3D printer makerbot video

Learn 3D Printing - Get Started With 3D Printing

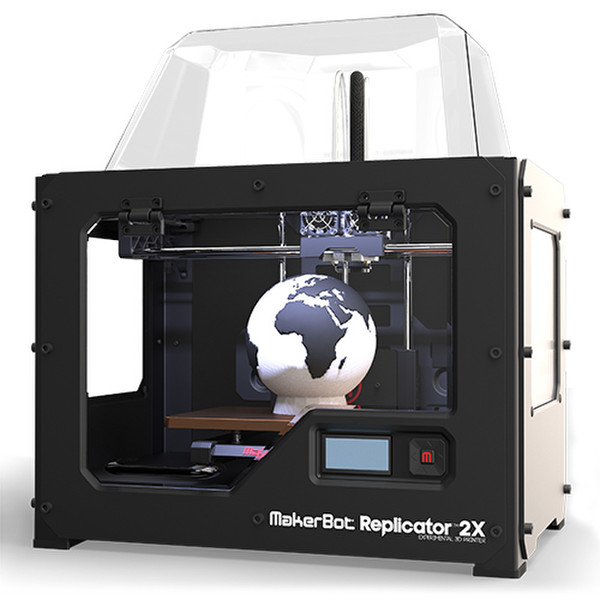

Scroll down for more information about how to use your MakerBot 3D Printer and MakerBot software. For MakerBot set-up questions, go to www.makerbot.com/getstarted.

Explore the key technologies that work together to make MakerBot 3D Printers possible.

FDM or Fused Deposition Modeling

MakerBot's 3D Printers rely on a technology called Fused Deposition Modeling or FDM. It uses an extruder, which acts similar to a hot glue gun. Plastic filament is fed in through the top, is melted at 215℃, and finally is “extruded” out of a small nozzle into the layers that build a 3D print.

Cartesian Coordinates

MakerBot 3D Printers know where to move using a three dimensional cartesian coordinate system which defines every point of a 3D model with a unique position along the X, Y, and Z axes. The coordinates are fed to the printer from MakerBot Print and MakerBot Mobile.

MakerBot PLA Filament

MakerBot PLA Filament is the best and most consistent filament optimized for use in MakerBot 3D Printers. Safe for the classroom, office, or home, this filament is non-toxic and easy-to-print with minimal warping or curling.

MakerBot Tough Filament

Created for engineers and designers, MakerBot Tough Filament allows you to print durable, high-impact strength prototypes and fixtures. This filament is tested and optimized to print reliably and easily with the Tough Smart Extruder+.

To print on a MakerBot 3D Printer, you must obtain a 3D file, prepare it in MakerBot Print, and send it to your MakerBot 3D printer.

Step 1: 3D File

In order to 3D print, you must have a 3D file. Here are a few ways to get a file:

Design an object to print in a 3D modeling or CAD program.

Scan an existing object with a 3D scanner.

Find a file online from websites like thingiverse.com

Step 2: Prepare

Before sending a 3D file to your MakerBot, you must prepare the file. Preparing an object in our softwares translates your objects into a language the 3D printer can understand. This is referred to as slicing.

This is referred to as slicing.

MakerBot Print

MakerBot Print is free software that optimizes and streamlines the 3D printing process. It allows you to discover, prepare, manage, and share 3D prints.

MakerBot Mobile

MakerBot Mobile is a free app that gives you the power to wirelessly set up, monitor, and control all of your network-enabled MakerBot 3D Printers over the Cloud.

Rafts and Supports

Print with Overhangs

An overhang is when a layer extends outward, potentially unsupported, over the previous layer.

If your models have overhangs greater than 68 degrees (measured from the vertical axis) for MakerBot PLA Printers, then you will need to print with support material.

What Are Rafts & Supports?

Supports are printed scaffolding for overhangs. You can turn on supports in MakerBot Print.

A Raft helps with adhesion to the build plate by laying down an even flat foundation. Rafts are turned on by default in MakerBot Print.

Rafts are turned on by default in MakerBot Print.

Completed Print

Both rafts and supports are physically removed after the print is finished. Once rafts and supports are removed, your model is complete!

Infill Percentage

Infill is the support structure inside your object. Changing Infill affects your print’s density. A higher percentage will result in a more solid object, while 0% infill will make your object hollow.

0% infill

10% infill

40% infill

Number of Shells

Shells are the outer layers that make up the surface of your prints. Adding more shells does not affect its external dimensions, but can make your object stronger.

1 Shell

2 Shells

5 Shells

Layer Height and Print Resolution

Layer Height, also known as Print Resolution, changes the surface quality of a 3D print. Low resolution means the layers are thicker, objects print faster, and the surface quality is rougher. High resolution means the layers are thinner, objects print slower, and the surface is smoother. We suggest printing at our standard print quality.

High resolution means the layers are thinner, objects print slower, and the surface is smoother. We suggest printing at our standard print quality.

Low 0.3mm (300 microns)

Standard 0.2mm (200 microns)

High 0.1mm (100 microns)

Step 3: Print

Follow these steps before printing: Attach your extruder and build plate to your MakerBot 3D Printer, then load the filament. If you have any questions about your specific model MakerBot 3D printer, please refer to the manuals at support.makerbot.com/learn

Remote Monitoring

Once a print has begun, you can monitor its progress from MakerBot Print or MakerBot Mobile. Your MakerBot 3D Printer will need to be connected to a network over Wi-Fi or Ethernet to monitor remotely.

Sanding

Learn how to sand your 3D prints to create an amazing surface finish, or prepare them for painting or silicone molding.

Painting

Learn how to create a nearly automotive quality paint job on any of your 3D prints.

MakerBot NYC Training

Get scaled up on your MakerBot 3D Printers faster with hands-on, education-specific sessions taught by MakerBot's knowledgeable, friendly experts.

MakerBot Certified Trainers

Your teachers, team, or staff can quickly learn about our products and solutions in The MakerBot Fundamentals Workshop. It's a 3-hour session conducted by a MakerBot Certified Trainer near you.

Free 3D Design Program Overview

Learn all about how 3D files are created in this overview that covers 3D scanning, popular 3D design programs, and popular websites for downloading 3D files, like MakerBot Thingiverse.

3D Design Tips and Tricks

In this webinar, Drew Lentz, a 3D design expert on the MakerBot Learning Team, offers tips on topics like overhangs, build plate orientation, print-in-place assemblies, and more.

Makerbot Australia - Easy and reliable 3D printing

Search for:

3D Printer Sale on now!

3D Printers Australia

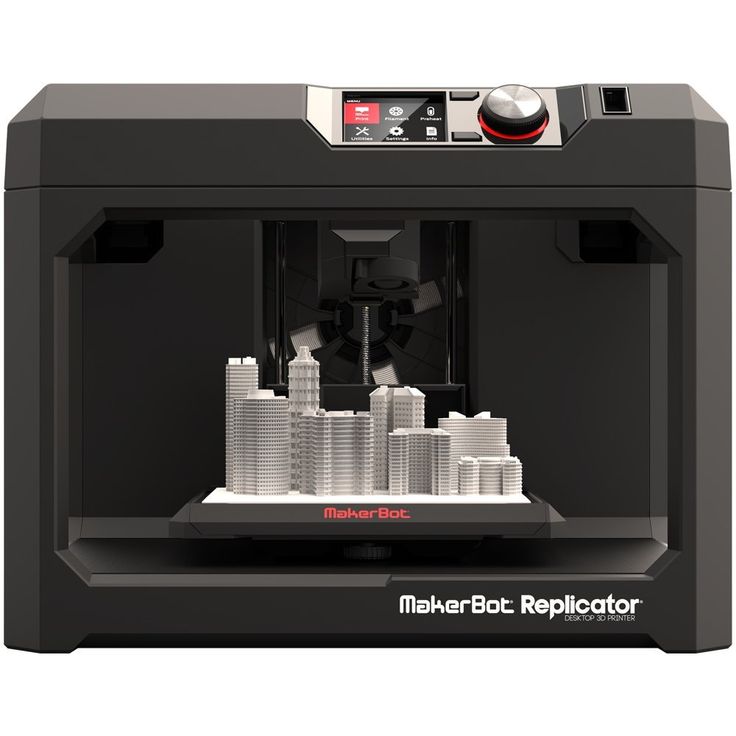

MakerBot believes there’s an innovator in everyone. As a global leader in desktop 3D printing, we set the standard in reliability and ease-of-use by providing effective solutions for every stage of the desktop 3D printing process.

As a global leader in desktop 3D printing, we set the standard in reliability and ease-of-use by providing effective solutions for every stage of the desktop 3D printing process.

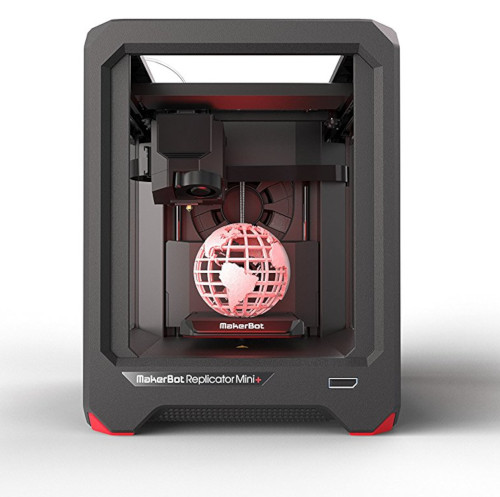

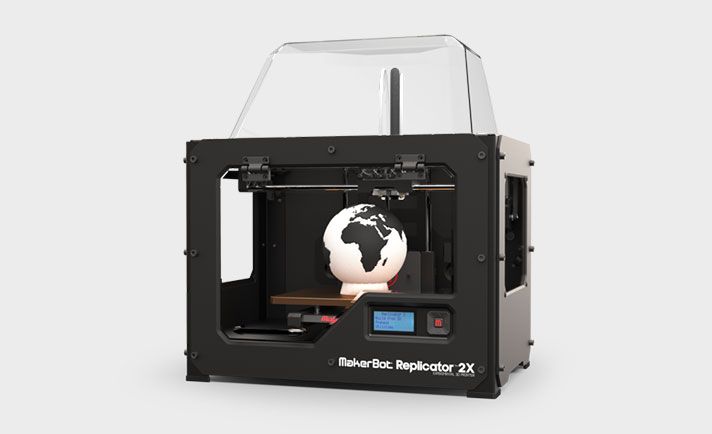

MakerBot deliver an award-winning 3D Printer range suitable for both Educators and Professionals, with local Australia Warranty and support.

Our Education range of best 3D printers in Australia are easy to use for both teachers and students.

The Method 3D printing platform offers a desktop replacement for industrial 3D printers.

MakerBot’s reliability and ease of use sets us apart and promises you maximum innovation for minimal investment.

You can see our 3D Printers in action at our showrooms in Sydney, Brisbane, Melbourne and Adelaide. We also have a network of certified resellers Australia wide.

Contact us for more information or to find your closest authorised reseller.

3D Printer Models

Print carbon fiber reinforced nylon and other engineering-grade composite parts with three dimensional strength and accuracy like never before on METHOD’s unique industrial desktop platform. The most affordable and versatile Carbon Fibre 3d printer

The most affordable and versatile Carbon Fibre 3d printer

Why choose MakerBot?

- MakerBot produce Robust 3D printers

- Easy and reliable 3D printing

- MakerBot is the leading 3D printer brand in education

- Dimensional accuracy in our professional range and the ability to print with a wide variety of materials

- MakerBot Cloudprint streamlines the 3D printing process and allows you to print from anywhere. Standard across the range

- MakerBot Thingiverse Education: thousands of ready to use lesson plans spanning many classroom subjects

- MakerBot 3D printing Certification program for teachers and students

- Industry leading local Australia 3D Printer warranty and support

Learn More

MakerBot Method bridges the gap between desktop & industrial 3D printers.

MakerBot 3D printers deliver outstanding results across both the professional and education sectors due to their quality, innovative design & ease of use.

Makerbot 3D Printing

Software & Apps

Discover, import, prepare, monitor and share your 3D print. Makerbot’s software and apps optimize and streamline the 3D printing process for any workflow or environment.

Learn More

Contact Us

Enquiry 1300 118 308

Service 1300 448 384

[email protected]

Success!

Subscribe

HEAD OFFICE: 40 Koornang Rd, Scoresby

Victoria Australia 3179

3D Printers Australia : Melbourne, Adelaide, Brisbane, and Sydney

Designed by Kiodo Design & Marketing

Designed by Kiodo Design & Marketing

Work 3d printer: characteristics, pictures and description.

Contents:

- How does a 3D printer work?

- What is it?

- How does it work? General principles

- How a 3D printer works. Video

- What materials are used?

- What items can be crafted?

As a result of the appearance on the world market of printers that support 3D printing technology, a new era of production of things has appeared. Three-dimensional creation of details has only recently spread in everyday life, since manufacturing and industrial enterprises have long used it. We offer you to find out how a 3d plastic printer works, what this equipment is and what consumables are used.

Three-dimensional creation of details has only recently spread in everyday life, since manufacturing and industrial enterprises have long used it. We offer you to find out how a 3d plastic printer works, what this equipment is and what consumables are used.

What is this machine?

A 3D printer is a device that allows you to create three-dimensional objects created by analogy with virtual models of objects. Compared to a conventional printer that prints text on paper, a 3D device outputs three-dimensional information. In other words, it reproduces an object that has real physical parameters.

How does it work? General principles

The work begins with the design of a virtual template thanks to a special computer program.

Next, the model is processed programmatically to separate it into layers. Then the following steps are performed:

- Layer-by-layer formation of a mass formed using composite powders.

- Distribution of mass over the working surface as the chamber is filled.

- Applying adhesive after each layer.

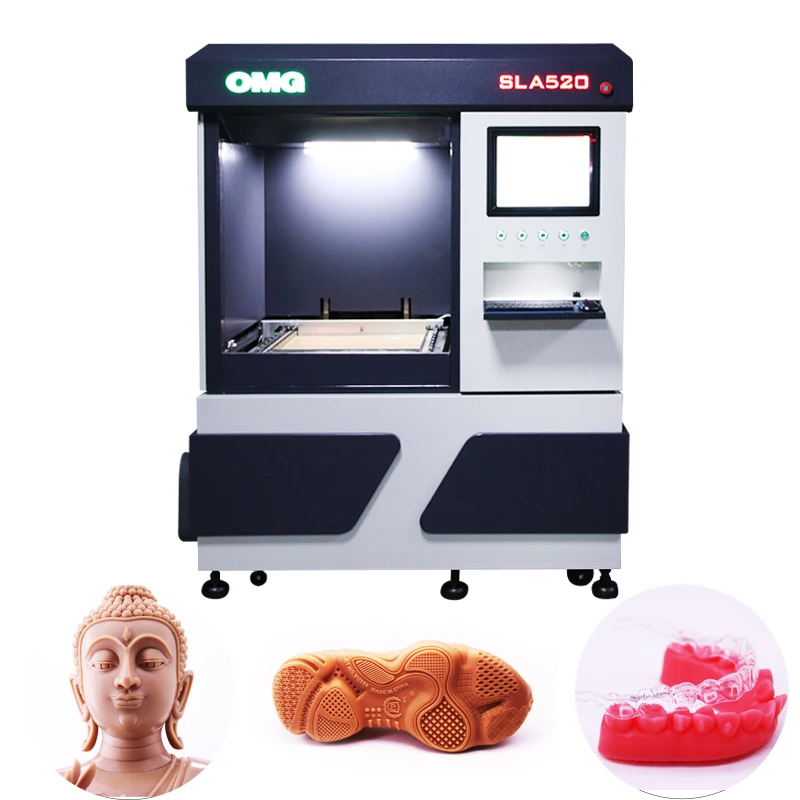

After that, you can pull out the finished object from the working chamber. It is important to understand that the equipment used for printing differs in how it works. Today the following technologies are used:

- rapid prototyping;

- layer-by-layer thermoplastic welding;

- laser stereolithography;

- laser sintering.

How a 3D printer works. Video

What materials are used?

The choice in favor of one or another material with which you can print models depends on the specifics of the technology. The most popular materials are plastic such as FDM and PLA. It is possible to use polycarbonate, nylon, polyethylene and other types of raw materials used in industry. In some installations, mixing of materials is allowed, the use of additional substances that improve the quality characteristics of the finished product. High-quality plastic not only provides an excellent result - it guarantees the reliability of the product as a whole. The most exotic type of material is metal. Here you have to use a special metal powder. The result is not welded, but layer-by-layer glued product.

In some installations, mixing of materials is allowed, the use of additional substances that improve the quality characteristics of the finished product. High-quality plastic not only provides an excellent result - it guarantees the reliability of the product as a whole. The most exotic type of material is metal. Here you have to use a special metal powder. The result is not welded, but layer-by-layer glued product.

What items can be crafted?

A home 3D printer can easily reproduce plastic parts for use in household appliances. Also, the technology was highly appreciated by medical workers. With specially adapted devices, a single organ sample can be obtained faster and cheaper than with alternative types of devices. It all depends on the scope of application and the type of plastic used in the manufacture.

Although 3D printing is still considered a new technology, today its relevance remains beyond doubt.

robots, 3D printers and CNC machines in electronics manufacturing

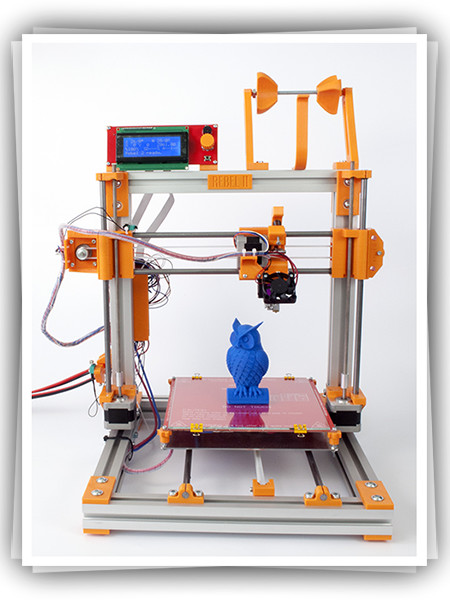

The fourth industrial revolution is already changing the world – manufacturing processes are gaining speed, process chains are shrinking, and rapid prototyping is one of the areas whose development is most conducive to this. Robots and 3D devices are becoming common equipment in large enterprises and small businesses for the rapid production of functional prototypes.

Robots and 3D devices are becoming common equipment in large enterprises and small businesses for the rapid production of functional prototypes.

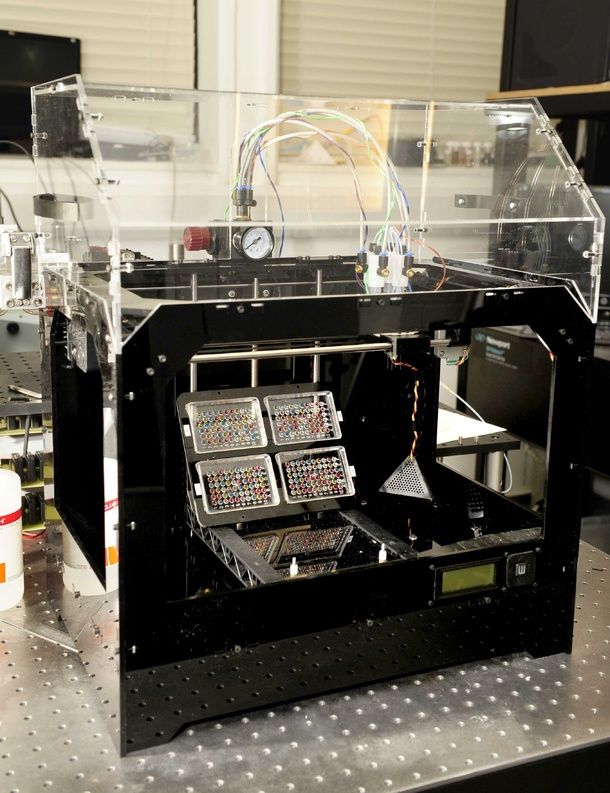

St. Petersburg company "Kreotek" specializes in the development of electronic equipment. In 2020, representatives of the company ordered a number of devices from Top 3D Shop that will help increase the company's productivity.

In this case, we demonstrate the capabilities of 3D printers, cutters, and robotics in the development and manufacturing of electronics.

Video

Customer

"Creoteca" offers a turnkey electronic equipment development service - from the approval of the project to the serial production.

The company fulfills orders for various industries - agriculture, defense complex enterprises and others. The leading areas of activity are security systems, industrial and telecommunications equipment, augmented reality systems.

The leading areas of activity are security systems, industrial and telecommunications equipment, augmented reality systems.

Creotek positions itself as a "custom solution developer" and is focused on fabless production.

Fabless-production is a format of activity in which a manufacturer develops and sells products, outsourcing serial production. Niche leaders such as Apple, Nvidia, Broadcom, and Texas Instruments manufacture all or part of their products in third-party factories.

Equipment

The equipment purchased from Top 3D Shop solved the problem of reducing the time for creating prototypes, searching for and implementing new technological processes.

Hanwha HCR-3

One of the Hanwha HCR-3 COBOT. According to employees, the equipment was purchased to test the possibility of including robotic manipulators in the technological processes for the production of case products.

Specialists are exploring the possibilities of collaborative robots in relation to company tasks. The question of their inclusion in existing technological processes is still open.

Raise 3D PRO2 PLUS

using the RAISE 3D PRO2 PLUS FDM PLUS Specialists of the Creteecs quickly and relative cheap variants of prototypes are created.

The choice of a 3D printer was determined by the ratio of its price and capabilities. It was decided to purchase a model that can print both small and large parts.

Initially, the choice was between Raise 3D and Picaso 3D. As a result, preference was given to the first.

As a result, preference was given to the first.

Sinterit Lisa Pro

The Sinterit Lisa Pro SLS printer was purchased to create final functional prototypes for subsequent serial production.

By the end of 2019, the Polish 3D printer was the best option for solving Kreotek's tasks in terms of price-quality-opportunity ratio.

Raylogic 11G 1620

In some projects, it is necessary to tightly place the elements in the product after an accurate calculation; ready-made standard designs are not suitable for this.

Laser machine Raylogic 11G 1620 was chosen for cutting metal sheets and engraving. Working field parameters allow to produce cabinets of any size.

Benefits of Own Equipment Fleet

Before contacting us, Creotek outsourced prototyping work. Despite the high quality of order fulfillment, the speed of work of subcontractors did not always meet the requirements.

Despite the high quality of order fulfillment, the speed of work of subcontractors did not always meet the requirements.

According to Creotek, the creation of a prototype, which in the project took 1-3 days, could take several weeks.

Now Creotek engineers use new equipment to independently produce samples that are not inferior in quality to outsourcing ones.

The company has already appreciated the time savings. Now there is no need to send orders to other companies, wait in line, use your qualified designers as couriers when accepting finished parts, which was also not uncommon before.

Conclusions

The right choice of technologies and equipment increases the efficiency of even well-optimized processes.

Prototyping using additive technologies greatly reduces development time, sometimes by several times. Given the constant decline in prices for 3D equipment, the introduction of new technical processes is becoming affordable and profitable for a large number of companies.