Local 3d print

Local 3D Printing Service in Chicago Il

Email yourself a 10% off coupon

Send

Coupon sent! Check your email

Proceed to checkout: €

Add more 3D models

Upload 3D model

get an instant quote

or

Find 3D models

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl

Proceed to checkout: €

discount applied: was €

+ Upload more 3D models

Proceed to checkout: €

discount applied: was €

"That’s why MakeXYZ.com is so important...simply contact a MakeXYZ maker and they’ll print off your item."

Read More

"Let MakeXYZ handle all of the dirty work for you. ..and watch the results unfold before your eyes."

Read More

"Makexyz is a 3D printing service with a brilliantly simple premise...It’s like Airbnb for 3D printers."

Read More

"Make local 3D printing possible, without ever owning a printer of your own..."

Read More

"Creating A Kinkos For 3-D Printing...connects people who need 3-D printers with those who have them."

Read More

Chicago Il

change location

AnyPLA PlasticBrassNylonCeramicBronzeStainless SteelABS PlasticFull Color SandstoneAluminumWoodResinPolycarbonateBiomed/Industrial PlasticPaperFlexible PlasticSandstonePET PlasticHIPSConcreteFiberglassCarbon FiberFull Color PlasticFull Color PlasterConductive PLAWax

AnyFDMSLASLSPOLYJET

Any3D printingCAD DesignCNC3D scanning

Check me out on Instagram at: https://instagram. 3 but can be somewhat lower or higher depending on specifics and circumstances. If you want a small, cheap part and are willing to wait a day or two for it, I can …

3 but can be somewhat lower or higher depending on specifics and circumstances. If you want a small, cheap part and are willing to wait a day or two for it, I can …

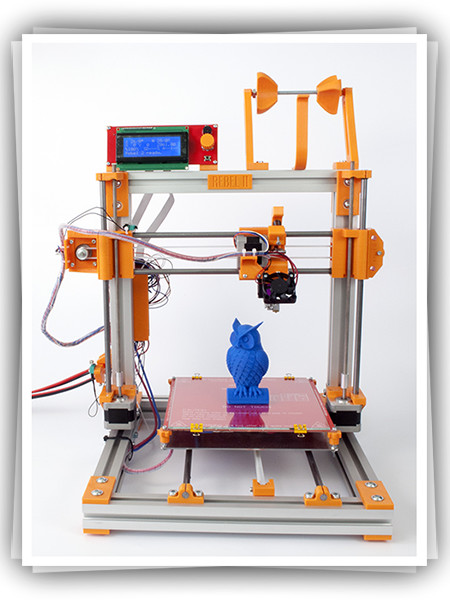

Services: printer, 3D printing, CAD design

Printers & Materials: Lulzbot Taz3 (ABS Plastic), Makerbot Replicator 5th Generation (PLA Plastic)

Get A Quote

Hello my name is James Zatopa, I am the owner of Zatopa.com, a 3D printing supply company. I have been working with 3D printing for years and will be expanding my capabilities as my store grows. I currently offer 3D printing on two different machines. The first is a Mendelmax …

Services: printer, 3D printing

Printers & Materials: Mendel Max 1.5 (Nylon, PLA Plastic, ABS Plastic), CubeX Duo - professional quality prints (PLA Plastic)

Get A Quote

We are GetPrinting3D, a 3D printing retail showroom in Evanston, Illinois! We sell the printers, filament, and printer accessories, as well as rental time on the machine for individuals through makeXYZ. We are primarily a 3D Systems Authorized Reseller, but we also carry the Afinia H-Series, the MakerBot Desktop 3D …

We are primarily a 3D Systems Authorized Reseller, but we also carry the Afinia H-Series, the MakerBot Desktop 3D …

Services: printer, 3D printing

Printers & Materials: 3D Systems Cube Desktop 3D Printer (ABS Plastic, PLA Plastic), Afinia 3D Printer H-Series (ABS Plastic), CubePro Single (PLA Plastic, ABS Plastic), XYZ Da Vinci 1,=.0 (ABS Plastic)

Get A Quote

Looking for High Quality, Great Pricing and Instant Turnaround? So were many of our customers…until they found The UPS Store 3D Printing Solutions! Now our customers consistently enjoy all 3!! Our Stratasys Uprint SE Plus uses Fused Deposition Modeling (FDM) Technology to build in real ABSplus thermoplastic, creating models and …

Services: printer, 3D printing

Printers & Materials: Stratasys Uprint (ABS Plastic)

Get A Quote

Very interested in Additive manufacting I run a small print farm to mainly supply small parts for my job in aerospace. This is where I offer my excess capacity.

This is where I offer my excess capacity.

Services: printer, 3D printing, CAD design

Printers & Materials: Prusa Mk3S (PLA Plastic, ABS Plastic, PET Plastic, HIPS), Prusa mk3s (PET Plastic), Prusa mk3 (PET Plastic), Peopoly Moai (PLA Plastic), Peopoly Moai (Resin)

Get A Quote

Sponsered Ad

I'm Matthew, and a bought a Makerbot. I love this thing, and have been printing on it non-stop! If you have any questions or just want to see one in action, I'd love to hear from you! Also, I do personal 3D scans, get a head of yourself made today! …

Services: printer, 3D printing, CAD design

Printers & Materials: Makerbot Replicator (5Th Gen) (PLA Plastic)

Get A Quote

I am a recent college graduate with a degree in Systems Engineering and Design. I'm currently working as a 3D printing technician and specialist and have several years of additive manufacturing experience. In my free time I am a maker and I enjoy working on my printers and designing fun …

I'm currently working as a 3D printing technician and specialist and have several years of additive manufacturing experience. In my free time I am a maker and I enjoy working on my printers and designing fun …

Services: printer, 3D printing, CAD design

Printers & Materials: Creality Ender 3 (PLA Plastic), Elegoo Mars (Resin), Kodak Portrait (PLA Plastic, ABS Plastic)

Get A Quote

I have a bunch of Pla + and abs in stock in different colors. Blue nylon in stock as well. Fast turnaround on small orders. Can mail parts or meet for a pickup. If you want something printed out in a special material or color i can order it if …

Services: printer, 3D printing, CAD design

Printers & Materials: Rostock Max (Nylon, ABS Plastic, PLA Plastic, Brass)

Get A Quote

Services: printer, 3D printing

Printers & Materials: Maker Select V2 (PLA Plastic)

Get A Quote

Curretly I run an Ender 3. The build volume is 220mm cubed. The colors I can print in are ever changing because I print so many things. If you need a specific color let me know and I'll try to get it if I can. I am working on teaching …

The build volume is 220mm cubed. The colors I can print in are ever changing because I print so many things. If you need a specific color let me know and I'll try to get it if I can. I am working on teaching …

Services: printer, 3D printing, CAD design

Printers & Materials: Ender 3 (Carbon Fiber, ABS Plastic, PLA Plastic, Wood)

Get A Quote

Design, Modeling, Prototyping, Printing and Finishing 3D Printing services for Product Prototypes, Industrial Tooling/Jigs, Medical Prototypes, Custom Jewelry, Games, Gifts, Toys, etc. SLA Resin printing and FDM Printing. Laser cutting available. Equipment: Elegoo Mars, e3d Bigbox Dual or Rostock Max v2 Sample of Materials: e3d Edge, ABS, PLA, Taulman Bridge …

Services: printer, 3D printing, CAD design

Printers & Materials: E3D Bigbox And Rostock Max V2 (Wood, Carbon Fiber, Flexible Plastic, PET Plastic, PLA Plastic, Nylon, Bronze, ABS Plastic)

Get A Quote

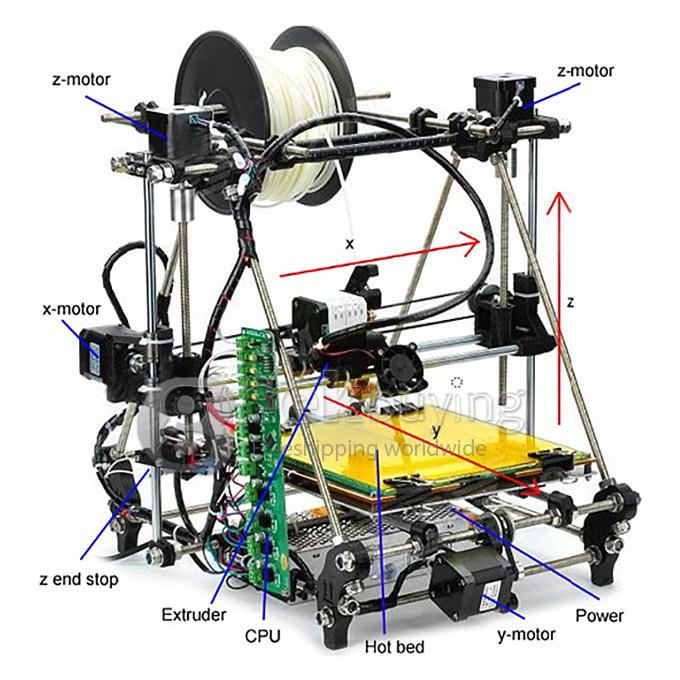

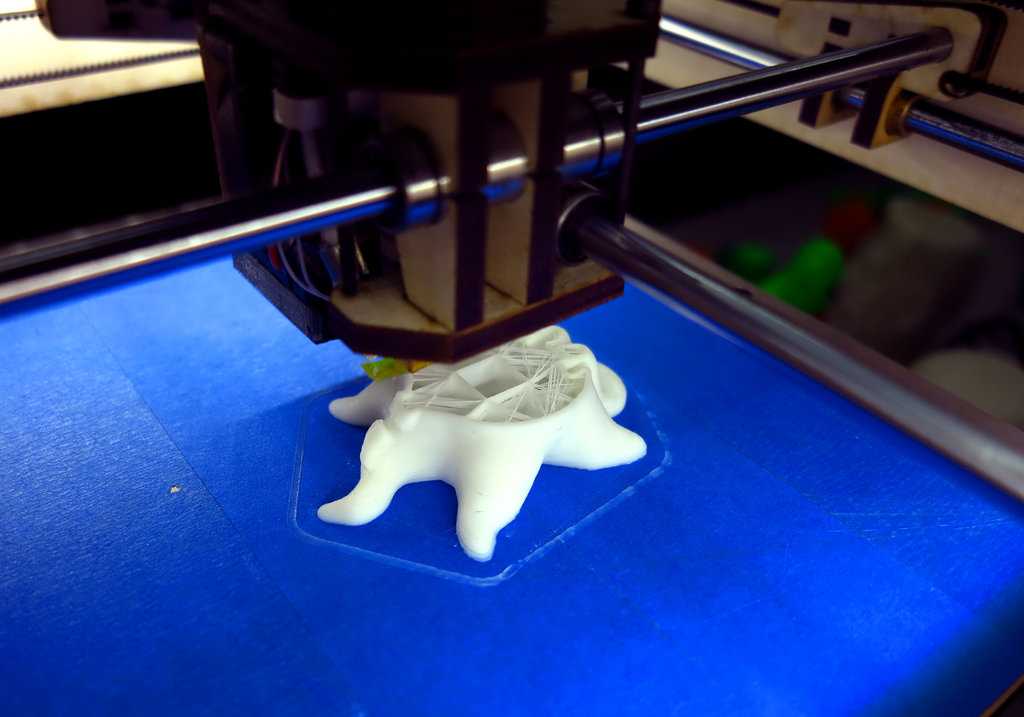

FDM: Fused deposition modeling

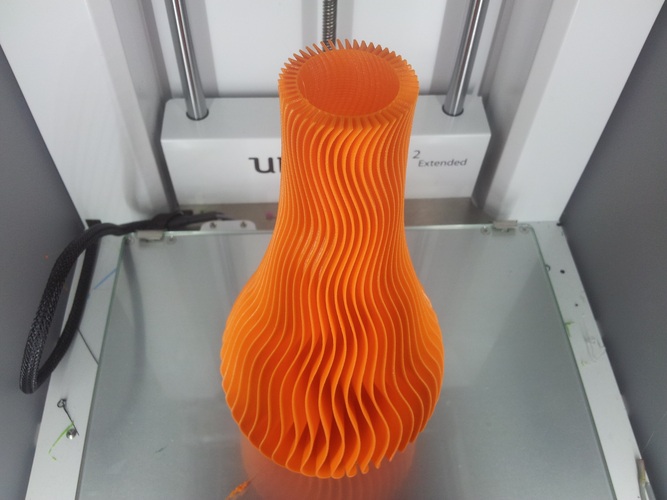

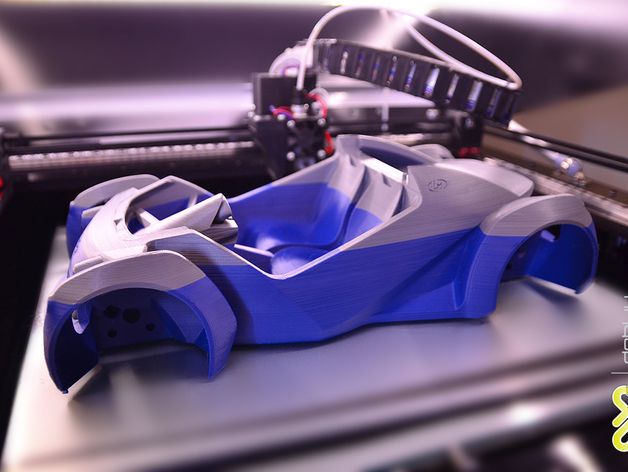

FDM: Fused deposition modeling or FDM 3D Printing is the go-to choice for affordable and fast prototypes, the creation of marketing items like 3D logos and just-for-fun projects. FDM handles difficult geometry including undercuts. Turn-around time from most printers is quick.

FDM handles difficult geometry including undercuts. Turn-around time from most printers is quick.

A diverse range of materials are used, but deposited layers are often visible. FDM objects are 50% weaker than injection molded parts. Did you know that FDM is also called FFF ' fused filament fabrication?

Get Instant quote

Learn More

SLA: Stereolithography

SLA: Stereolithography or SLA 3D Printing produces smooth surfaces and offers excellent detail. Printed objects have the feel of injection molded parts. SLA is popular for prototyping, manufacturing in single and small batches and producing dental/medical models and prosthetics.

DLP, or digital light processing, is a form of SLA that offers quicker printing but less resolution. The surface of DLP-printed parts is not as smooth. SLA/DLP parts are strong, resistant to water. Additional properties depend on the material, usually resin, that is used. Because SLA printers and materials are expensive, print costs can be higher.

The surface of DLP-printed parts is not as smooth. SLA/DLP parts are strong, resistant to water. Additional properties depend on the material, usually resin, that is used. Because SLA printers and materials are expensive, print costs can be higher.

Get Instant quote

Learn More

SLS: Selective laser sintering

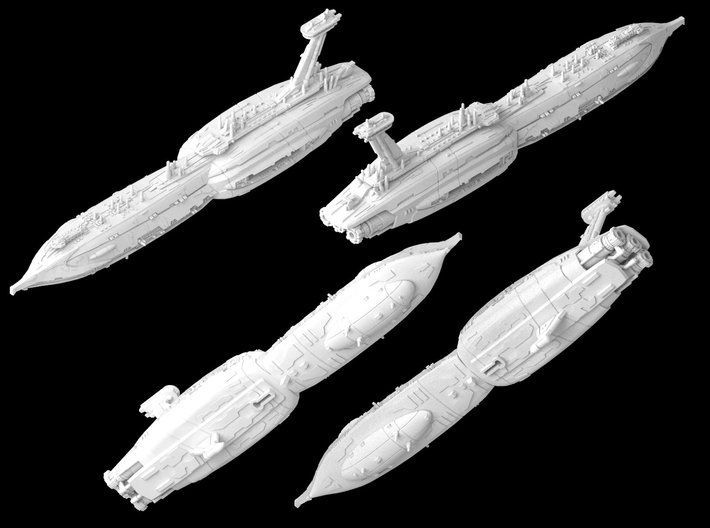

SLS: Selective laser sintering or SLS 3D Printing is direct digital manufacturing with tremendous accuracy. It is used in rapid prototyping, small-batch manufacturing and custom tool production. It is used with sand, rubber, metal, glass and polymers including nylon and polystyrene.

SLS is used to manufacture functional and non-functional parts. Complexity is not a problem. Some parts require machining after printing to improve the surface. Longer lead times of several days are often required with SLS.

Get Instant quote Learn More

Jetting or PolyJet:

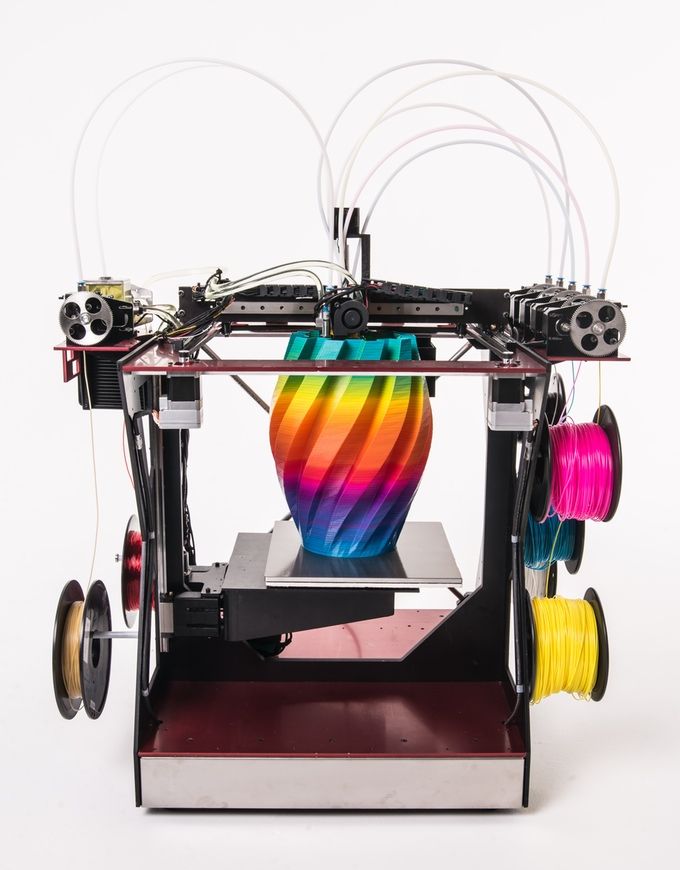

Jetting or PolyJet: PolyJet material printing is used when dimensional precision are smooth surfaces are demanded. It offers an excellent range of plastic photopolymer options and is used for concept models, rapid prototyping, small-batch manufacturing, and producing jigs, fixtures and tools. Materials used can be brittle, so using material jetting for functional parts is not recommended. Polyjet prints are highly customizable and our sales staff is happy to help. Please email part files and print requirements to [email protected]

Get Instant quote

Learn More

ABS

This tough, precise plastic is used in LEGOs. FDM with ABS is affordable and has excellent mechanical. ..

..

Get Instant quote

Learn More

PLA

This is today's green print plastic used in FDM printing. Polylactic acid is made from biodegradable...

Get Instant quote

Learn More

NYLON

Used with SLS and FDM printing, nylon is a strong and versatile material for single-part...

Get Instant quote

Learn More

RESIN

When precision detail and a smooth surface are essential, resin is ideal. Used in SLA, DLP and...

Get Instant quote

Learn More

TPU

This thermoplastic elastomer is right for SLS and FDM printing. TPU is flexible, even rubberlike, but...

Get Instant quote

Learn More

PETG

Polyethylene terephthalate glycol is an FDM material with quick turnaround time. This thermoplastic...

This thermoplastic...

Get Instant quote

Learn More

PEKK

Biomedical and Industrial plastic/PEKK: Polyetherkeytonekeytone is strong...

Get Instant quote

Learn More

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

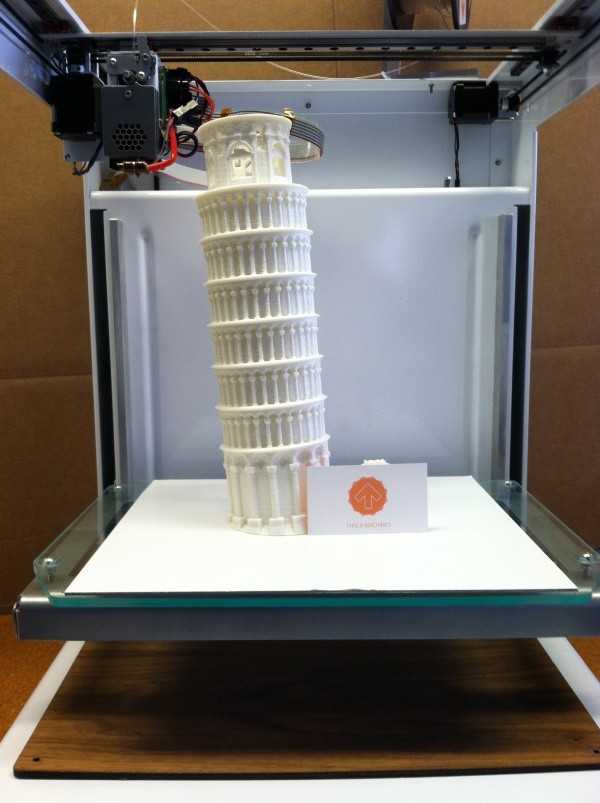

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

What is 3D printing?

-

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

What kinds of things can I 3D print?

-

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process.

With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables. -

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

Is it possible to combine local materials and 3D printing?

Is it possible to combine local materials and 3D printing?

The art of building an ice block shelter is passed down from father to son among the Inuit, the indigenous peoples who inhabit the northernmost regions of the planet. The circular plan, inlet tunnel, air outlet and ice blocks form a structure in which the heat generated inside melts the surface layer of snow and seals the gaps, improving the thermal insulation of the ice. During a storm, an igloo can be the difference between life and death, and is perhaps the most iconic and radical example of what it means to build with local materials, few tools, and lots of knowledge. In this case, ice is all you have.

The circular plan, inlet tunnel, air outlet and ice blocks form a structure in which the heat generated inside melts the surface layer of snow and seals the gaps, improving the thermal insulation of the ice. During a storm, an igloo can be the difference between life and death, and is perhaps the most iconic and radical example of what it means to build with local materials, few tools, and lots of knowledge. In this case, ice is all you have.

The use of rich resources and local workforce are key concepts of sustainable architecture that are often overlooked by solutions replicated from other contexts. Is there room for local materials given the new requirements and technologies, the globalization of building materials and building technologies? In particular, with regard to 3D printed structures, are we destined to build them only from concrete?

When we searched for 3D printing on the Internet, we quickly came up with two main results. The first has to do with the boom in 3D printing buildings made of concrete, the most commonly used building material in the world but also responsible for high levels of carbon emissions. The second group is experimental and innovative construction projects on other planets.

The second group is experimental and innovative construction projects on other planets.

On the surface of Mars, which is more inhospitable than the North Pole, the idea of using only what is available locally makes the most sense. If the desire to colonize the planet continues to gain momentum, supplying spaceships with building materials (bags of cement, gravel or plywood sheets) is clearly out of the question. The Marsha prototype, developed by Ai SpaceFactory, won the NASA Centennial Challenge. Like the vast majority of current offerings, Marsha uses 3D printing techniques using a mixture of basalt fiber extracted from Martian rocks and a renewable bioplastic (polylactic acid or PLA) derived from plants that could be grown on Mars. The recyclable polymer composite outperformed concrete in NASA tests for strength, durability, and crushing.

Research is also underway on lunar surface shelters, also 3D printed using "lunar concrete". The main ingredient in the mixture will be the powdery soil found all over the Moon's surface, known as lunar regolith. It was noted that astronauts' own urine could be used to bind and create concrete. “Researchers have found that adding urea to the lunar geopolymer mix, a concrete-like building material, works better than other common plasticizers like naphthalene or polycarboxylate to reduce water requirements. The mixture coming out of the 3D printer proved to be stronger and retained good machinability.”

It was noted that astronauts' own urine could be used to bind and create concrete. “Researchers have found that adding urea to the lunar geopolymer mix, a concrete-like building material, works better than other common plasticizers like naphthalene or polycarboxylate to reduce water requirements. The mixture coming out of the 3D printer proved to be stronger and retained good machinability.”

But back to planet Earth, 3D printing of buildings has been identified as a technique that has the potential to streamline designs, create organic shapes, reduce material consumption, construction time, labor required, logistical requirements, and future costs. Several interesting examples have emerged, but most of them are based on concrete. In other words, while 3D printing can be decentralized, the raw materials used for construction are rarely available locally.

A paper by several University of Texas researchers evaluating materials for 3D printing of buildings highlights the importance of focusing on concrete and its environmental impact. “Additive manufacturing methods are poised for a major industry transformation by increasing automation, saving on material usage and enabling an unparalleled combination of form and function; however, the use of concrete as the extrusion material of choice could greatly exacerbate growing environmental concerns.”

“Additive manufacturing methods are poised for a major industry transformation by increasing automation, saving on material usage and enabling an unparalleled combination of form and function; however, the use of concrete as the extrusion material of choice could greatly exacerbate growing environmental concerns.”

Researchers note that considerable attention has been paid to finding more environmentally sustainable alternatives to concrete, especially soil itself, which can be collected and planted without the need to transport materials over long distances, thus significantly reducing the carbon footprint and building-in energy costs.

There are already some initiatives in this direction. The collaboration between the team of Mario Cucinella Architects (MC A) and WASP, 3D printing specialists in Italy, resulted in the first 3D printed structure made from a completely natural, recyclable and carbon neutral material: raw earth. The round prototype is called TECLA (a combination of the words Technology and Clay) and was built in Massa Lombarda (Ravenna, Italy) using several synchronized 3D printers working simultaneously. It is a round house created from recyclable and reusable materials taken from local lands.

It is a round house created from recyclable and reusable materials taken from local lands.

The Urban Dunes project in Abu Dhabi creates organic structures such as "urban oases" from a thick layer of sand, mixing active passive and low-tech systems for maximum thermal comfort. The vaults are made up of stereotomic 3D printed sandstone blocks using local sand as the base material. The desert sand is cured using binder blasting technology, and the 55 cm thick 3D printed vaults are expected to prevent urban space in the middle of the desert from overheating.

When thinking about large cities, we must also take into account that there is a huge amount of municipal solid waste and construction waste. A team from the Polytechnic University of Valencia (UPV) has developed an alternative to reinforced concrete beams by creating beams from recycled plastic using additive manufacturing. The result is a significant weight reduction (by 80%), which facilitates transportation and reduces assembly energy costs while maintaining structural rigidity.

A team from the Polytechnic University of Valencia (UPV) has developed an alternative to reinforced concrete beams by creating beams from recycled plastic using additive manufacturing. The result is a significant weight reduction (by 80%), which facilitates transportation and reduces assembly energy costs while maintaining structural rigidity.

There are many opportunities to include other materials for additive manufacturing - raw earth, sand, agricultural waste, plastics and other waste. Uses, in turn, range from finished buildings and pavilions to assisting in ecosystem restoration, prosthetic limbs and printing organs.

Like ice for the Eskimos, local materials are often better adapted to climatic conditions and therefore lessen the impact of construction. In addition, they can provide a longer lifespan for a structure, whether it is recycling or decomposing on the ground. The innovations associated with 3D printing in construction will forge new paths to architecture when they can finally bring together local materials, knowledge and the needs of the general public.

This article is part of the section : Local materials. Every month we explore the topic in depth through articles, interviews, news and projects. Learn more about our monthly themes. As always, we welcome contributions from our readers; if you would like to submit an article or project, please contact us.

.

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- Civil engineering 3D printing

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How 3D printing can be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

3D printing for construction uses both a 3D printer, which has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

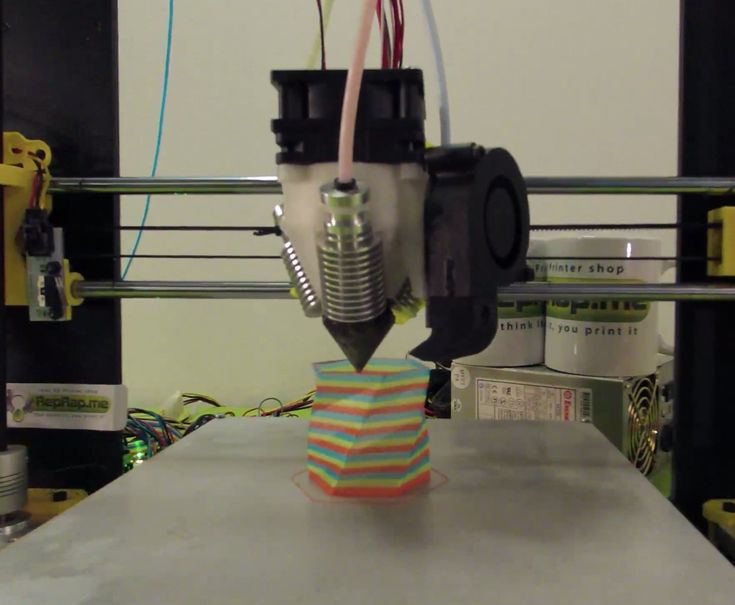

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, layer by layer, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also used factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed number plate in Lewis Grand Hotel, Philippines

3D printed number plate in Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs help construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure, thanks to a new design and manufacturing method. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future more people will be able to buy houses of their own design, according to their individual needs

Reverse side of medal

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Lack of skilled labor

With the current problem of a shortage of skilled labor in the construction sector in general, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional construction process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and it is likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.