based biofabrication company Dimension Inx has been granted a U.S. patent covering its 3D-Painting System, a platform built for designing and manufacturing next-gen biomaterials for organ and tissue repair and regeneration. The company says the patent issuance strengthens its position on the market by showcasing the differentiation of its biomaterials…

Read More -

FATHOM, an advanced manufacturer with extensive expertise in 3D printing and additive manufacturing was issued a United States Patent for the systems and methods powering its online digital manufacturing platform. The team also received its seventh consecutive ranking on the Inc 5000 list of fastest-growing private companies in America—only 1.5%…

Read More

Load More

Stratasys heated build chamber for 3D printer patent US6722872B1 set to expire this week

0Shares

For over two decades, 3D printer manufacturer Stratasys has held the patent rights for a relatively simple piece of technology in the 3D printing community.

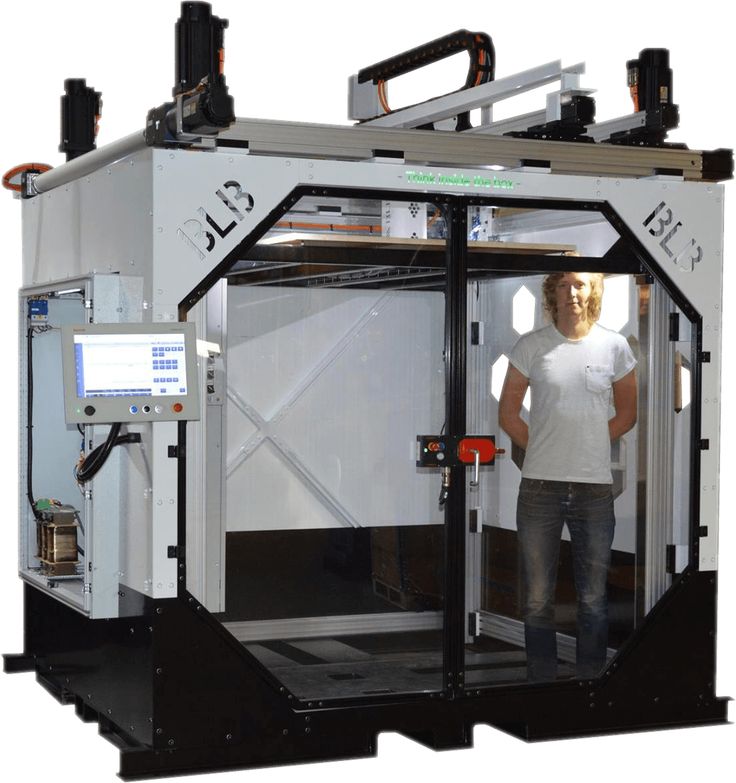

Owing to three relevant pieces of IP, the company has had exclusive rights to use its own heated build chamber design in its FDM 3D printers since June of 2000. This has meant that manufacturers worldwide have been unable to develop and sell commercial 3D printers with their electronic motion control components isolated from the rest of the build chamber. Naturally, this has made it very difficult to break into the high-temperature industrial FDM market, with companies such as AON3D, INTAMSYS, Roboze, and 3DGence finding novel workarounds.

Of the three patents, US7297304B2 and US20040104515A1 expired back in November 2020. The third and final patent, US6722872B1, is set to expire on the 27th of February 2021 following a previous extension several years before. With the last blockade on its way out, we could very well see a major shift in the way high-temperature FDM 3D printers are produced in the near future.

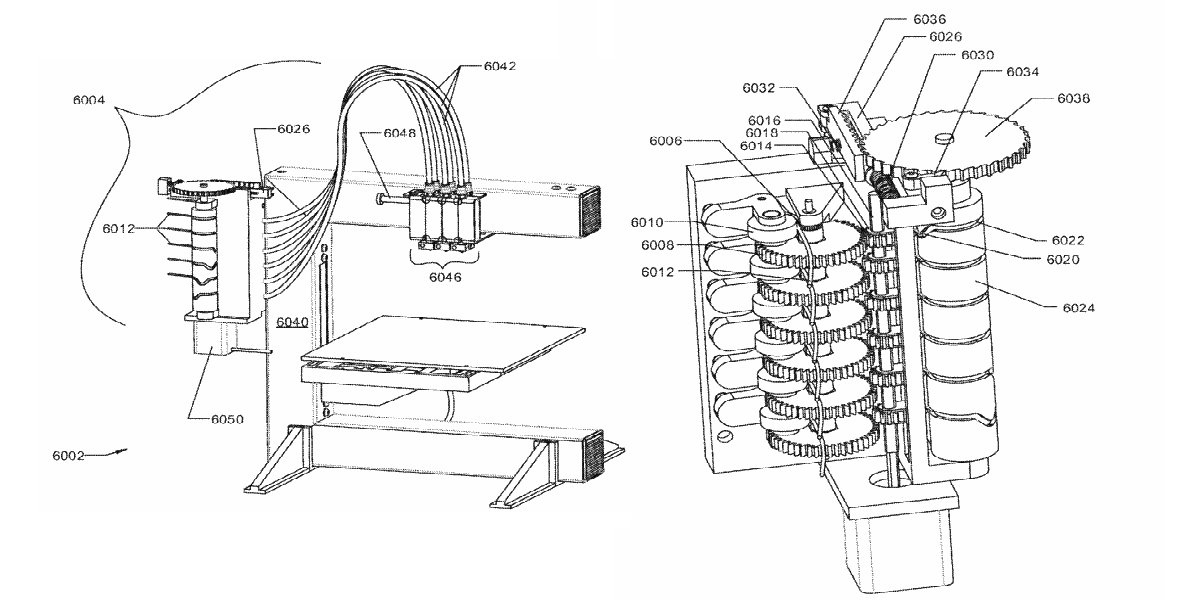

US6722872B1 details the design of a heated build chamber isolated from the printer’s motors and electronic components. Image via US6722872B1.

Image via US6722872B1.A trip down memory lane

To predict what kind of effect the expiration of US6722872B1 might have, it’s worth looking at the historical timeline of the company itself. Stratasys was co-founded by Scott and Lisa Crump in 1989. That same year, Scott had filed a patent application for what he called fused deposition modeling, a 3D printing process he had developed a year prior when attempting to produce a toy frog for his daughter.

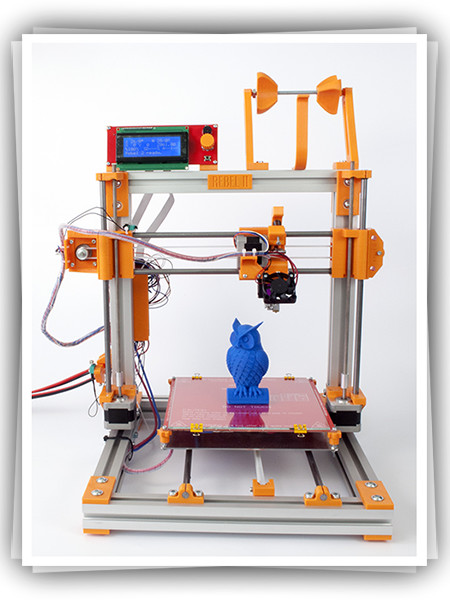

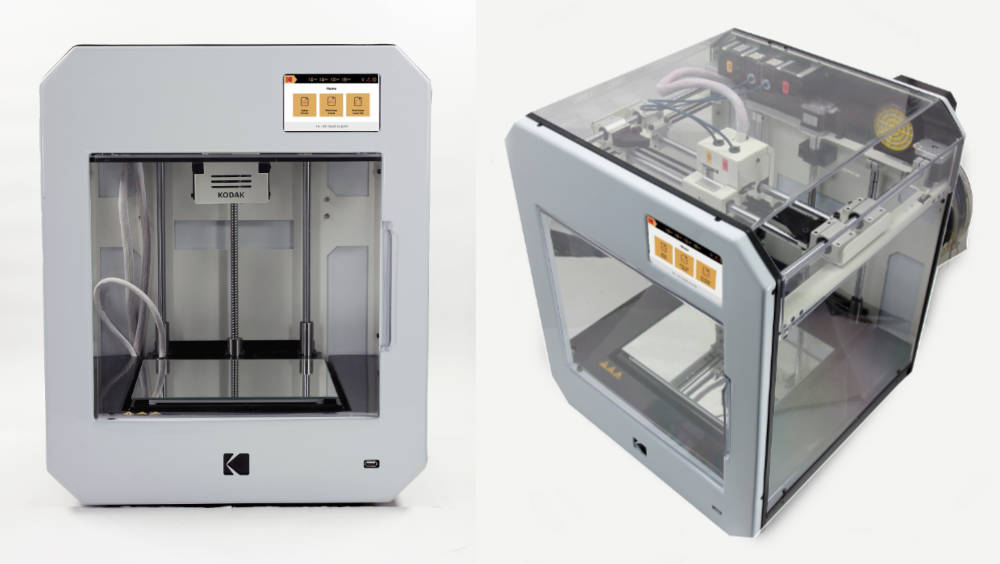

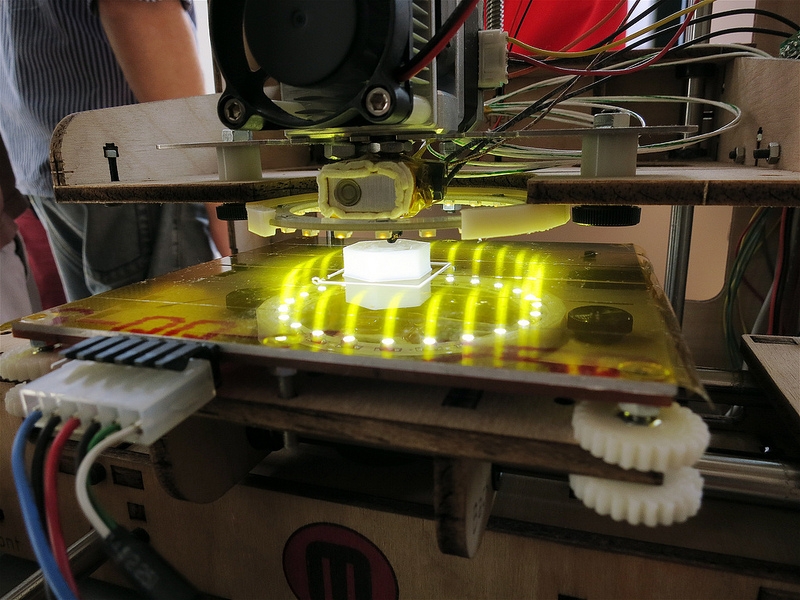

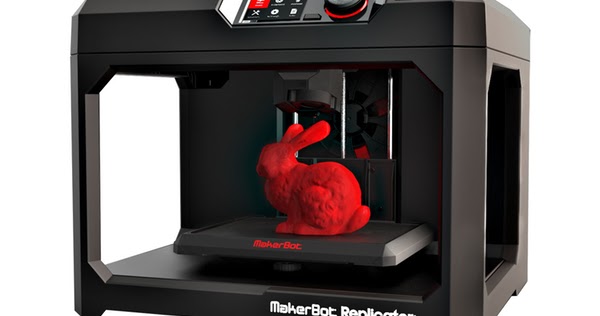

After 20 years, in 2009, that FDM patent expired and what came next is often considered the birth of mainstream consumer 3D printing via the RepRap Project led by Dr. Adrian Bowyer’s work at the University of Bath.

While the RepRap project began in 2004, the official anniversary is marked from May 29th, 2018, the date when the first RepRap made another RepRap 3D printer.

With the opening of the floodgates in 2009 and the spread of the open-source RepRap movement, hundreds of 3D printing startups materialized, resulting in a number of subsequent household names such as MakerBot, FlashForge, and Prusa to name a few. FDM/FFF 3D printing is now the poster child for hobbyist 3D printing and is the most commonly used additive manufacturing technology to this day.

FDM/FFF 3D printing is now the poster child for hobbyist 3D printing and is the most commonly used additive manufacturing technology to this day.

The expiration of US6722872B1

It’s fair to say the expiration of US6722872B1 probably won’t have the same seismic effect as the 2009 event. However, it will probably cause an influx in simple heated build chambers, making the high-temperature industrial FDM market much more competitive.

Smaller-scale manufacturers will no longer have to resort to just using more durable electronic components, which often increases the price point of the entire system. With the ability to isolate their motors and other electronic components from the heated build chamber, companies will find it much easier to develop high-temperature FDM systems with PEEK, PEKK, and ULTEM printing capabilities.

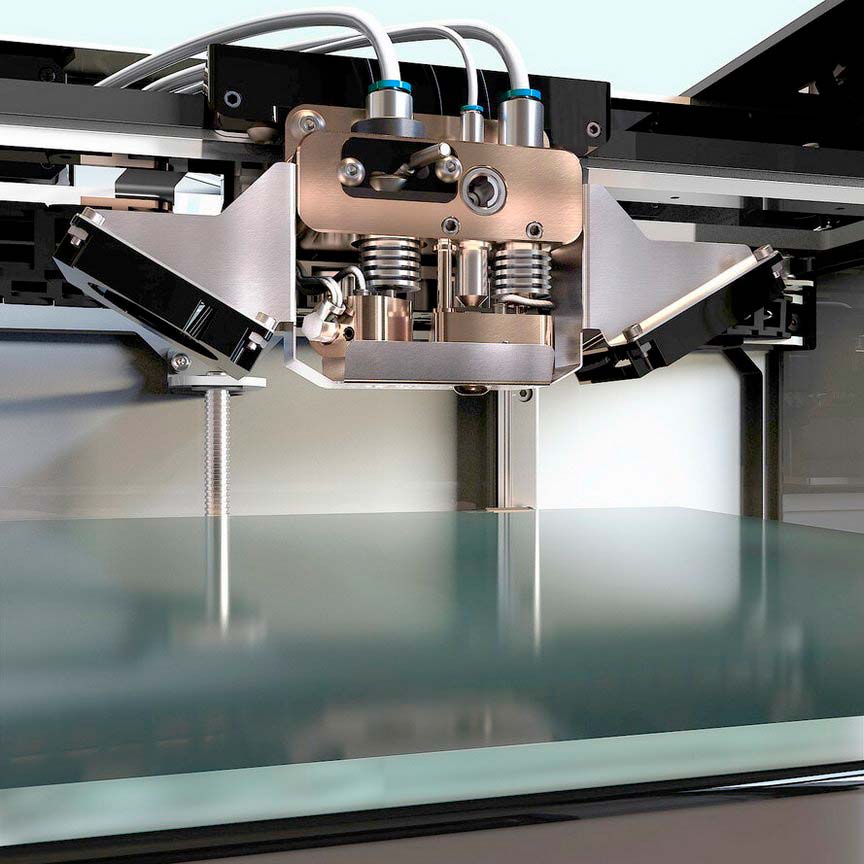

The Stratasys Fortus 450mc features the proprietary heated build chamber, enabling chamber temperatures up to 350°C. Photo via Stratasys.

Looking at its effect on the consumer market, the existence of US6722872B1 likely prompted the invention of the heated bed (an alternative at the time) back in 2010, which RepRap founder Dr. Adrian Bowyer MBE has previously attributed to Chris Palmer (Nophead). Now found in most FDM 3D printers, the heated bed is crucial for part adhesion and the alleviation of delamination and warping issues. Last year, Bowyer even made a blog post detailing the design of his own open-source solenoid bed heater for use with FDM 3D printers.

While integral to day-to-day 3D printing, the heated bed is quite simply not enough when it comes to engineering filaments. Demonstrating the importance of the heated build chamber, Michigan Technological University’s Joshua Pearce has previously released the open-source design plans for a low-cost FDM printer with PEKK and ULTEM extrusion capabilities. Dubbed the ‘Cerberus’, the three-headed machine can be built for less than $1000 and, much like the Stratasys design, houses all of the low operating temperature electronics outside of the heated chamber.

Stratasys has been contacted for comment on the expiry of the patent and whether it plans to apply for an extension.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows US6722872B1 detailing the design of a heated build chamber isolated from the printer’s motors and electronic components. Image via US6722872B1.

Tags 3DGence Intamsys RepRap Roboze Stratasys

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Robbo received a patent for a 3D printer

Technique

|

Share

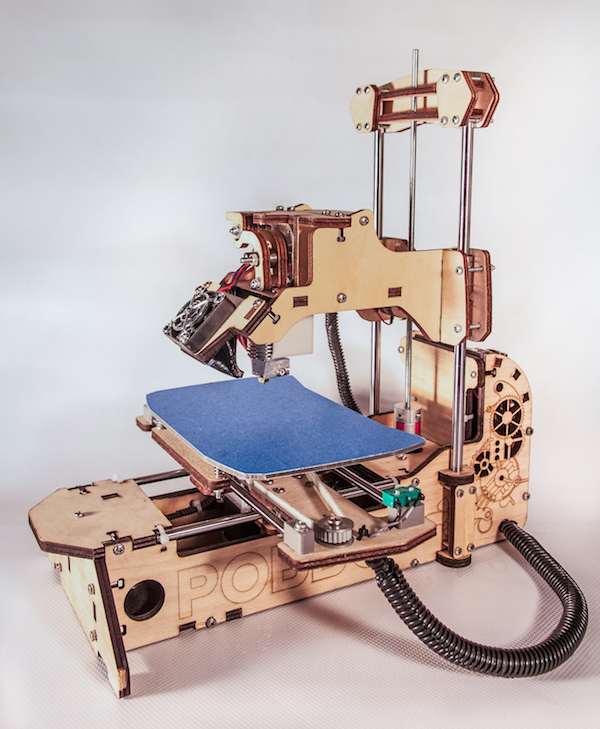

Robbo, a Russian manufacturer of educational robotics for children, received a patent from the Federal Service for Intellectual Property for one of its developments, the Robbo Mini 3D Printer, designed for teaching children 3D modeling and 3D printing at home. The decision to grant a patent was made on the basis of the patentability conditions "novelty" and "originality" provided for in paragraph 1 of Art. 1352 of the Civil Code of the Russian Federation.

The decision to grant a patent was made on the basis of the patentability conditions "novelty" and "originality" provided for in paragraph 1 of Art. 1352 of the Civil Code of the Russian Federation.

Robbo's patent application was filed in August 2020. As a result of the examination, the compliance of the 3D printer with the requirements of articles 1231.1, 1349 and 1352 of the Civil Code of the Russian Federation was established, on the basis of which a patent for industrial design No. 122799 was issued. The patent will be valid until August 2025

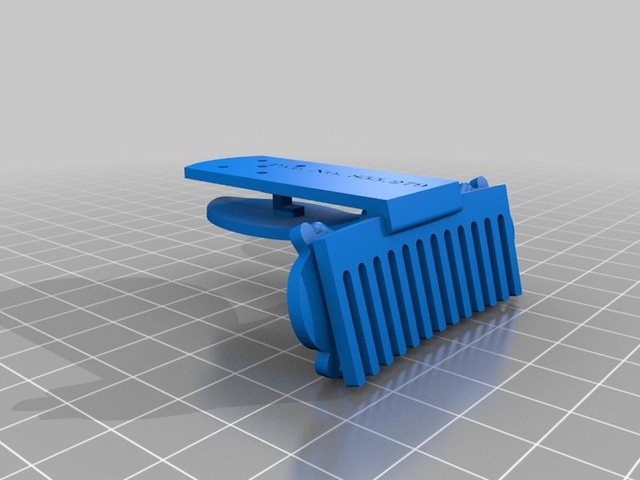

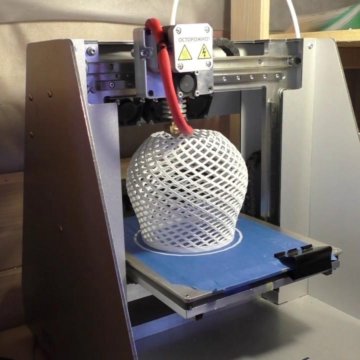

Robbo Mini 3D Printer is designed as a 3D printing tutorial and runs on open source software and hardware. The 3D printer turns any model drawn by a child into a real three-dimensional object made of safe, biodegradable PLA plastic. Children can create models of products and plastic mechanisms up to 170x100x100 in size. At the same time, thanks to its compact design, the 3D printer takes up little space: its dimensions are 370x280x350 mm, and its weight is only 3. 5 kg. In addition to the printer itself, the kit also includes a USB stick with software and settings, a bar filter, a power supply, and a USB cable.

5 kg. In addition to the printer itself, the kit also includes a USB stick with software and settings, a bar filter, a power supply, and a USB cable.

Already in the near future, as noted by the company, additive technologies will be widely used in domestic production, medicine and the space industry. And "Robbo" will take a direct part in the training of personnel for the new segment of the IT industry.

Alexander Golubchikov, MegaFon: Cloud solutions and cybersharing are gaining popularity to expand the SecaaS concept

Safety

“The global 3D printing market is forecast to grow by almost 2.5 times over the next five years. However, unlike other countries where additive technologies have been actively used for several decades, for example, in industry and manufacturing, in Russia the 3D prototyping industry is only in its infancy. The appearance of the product “Robbo 3D-printer Mini” in Russian homes and schools will make it possible to prepare a pool of specialists capable of bringing the domestic industry of additive technologies to a qualitatively new level in the future. Moreover, our educational 3D printer has no analogues yet,” said Pavel Frolov , founder and producer of the Robbo company.

Moreover, our educational 3D printer has no analogues yet,” said Pavel Frolov , founder and producer of the Robbo company.

- How to start import substitution of SAP, Oracle and IBM?

New ORNL 3D printing patent scandal

News

positioning system. The fact of issuing a patent caused a flurry of criticism from the developers of open source systems, who have been designing such additive equipment for a long time.

Hangprinter additive system. Photo: Thomas Sanladerer

ORNL and the patent office were criticized by two well-known promoters of open source additive technologies, Professors Dshoshua Pearce and Adrian Bower. Pierce is known for projects such as an inexpensive homemade 3D printer for printing metals using arc deposition technology, a homemade Cerberus additive system for working with refractory structural thermoplastics, a grinding machine from a grinder and 3D printed parts for making compression screws used in 3D printers for printing with granulates, and many other works. Bower needs no introduction at all - he is none other than the founder of the RepRap movement.

Bower needs no introduction at all - he is none other than the founder of the RepRap movement.

Adrian Bower gets to know Hangprinter. Photo: Sally Bower

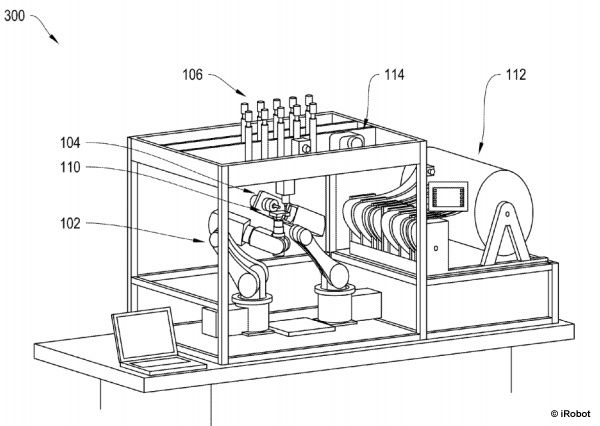

Academics defended a young Swedish engineer named Torbjorn Ludwigsen, who asked on Twitter about the implications for his own project called Hangprinter. The fact is that the ORNL patent very closely repeats the development of the Swede five years ago, which we have already talked about in the material at this link. The essence of the project is in an unusual positioning system using cable guides with a suspended extruder. Such a scheme makes it possible to build simple and inexpensive, but at the same time large-format additive systems.

Hangprinter additive system. Photo: Torbjorn Ludwigsen

Torbjörn has built a "home" FDM 3D printer, and ORNL's patent US 11230032 considers a construction option for outdoor cement 3D printing suspended from a truck crane. There is no fundamental difference between these developments, the differences mainly relate to the purpose of the equipment.

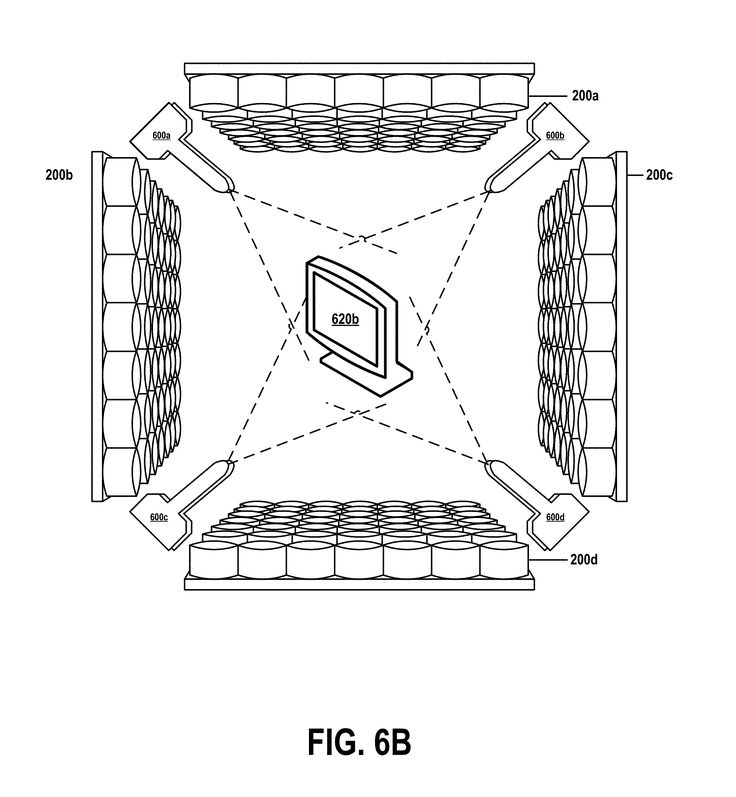

SkyBAAM 3D printer illustration from ORNL patent

To be fair, the Hangprinter concept is not unique either. Similar options were considered by other designers, examples include Brandon Heller's SkyPrinter 2013 and RigTig's Big 3D Printer 2016. Torbjorn himself took up the job in 2014, and presented the first prototype in 2017. The problem is that none of the previous authors on this topic, including Torbjorn Ludwigsen, have applied for patents, preferring to put their developments in the public domain.

SkyDelta 3D printer prototype. Photo: Brandon Heller

Bower and Pierce believe that the ORNL patent should be invalidated because it repeats someone else's design and differs only in minor modifications that do not give the right to a patent. The piquancy of the situation is also in the fact that in the notes to the patent application there is a footnote to the news about Hangprinter, and therefore the patent office could not have been unaware of the project of the Swedish engineer.

Hangprinter additive system. Photo: Torbjorn Ludwigsen

The question arises: why did ORNL need this at all? There are several options here. In addition to the obvious versions of appropriation of foreign technologies or patent trolling, one can also assume the opposite version. The fact is that many companies, on the contrary, issue not protective, but so-called defensive patents, and they do this precisely to protect against potential exploiters of other people's developments. The concept of a defensive patent, as a rule, provides for the voluntary waiver of exclusive rights. In other words, "we have patented, but everyone can use it, the main thing is not to bother us with claims."

Thorbjorn Ludwigsen with the 3D printed Tower of Babel demonstration. Photo: Make magazine

Ludwigsen himself takes a rather reserved view of the situation, suggesting that this may just be an attempt to justify receiving a research grant.