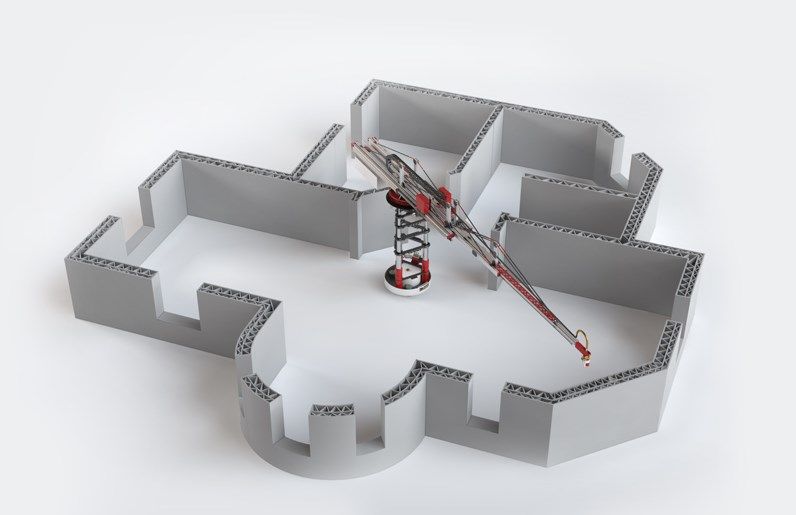

Contour crafting 3d house printer

Contour Crafting Corporation | Construction 3D Printing

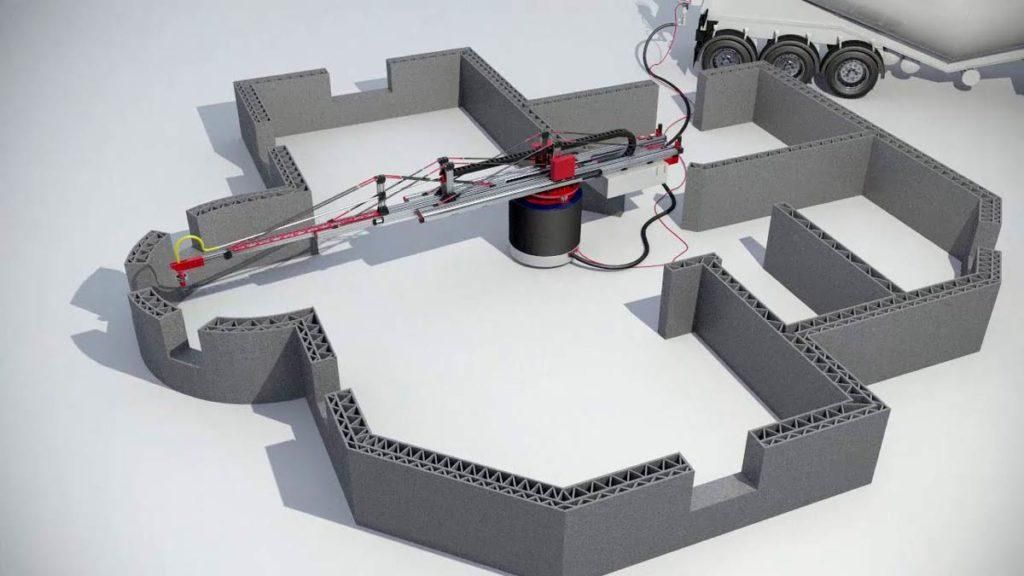

CrafTrans - CC Corp's Transformable and Rapidly Deployable Construction 3D Printer

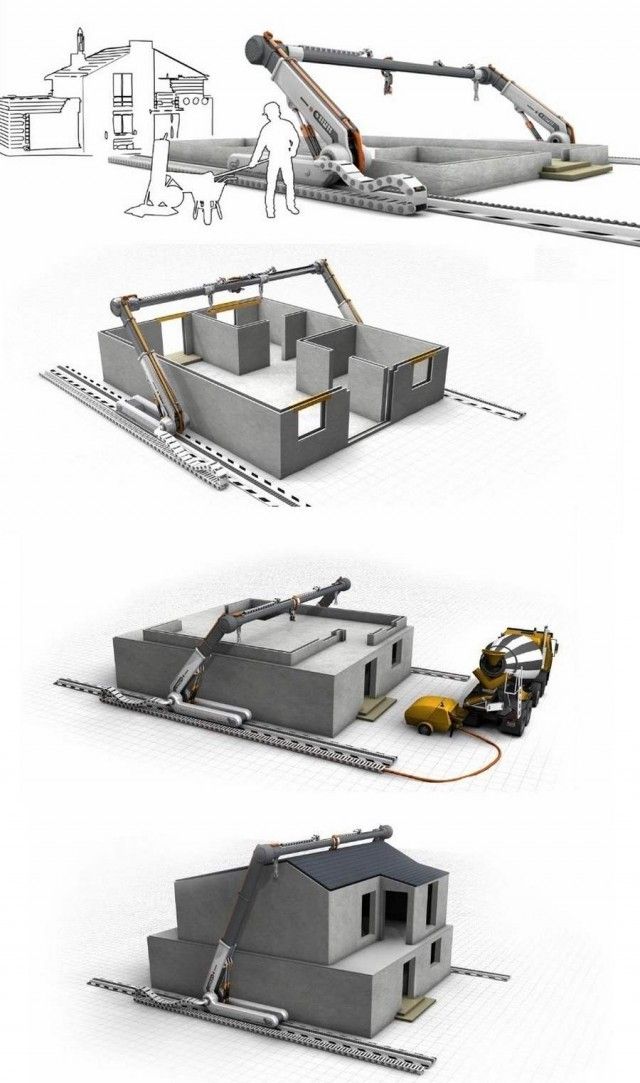

Over two decades ago Contour Crafting® marked the beginning of the construction 3D printing era. Contour Crafting Corporation aims to advance its technologies to revolutionize construction in building, infrastructure, and space construction fields.

Contour Crafting®

This timeline depicts the history of the Construction 3D Printing field - Produced by ELstudio, Amsterdam

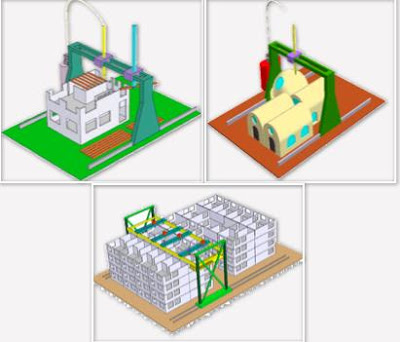

Applications of the CC Corp technology may include various types of building constructions including housing, commercial and government buildings. Another application domain is infrastructure construction which could include foundations, slabs, bridges, pylons, etc. And finally extraterrestrial construction, that is, building on Moon and Mars for planetary exploration, exploitation, habitation and colonization is another major field of use of CC Corp technology in which the company technologies have excelled to receive high recognition by various space programs in various countries.

Building Construction

Infrastructure

Space Applications

Contour Crafting Corporation (CC Corp) is an early stage company with the mission to commercialize disruptive construction technologies, starting with Contour Crafting® (CC), CC Corp’s flagship technology. CC Corp was founded by Dr. Behrokh Khoshnevis (www.bkhoshnevis.com), who is the President and CEO of CC Corp and is the Louise L. Dunn Distinguished Professor of Engineering at the University of Southern California. Dr. Khoshnevis is recognized worldwide as the pioneering inventor of construction scale 3D printing who has so far received over 100 US and international patents in the field. In 2014 Contour Crafting® was selected to receive Grand Prize by NASA among 1000+ globally competing technologies, and was earlier named as one of “25 Best Inventions of the Year” by National Inventor’s Hall of Fame and History Channel’s Modern Marvels Program. CC Corp’s other large-scale 3D printing technology called Selective Separation Shaping received another NASA international competition Grand Prize in 2016.

CC Corp was established in partnership with a major European multinational construction technology company to commercialize Contour Crafting® and other large scale 3D printing technologies. Numerous patents by Dr. Khoshnevis have been licensed to CC Corp by the University of Southern California and a significant number of additional patent applications are independently in progress at CC Corp.

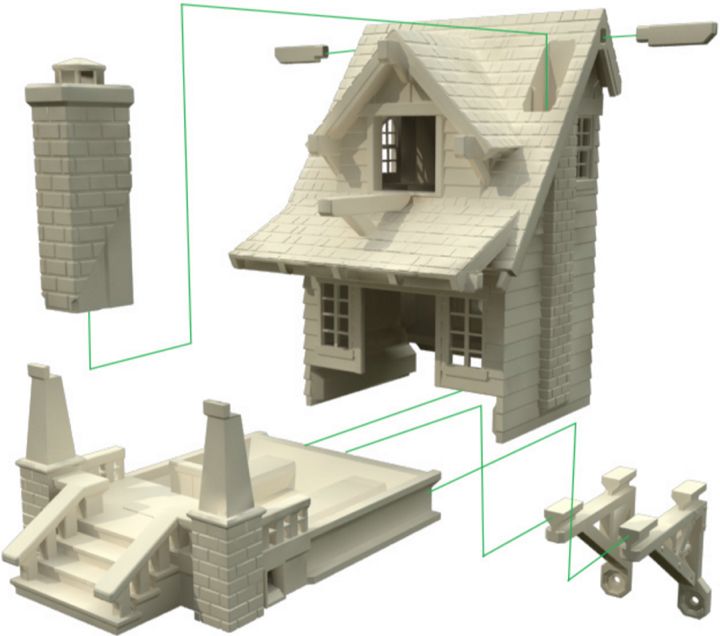

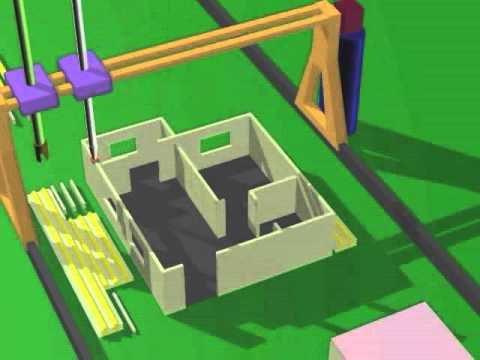

CC Corp’s technologies use specially designed robotic systems to quickly construct buildings using data from 3D CAD designs. While there are numerous applications for these technologies, CC Corp is initially focusing its efforts on transforming and revolutionizing building construction.

The Company’s business plan is to initially leverage the CC technology to support building of low-cost and emergency housing projects in various areas of the world, including in developing countries. This plan will soon be extended to construct larger average size residential and commercial buildings. The company’s business strategy entails Technology Deployment Agreements with a highly selective number of strategic partners, These partnerships could also be in form of joint ventures. CC Corp has developed a multi-phase business plan for the design and development of commercial grade and saleable automated construction machines.

The company’s business strategy entails Technology Deployment Agreements with a highly selective number of strategic partners, These partnerships could also be in form of joint ventures. CC Corp has developed a multi-phase business plan for the design and development of commercial grade and saleable automated construction machines.

Andreas Saar is a Senior Advisor for the Additive Manufacturing Industry supporting companies and startups developing, verifying and refining their technology directions and roadmaps as well overall market strategies. He retired as V.P of Manufacturing Engineering Solutions from Siemens Digital Industry in 2021.

Andreas is a senior Manufacturing Engineering expert with over 35 years of experience in Discrete Manufacturing Industry, managing organizations with international, world-wide distribution, specializing in the area of CAD/CAM/PLM software. Responsible for the strategic product direction, portfolio planning, development and exploitation of products and solutions.

Andreas holds a Masters Degree in mechanical engineering and Business Administration (Dipl.-Wirtsch.-Ing) from the Technical University of Darmstadt/Germany. After working as managing director of a small CAD/CAM software company in Germany responsible for R&D and Operations he relocated with his family to California at the end of the nineties to take over the lead of the software development teams for all manufacturing applications in Unigraphics Solutions, later Siemens PLM. In 2014 he started and spearheaded the Additive Manufacturing Program initiative for Siemens Digital Industries Software with an aggressive plan to develop a full end-to-end solution for Additive Manufacturing Software based on partnerships with leading hardware and software technology providers in the AM Industry.

Throughout his career he has worked with large enterprises as well as small and mid-size manufacturing companies with the goal of helping them become more productive. He helped to optimize their processes through the development and adaptation of highly innovative technologies in the fields of subtractive and additive manufacturing. During this time, he was also involved and participated in multiple European and American research projects as well as being on the BOD for research centers like CCAM (Commonwealth Center of Advanced Manufacturing) in Virginia.

He helped to optimize their processes through the development and adaptation of highly innovative technologies in the fields of subtractive and additive manufacturing. During this time, he was also involved and participated in multiple European and American research projects as well as being on the BOD for research centers like CCAM (Commonwealth Center of Advanced Manufacturing) in Virginia.

In 2019 Andreas was nominated to the Board of Directors of Evolve Additive Technologies, a US based Startup developing industrial printing technologies for mass production of polymer parts. In 2022 he joined Contour Crafting Corp in El Segundo, CA as Senior Advisor.

Professor Soibelman obtained his BS and MS Degrees from the Civil Engineering Department of the Universidade Federal do Rio Grande do Sul, Brazil. He worked in the construction industry for 10 years as a chief engineer of a geotechnical engineering company, as a developer and construction manager, and as an owner and president of an engineering company before moving in 1993 to the US where he obtained in 1998 his PhD in Civil Engineering Systems from the Civil and Environmental Engineering Department at the Massachusetts Institute of Technology (MIT).

In 1998 he started as an Assistant Professor at the University of Illinois at Urbana Champaign. In 2004 he moved as an Associate Professor to the Civil and Environmental Engineering Department at Carnegie Mellon University (CMU) and in 2008 was promoted to Professor. In January 2012 he joined the University of Southern California as the Chair of the Sonny Astani Department of Civil and Environmental Engineering. In June 2021 he stepped down as the Astani Department Chair.

During the last 25 years he focused his research on advanced data acquisition, management, visualization, and mining for construction and operations of advanced infrastructure systems. He published over 200 books, books chapters, journal papers, conference articles, and reports and performed research with funding from NSF (NSF career award and several other NSF grants), NASA, DOE, US Army, NIST, IBM, Bosch, IDOT, RedZone Robotics among many others funding agencies. He is the former chief editor of the American Society of Civil Engineers Computing in Civil Engineering Journal. In 2010 he received the ASCE Computing in Civil Engineering Award, in 2012 received the 2011 FIATECH Outstanding Researcher Celebration of Engineering & Technology Innovation, or CETI, Award, in 2016 he received the ASCE Richard R. Torrens Award, in 2017 he received the ASCE Construction Institute Construction Management award, in 2013 he was elected an ASCE fellow, in 2016 he was appointed as Viterbi Dean Professor at USC and was appointed as a Distinguished 1,000 talent Professor at Tsinghua University, in 2019 was elected to the National Academy of Construction, and in 2020 he was appointed as the Fred Champion Estate Chair in Engineering Professor at USC, in 2021 was elected as an ASCE Distinguished Member, and in 2022 received the ASCE Peurifoy Construction Research Award.

In 2010 he received the ASCE Computing in Civil Engineering Award, in 2012 received the 2011 FIATECH Outstanding Researcher Celebration of Engineering & Technology Innovation, or CETI, Award, in 2016 he received the ASCE Richard R. Torrens Award, in 2017 he received the ASCE Construction Institute Construction Management award, in 2013 he was elected an ASCE fellow, in 2016 he was appointed as Viterbi Dean Professor at USC and was appointed as a Distinguished 1,000 talent Professor at Tsinghua University, in 2019 was elected to the National Academy of Construction, and in 2020 he was appointed as the Fred Champion Estate Chair in Engineering Professor at USC, in 2021 was elected as an ASCE Distinguished Member, and in 2022 received the ASCE Peurifoy Construction Research Award.

His areas of interest are: Use of information technology for economic development, information technology support for construction management, process integration during the development of large-scale engineering systems, information logistics, artificial intelligence, data mining, knowledge discovery, image reasoning, text mining, machine learning, advanced infrastructure systems, sensors, streaming data, construction robotics, and Multi-reasoning Mechanisms.

Building Construction | CC Corp

Contour Crafting® can significantly reduce the cost of commercial construction. Projections indicate costs will be around one fifth as much as conventional construction. Contour Crafting® promises to eliminate waste of construction materials. Contour Crafting® construction projects will be extremely accelerated; for example a 2000 square foot house can be constructed in less than 24 hours. This rapid construction time minimizes the financing costs of construction projects that typically take six months or longer to complete. While the costs of manual labor will be significantly reduced, physical power will be exchanged for brain power in the construction industry. For the first time women and the elderly will be able to take part in the construction industry. Construction could become a consumer market, wherein a house or other structure could be designed and built by the family that will occupy it. Reduced costs, and automated building will make construction accessible to anyone. Imagine a Contour Crafting® machine for lease at your local Home Depot.

Imagine a Contour Crafting® machine for lease at your local Home Depot.

CC Corp’s revolutionary technologies use modern robotics to build custom designed houses in a few hours. At the present time, the technology would be most useful for low-income housing and emergency reconstruction by disaster relief agencies working in places devastated by earthquakes, floods, wars, and other natural disasters. Followings are some of the major advantages of CC Corp technologies for building construction:

Fact: It currently takes 6 to 9 months to construct an average house in the US.

Fact: Nearly 30 million S. households face one or more of the following housing problems: cost burdens, overcrowding, and space inadequacy. Worldwide, while large cities in developing countries have been growing at rates nearing 5% per year, slums and squatter settlements have been growing nearly twice as fast.

Fact: Currently it may take several months or years before disaster (earthquake, flood, war, etc. ) victims are placed in permanent shelters.

) victims are placed in permanent shelters.

Fact: Construction accounts for a significant amount of various harmful emissions and construction activities generate an exorbitant amount of waste. Construction of a typical single-family home generates a waste stream of about 3 to 7 tons. In terms of resource consumption, more than 40% of all raw materials used globally are consumed in the construction industry.

Fact: Labor injuries and fatalities happen frequently at construction sites. 400,000 workers get seriously injured or killed in construction annually in the US alone, a country in which stringent safety codes are regulated.

Fact: Any departure from standard designs (e.g., use of curvilinear features instead of straight walls) significantly increases the cost of conventional construction.

Implementation of this technology in the United States may be initially complicated by prevailing policies that regulate labor, zoning, and land costs. Nevertheless, the availability of this new technology has the potential to change the building industry in the United States. For Californians, it can the solution to homelessness, and an emergency solution when the “big one” comes. The impact of the Contour Crafting® technology will be significant, given the current US construction-related expenditures which total $300 billion in the public sector and $700 billion in the for-profit sector, annually.

For Californians, it can the solution to homelessness, and an emergency solution when the “big one” comes. The impact of the Contour Crafting® technology will be significant, given the current US construction-related expenditures which total $300 billion in the public sector and $700 billion in the for-profit sector, annually.

The following table summarizes the economic impact of construction automation by Contour Crafting® in the developed countries. In the developing countries the proportion of the cost of labor is lower while that of material cost is higher. Regardless, as demonstrated by the success of other advanced construction equipment (as those used for road construction) even in the least developed countries major construction projects use advanced construction technologies because of higher productivity, higher safety, and less construction logistics and project management complexities that modern technologies offer.

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix Flash Forge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao Flash Forge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT nine0003

Delivery

Assembled printer Assembly kit

Application

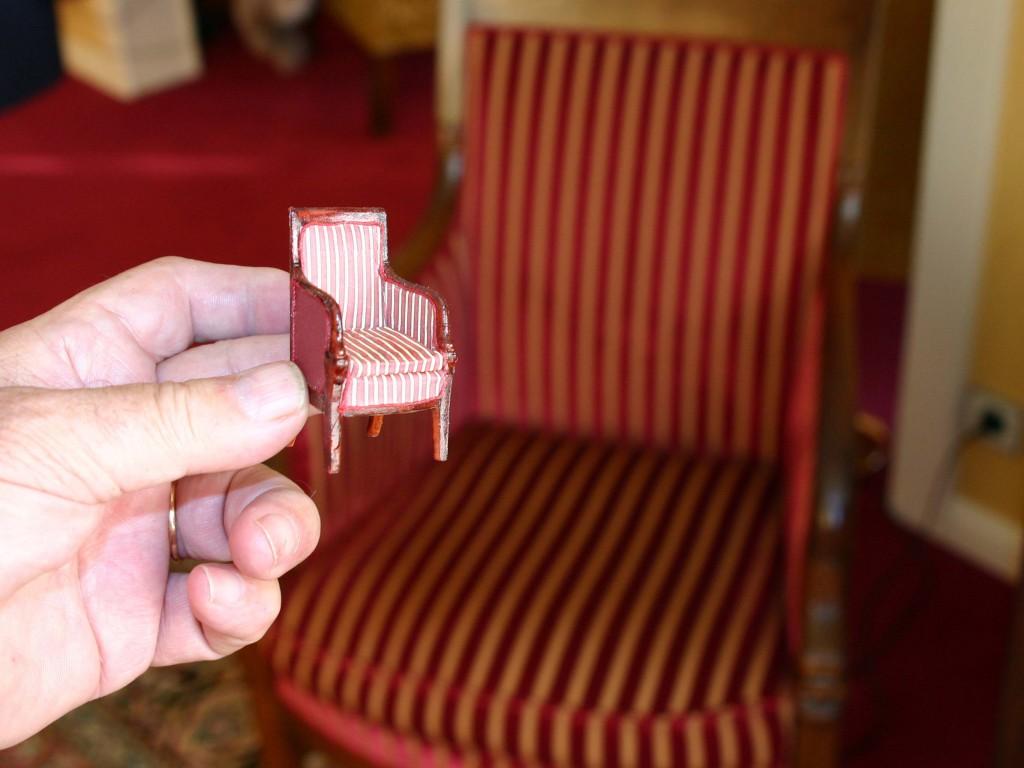

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry nine0003

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm nine0003

75 mm 2.85 mm 3.00 mm nine0003

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH) nine0003

Number of extruders (print heads)

Heating table

Yes No

Wi-Fi or other wireless network

Yes No

Country of origin

China Russia USA Taiwan Hong Kong nine0003

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On order/Transit | Goods in transit |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 235x235x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit | nine0064

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | nine0060 Anycubic|

| On order/Transit | Goods in transit |

| Construction area size | 180 x 163 x 102 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | nine0060 Flyingbear|

| On order/Transit | Goods in transit |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Creality |

| Construction area size | 350x350x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go nine0003

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On request/Transit | Goods in transit |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 l |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On order/Transit | Goods in transit |

| Construction area size | 450 x 400 x 400 mm (capacity 72 l) |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go nine0003

| Manufacturer | Creality |

| Construction area size | 198 × 123 × 210 mm |

| Country of origin | China |

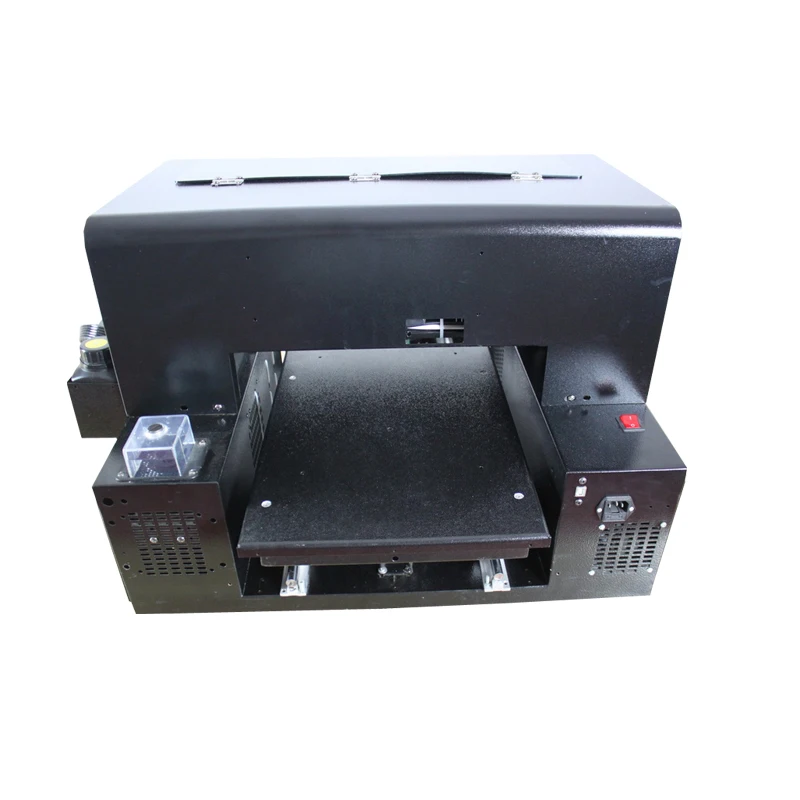

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory. nine0003

Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory. nine0003

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models. nine0003

nine0003

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems? nine0003

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers. nine0003

nine0003

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together. nine0003

In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together. nine0003

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees. nine0003

nine0003

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary. nine0003

Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary. nine0003

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs.

This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits. nine0003

They have their pros and cons. But most of them have advantages over moving table printer circuits. nine0003

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it. nine0003

For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it. nine0003

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology. nine0003

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials.

This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.