Btsm helmet 3d print

BTSM Helmet - Axis

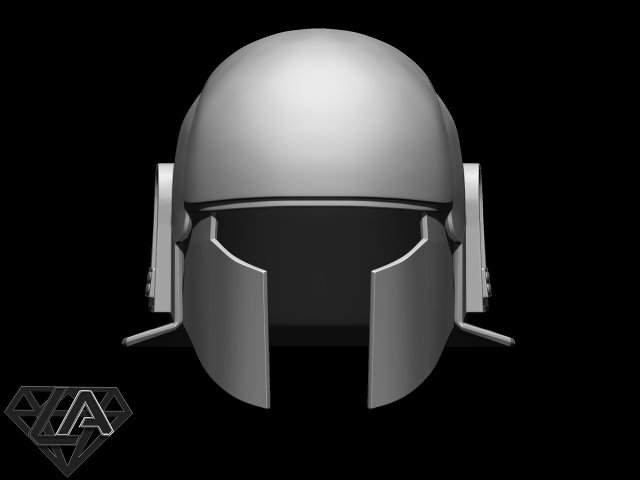

BTSM Helmet - AxisFor BTSM, a Montreal based music trio, their Black Tiger Helmets are more than a logo. Worn by each member, they are an integral part of the group’s unique trademark distinguishing them as one of the many diverse clients we collaborate with on a daily basis here at Axis Prototypes. To accomplish their vision of a durable yet visually stunning end product, BTSM turned to Axis Prototypes for our expertise and innovation in additive manufacturing to design and construct the signature Tiger Helmet.

- Objectve & Challenges

- Solution & Material

- Finishing & Post processing

- Final notes

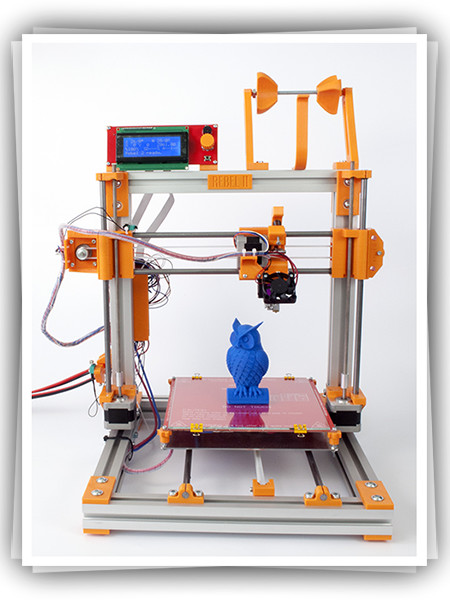

Wanting to escape the constraints imposed by traditional means of production, BTSM worked closely with our professional technicians to explore the vast array of solutions that 3D printing has to offer. The project needed to balance both visually aesthetic and sturdy functionality, as the trademark look of the helmet is used in high energy performances, photo and video shoots, and must be capable of packing down to travel. Collaborating with Axis technicians gave BTSM freedom and input over the design process, and the use of 3D printing allowed for customizable solutions in the weight and finish of the helmet. Working within the budgetary limitations of our client, each specification of the helmet was personalized to best fit their needs without negating the visual impact of the product.

Knowing our client needed a sleek and durable prototype, our experts chose to print the helmet with the Selective Laser Sintering (SLS) solution and using the Nylon 12 material, a powerhouse in 3D printing for producing strong and resilient end-use parts. As the helmet needed top levels of finishing, we recommended SLS over Fused Deposition Modelling (FDM) for its superiority in producing precise prototypes with less noticeable build lines, along with Nylons capacity to be primed and painted, as opposed to FDM’s filaments which do not support our finishing options to the same extent. Nylon 12’s advantage lies as well in its heat and chemical resistance which was essential to the prototype as it included LED light fixtures set within the helmet and required a material that could withstand heat without deforming or burning. SLS printing provided another unique bonus for the client; the powders used in printing generated a lightweight model of the helmet, allowing the performers to wear them for prolonged periods of time with maximized comfort.

SLS printing provided another unique bonus for the client; the powders used in printing generated a lightweight model of the helmet, allowing the performers to wear them for prolonged periods of time with maximized comfort.

For the outer and most visible parts of the helmets, we provided our top level of finishing, Showroom Level, which consists of the highest standard of sanding, primer coating, and automotive grade paint available in 3D printing to create a polished effect, perfect for the stage. However, in an attempt to be cost effective without compromising quality, our technicians adapted the design to include a second level of colourization for the model. For the smaller pieces and inside surfaces we provided our Dye Level finishing to colourize parts while maintaining a cheaper cost and maximizing time efficiency when compared to other means of colourization such as spray painting. Finally, the installation of inserts served to strengthen the fastened parts allowing the helmets to be assembled and taken apart efficiently and easily, ideal for travel and packing. BTSM filmed the final two prints and assemblies, including the finish, of the Tiger Helmet in house at Axis to present for their large fanbase.

BTSM filmed the final two prints and assemblies, including the finish, of the Tiger Helmet in house at Axis to present for their large fanbase.

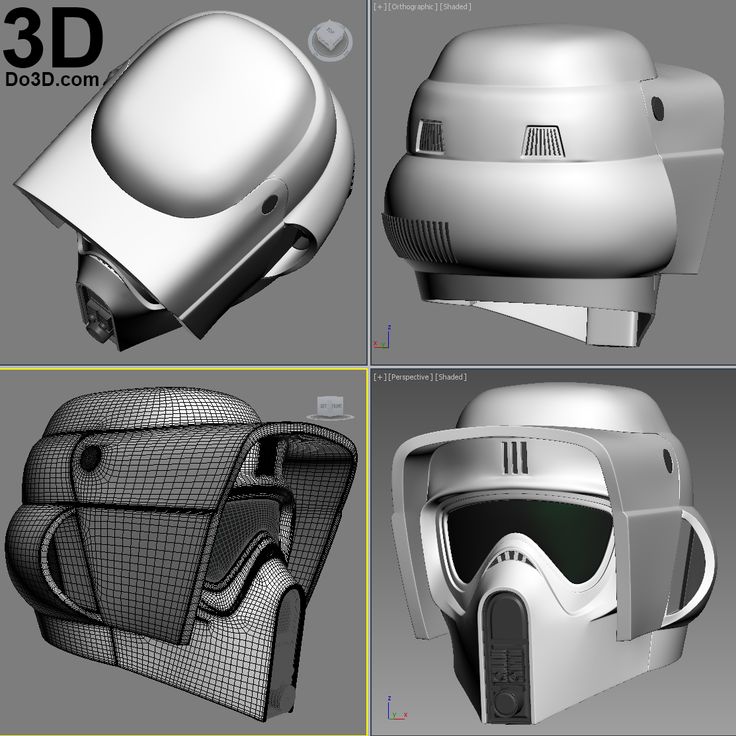

▷ btsm helmet 3d models 【 STLFinder 】

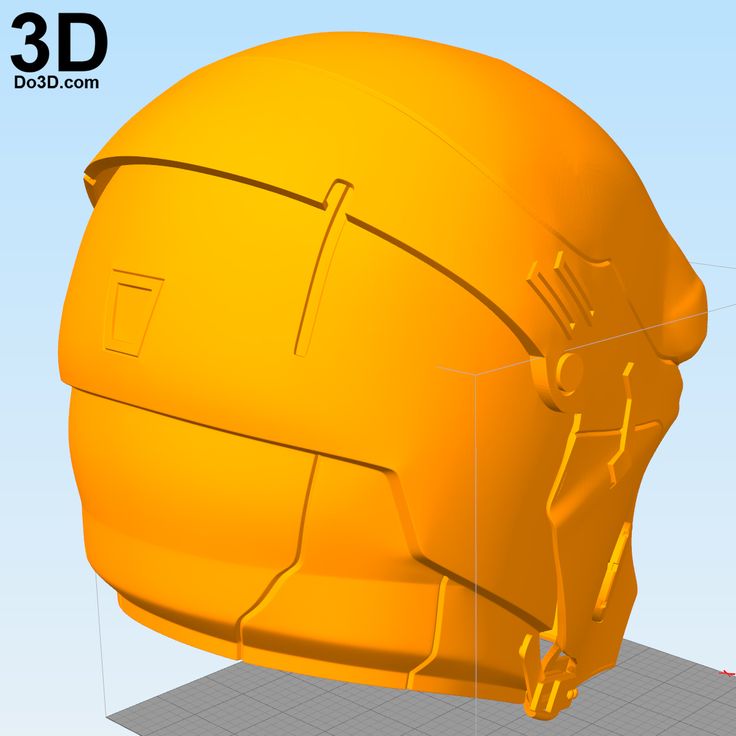

BTSM Helmet

thingiverse

Replica of BTSM helmet ready for 3d printing! ... Might need to scale to size.

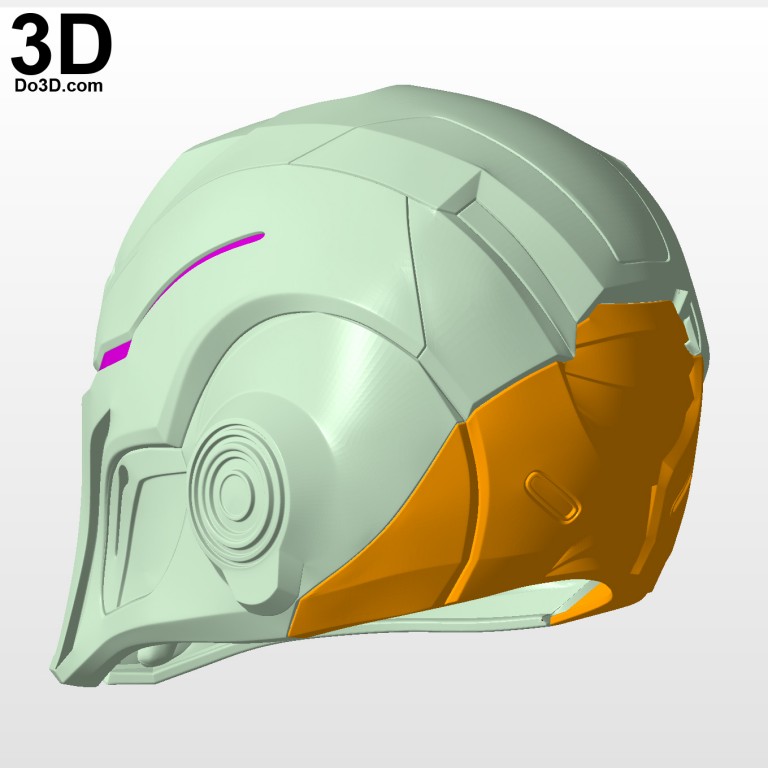

BTSM Helmet w/ LED channels (mesh fix)

thingiverse

This design is a modification of the original design via Thingiverse: BTSM Helmet by EstebanyAmaya on Thingiverse: https://www. thingiverse.com/thing:4540957 Designed to be better suited for wearing and printing. This helmet is scaled for the average...

thingiverse.com/thing:4540957 Designed to be better suited for wearing and printing. This helmet is scaled for the average...

Helmet

grabcad

Helmet

helmet

thingiverse

helmet

Helmet

grabcad

helmet

Helmet

grabcad

Helmet

helmet

grabcad

helmet

helmet

grabcad

helmet

Helmet

grabcad

helmet

Helmet

grabcad

Helmet

helmet

grabcad

helmet

Helmet

grabcad

Helmet

Helmet

thingiverse

Helmet

Helmet

grabcad

Helmet

Helmet

grabcad

Helmet

Helmet

grabcad

Helmet

Helmet

grabcad

HELmet

helmet

grabcad

helmet

Helmet

grabcad

Helmet

Helmet

grabcad

Helmet

Helmet

thingiverse

helmet

helmet

grabcad

helmet

helmet

grabcad

helmet

Helmet

thingiverse

Helmet

Helmet

grabcad

Helmet

helmet

grabcad

helmet

helmet

grabcad

helmet

Helmet

grabcad

Helmet

Helmet

grabcad

Helmet

Helmet

grabcad

helmet

Experience with 3ntr 3D printers in the development of a motorcycle helmet by the Italian company Momodesign

The Italian company Momodesign is an important player in the vehicle accessories market. Since the 1980s, Momodesign has been designing city bikes, including electric bikes, helmets and other accessories. 20 years ago, the design bureau introduced its first motorcycle helmet to the market, which subsequently won serious international recognition. Today, the company is breaking new ground with its latest product, the innovative Aero Helmet, featuring a unique design and high performance.

Since the 1980s, Momodesign has been designing city bikes, including electric bikes, helmets and other accessories. 20 years ago, the design bureau introduced its first motorcycle helmet to the market, which subsequently won serious international recognition. Today, the company is breaking new ground with its latest product, the innovative Aero Helmet, featuring a unique design and high performance.

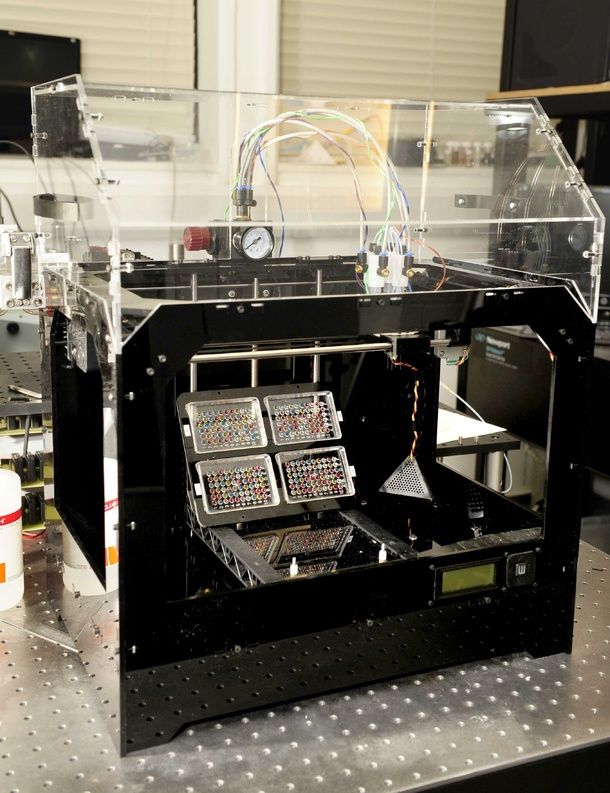

The Aero motorcycle helmet project was realized using 3ntr 3D printers, which once again confirmed the ability of the latter to meet the requirements of professional 3D printing. In this case, we are talking about the use of 3D equipment for rapid prototyping, but not for the production of final products. Nevertheless, the solutions offered by 3ntr provided the project with a number of important competitive advantages.

“The aim of the Aero project was to offer a revolutionary solution to the market, using tools that our competitors have never used,” says Commercial Director Mirco Rigo. “3D printing has made it possible for us to get functional prototypes in a very short time and it is quite easy to find answers to all questions related to product development. Moreover, this technology was extremely helpful whenever we needed to make the right choice between several possible design and functional solutions.”

“3D printing has made it possible for us to get functional prototypes in a very short time and it is quite easy to find answers to all questions related to product development. Moreover, this technology was extremely helpful whenever we needed to make the right choice between several possible design and functional solutions.”

It's easy to imagine how important the prototyping stage is to the realization of such a project. At the same time, the production of prototypes using classical methods was not economically feasible and took an extremely long time. However, their production using 3ntr 3D printers has become much more profitable both in terms of material costs and in terms of their production time. At the same time, the printed models were reliable and had all the necessary functionality.

“We were extremely short on time,” continues Mirco Rigo. “We set ourselves the goal of completing the project in 1.5 years, although it usually takes two to three years. With clean 3D-printable plastics at our disposal, we were able to make various helmet parts from several materials, compare them and choose the best solution.”

With clean 3D-printable plastics at our disposal, we were able to make various helmet parts from several materials, compare them and choose the best solution.”

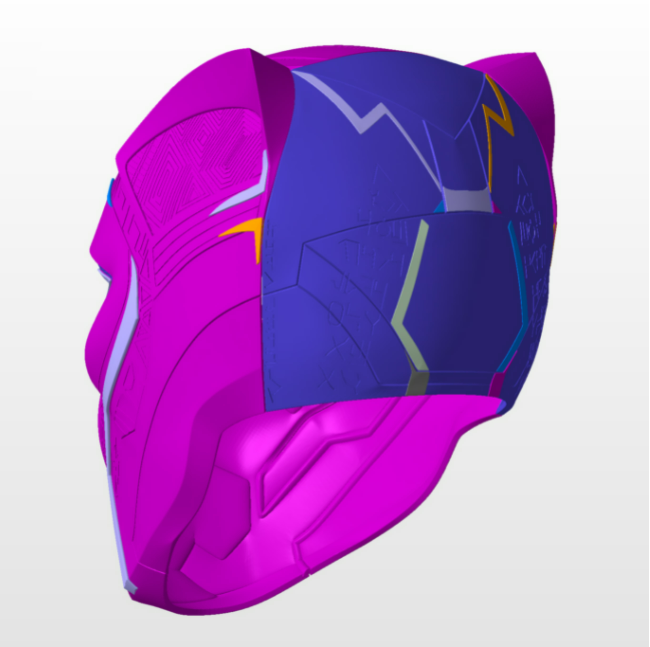

The result of this work was a high-tech helmet, the design of which combined futuristic and military elements. Innovative solutions include a smart ventilation control system (Tornado ventilation system, an optional accessory activated with a special application) and the absence of a classic external visor, which raises rider safety to a new level. The visor of the Aero helmet is integrated into the main body of the helmet and is fixed, this linear design significantly reduces the risk of the helmet getting stuck in the event of a fall from the motorcycle.

As Momodesign CEO Paolo Cattaneo points out, the Aero helmet is designed specifically for motorcyclists and fully meets their needs. “People with their desires, needs and urban lifestyle have always been at the center of our attention, and the ongoing evolution of the metropolis and the emergence of new trends remain a constant source of inspiration for us. All this is the starting point for creating products whose design, style and functionality best meet the needs and expectations of our customers”, - Paolo Cattaneo.

All this is the starting point for creating products whose design, style and functionality best meet the needs and expectations of our customers”, - Paolo Cattaneo.

The Aero Helmet is a striking example of the benefits that great design can bring to a product, as well as how useful 3D printing technology can be to bring the most daring and complex projects to life. The new Momodesign product perfectly demonstrates the desire for innovation, including at the level of tools used in production.

“We believe Aero, with its unique features, can become the flagship of our portfolio and open up a new future for the company. Safety, design and innovation are the cornerstones of our philosophy, and we will strive to continue this principle in future projects,” Eleonora Cattaneo, Marketing Director.

Today, Momodesign and their latest Aero motorcycle helmet project have already received public recognition and a number of awards. In particular, this year Momodesign won the 26th Compasso d'Oro award, and the Aero helmet is on display at the ADI Design Museum in Milan.

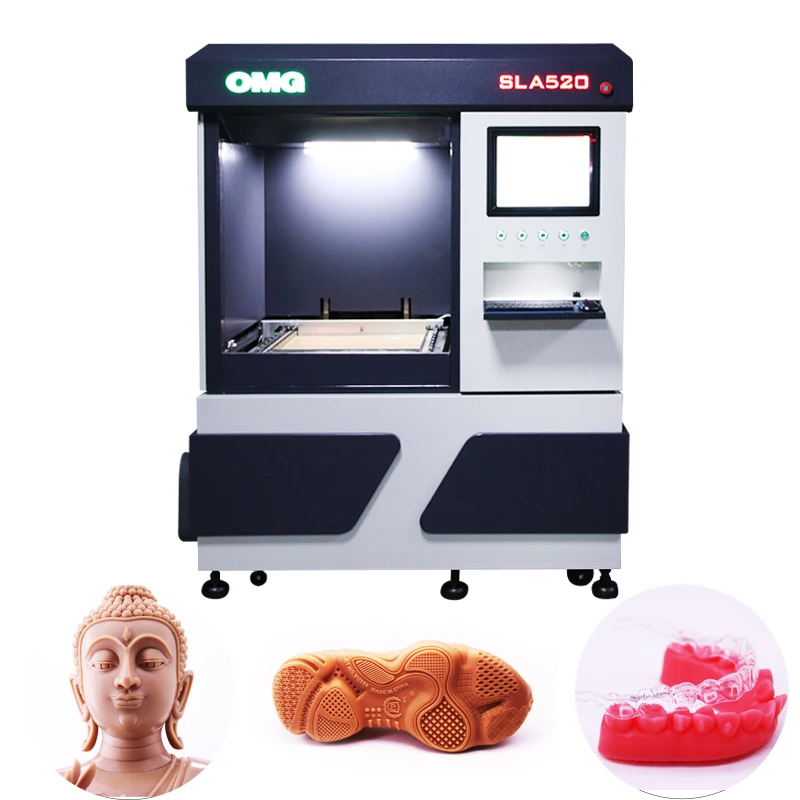

Project of 3D printing of a photopolymer ski helmet

Implementation stories

Rapid prototyping

Art and design

Author: Alexey Chekhovich

Author: Alexey Chekhovich

Concept | Project analysis | Challenges | Solutions | Stages of work

Laser stereolithography is one of the most widespread 3D printing technologies, providing undoubted advantages in prototyping compared to traditional production methods. Let's see how ProtoFab completed a complex project in a short time using a photopolymer 3D printer to create a high-quality model of a ski and snowboard helmet.

- Model: Blizzard ski helmet with drone

- Material: ProtoFab Formula W photopolymer

- Fabrication Technology: 3D Stereolithographic Printing

- Lead time: 3 days

- Customer requirement: eye-catching lines, uniform coloration, clear color contrast, stylish and attractive overall appearance

ProtoFab was contacted by the organizing committee of the Cross-Strait Industrial Design Awards with a request to produce prototypes for each of the contestants. It will be much easier for the participants to showcase their innovative and original designs if they submit high quality models to the competition. The creators of the ski helmet contacted ProtoFab and sent in their drawings. They wanted bold, streamlined lines to be used in the design, and the quality of the finish to be as high as possible.

It will be much easier for the participants to showcase their innovative and original designs if they submit high quality models to the competition. The creators of the ski helmet contacted ProtoFab and sent in their drawings. They wanted bold, streamlined lines to be used in the design, and the quality of the finish to be as high as possible.

Concept

The Blizzard (Snowstorm) helmet is designed primarily for skiers and snowboarders. These extreme sports involve certain risks and can lead to serious injury. Therefore, it is extremely important to use the proper equipment that would provide increased safety. The Blizzard helmet is equipped with a GPS tracking chip, which can significantly speed up the search for an athlete in the event of a fall, disorientation or avalanche. This is especially important in frosty weather, which is typical for alpine skiing.

The Blizzard helmet also features a high-speed camera capable of capturing breathtaking moments with incredible clarity and detail. However, the most unique feature of the helmet is the support for an unmanned aerial vehicle. The video recording drone inside the helmet can fly out of the helmet and return to its place at any time.

However, the most unique feature of the helmet is the support for an unmanned aerial vehicle. The video recording drone inside the helmet can fly out of the helmet and return to its place at any time.

Project analysis

After receiving the drawings from the client, the ProtoFab team had to decide which technology to choose - CNC machining or 3D printing. It immediately became obvious that additive manufacturing would be the best solution. Traditional CNC machining includes careful design analysis, programming, direct machining on the machine, and a number of other complex and time-consuming tasks. All this usually leads to high costs. In turn, 3D printing is a much simpler process, which can significantly reduce the lead time. And for such projects, where the product does not have to withstand a lot of weight, 3D printing is especially suitable.

Calls

Surface quality played a major role in the project. Polishing and painting had to be done exactly according to the client's vision. The design of the helmet features multiple protrusions and four colors - Matte Black, Gloss Black, Gloss Orange and Steel Grey. The experienced ProtoFab team faced some challenges in polishing and ensuring perfect contrast between different colors.

The design of the helmet features multiple protrusions and four colors - Matte Black, Gloss Black, Gloss Orange and Steel Grey. The experienced ProtoFab team faced some challenges in polishing and ensuring perfect contrast between different colors.

Solutions

Since the model could be printed as a single piece, the technicians only needed to correct the drawings in the software and add the necessary supports. The use of supporting structures ensures the stability of the product during printing and prevents possible deformations. In addition, the entire model can be printed in one session, without the need to break it into parts.

Complex post-processing

Upon completion of printing, the model was carefully removed from the 3D printer and washed with alcohol. This removed any residual liquid material that may have remained in the helmet after printing. The next step - removing supports - requires special care so as not to cause any damage to the model. Below is a view of the product after separation of all supporting structures.

Below is a view of the product after separation of all supporting structures.

The printed object may be slightly rough and have visible surface defects. ProtoFab sanded the model, starting with coarse sandpaper (400) and gradually moving to fine sandpaper (1500). Polishing was a particular problem due to the complex surface texture on the top of the helmet. The application of paint also required special care. In order to ensure an absolutely uniform coating, three separate polishing and painting cycles were carried out.

Top coat application

To get the look the client wanted, it was important to choose the right paint color. The ProtoFab team needed to use all their experience to ensure that the color separation was perfectly sharp and the shades were completely uniform. One of the photos below shows how the paint was matched against the reference shade map provided by the client.

Choosing the right color requires patience and great care.