The dangers of 3d printing

3D Printing Safety at Work | NIOSH

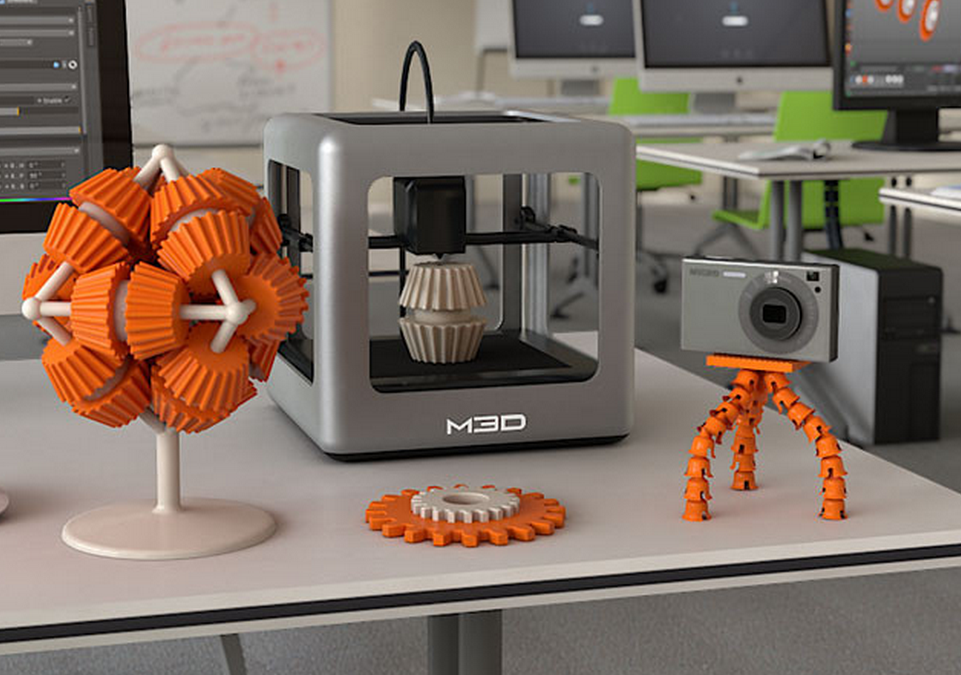

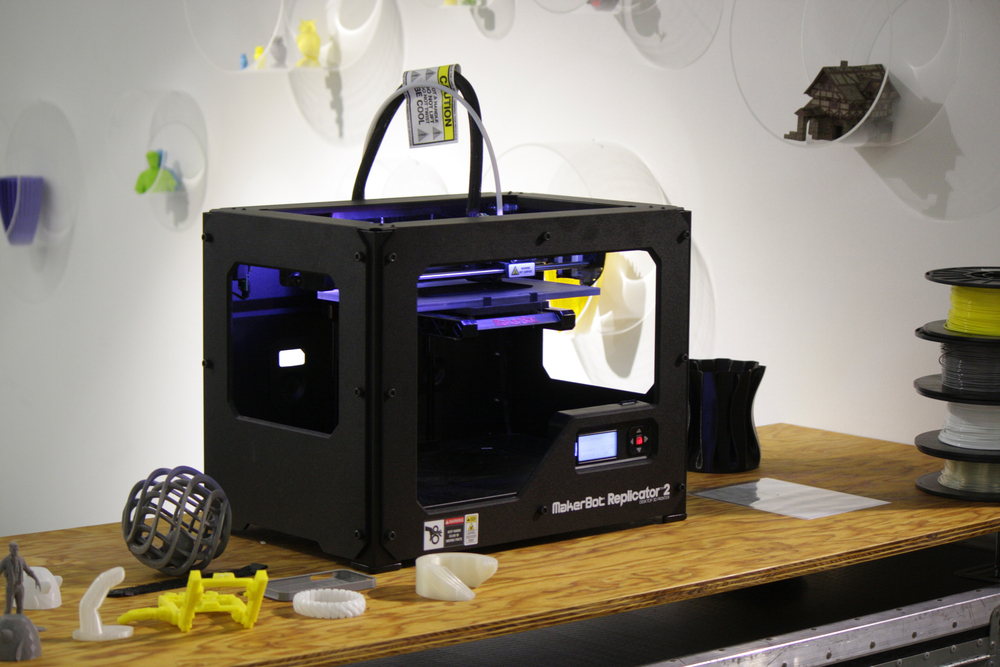

3D printing, or additive manufacturing, is increasing in popularity. This technology is becoming less expensive and more accessible to both businesses and consumers. It is currently used in a wide variety of settings, such as labs, factories, hospitals, schools, libraries, and homes. Despite its popularity, 3D printing is still a relatively new technology and there are many gaps in the information available about health and safety risks. The National Institute for Occupational Safety and Health (NIOSH) is studying the potential hazards of 3D printing and ways to reduce health and safety risks for workers.

What is 3D printing?

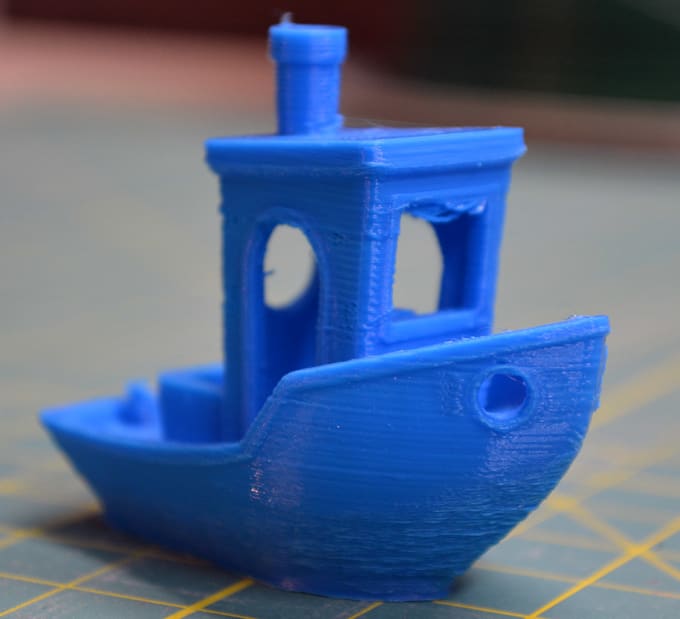

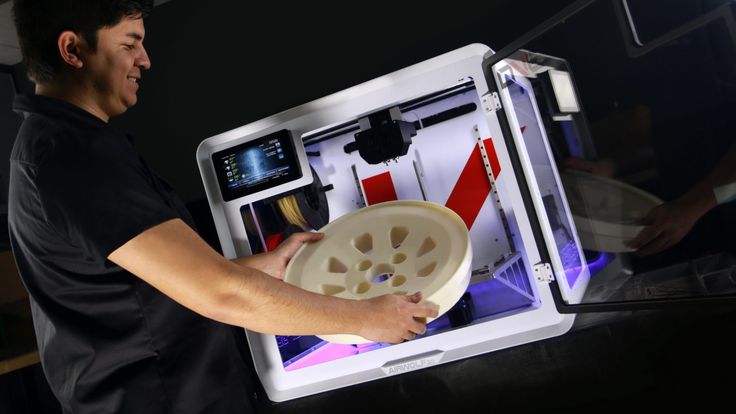

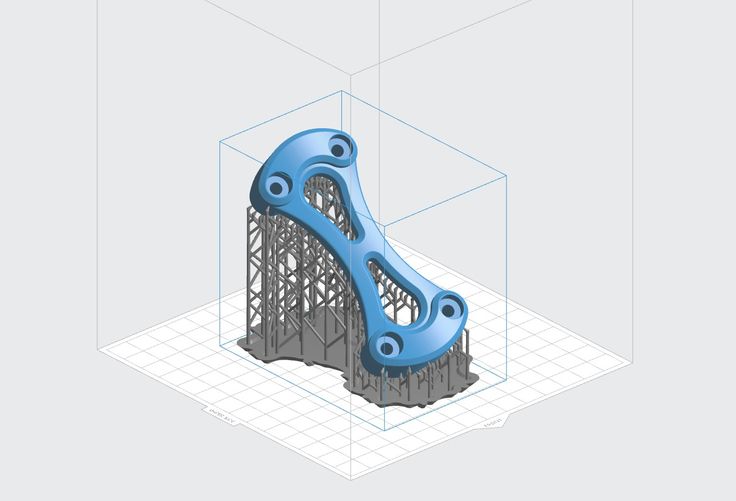

3D printers create three-dimensional (or 3D) objects via computers. A computer file “tells” the 3D printer what object to create and how. 3D printers essentially stack layers of a material to get the desired product. Different types of 3D printers do this in different ways. For example, some use high temperatures, some use ultraviolet light, and others use lasers. 3D printers also use different print materials, such as plastics, rubbers, and metals.

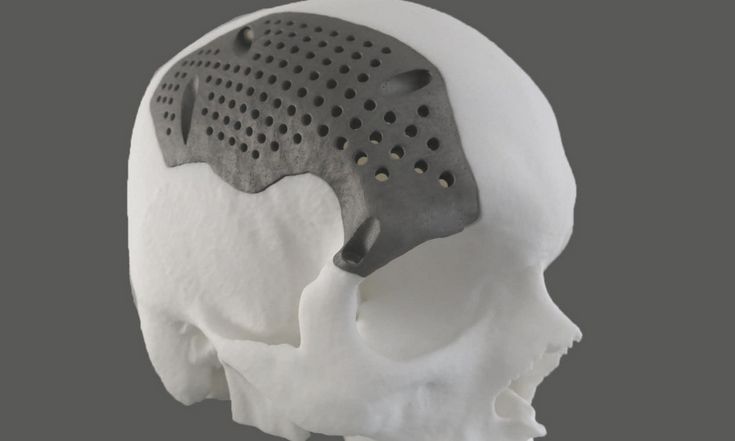

Industries traditionally used 3D printing for prototyping. However, it is now also used for production. Industries using 3D printing include the automotive, aerospace, electronics, medical, and many others.

Potential Hazards of 3D Printing

3D printing hazards vary depending on the type of printer and materials used. For example, print materials that are powders are more likely to be inhaled or cause skin problems than others. 3D printers that use lasers have different hazards than printers that use high temperatures to melt materials. Some common hazards include:

- Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air.

- Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

- Static, fire and explosion: Some materials used can be flammable or combustible.

High temperatures from some printers can cause burns.

High temperatures from some printers can cause burns.

Ways to Protect Workers from 3D Printing Hazards

NIOSH has studied multiple ways to reduce exposure to 3D printing hazards. Some options include

- Limiting equipment access to trained or authorized personnel

- Using enclosures for 3D printers and ventilation to capture chemical emissions

- Using materials with lower emissions

- Reducing time spent near the printer while it is running

- Training workers on potential hazards and how to protect themselves

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, or lab coats

The ways to reduce exposure depend on the type of printer and materials used. NIOSH has created two posters to help workers explore ways to reduce potential 3D printing hazards. One poster focuses on 3D printing with metal powders and the other focuses on filaments:

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Help NIOSH Learn More about 3D Printing

Do you use 3D printing in your workplace? You can help NIOSH continue assessing 3D printing hazards and controls. Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

More Information

- Additive Manufacturing

- NIOSH Science Blog: Characterizing 3D Printing Emissions and Controls in an Office Environment

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

The dark side of 3D printing: 10 things to watch

The dark side of 3D printing: 10 things to watch

The 3D printer is a double-edged sword. It stands to transform technology and society for the better, but we also can't ignore the potential negative consequences.

As with any new technology, it’s easy to get swept up in the benefits of 3D printing. It opens up a world of new possibilities for all industries, and stands to lessen transportation costs, environmental impacts, waste, and reliance on corporations by enabling the maker movement.![]()

But 3D printers are still potentially hazardous, wasteful machines, and their societal, political, economic, and environmental impacts have not yet been studied extensively. To make sure you aren’t thrown off guard by the conversations to come, we’ve compiled a list of 10 things you need to know about the dangers and potentially negative impacts of 3D printers.

1. 3D printers are energy hogs

When melting plastic with heat or lasers, 3D printers consume about 50 to 100 times more electrical energy than injection molding to make an item of the same weight, according to research by Loughborough University. In 2009, research at MIT’s Environmentally Benign Manufacturing program showed that laser direct metal deposition (where metal powder is fused together) used hundreds of times the electricity as traditional casting or machining. Because of this, 3D printers are better for small batch runs. Industrial-sized 3D printers may not be the answer to lessening our use of coal power any time soon.

2. Unhealthy air emissions

3D printers may pose a health risk when used in the home, according to researchers at the Illinois Institute of Technology. The emissions from desktop 3D printers are similar to burning a cigarette or cooking on a gas or electric stove. The 2013 study was the first to measure these airborne particle emissions from desktop 3D printers. While heating the plastic and printing small figures, the machines using PLA filament emitted 20 billion ultrafine particles per minute, and the ABS emitted up to 200 billion particles per minute. These particles can settle in the lungs or the bloodstream and pose health risk, especially for those with asthma.

3. Reliance on plastics

One of the biggest environmental movements in recent history has been to reduce reliance on plastics, from grocery bags to water bottles to household objects that can be made from recycled materials instead. The most popular—and cheapest—3D printers use plastic filament. Though using raw materials reduces the amount of waste in general, the machines still leave unused or excess plastic in the print beds. PLA is biodegradable, but ABS filament is still the most commonly used type of plastic. The plastic byproduct ends up in landfills. If 3D printing is going to be industrialized, that byproduct or other recycled plastic needs to be reused.

Though using raw materials reduces the amount of waste in general, the machines still leave unused or excess plastic in the print beds. PLA is biodegradable, but ABS filament is still the most commonly used type of plastic. The plastic byproduct ends up in landfills. If 3D printing is going to be industrialized, that byproduct or other recycled plastic needs to be reused.

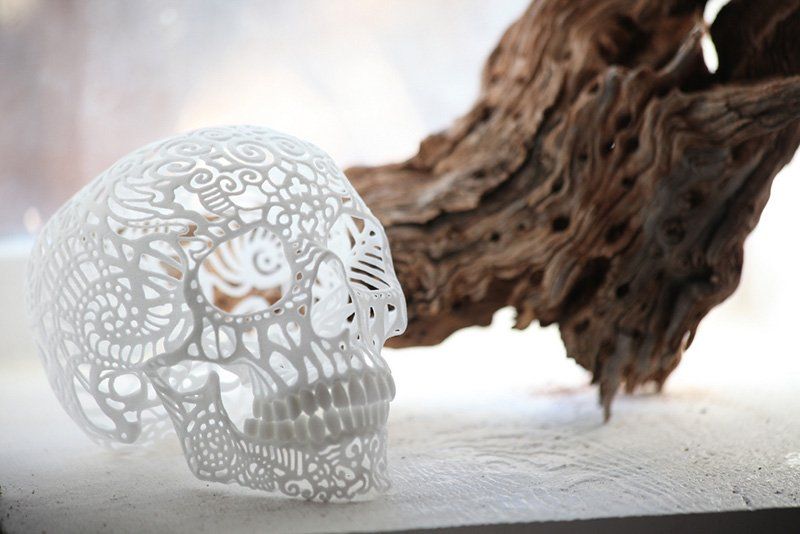

4. IP and licensing deals

In January, 3D Systems acquired Gentle Giant Ltd., which owned the licensing rights to toy franchises such as The Hobbit, The Walking Dead, Harry Potter, Alien, and Star Wars. Gartner has said that companies may lose at least $100 billion in four years to licensing or IP owners. 3D printing will change the business market—and the black market for these items—and the legislation will have to rush to catch up. This potential digital piracy situation is comparable to the way the internet challenged the movie and music industries for copyrights, trademarks, and illegal downloads.

5. Gun control loopholes

The first successful 3D printed gun is old news, but its ramifications are very important. Companies are popping up around the world, attempting to sell these guns and/or the CAD designs for them. Engineering firm Solid Concepts has even fired rounds out of the first 3D printed metal gun. Congress’ Undetectable Firearms Act, which bans guns that can’t be detected by metal detectors or x-ray scanners, was renewed for 10 years. It left a loophole in the law, however: 3D printed guns with a tiny piece of metal aren’t banned by the Act. Legislators are attempting to close that loophole now, after Congress ignored the issue for quite some time, with special requirements for printed guns.

6. Responsibility of manufacturers

Weapons can be 3D printed. So can safety equipment such as helmets, wheels for bikes, and toys for small children. Of course there is the issue of intellectual property and trademark, but the larger issue involves responsibility. If a person shoots a gun and harms or kills someone, stabs someone with a 3D printed knife, or breaks their neck while riding on a bike with a 3D printed helmet, who is held accountable? The owner of the printer, the manufacturer of the printer, or the irresponsible person who thought it was a good idea to produce and use an untested product?

If a person shoots a gun and harms or kills someone, stabs someone with a 3D printed knife, or breaks their neck while riding on a bike with a 3D printed helmet, who is held accountable? The owner of the printer, the manufacturer of the printer, or the irresponsible person who thought it was a good idea to produce and use an untested product?

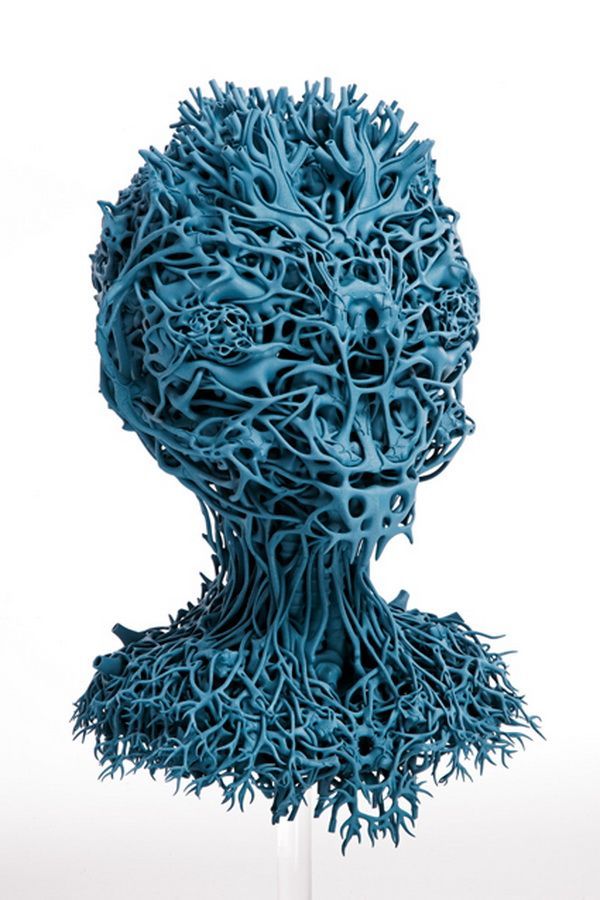

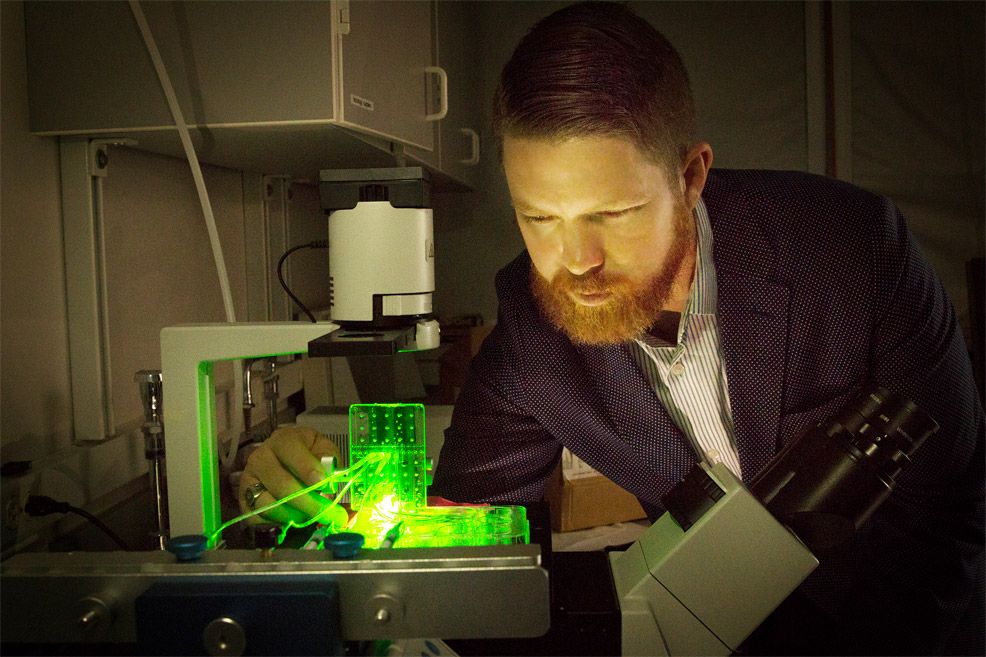

7. Bioprinting ethics and regulation

The conversations about the ethics of bioprinting have already begun. Organovo is printing liver cells as well as eye tissue cells in a partnership with the National Eye Institute and National Center for Advancing Translational Sciences. Scientists have also proposed mixing human stem cells with canine muscle cells to create enhanced organ tissue. Printing cartilage is still the most realistic type of bioprinting, and printing whole organs is still many years away, but 3D printing is growing in medicine quite rapidly. Conversations about the moral, ethical, and legal issues surrounding bioprinting have started, but they will inevitably cause a lot more controversy as it becomes more commonplace.

8. Possibility of 3D printed drugs

Assembling chemical compounds on a molecular level using a 3D printer is possible. A researcher at the University of Glasglow created a prototype of a 3D “Chemputer” that makes drugs and medicine. He wants to revolutionize the pharmaceutical industry by allowing patients to print their own medicine with a chemical blueprint they get from the pharmacy. Of course, this is a very long way off, but it stands to enable DIY chemists to create anything from cocaine to ricin.

9. National security risks

A white paper released from the National Defense University highlighted national security risks from 3D printing technology. Since there will be significant legal and economic implications on the business sector and 3D printers offer the ability to produce a wide range of objects that cannot be controlled yet, the paper noted that there are definitely national security risks that need to be analyzed in the near future.

10.

Safety of items that come into contact with food

Safety of items that come into contact with food You can print out a fork or spoon with your MakerBot, but if you use ABS plastic, it is not BPA-free. Luckily, new filaments that are safer to put in your mouth are being created for this specific reason, but they aren’t widely available yet. Many 3D printers have spaces where bacteria can easily grow if they aren’t cleaned properly, as well. In order to more safely-produced 3D printed food and kitchenware, there may be a need for an FDA-approved machine. People probably don’t want to eat genetically-engineered pizza off of toxic plates.

Lyndsey Gilpin

Published: Modified: See more HardwareAlso See

- 10 industries 3D printing will disrupt or decimate

- 10 facts on 3D printing: Understanding tech's next big game-changer

- Photos: Cool 3D printed products destined to be squashed by lawyers

- 3D printing: 10 factors still holding it back

- Hardware

Editor's Picks

- Image: Rawpixel/Adobe Stock TechRepublic Premium

TechRepublic Premium editorial calendar: IT policies, checklists, toolkits, and research for download

TechRepublic Premium content helps you solve your toughest IT issues and jump-start your career or next project.

TechRepublic Staff

Published: Modified: Read More See more TechRepublic Premium - Image: diy13/Adobe Stock Software

Windows 11 22h3 is here

Windows 11 gets an annual update on September 20 plus monthly extra features. In enterprises, IT can choose when to roll those out.

Mary Branscombe

Published: Modified: Read More See more Software - Image: Who is Danny/Adobe Stock Edge

AI at the edge: 5 trends to watch

Edge AI offers opportunities for multiple applications.

See what organizations are doing to incorporate it today and going forward.

See what organizations are doing to incorporate it today and going forward. Megan Crouse

Published: Modified: Read More See more Edge - Image: Apple Software

iPadOS cheat sheet: Everything you should know

This is a complete guide for Apple's iPadOS. Find out more about iPadOS 16, supported devices, release dates and key features with our cheat sheet.

TechRepublic Staff

Published: Modified: Read More See more Software - Image: Worawut/Adobe Stock

- Image: Bumblee_Dee, iStock/Getty Images Software

108 Excel tips every user should master

Whether you are a Microsoft Excel beginner or an advanced user, you'll benefit from these step-by-step tutorials.

TechRepublic Staff

Published: Modified: Read More See more Software

Potential dangers of a 3D printer. Part 2 Consumables

In the first article, we talked about the dangers that await the owner of the printer if the device is used improperly. Let's imagine a situation where a person received an electric shock due to the open body of the device or inadvertently touched a heated extruder, receiving an unpleasant burn. These events will clearly indicate the culprit of the incident, his negligence and disregard for safety requirements. They cannot be completely eliminated, but the likelihood of their occurrence can be seriously reduced by following the manufacturer's instructions and common sense.

However, when working with a 3D printer, we inevitably expose ourselves to the risk of another property, which is much more difficult to deal with: inhalation of harmful substances released during the melting of consumables.

Let's make a reservation right away - in this material we do not set ourselves the goal of describing all possible consumables. Despite the expansion of the range, the main raw materials for the FDM printer are still two types of plastic: ABS and PLA. In addition to them, other filaments will be mentioned in the article, however, we will focus on these polymers. So, let's try to understand together how dangerous printing consumables are. First, a few terms.

ABS (acrylonitrile butadiene styrene, ABS) is an opaque thermoplastic material made from acrylonitrile, 1,3-butadiene and styrene monomers. Hard and strong even at low temperatures, it has good resistance to heat, chemicals and is easy to process.

PLA (polylactide, PLA) is a polyester based on lactic acid. Plants are used as its basis: corn or sugar cane.

Plants are used as its basis: corn or sugar cane.

Plastics are not hazardous at normal room temperature. A huge number of things are made from ABS, including cases of household appliances, stationery and children's toys. Polylactide is used for the manufacture of disposable tableware, medical products and other items with a short service life.

In Russia, plastic products are certified or declared (depending on the type of product) for compliance with safety requirements upon release. In our country, these requirements are spelled out in GOSTs or the Technical Regulations of the Customs Union. For example, there are TR “On the safety of toys”, “On the safety of packaging”, and so on, where, among other things, the standards for the content of residual chemicals are prescribed.

A certificate or declaration guarantees that the items in question are safe under normal use, which is why most plastic toys are made of ABS plastic. The main problems begin when the polymers are heated and melted. Surely everyone is familiar with the unpleasant smell of melting plastic. This smell indicates the release of various chemicals into the air, not all of which are harmless.

Surely everyone is familiar with the unpleasant smell of melting plastic. This smell indicates the release of various chemicals into the air, not all of which are harmless.

So, let's try to figure out what are the dangers of heated plastic?

1. Harmful fumes of the starting material

During melting, part of the polymer inevitably passes into a gaseous state and mixes with air. The type of starting material depends on the plastic. Due to the fact that natural ingredients are used to make PLA, it is considered to be biocompatible and safe for humans when melted. But in fact, there are practically no laboratory studies confirming this fact.

ABS plastic is a petroleum-based material, which already implies increased toxicity when heated. Unfortunately, the standards for the content of acrylonitrile butadiene styrene in the air in our country have not yet been released. GN 2.1.6.1338-03 “Maximum Permissible Concentrations (MACs) of Pollutants in the Atmospheric Air of Populated Areas” mentions acrylonitrile butadiene styrene dust, but it can be obtained at home only by grinding a plastic product, and not by printing.

Is ABS plastic safe? We asked an expert to answer this question.

Denis Cherepovich, head of Alfa-filament:

“ABS (acrylonitrile butadiene styrene) is a copolymer of acrylonitrile with butadiene and styrene. From the name it is clear that three monomer substances are used in the production of this polymer. Accordingly, these three monomers may be present in residual amounts in the total bulk of the polymer. All, absolutely all, without exception, manufacturing plants have strict output control on the content of residual monomers. This data can be found in the hygiene certificates for ABS granules.

During printing, heating of the polymer in the nozzle causes it to melt and, accordingly, a certain amount of residual monomers is released from the plastic mass. I note right away that not all of the mass of residual monomers enters the air during melting.

Next, I will make a small reference to normative documents and concepts in order to freely use the data in the future and not cause questions from readers.

Maximum allowable concentration of a hazardous substance. This parameter shows the maximum concentration of a substance in the air, which does NOT have harmful effects and does NOT lead to the development of pathologies and diseases in the human body. There are quite a lot of MPC values for different living conditions, I will give further MPC of substances in the working area of enterprises (MPC). The data are taken from the normative legal document "Maximum Permissible Concentrations (MPC) of harmful substances in the air of the working area GN 2.2.5.1313-03", approved by the Chief State Sanitary Doctor of the Russian Federation on April 27, 2003.

MPCrz - the maximum concentration of substances in the air of the working area, with which, with an 8-hour working day and 40 working hours a week, no harmful changes occur in the human body.

Hazard class - conditional value, designed for quick classification of substances according to the degree of danger:

1st class - extremely dangerous

2nd class - highly dangerous

3rd class - moderately dangerous

4th class - low hazard

5th class - practically non-hazardous.

Let's analyze what kind of substances can be contained in ABS plastic and what are their properties:

Butadiene - a gas with a characteristic unpleasant odor, hazard class 4, MPCrz=100mg/m3. This gas is practically not dangerous to the body.

Styrene - MPCrz = 30 mg/m3, hazard class 2. Colorless liquid with a pungent odor, practically insoluble in water, volatile. Causes complex lesions of the nervous system, irritation of the mucous membranes.

And finally, the most dangerous substance:

According to the hygiene certificates of Russian manufacturers of conventional ABS, the content of residual acrylonitrile in the granulate is no more than 0.001%. For foreign manufacturers (Samsung, LG, Kumho, Ineos, etc.), these figures are even lower. In food and medical ABS plastics, this value is almost zero.

Now, having all the data, we can calculate how much ABS plastic needs to be processed/printed per hour in our room in order to reach the MPC of acrylonitrile equal to 0. 5 mg/m3 (we make all calculations in terms of 1 hour, because do not forget that in 1 hour all the air in the room changes):

5 mg/m3 (we make all calculations in terms of 1 hour, because do not forget that in 1 hour all the air in the room changes):

1) MPC = 0.5 mg/m3 multiplied by the volume of the room 25 m3:

0.5 x 25 = 12.5

12.5 mg of gaseous acrylonitrile is the maximum allowed in our room

2) Next, we find what is the mass of ABS plastic contains 12.5 mg of acrylonitrile:

12.5 / 0.001% = 12.5 / 0.00001 = 1,250,000 mg, which is equal to 1250 g or 1.25 kg

Thus, we conclude: to achieve MPC of acrylonitrile in a room with a volume of 25m3, we need to process / print 1.25 kg of ABS plastic per hour, which is absolutely unrealistic.

Also, do not forget that in order to predict the most pessimistic scenario, we took into account many conventions: ABS is the most common and contains the maximum possible amount of acrylonitrile, all the monomer was released into the air during printing, the operator is constantly indoors, the ventilation in the room is only natural .

I hope that the calculation principle has been explained clearly, and exactly the same principle the reader will be able to calculate the "dangerous print speeds" of PLA, HIPS, SAN, MABS, PEEK, ASA, POM and other polymers.

In conclusion, I would like to once again assure users of the safety of FDM technology and wish them good luck in all their endeavors.”

2. Decomposition of the substance into monomers

Another danger is the decomposition of a part of the plastic into toxic components when heated and melted.

Irina Nikitina, Head of the Occupational Safety Control Department of the Federal State Budgetary Institution TsNMVL, an expert in special assessment of working conditions:

“The process of heating or melting plastics releases extremely toxic gases into the environment. Much depends on the type of active substance. In the solid state, plastics are relatively safe, but when melted, they can partially decompose into components, or oxidize and form other chemicals.

Let's take ABS plastic, that is, acrylonitrile butadiene styrene. It is a strong and resistant polymer used in many industries. Non-toxic under normal conditions. At present, there are no maximum permissible indicators regulating the concentration of this substance in the atmospheric air and the air of the working area in Russian state standards. However, the monomers that make it up are well known - these are acrylonitrile, butadiene, styrene (the very name of ABS plastic is formed from the initial letters of the names of the monomers). At a temperature of about 400ºС, acrylonitrile butadiene styrene partially decomposes into these monomers.

When released into the air, styrene can cause both acute reactions and chronic diseases of the liver, kidneys, and circulatory system. Butadiene-1,3 has a general toxic and irritating effect. Vapors of poisonous acrylonitrile are 20 times more toxic than styrene, signs of poisoning are headaches, weakness, sleep disturbances, memory loss, and general fatigue.

At elevated concentrations of these substances in the air, a person may experience a sharp and unpleasant odor. For example, the smell of styrene partially resembles acetone and alcohol.

To determine the exact concentration of a harmful substance released into the atmosphere, it is necessary to use chemical analysis methods and special equipment, such as gas analyzers. Therefore, regardless of whether a specific type of polymer is in the regulatory documents or not, it is necessary to follow simple rules: work in rooms with a ventilation system or good ventilation, install a local suction and pay attention to pungent odors. If any appear, it is better not to risk it, but to leave the room and ventilate the room.

It must be remembered that in industrial enterprises, the employer monitors and is responsible for working conditions, while when working at home, all potential dangers fall on the shoulders of the owner and household members.

Let's give an example from foreign practice. A study conducted in 2016 by a group of scientists from the Illinois Institute of Technology confirmed that the threat of releasing harmful substances into the air does not come from printers, but from consumables. More than 10 types of filament were tested by the Institute staff. The results showed that the level of harmful particles and vapors depends mainly on the filament material, and not on the type of printer.

A study conducted in 2016 by a group of scientists from the Illinois Institute of Technology confirmed that the threat of releasing harmful substances into the air does not come from printers, but from consumables. More than 10 types of filament were tested by the Institute staff. The results showed that the level of harmful particles and vapors depends mainly on the filament material, and not on the type of printer.

When using ABS plastic, traces of styrene, a substance that is dangerous and carcinogenic, were found in the air. Nylon-based materials exuded caprolactam, less harmful than styrene, but also capable of causing poisoning. Polylactide released a harmless substance called lactide into the air. At the same time, nothing is reported about the concentrations of substances.

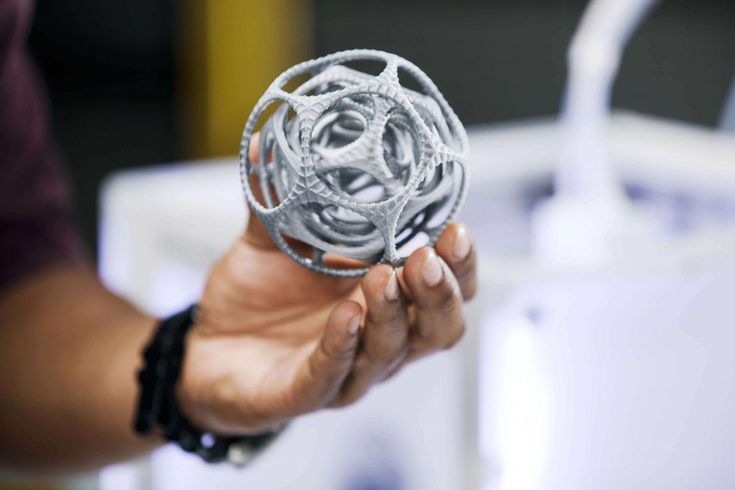

3. Ultrafine particles (nanoparticles)

Another risk factor is associated with ultrafine particles (nanoparticles) with a diameter of less than 1 micron, which are released in large quantities during 3D printing. These particles can penetrate directly into the alveoli of the lungs and the epidermis, causing various respiratory disorders and allergic reactions. Inhalation of toxic nanoparticles can cause lung pathologies in humans, such as bronchitis, tracheitis, and asthma. At the same time, the risk index for ABS is 3 to 30 times higher than for PLA. In tests conducted by Italian scientists Fabrizio Merlo and Stefano Mazzoni, it turned out that the time for which the content of nanoparticles in the air returns to normal levels is from 10 to 30 minutes after the end of the 3D printing process.

These particles can penetrate directly into the alveoli of the lungs and the epidermis, causing various respiratory disorders and allergic reactions. Inhalation of toxic nanoparticles can cause lung pathologies in humans, such as bronchitis, tracheitis, and asthma. At the same time, the risk index for ABS is 3 to 30 times higher than for PLA. In tests conducted by Italian scientists Fabrizio Merlo and Stefano Mazzoni, it turned out that the time for which the content of nanoparticles in the air returns to normal levels is from 10 to 30 minutes after the end of the 3D printing process.

How can this be dealt with and the risks minimized? First, filtering. A number of devices are already using high efficiency (HEPA) filters that can purify the air before it leaves the 3D printer. Of course, this is not a panacea. Some ultrafine particles are as small as 15 nm, while HEPA filters typically have a bandwidth of 300 nm.

An additional barrier is also the closed housing of the device, which partially traps harmful fumes. It is these two factors that can contribute to protection against the overwhelming number of nanoparticles. According to the latest study from the Illinois Institute of Technology, a closed chamber 3D printer reduced UPF emissions by 74%, and an additional HEPA filter helped to increase this figure to 9one%.

It is these two factors that can contribute to protection against the overwhelming number of nanoparticles. According to the latest study from the Illinois Institute of Technology, a closed chamber 3D printer reduced UPF emissions by 74%, and an additional HEPA filter helped to increase this figure to 9one%.

Scientists also advise to work in well-ventilated rooms: it is ideal to use a ventilation system that can change the entire volume of air in the room three times per hour. This means that a 100 m3 room would require a ventilation system capable of handling 300 m3 of air per hour.

4. Other substances and impurities that are released when using plastic

The results of a study by Fabrizio Merlo and Stefano Mazzoni, already mentioned by us, showed that during the melting and mixing of plastic, fumes of many toxic substances are released, among which, for example, ammonia, cyanuric acid, phenol and benzene.

The presence of specific substances depends on the thread, or rather on the polymer of which it is composed. Both the filament itself and the plastic must have documents confirming the composition of the material and the residual content of impurities. Often these are the same certificates of conformity that we wrote about at the beginning of the article.

Both the filament itself and the plastic must have documents confirming the composition of the material and the residual content of impurities. Often these are the same certificates of conformity that we wrote about at the beginning of the article.

Plastics produced abroad have their own safety certificates. For example, the Alfa-filament company uses granules for the manufacture of ABS filament, which have food and biocompatible approvals from the FDA - the US Food and Drug Administration. However, regardless of the country of manufacture, the plastic manufacturer is obliged to have such documents and make them available to potential buyers.

Unfortunately counterfeit filament is not uncommon in the world market. In low-quality materials, the amount of harmful substances is many times higher than the established norms. For example, poisonous hydrocyanide was found in one type of Chinese ABS plastic. Therefore, before purchasing consumables for 3D printing, make sure the seller is reliable and, if necessary, ask him to provide documents confirming the safety of the filament.

But do not despair, because the problem of counterfeit filament is still more relevant for the world market than for the domestic one. The largest Russian companies guarantee the quality of their own products and often post all permits on their own websites, and sometimes conduct independent tests of their products. So, in 2015, the Russian manufacturer of consumables REC, with the help of an accredited testing laboratory, carried out its own measurements of the concentration of chemicals in the air during 3D printing with its own filament. In total, 5 types of plastic were used: ABS, PLA, FLEX, RUBBER, HIPS.

It turned out that HIPS, FLEX and RUBBER filament do not emit toxic substances at all during printing. When printing PLA plastic, acetone is formed, ABS plastic exuded vinyl chloride, however, in no case were values even close to the MPC of the air in the working area recorded.

Let's summarize how to protect yourself from the harmful effects of plastic fumes:

1. Use a ventilation system. In particular, the researchers advise working in well-ventilated areas: it would be ideal to use a ventilation system that can change the entire volume of air in the room three times per hour. If there is no ventilation, open windows and try to be as little as possible in the same room as the printing printer.

Use a ventilation system. In particular, the researchers advise working in well-ventilated areas: it would be ideal to use a ventilation system that can change the entire volume of air in the room three times per hour. If there is no ventilation, open windows and try to be as little as possible in the same room as the printing printer.

2. Pay attention to smells. A strong odor indicates an increase in the concentration of the active substance. Take extra precautions or leave the room altogether.

3. Operate with closed case and HEPA filter. Thus, you will reduce the concentration of harmful substances released into the room. In addition, a number of new printers are already equipped with an internal ventilation system, which makes them relatively safe.

4. Purchase supplies from reputable manufacturers. Quality consumables have certificates or declarations of conformity.

5. Use caution and safety when using 3D equipment.

Tags: FSBI TsNMVL, Denis Cherepovich, Alfa-filament, toxic fumes, consumables, safety, REC, PLA, ABS, 3D printing

Potential dangers of a 3D printer.

Part 1

Part 1 In early February, a great tragedy occurred in the United States - a young family and pets died in their house under unclear circumstances. And the first suspect was a 3D printer. Allegedly, carbon monoxide released during 3D printing could cause poisoning for people and their pets. While the police cannot reliably establish the source of the gas leak and the causes of the tragedy, however, we decided to remind once again what potential dangers lie in wait for the owners of home printing devices and how to protect yourself and your loved ones from their impact.

1. Getting burned

It must be remembered that the principle of operation of the FDM printer is based on the melting of a plastic filament. Thus, the heating elements of the device present a great danger when touched. As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

The melting temperature of the filament used in printers is sufficient to cause burns. For ABS plastic, it is about 210-270ºС, for PLA - 180-190ºС. This is enough to get painful damage in contact with both the material itself and the heating elements of the printer: the table and the extruder nozzle.

For PLA printing, this risk is lower because a heating bed is not needed, but if you are working with ABS, be extremely careful not to touch the hot elements. The risk of injury is directly proportional to the area of the heating surfaces. Remember that the temperature should be checked only by the readings of the sensors that are displayed in the printing program or on the display of the device, and not by hand or improvised means.

In situations where direct contact with hot surfaces is required, such as when cleaning the nozzle, special tools and personal protective equipment must be used, and extreme care and discretion must be exercised.

Also, keep children and pets away from the printer and never leave them alone with the printer. It is always easier to prevent danger than to deal with its consequences.

It is always easier to prevent danger than to deal with its consequences.

2. Electrical injury

Like any mains powered device, a 3D printer can cause electrical injury to a person. Naturally, with proper operation of the device this will not happen. Even in the event of a ground fault, the voltage in the exposed parts of the 3D printer will usually not exceed 12-24 V, which is considered safe and will only cause a slight shock.

However, when disassembling the case of the device for repair, replacement of a part, or cleaning of plastic, the possibility of receiving a 220 V electric shock increases many times over.

It must be remembered that any electrical appliance must be disconnected from the mains before servicing. Some printers have an external rather than an internal transformer, but this should not be a reason to forget about safety and leave the plug in the outlet.

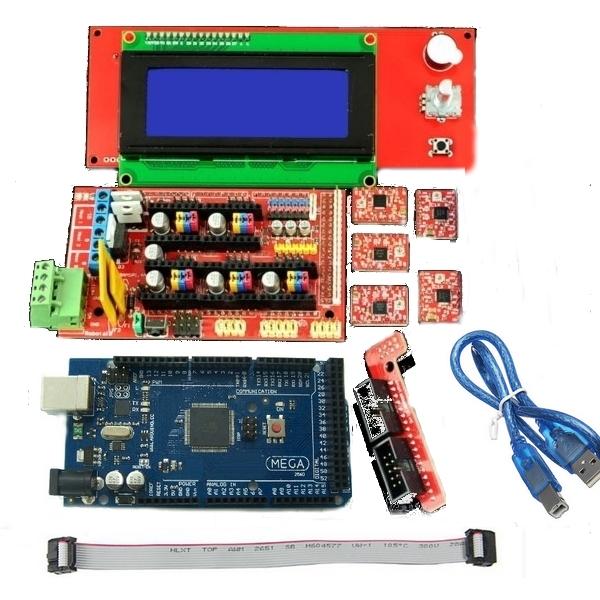

Also not to mention the risks of short circuits. The probability of such an event in a 3D printer, as in any other household appliance, is small. But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire.

The probability of such an event in a 3D printer, as in any other household appliance, is small. But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire.

Evgenia Kurochkina, Development Director at ZENIT 3D, comments:

“There is no more danger from using a 3D printer than from any other electrical device used in everyday life or in professional activities. But, nevertheless, they are presented on the market as 3D printers with a high degree of security and, let's say, ordinary ones. What you should pay attention to when choosing a 3D printer using FDM technology and when working with it.

Such devices, as a rule, have two heating elements: an extruder and a heated platform or simply a table. The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

Many manufacturers save money at the expense of safety. One of the options for such savings is to "power" the heating table directly from 220 V. In our opinion, this is wrong and unsafe. For example, when working with a 3D printer, many people use a spatula to remove a part, it is quite sharp, and any inaccurate action with a spatula when the table is on can lead to a short circuit and a 220 V current shock. Realizing this, we went the other way, and instead of 220 All ZENIT 3D printers supply only 24V to the table.

The extruder is the hottest part and must be handled with the utmost care. To remove the remaining plastic from the extruder, it is imperative to use a special tool.

As for the electrical part, there is also something to look for when choosing a 3D printer. All wires and connections must be insulated, and best of all, hidden in the printer case. Any open connections, contacts, wires, boards in the event of an accidental short circuit can at least damage the equipment, at worst - harm health

Our company, developing 3D printers, considers the safety of its devices to be one of the important tasks. In particular, when developing the new ZENIT 3D model, which will be launched on the market in 2017, we paid a lot of attention to the safety aspect.”

3. Fire hazard

While we're talking about fires, we need to talk about fire hazards that are not related to electricity. In point 1, we already wrote about high temperatures of heating surfaces in the context of burns, but an open printer case can also ignite materials lying around the printer. Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type.

Another problem could be overheating of the extruder. For example, the ignition temperature of PLA plastic is about 388ºC. Purely theoretically, it may happen that a broken printer temperature sensor will cause spontaneous combustion of the material. If your printer also has a plywood or plastic case, this automatically turns it into fuel for the resulting fire.

Therefore, it is recommended that you install a fire alarm in areas where you print and keep a fire extinguisher handy at all times. Also, you can not leave a working device alone for a long time. It is clear that it is impossible to constantly monitor the printing for several hours, but it is better to monitor the operation of the printer from time to time.

A compromise would be to purchase a compact camera installed in the print room and broadcast to a smartphone or tablet.

4. Moving parts

3D printers have a lot of moving parts. These are motors, pulleys, threaded rods, carriage and fans. All this can easily grab you by the protruding part of the body and cause a lot of trouble. Avoid contact with moving parts of the printer while it is in operation! Do not reach in or attempt to correct a sliding object or push the carriage by hand.

All this can easily grab you by the protruding part of the body and cause a lot of trouble. Avoid contact with moving parts of the printer while it is in operation! Do not reach in or attempt to correct a sliding object or push the carriage by hand.

If your 3D printer is an open type, wear tight-fitting clothing and keep an eye on your hair to minimize the risk of cloth and hair getting caught in moving parts. It is also worth worrying about the placement of the spool with consumables in advance, so that in the future the thread does not catch on foreign objects and knock the printer to the floor.

If the device does grab your clothing or hair, turn off the printer immediately and manually move the carriage until the pinched part of your body is completely free.

Irina Solomnikova, Commercial Director of IMPRINTA comments:

“If we talk about the possibility of carbon monoxide poisoning, then yes, such tragedies as in the USA are possible and, unfortunately, common. If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

But it is definitely worth remembering that when using a 3D printer, you should follow safety precautions and use it for its intended purpose. Misuse of any appliance, such as a game console, microwave oven, telephone, iron, etc., can lead to unpleasant consequences.

The rules for using the 3D printer are very simple:

- The 3D printer must be installed in a ventilated area.

- The 3D printer must be placed on a level, stable surface.

- Before connecting to the mains, it is worth checking the reliability of the power supply.

- Some parts of the printer get very hot. Do not touch them while the printer is in operation to avoid burns.

- The printer has moving parts. During the operation of the 3D printer, it is necessary to avoid getting foreign objects into the moving mechanisms of the printer, this can lead to injury and damage to the equipment.

- Do not place anything on the 3D printer.

- Please be aware that some media may be toxic. When choosing a material, you must carefully read the description, temperature conditions and use only trusted manufacturers of printing materials.

- Do not leave small children unsupervised while the printer is in operation.

- Don't leave your printer running when you leave home.

If you follow these simple rules, as well as following the instructions, the use of a 3D printer will be safe both in the office and at home.

In conclusion, we add that a 3D printer, like any device, can harm a person.