3D printer metal casting

Introduction to Metal Casting and Ways to Combine 3D Printing With Casting Workflows

Metal casting is an age-old metalworking process in which molten metal cools and solidifies in a mold to form metal parts. Despite its ancient roots, metal casting is still one of the most popular processes for companies looking to produce metal parts.

This article will cover what metal casting is, how it works, and walks you through the most common metal casting processes and the benefits manufacturers can attain by combining modern digital tools like 3D printing with traditional casting workflows.

White Paper

Get design guidelines for creating 3D printed patterns, walk through the step-by-step direct investment casting process, and explore guidelines for indirect investment casting and sand casting.

Download the White Paper

Metal casting step-by-step from the original design through final casting.

Since the advent of metal casting, the methods have evolved and varied. Its core techniques, however, have remained constant. Here is a general step-by-step process for metal casting:

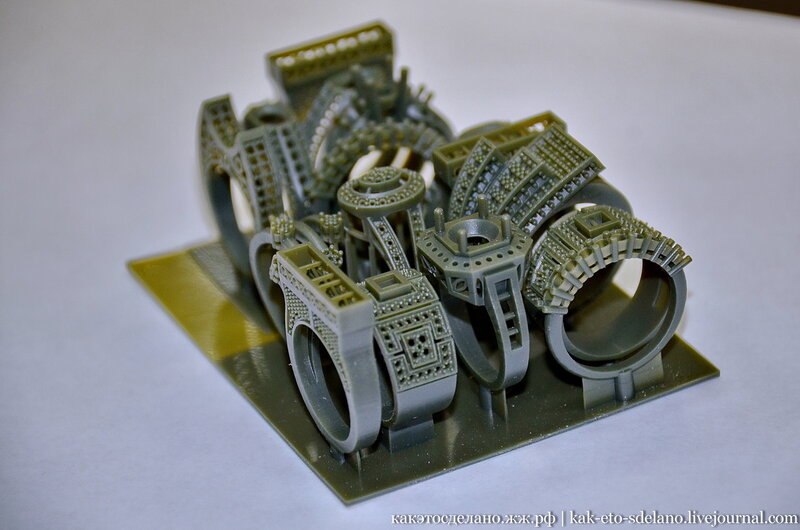

Ring patterns 3D printed in Castable Wax 40 Resin.

In order to begin the metal casting process, a manufacturer first must develop a representation of the desired pattern. This pattern is essential in designing the mold used for the cast. It is traditionally made from wood, foam, plastic, or wax and ensures that the mold accurately produces the finished metal part. Today, 3D printing is also a common method to produce patterns, which allows designers to create accurate patterns directly from digital CAD software tools.

A pattern is not an exact replica of the desired part. It has additional elements that make the casting process possible, including gates that allow molten metal to flow at a steady rate and vents for gas to escape. Additionally, patterns are also larger than the parts they represent to account for the shrinkage that occurs during cooling.

When the casting piece is hollow, the manufacturer also creates a core of sand or metal to shape the internal form. This core gets removed upon completion of the casting.

This core gets removed upon completion of the casting.

The next step is creating a casting mold, which can be either reusable (non-expendable) or non-reusable (expendable). Non-reusable molds are usually made out of sand, plaster, wax, or by 3D printing, and just as the name suggests, they get destroyed in the casting process. Reusable molds are made out of metal and other durable materials and can be reused for multiple casting cycles.

Ceramic shells after burnout and 3D printed patterns in Clear Resin.

Molten pewter poured into a High Temp Resin 3D printed mold for metal casting.

During this step, the metal gets heated in a furnace until it melts. Depending on the application, manufacturers can use a variety of different metals, with the most commonly cast metals being iron, aluminum, aluminum alloy, steel, copper, and zinc, as well as precious metals like gold and silver. Once the metal melts, the manufacturer pours it into the mold cavity and allows it to cool and solidify.

Metal casting post-production.

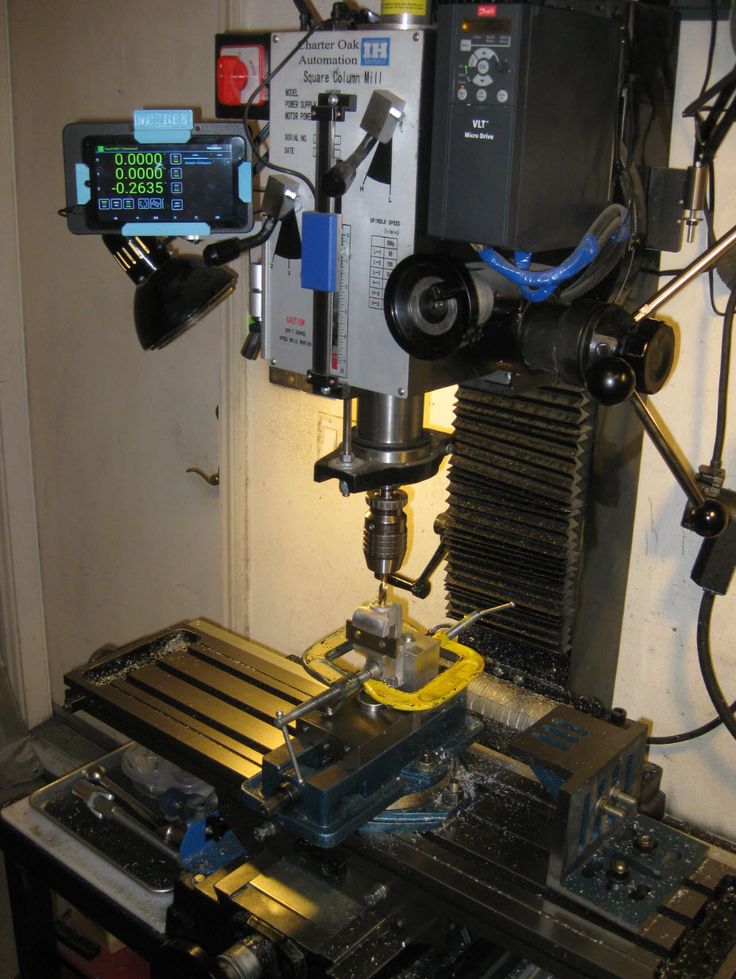

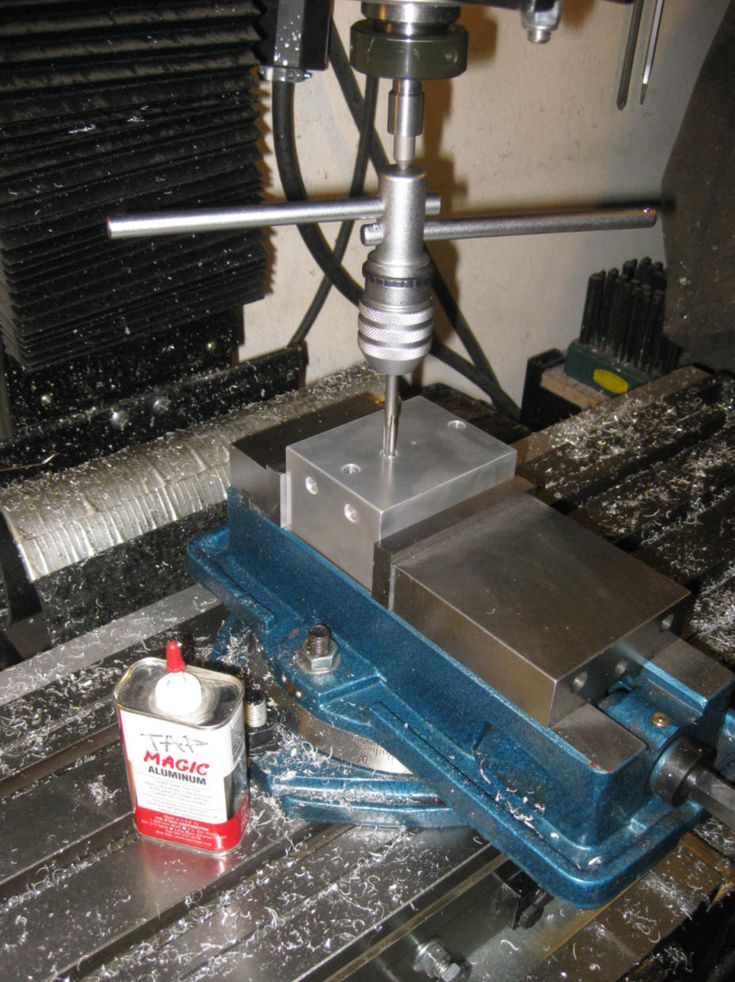

Once the metal cools down and solidifies, the parts get removed from the mold. Depending on the mold type, this can be done by vibrations in a shakeout process, washing away the investment material, or by ejector pins. Then, excess material, such as vents, gates, and feeders, are removed from the parts. Finally, the parts get filed, grated, machined, or sandblasted to smooth the surface and reach the final shape requirements.

Though all metal casting techniques share the same core process, there are various methods better suited for different applications. Some of the most common methods include die casting, investment casting, and sand casting.

Die casting uses a steel mold and high pressure. (Source: buhlergroup.com)

Die casting is a metal casting process in which a manufacturer pushes molten metal into a steel mold cavity at a high pressure to quickly produce metal parts. In die casting, the manufacturer fixes two halves of a die or reusable mold together and uses a nozzle to inject pressurized molten metal into the die. When the metal cools, the die opens, and ejector pins push out the cast.

When the metal cools, the die opens, and ejector pins push out the cast.

The two most common die casting processes are hot-chamber and cold-chamber casting. While the specifics of these processes vary, there are several shared characteristics of the die casting process as a whole.

Hot-chamber die casting is the most common of the two main die casting processes. Hot-chamber die casting machines have a built-in furnace to heat the metal within the machine. Once the metal reaches a molten state, the machine lowers a cylindrical chamber into the molten metal. The gooseneck shape of the metal injection system allows the chamber to quickly fill itself, and then push the material into the mold with air pressure or a piston.

Immersing the injection mechanism to fill it allows for rapid and streamlined mold injection in this casting process. Because the chamber is subject to direct heat from the molten metal, however, hot-chamber die casting systems are at risk for corrosion, making them a less viable option for metals with high melting points. Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

Instead, it is better suited for materials with low melting points and high fluidity, like lead, magnesium, zinc, and copper.

By contrast, the cold-chamber die casting process works more slowly to avoid corrosion. With this method, a foundry worker ladles molten metal into the injection system. A piston then pushes the metal into the mold.

This process limits the corrosion that is more common in hot-chamber die casting. It is an ideal option for metals with high melting points, like aluminum and aluminum alloy.

The die casting process is rapid and produces highly detailed parts. It is ideal for the production of high volumes of complex parts and can also produce strong parts with smooth surface finishes. Die casting’s capacity to produce a high volume of parts makes it a crucial process in the automotive and aerospace industries.

As die casting tooling and equipment are expensive, this process is not cost-effective for smaller production runs. In addition, the malleability of metals used in the process can impact the complexity of the product.

Cast parts from SLA patterns printed in Clear Resin on a Formlabs 3D printer.

Investment casting, also known as lost-wax casting, is a process that uses wax, slurry, and molds to produce complex parts. It is one of the oldest metal casting techniques but is still valued for its ability to create precise metal parts with intricate shapes.

This process is still widely used for producing jewelry, dentistry, and art. Its industrial form, investment casting, is a common way to create precision metal parts in engineering and manufacturing.

Investment casting patterns are typically made out of wax or 3D printed polymers. The patterns are assembled into a tree-like structure and dipped into a slurry of silica, or put into a flask and surrounded by the liquid investment plaster. After the investment material dries, the flask is placed upside down into a kiln, which melts the pattern, leaving a negative cavity in the shape of the original model. Metal is melted and then poured, using gravity or vacuum pressure to pull the metal into the cavity. The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

The casted parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish.

Sprue trees with cast rings.

Investment casting is a versatile process. It allows manufacturers to produce accurate and repeatable parts out of nearly any metal available for casting and complicated shapes that would be difficult or impossible with other casting methods. Casted parts also have excellent surface qualities and low tolerances, with minimal surface finishing or machining required.

These features make investment casting ideal for complex parts in automotive, aerospace, and industrial applications, medical tools, dental implants, as well as fine jewelry and art.

Investment casting is a complex and labor-intensive process. It requires specialized equipment, costly refractories and binders, as well many manual operations to make a mold. It can be difficult to cast parts that require cores and the process is better suited to small parts.

One half of a sand casting mold.

Sand casting is a metal casting method that was first in use 3,000 years ago but remains the most widely used casting method to this day. This process allows manufacturers to cast metal without relying on machining.

In the sand casting process, the manufacturer first creates a foundry pattern, or replica of the casting, most commonly from wood or plastic. The pattern is oversized to allow for shrinkage. Parts with features on one side only require an open-faced mold. For parts with multiple detailed surfaces, the manufacturer separates the foundry pattern into two mold boxes to form a closed cavity mold. The top half is called a cope and the bottom a drag.

Once the manufacturer creates the pattern, they tightly pack sand around the pattern. Then, they add sprues and gates to ensure that the molten metal flows smoothly through the mold cavity. The manufacturer removes the pattern then clamps the two halves of the sand mold together. Once the metal melts to a molten state, it is poured into the mold and left to cool. From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

From here, the sand mold is removed using vibrations or high-pressure water. Finally, the manufacturer refines the part by removing sprues and gates, and polishing the cast metal part.

Sand casting is an adaptable process that functions outside the limitations of machinery. Because of this, it can create complex parts of virtually any size. Sand is inexpensive and plentiful, which lowers the setup cost and makes modifications possible. It is the only practical or economical way to produce very large castings. The lead time of sand casting is also short, making it a viable process for short production runs.

Sand casting’s versatility makes it a manufacturing option across a wide array of industries. It can produce medical equipment, automobile parts, electronic equipment, gas tanks, and engine blocks, and more.

Sand casting creates highly porous, textured metals. The shrinkage and rough surface finish also lower the dimensional accuracy of parts. This results in a low-strength final product that requires time-consuming post-processing to achieve a higher quality finish.

In order to choose the right industrial metal casting process, several factors must be considered. We’ve created this comparison table to help you compare die casting, investment casting, and sand casting in terms of types of metals, production volume, costs, production time, part complexity, and for which industries they are generally used.

| Die Casting | Investment Casting | Sand Casting | |

|---|---|---|---|

| Compatible metals | Aluminum, copper, lead, magnesium, zinc | Most metals | Most metals |

| Production volume | High volume | Low to high volume | One-off to medium volume |

| Unit costs | Low | Moderate to high | Moderate |

| Tooling costs | High | Moderate | Low |

| Cycle time | Rapid | Long | Moderate |

| Industries | Automotive, aerospace, consumer products, furniture, power tools | Automotive, aerospace, jewelry, medicine, dentistry, art | Automotive, aerospace, industrial equipment, electronics, consumer products |

3D printed jewelry ring pattern and cast metal part.

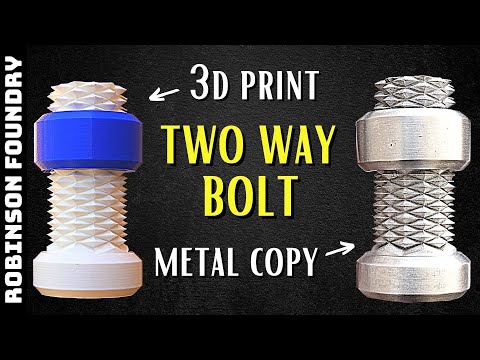

Engineers, designers, jewelers, and hobbyists can capitalize on the speed and flexibility of 3D printing by combining castings processes like indirect investment casting, direct investment casting, pewter casting, and sand casting with 3D printed patterns or casting metal into 3D printed molds. Cast metal parts using 3D printed rapid tooling can be produced in a fraction of the time invested in traditional casting and at a significantly lower cost than metal 3D printing.

Stereolithography (SLA) 3D printers offer high precision and a broad material library that is well-suited for casting workflows and can produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Webinar

In this webinar, we will look at how desktop stereolithography (SLA) 3D printers are being used to directly print patterns, how to work with SLA patterns for investment casting, and how the benefits of generative design are increasing the demand for printed patterns.

Watch the Webinar Now

A 3D printed mold in Clear Resin for wax injection.

The process of making patterns from molds or tooling is referred to as indirect investment casting because it requires creating molds for producing the patterns in addition to final investment molds.

Rigid molds for wax (often referred to as tools) are commonly fabricated by machining aluminum or steel. Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work before first shots can be run and pattern parts evaluated within a casting process.

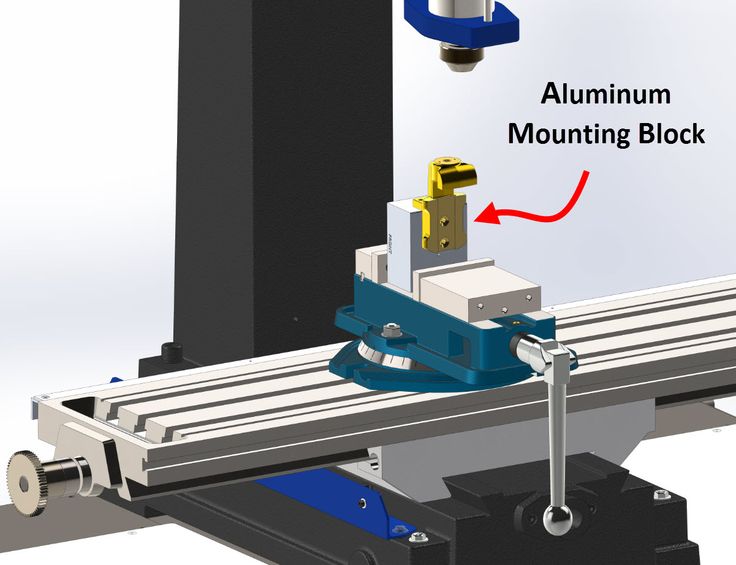

With 3D printing, manufacturers can directly 3D print the mold for their pattern using materials like High Temp Resin or Rigid 10K Resin, resins with high-temperature resistance. For an optimal surface finish of molded parts, treat the interior surfaces of the mold by sanding and polishing for a smooth look, or bead blasting if a uniform matte look is desired. To ensure the final cast parts are dimensionally accurate, compensate for shrinkage by scaling up the printed mold. The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

The exact shrinkage of the wax and the casting process can be obtained from supplier specifications.

3D printed molds for metal casting shorten the time between concept and first tests to a matter of days because manufacturers can directly print the tooling necessary for running and evaluating parts.

While molded pieces must follow design rules for moldability (e.g., no undercuts, draft is beneficial, etc.), you can achieve increased pattern complexity by using assembly jigs to combine multiple components into a single structure.

White Paper

Download our white paper to learn about six moldmaking processes that are possible with an in-house SLA 3D printer, including injection molding, vacuum forming, silicone molding, and more.

Download the White Paper

3D printed jewelry patterns and metal casted rings.

Direct investment casting is a version of investment casting where the process moves directly from pattern creation to surrounding the pattern with investment material. It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

It is ideal for producing parts with geometries that are too complex to be molded or for parts with extensive undercuts and fine surface texture details, where molding is possible but carries high tooling costs.

Traditionally, patterns for direct investment casting are carved by hand or machined if the part is a one-off or expected to be only a handful of units. With 3D printing, however, manufacturers can directly print the patterns, removing the design and time constraints common in other processes.

With 3D printing, engineers, designers, and jewelers can direct 3D print patterns in order to achieve shorter lead times and geometric freedom that exceeds the design for manufacturability constraints of molding processes. Formlabs developed a range of castable materials suitable for direct investment casting, in particular for the jewelry industry.

White Paper

The way jewelers work is changing, and castable photopolymer resins are leading the way. In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

In this guide, learn how to cast fine jewelry pieces 3D printed on Formlabs printers.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Grey Resin printed pattern and finished aluminum casting from an open-faced sand mold.

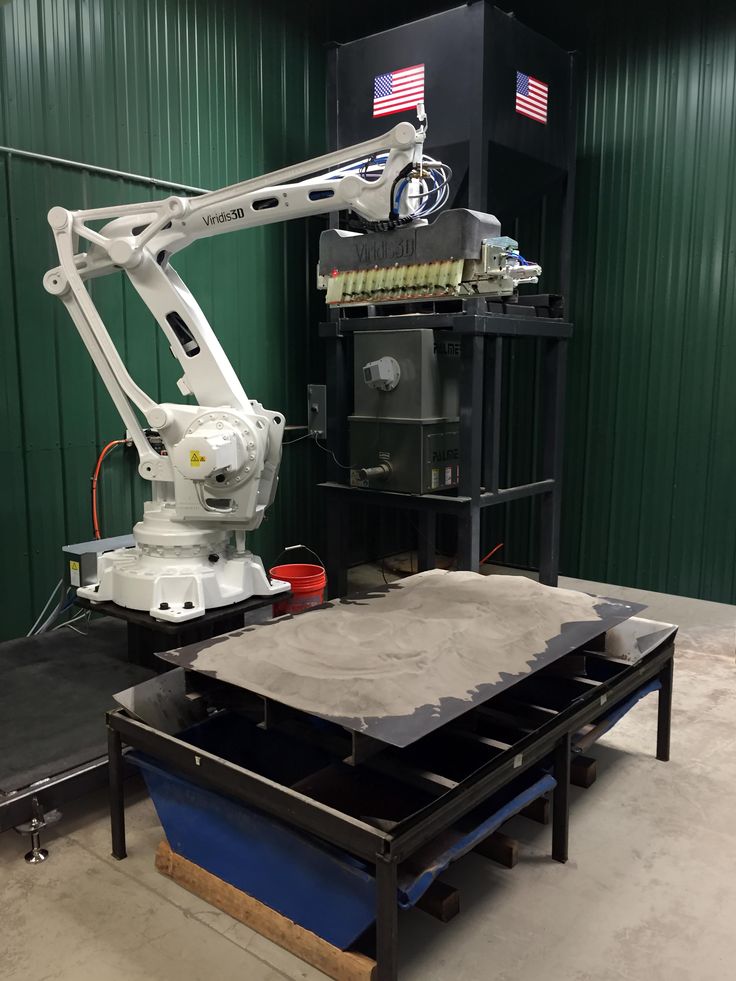

Similar to investment casting, 3D printing can be used to create patterns for sand casting.

In comparison to traditional materials like wood, 3D printing allows manufacturers to create complex shapes and go straight from digital design to casting.

Metal Miniatures made with pewter casting and 3D printing.

Pewter is a malleable metal alloy with a low melting point that can be used for making fully metal objects for decorative applications such as detailed metal miniatures, jewelry, scale models, and replicas of antiques.

With recent developments in temperature-resistant 3D printing materials, like High Temp Resin for Formlabs SLA 3D printers, it’s now possible to 3D print molds for direct pewter casting.

There are two options for mold designs: a sacrificial or pull-apart mold. In a sacrificial mold, there is a shell designed to be broken apart in the process. Pull-apart molds function with separate halves so the mold can be reused.

Compared to directly printing metal, the casting pewter in 3D printed molds offers significantly better detail and surface finish at a small fraction of the cost. Compared to wax casting, directly 3D printing a mold has fewer steps and requires less manual effort, while preserving the most possible detail.

Webinar

Watch our webinar to learn how moldmaking using 3D printed masters and reusable or sacrificial molds can allow you to produce parts in porcelain, precious and non-precious metals, silicone and biocompatible flexible materials, and more.

Watch the Webinar Now

Jewelry investment casting process with 3D printed patterns.

Businesses looking to boost design freedom or cut costs and lead times have a strong solution in metal casting with 3D printing.

Certain types of complex metal castings, such as large shapes with cross-sections and pieces with multiple cores, are difficult to create using traditional metal casting methods. 3D printing allows manufacturers to produce these complex designs. For example, jewelers can create intricate and custom designs that might be impossible without a 3D printed pattern.

3D printing also eliminates reliance on multiple machines or service providers to create parts. Instead, companies just need a digital file, a 3D printer, and printing material. This can cut costs and waste, as all the material used goes into the final product.

Finally, the combination of 3D printing with metal casting can cut costs and lead time. Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Rather than waiting weeks for expensive tooling before being able to cast a final product, a 3D printer can create a pattern or mold in hours.

Metal casting combined with 3D printing help companies quickly and efficiently create metal parts. With a Formlabs SLA 3D printer, you can expedite the metal casting process and cut costs along the way.

Learn more about the Form 3 desktop SLA 3D printer and request a free sample part to evaluate the quality firsthand.

See the Form 3Request a Free Sample Part

The battle of innovation and tradition

3D Learning Hub

See all categories

Contents:

- Introduction

- Traditional Metal Casting

- Metal 3D printing technologies

- Metal casting and 3D Printing: Making friends with the enemy

- When to use traditional Metal Casting

- How can you improve your production with Metal 3D printing?

- Is Metal 3D printing the new industrial revolution?

Introduction

Traditional Metal Casting

The history of Classical Metal Casting methods dates back to the middle ages. The process involves several steps. First of all, you need to produce a replica of your final product. To create replicas you can use different materials, one of them is wood, as shown in the example video. The design on the replica has to also include a filling system and some additional support. Then, you need to create a mold based on this replica. There are several techniques for working with molding materials, the most popular is sand.

The process involves several steps. First of all, you need to produce a replica of your final product. To create replicas you can use different materials, one of them is wood, as shown in the example video. The design on the replica has to also include a filling system and some additional support. Then, you need to create a mold based on this replica. There are several techniques for working with molding materials, the most popular is sand.

The first step is the preparation of the replica, this process will be different for different materials. Once you have the copy of your final product, the filling system has to be designed. It’s important to remember that the replica has to come out of the sand mold, so it can’t be wider at the bottom than on top. This is called an undercut and means the copy is unremovable.

While designing your parts and the filling system, you also have to think about the fact that liquid metal hardens fast and it might not reach a higher level of your design before it concrets. To avoid that you have to design a feed head. It’s later removed from your part.

To avoid that you have to design a feed head. It’s later removed from your part.

Then it all has to be copied in a mold. It’s necessary to prepare two sand molds. Next step is to get the object mirrored in a special sand to create one mold. The second mold is used for the filling system, where the metal will be poured, and if necessary can also be used for the second part of your object. The molds are then stuck one of the top of the other, so the filling system matches the shape of your object.

Once two molds are connected, so the metal doesn’t leak between the two layers of sand, the metal is heated up and liquified. The casting processes involve the metal being poured into the mold through a filing system very quickly as it hardens fast.

The last step is to clean the object off the sand and remove the filling system. Now the object is ready for any additional polishing and removal of extra material if needed.

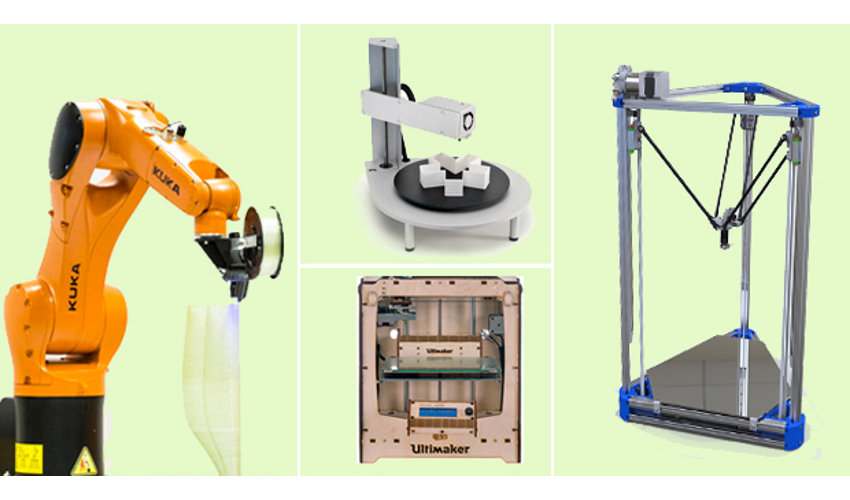

Metal 3D printing technologies

Selective Laser Melting

Selective Laser Melting (SLM) is an Additive Manufacturing technology that uses metal powder to create your parts. The metal 3D printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the shape of your 3D model. The next layer of powder is placed and the process repeats itself. The metal is melted at a high temperature, and the 3D printed parts require a cooling time.

With SLM technology you can integrate multiple components into a single object, which reduces the costs and saves time on assembling your parts. Choosing Selective Laser Melting for your production will also provide you with very strong parts, which at the same time can have thin walls lowering the weight of your parts. They also will have high-temperature resistance.

For SLM we offer Aluminium AISi10Mg0,6 composed mainly of aluminum (90%), silicon (7%) and magnesium (0.6%). This material has good mechanical properties and can be used for parts subjected to high voltages.

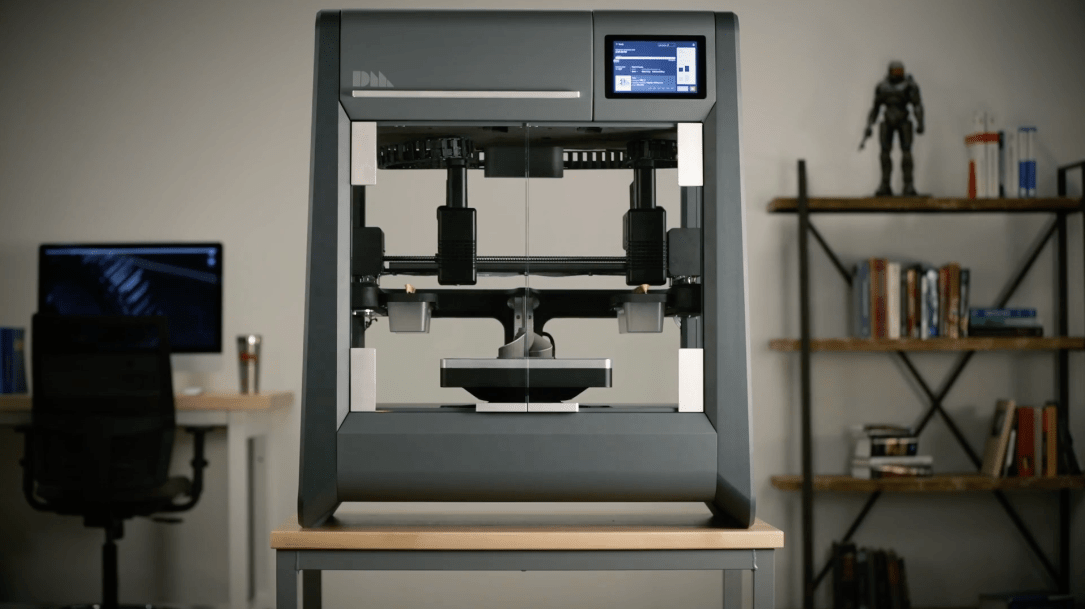

Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) technology also uses metal powder to 3D print your functional parts. The process is the same as for SLM, the metal 3D printer lays down a layer of metal powder, then a laser beam sinters the powder in the shape of your 3D model. The DMLS process is highly beneficial for those who need to produce their metal parts for prototyping or low-volume production by eliminating time-consuming tooling. It also allows creating complicated and highly detailed designs that wouldn’t be possible with any other technology, due to the limitations of the traditional manufacturing processes.

Properties of your parts metal printed using SLM and DSML will be similar. They will have good mechanical characteristics, your models can be quite detailed and also fully functional, prepared to be used or integrated into a larger object.

The difference between SLM and DMLS is the temperature the metal powder is melted at and the materials you can use. With DMLS we offer Stainless Steel 316L and Titanium 6AI-4V.

Binder Jetting

Like the technologies mentioned above, Binder Jetting is powder-based 3D printing method. However, with this Additive Manufacturing method, there is no laser involved. The metal powder is fused with a binding liquid agent and lightly cured between each layer. Binder Jetting is the fastest and the cheapest metal 3D printing process. The main benefit of Binder Jetting is high customization and fast production time, however, this technology is more suitable for prototyping needs, ornamental and decorative parts or jewelry.

At Sculpteo we offer two metal powders for 3D printing with Binder Jetting: Steel / Bronze 420SS/BR and Stainless Steel 316.

Lost-Wax Metal Casting

Lost-Wax Metal Casting is the only 3D printing method that doesn’t involve metal powder. The technology is based on injecting metal into a mold. The master model, typically built in wax, thanks to 3D printing is the perfect replica of the finished product. Once the master model is 3D printed, a mold made in plaster is poured over it. When the plaster mold is ready, liquid metal is injected into the mold to replace wax pattern which is drained away through a treelike structure to create the object.

To meet your needs for production, we offer you a variety of 3 metals for Casting: Silver, Brass, and Bronze.

Metal casting and 3D Printing: Making friends with the enemy

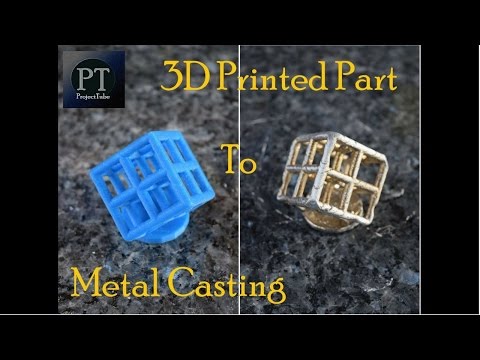

Additive Manufacturing doesn’t necessarily have to be a competitor to traditional metal casting. It can very well complement classical methods of production and improve them. The best example of combining Additive Manufacturing and Classical Foundry is to 3D print the replicas of the master objects. 3D printing allows a high level of details, which was not reachable before the use of Additive Manufacturing methods. And it also speeds up the pre-production process of traditional Metal Casting.

It can very well complement classical methods of production and improve them. The best example of combining Additive Manufacturing and Classical Foundry is to 3D print the replicas of the master objects. 3D printing allows a high level of details, which was not reachable before the use of Additive Manufacturing methods. And it also speeds up the pre-production process of traditional Metal Casting.

A good example of the two technologies working together is Lost-Wax Metal Casting. Thanks to Additive Manufacturing a high level of customization can be achieved for the 3D printed wax copy of the original design. The process is faster thanks to 3D printing and the wax replica is easily removable.

Another way of combining Additive Manufacturing and classical Metal Casting is to 3D print plastic copies of the final product. Like with the Lost-Wax Metal Casting, 3D printed replicas will melt out creating the perfect, custom-made mold that can be used for Traditional Foundry methods. The process is very well explained in the video below.

The process is very well explained in the video below.

Moreover, 3D printed models are also great for the most commonly used Metal Casting molds made with sand. Thanks to Additive Manufacturing the model will be detailed and will leave the exact shape of your design in the sand to produce accurate metal products. A great example of combining both technologies is shown in the video of a 3D printed metal hammer:

When to use traditional Metal Casting

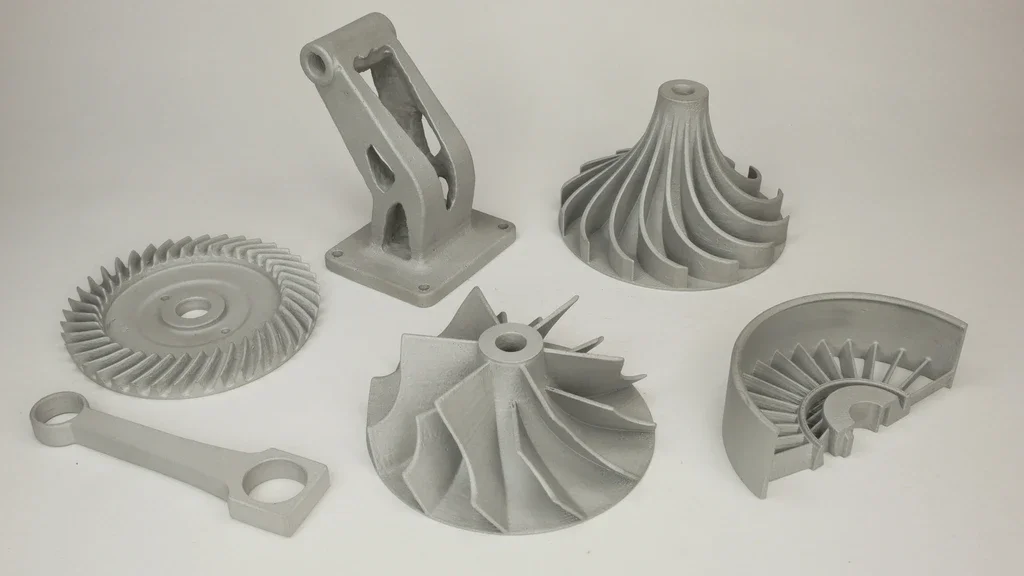

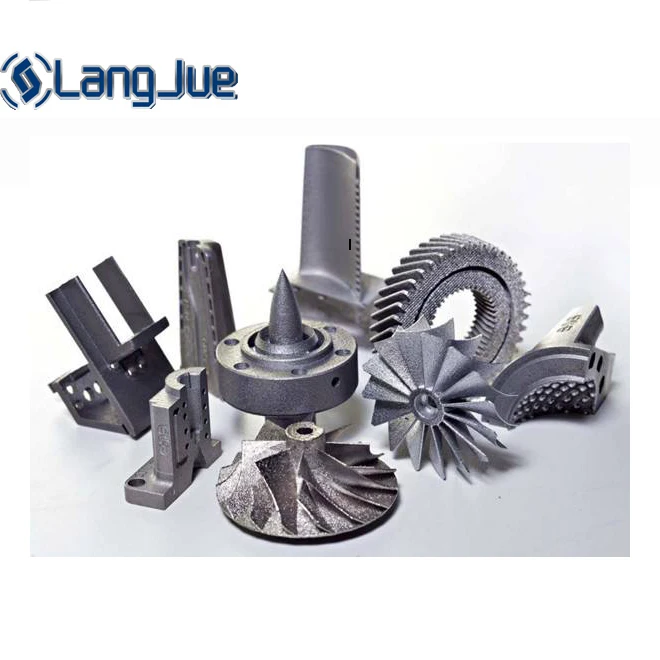

Classic foundry is great for big parts

If you’re planning to produce large mechanical parts, such as engine’s components, or big gears for machines, Classical Foundry is great for that purpose. Additive Manufacturing won’t be as effective with large sized parts due to the limitations of dimensions the 3D printer can reach. The main goal of producing mechanical parts is for them to be functional. The looks are not important at all, they have to have good mechanical properties and if big size is also essential for your production, traditional Metal Casting will provide you with great parts.

The main goal of producing mechanical parts is for them to be functional. The looks are not important at all, they have to have good mechanical properties and if big size is also essential for your production, traditional Metal Casting will provide you with great parts.

Traditional Metal Casting will be cheaper to produce a large number of parts

Classical foundry will also be beneficial if you need multiple copies of your parts. The costs of production decrease with the number of parts, whereas for using Additive Manufacturing, the cost stays the same.

How can you improve your production with Metal 3D printing?

As the process of metal 3D printing with Lost- Wax Metal Casting technology is quite similar to traditional Metal Casting in this chapter we will talk more about the benefits of using metal powder- based Additive Manufacturing.

Highly customized and articulated 3D printed parts

3D printing also allows for much more design freedom, a high level of details, customization, and if precision is important for your design, choose Additive Manufacturing. Moreover, with 3D printing, you can design your parts to be articulated which is impossible with traditional Metal Casting. It not only saves the assembly time but also gives you totally new design opportunities.

Moreover, with 3D printing, you can design your parts to be articulated which is impossible with traditional Metal Casting. It not only saves the assembly time but also gives you totally new design opportunities.

3D printing is faster

If time plays a big factor in your production process, Additive Manufacturing is the right solution for you. Metal 3D printing is much faster than traditional Metal Casting for several reasons. Starting with pre-production, to metal 3D print your parts you just need a 3D model. Compared to Metal Casting, where you not only need to design your parts, the filling system, and the feed head but also create a mold, 3D printing saves you a lot of time. For powder- based Additive Manufacturing technologies all you need to do it to upload the 3D model to our website.

Also, the post-production process is much quicker for metal 3D printed parts. Keep in mind that Metal Casting involves machining removal methods to unattach the filling system and feed head, as well as manual removal of metal that got spilled between the molds before you even move on to surface finishing. For 3D printed parts, the supports have to be removed, but that’s taken care of by our production team. We also provide you with several options for surface finishes such as polishing and plating which allows for your designs to reach another level of customization.

For 3D printed parts, the supports have to be removed, but that’s taken care of by our production team. We also provide you with several options for surface finishes such as polishing and plating which allows for your designs to reach another level of customization.

Additive Manufacturing gives you more control

The production itself might seem faster for Metal Casting as the liquid metal hardens quickly, but you have no control over the process. Additive Manufacturing has a much more stable process of production. There is a possibility for the 3D printer to crash, but we keep an eye on all our parts in production and if such situation happens, we can immediately react and stop the process. Metal Casting method doesn’t give you that option as you can’t see what’s happening inside the molds.

With traditional Metal Casting, there is also a risk of the liquid metal concreting before it reaches higher parts of your object. To avoid it, an additional part of the design has to be created called the feed head. It later has to be removed from the final product which slows down the post-production process. Also, during the filling, oxidation can cause the creation of bubbles in the metal, and small pieces of the sand mold can get inside of your part, which will affect the object’s properties.

It later has to be removed from the final product which slows down the post-production process. Also, during the filling, oxidation can cause the creation of bubbles in the metal, and small pieces of the sand mold can get inside of your part, which will affect the object’s properties.

3D printing helps you create lighter parts

If you need your parts to be light, Additive Manufacturing gives you lots of options to achieve that. To reduce the weight of your parts, your 3D printed parts can have walls filled with lattice structures. Your 3D model can also be hollowed, which is not the case with Metal Casting process.

Good mechanical properties

With Additive Manufacturing methods such as Selective Laser Melting and Direct Metal Laser Sintering, your metal printed parts will also be very strong and have high heat resistance. Metal 3D printed objects with SLM and DMLS will have better mechanical properties as they are produced at a higher temperature.

Is Metal 3D printing the new industrial revolution?

True that traditional methods of Metal Casting are beneficial if your parts have to be huge. However, if you require custom made and precise parts for your object to be fully functional, 3D printing is the way to go. Additive Manufacturing will give you the freedom you need to design exactly the model you need, provide you with fast results and can highly improve your production system. With the variety of 3D technologies your metal printed parts can be designed and manufactured on your computer, just upload your 3D model to our website.

However, if you require custom made and precise parts for your object to be fully functional, 3D printing is the way to go. Additive Manufacturing will give you the freedom you need to design exactly the model you need, provide you with fast results and can highly improve your production system. With the variety of 3D technologies your metal printed parts can be designed and manufactured on your computer, just upload your 3D model to our website.

It’s very important to choose the right material to decide which metal 3D printing technology to use with the best results to empower your manufacturing process. To help you with that we prepared for you a blog post explaining in detail each of our metal materials, and you can always ask one of our consultants.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Create metal castings with 3D printed PLA molds

It was my first time experimenting with casting metal in PLA molds, for this project I used recycled aluminum scrap. In the past, I created two forms with 3D printer photogrammetry of two statues, since then I've been creating 3D printed statues of different sizes, but always wanted them to be made from a more durable material such as metal. Below is a brief description of the creation steps, but to see this method in more detail, watch the attached video showing the entire process from start to finish. When performing this project, please use all personal protective equipment presented in the video, remember safety above all else. nine0003

Note: This article is a translation.

Step 1: Full video on how to use the method of creating castings with PLA molds

Step 2: Using the photogrammetry method to convert images into objects for 3D printing

I started by using the photogrammetry method, taking about 80 shots of each of the objects that I planned to cast in metal. The main software I worked with was Autodesk ReCap Photo. After completing the meshing and texturing phase, I did the final touches by removing additional backgrounds and cosmetic fixes on the surface of the object. The next step was to load the files into the Ultimaker Cura 3D printing software and test some real 3D prints. On the images, you can see the stages of preparing photogrammetry, both for the owl statue and for the weeping statue (aka the Legend of the Yogi Man - "Orang Malu"). nine0003

The main software I worked with was Autodesk ReCap Photo. After completing the meshing and texturing phase, I did the final touches by removing additional backgrounds and cosmetic fixes on the surface of the object. The next step was to load the files into the Ultimaker Cura 3D printing software and test some real 3D prints. On the images, you can see the stages of preparing photogrammetry, both for the owl statue and for the weeping statue (aka the Legend of the Yogi Man - "Orang Malu"). nine0003

Step 3: 3D print two PLA statues for metal casting

I decided to experiment with 4 hollow 3D printed templates, 2 with 2mm shell thickness and 2 with 1mm shell thickness. I wanted to experiment to see if there would be a difference in the aluminum castings and my guess was correct: two 2mm aluminum castings didn't work, and the other two with 1mm wall thickness turned out much better, both not perfect but look great for the PLA test . I also learned that when casting in PLA molds it is important to expand the 3D print and add another 1cm of the base of the object as the PLA rises up after pouring molten aluminum and in my casting I lost 1cm of height compared to the original 3D print . nine0003

nine0003

Step 4: PLA 3D prints for metal casting

I wasn't sure if a 1mm thick print would work without internal support, but to my surprise it worked out really well, I changed the settings in Cura for outer shell thickness and 0% infill for all four shapes.

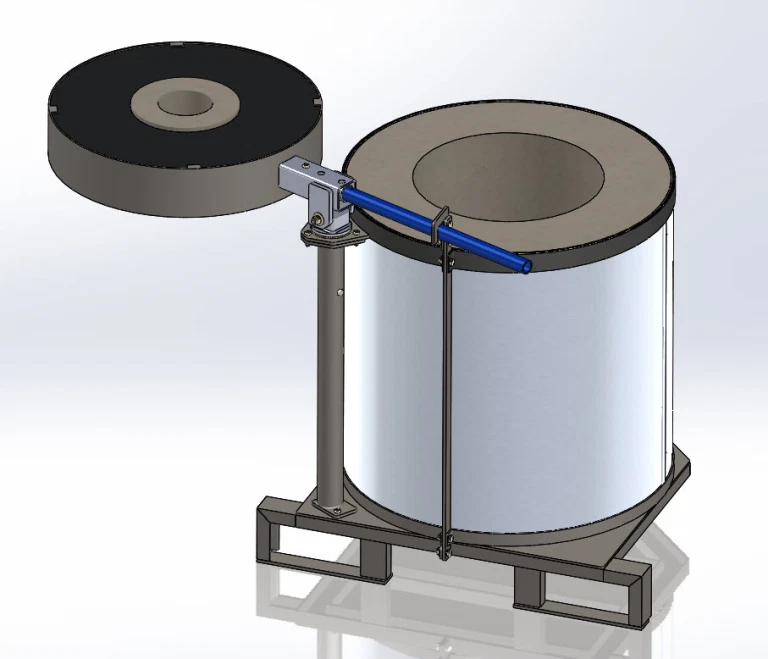

Step 5: Use oil-bonded sand for Lost PLA sand casting

I used my very old but still usable Petrobond (oil soaked sand) and buried the four 3D shapes in the sand, then I used my mini soldering torch to make a hole in the base where the molten aluminum was to be poured , the idea was to try and remove some of the PLA in the hope that this would reduce some of the casting defects as the PLA floats when the molten aluminum is poured into the mold. nine0003

Step 6: Casting aluminum according to the molding method, successes and failures

I used my good old furnace and melted down some recycled aluminum scrap, after degassing and removing impurities, I poured molten aluminum into four sand mold cavities. After the aluminum had cooled down a bit, I removed the fresh sand castings and was surprised that my guess was correct, and the 1mm thick 3D molds were successful, while the 2mm thick ones were not. You can see the difference in the pictures before I cleaned the metal a bit and polished it a bit. nine0003

After the aluminum had cooled down a bit, I removed the fresh sand castings and was surprised that my guess was correct, and the 1mm thick 3D molds were successful, while the 2mm thick ones were not. You can see the difference in the pictures before I cleaned the metal a bit and polished it a bit. nine0003

Step 7: Cleaning and light polishing of cast aluminum

I used a reciprocating saw to cut off the excess aluminum base and an angle grinder to clean and level it. After that, I lightly cleaned and polished the aluminum casting.

Step 8: Comparison of the statues taken as a basis and the resulting castings in aluminum

I hope you liked this tutorial, in my opinion the final result looks great, and the versatility of using this method thanks to printing molds for pouring on a 3D printer allows you to run wild . nine0003

We advise you to read the articles published earlier on our blog: "3D Printable Star Wars Stormtrooper Action Figure - Printable Files Included!" and "The Complete 3D Printing Guide [Part 1]".

If you liked the article, please like, share it with your friends and leave comments!

Casting from 3D printed models / Sudo Null IT News This page describes my first and successful attempt to cast aluminum parts directly from 3D printed PLA models. The process is almost identical to casting from a wax model, but instead of burning the wax, I burned the plastic PLA (bio-plastic)

I needed aluminum parts to mount the focusing lens for my 150W CO2 cutting laser. These parts had to be adjustable and had to be mounted on a frame assembled from scrap aluminum found.

I get excited when I think about being able to do it all in one day: concept -> design -> 3D printing -> finished metal casting

Step one - detail design.

I used the amazingly powerful OpenSCAD to quickly design the parts I needed. OpenSCAD reads the script in its own language to draw the 3D model. In my case, I just drew a shape in Adobe Illustrator and converted it to OpenSCAD format using the Inkscape plugin. nine0003

nine0003

Here is the design of the second piece. I drew two shapes in Illustrator and gave them depth in OpenSCAD. Very fast and easy. Now I have 3D models, it's time to print them!

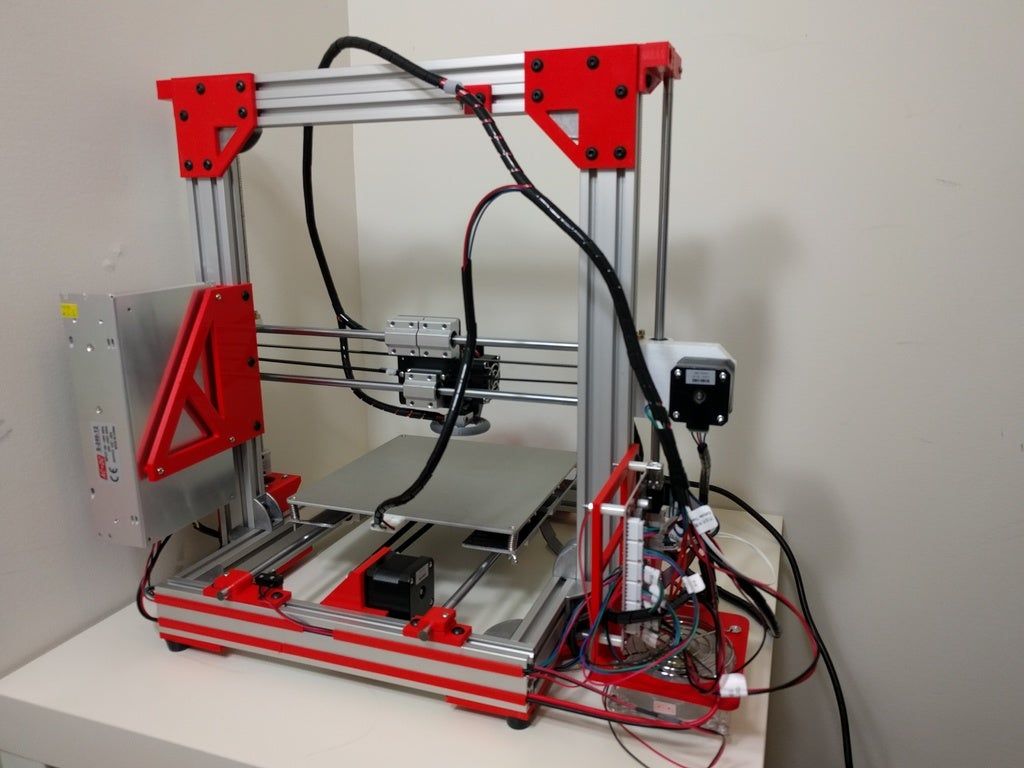

The process of printing the first part on my Ultimaker (fast shot).

The resulting part is in hand.

Printing the second part.

Second printed part in hand.

Checking how both parts fit together. nine0003

Sprues and air ducts are attached, everything is ready for pouring the molding mass.

Molding mass - 50% fine sand and 50% gypsum.

After adding water and mixing thoroughly, I used a home vacuum food sealer to get rid of air bubbles in the sand.

The second piece is ready to be molded!

The first detail is poured!

The part is completely immersed in the mixture - I hope everything works out. nine0003

nine0003

Both molds are set to dry.

After a couple of hours, I placed the molds in the oven on medium heat.

My new little oven. Heats up quickly for 10 pounds (~4.5kg) or less of molten aluminium. 2 times more when it flares up.

Forms are good and well done. Once heated to about 1200F (650C), the plastic doesn't stand a chance. After removing, I blew out the molds with compressed air to blow out any remaining ash. nine0003

The still hot molds are placed in dry sand. It serves several purposes:

- additional support as the molds are quite fragile

- insulates molds and retains heat when cured

- will allow me to install sprue extensions (see below). The expander gives extra pressure to the casting and also acts as a riser that stays molten and provides extra metal while the casting solidifies and contracts

My sprues are just cut aluminum cans. Works great!

After melting aluminum with a small addition of copper in the crucible, removing the slag - it's time to pour!

So cool! It looks like the forms filled out perfectly. Now the hard part is to wait long enough for the metal to cool for me to know if the parts are good or not.

Now the hard part is to wait long enough for the metal to cool for me to know if the parts are good or not.

Fine! The details are straight from the sand, only the sprues and air ducts are cut off. nine0003

I cut the center hole with a small 14mm tap. Everything seems to fit together nicely.

I like the details on the casting - you can see all the lines from the 3D printing, their width is only 0.2mm.

The moment of truth - do they fit the frame? YES! I made a plastic part to fit the frame perfectly, then printed it again at 102% size increase. When aluminum cools, it shrinks by exactly 2%.

The center of the black nipple is where the focused CO2 laser beam will come out. Tube - for compressed air to blow off smoke in the path of the laser (the so-called air-assist). nine0003

Looks like I can put this to good use!

The black hole in the center is a focusing lens.

I'm so happy that the parts fit the frame perfectly without any additional processing and even without a file!

This is the first test of my laser.