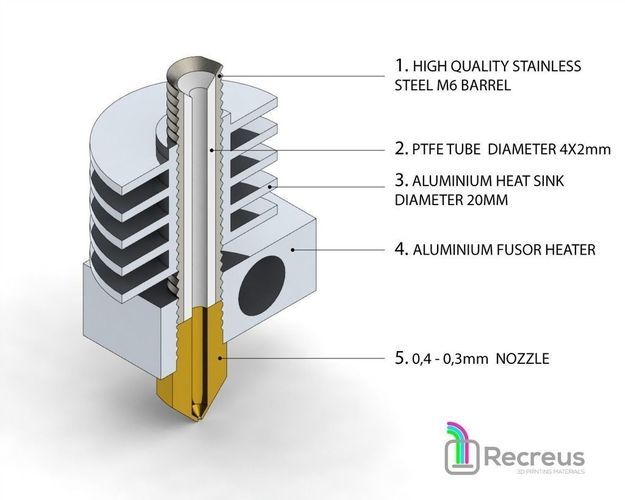

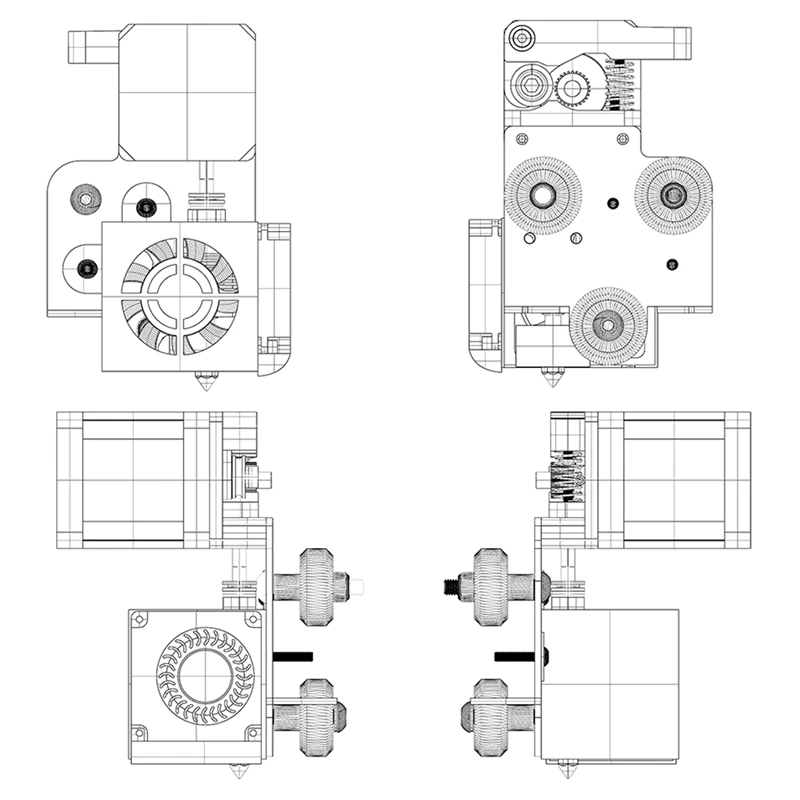

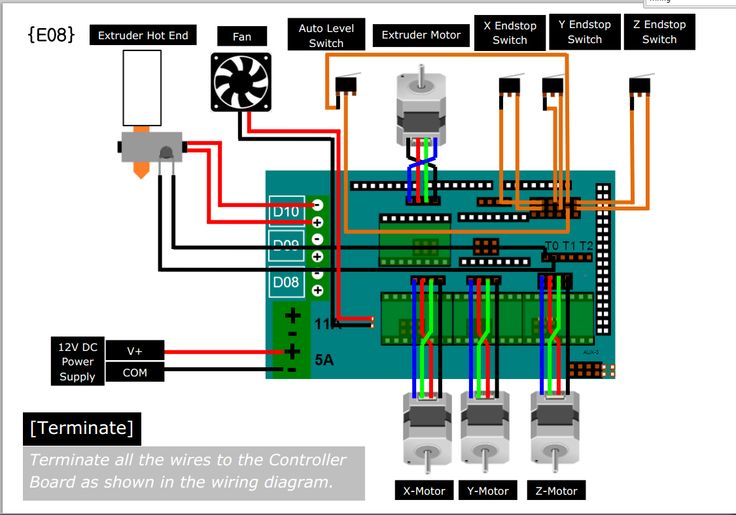

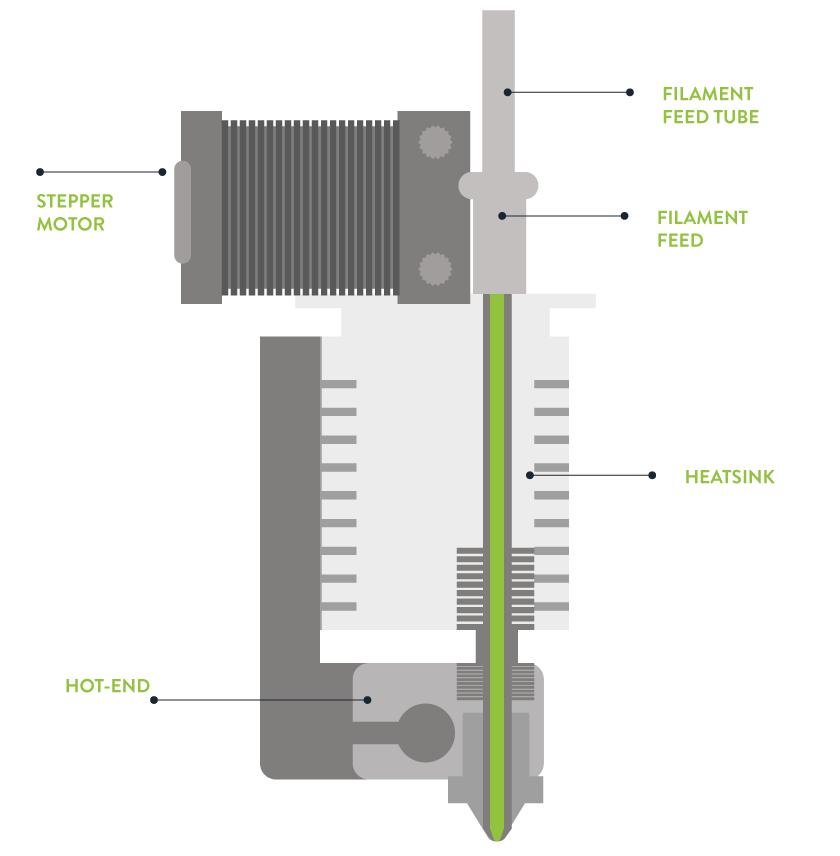

3D printer hotend diagram

Anatomy of a HotEnd – E3D Online

HotEnds, liquifiers, toolheads, extruders, shooty-squirty-plastic guns - just what are these and why are they so important to the 3D printers? What makes a good HotEnd, what makes a bad HotEnd, and what makes an excellent HotEnd? We at E3D have been making them since 2012, and we’ve learnt a thing or two.

A HotEnd is a component integral to the build of 3D printers; unlike many of other components, the HotEnd cannot be 3D printed and is thus known as a ‘Vitamin’ , (other vitamin parts include belts. Motors, pulleys, motherboards, etc).

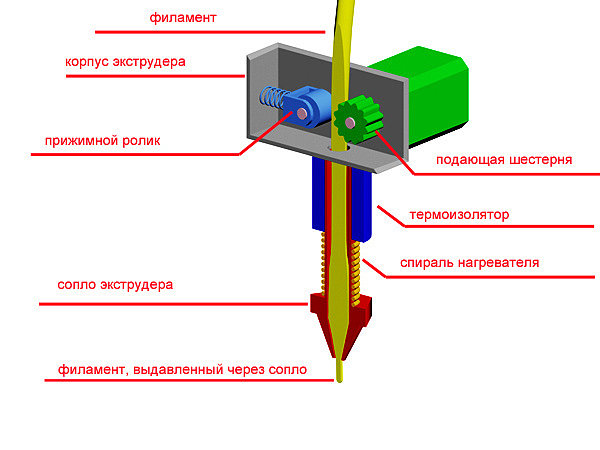

In a nutshell, HotEnds act as a ‘glorified glue gun’ which is fed spaghetti-shaped plastic by a filament drive, or as they’re more colloquially known, an extruder. Sometimes these two components are one and the same, sometimes they’re fixed together, and sometimes they’re a distance away and are connected by a tube of PTFE.

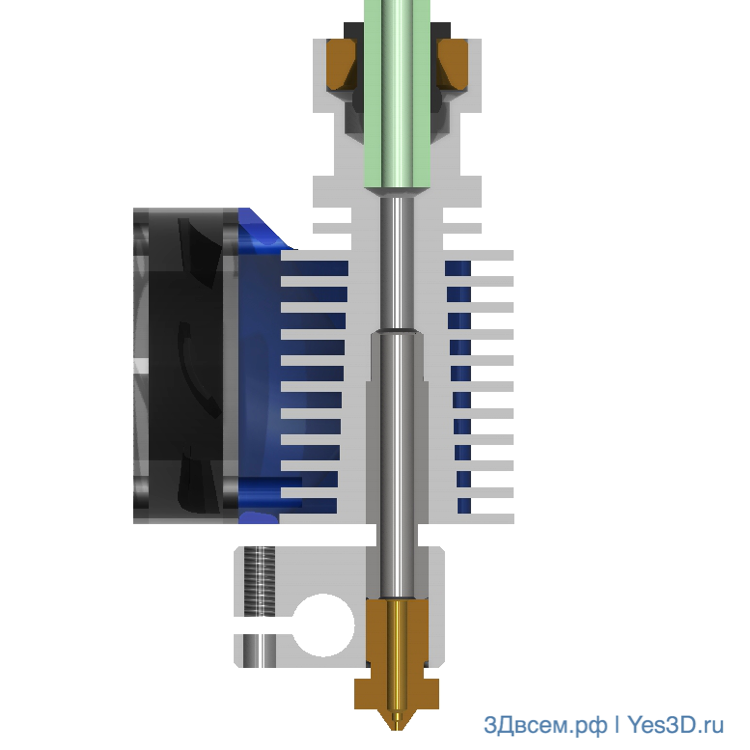

Either way, the filament is driven by the extruder into the top orifice of what’s known as the HotEnd’s ‘cold side’, through the HotEnd, and into the ‘hot side’, here the plastic becomes gooey, and then viscous, before eventually extruding through the nozzle at the bottom of the HotEnd’.

Once extruded, filament is laid down into a path; this path will eventually form one layer (or one slice) of the print.

Simple right? Not necessarily. HotEnds have seen continual development for the 30 or so years since their inception and are in fact quite complex components.

Although making a HotEnd of your own might sound easy - engineering a HotEnd capable of operating without leaks, clogs, heatcreep or other disruptions for 10,000s hours of continuous use is a totally different story. It even took us a number of goes to get it right, hence why our HotEnd is the V6.

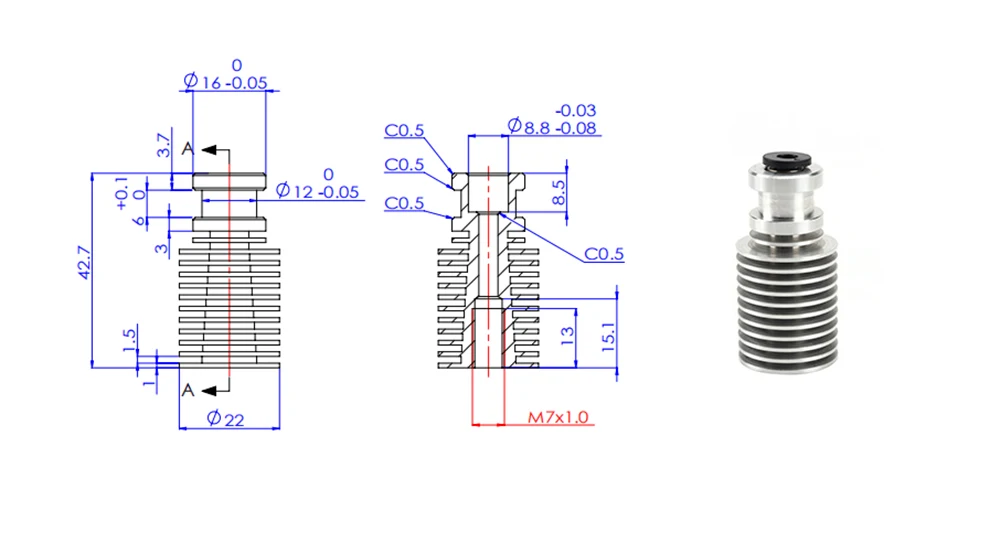

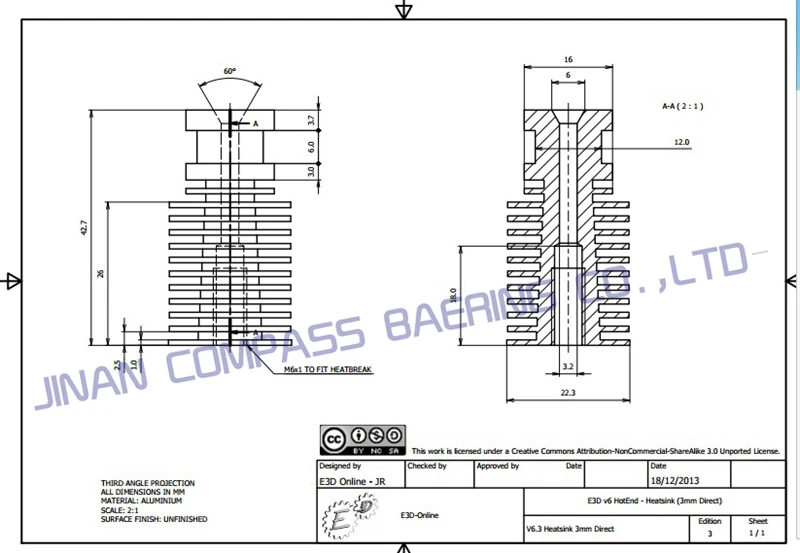

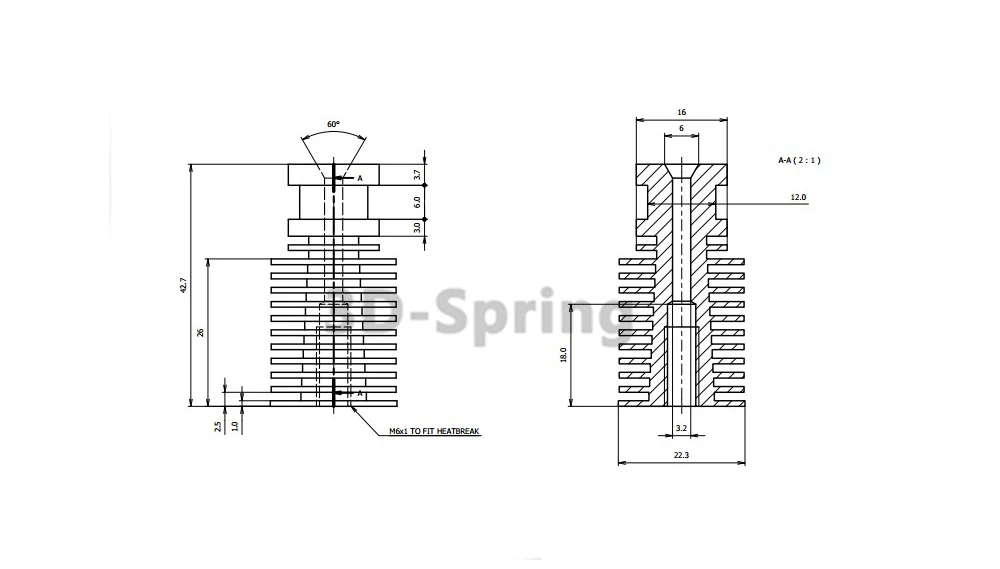

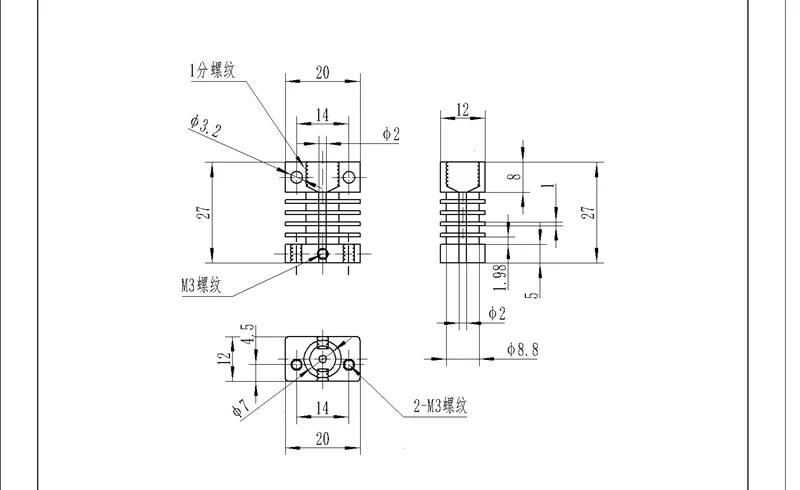

The HeatSink makes up the majority of what is known as the ‘coldside’ or cooling system for the hotend. It operates as a heat exchanger redirecting heat away from the filament path. This is achieved by maximising surface area exposed through the use of precisely machined fins; keeping the coldside cool, in what we call active cooling.

The active cooling’s effect is exemplified through the use of a mounted DC fan (using a duct) that blows air into the HeatSink’s fins - this ensures continuous circulation of the surrounding air and steers cool air in and around the fins.

In some more advanced cooling systems other techniques are used, such as passive cooling, pumped air cooling and even liquid cooling.

Liquid cooling is typically reserved for advanced extrusion systems and is more efficient than fan cooling. A continuous stream of cool water is pulled from a reservoir and through the HeatSink, continuously collecting heat transmitted as it travels through the HeatSink. This heated water is then delivered back into the fan-cooled reservoir and recycled.

Liquid cooling is the go-to cooling method when printing in heated enclosures (where fan cooling alone is less effective) or when working with high temperature polymers such as PEEK.

The HeatBreak is a threaded metal tube which both mechanically secures, and thermally separates the coldside of the HotEnd from the hotside. The HeatBreak is typically made of stainless steel, or in some cases titanium due to its lower thermal conductivity.

The HeatBreak is made up of 2 sides: one which threads into the HeatSink and stays cold; and the other which threads into the HeaterBlock and stays hot. It is within the HeatBreak that the filament’s property changes into one of a more viscous material in a process not too dissimilar to melting.

It is within the HeatBreak that the filament’s property changes into one of a more viscous material in a process not too dissimilar to melting.

Hot side versus cold side

As the material travels through the HeatSink, it is both cold and solid and easily slides down the bore of the HotEnd. The material then enters the HeatBreak and as it travels down further, the temperature of the surrounding HeatBreak begins to increase - both heating and softening the polymer. This softening transition happens in the most constricted point in the middle of the HeatBreak; a section we’ve (very creatively) named:

The property change experienced by polymers is unique. Unlike how an ice cube melts, the polymer doesn’t transition immediately into a liquid. Instead, the polymer enters a soft rubbery state, gradually becoming more and more putty-like. Eventually it becomes a viscous fluid of molten polymer at the hot side of the HeatBreak.

As the material softens, it resists downward travel by deforming and adhering to the walls of the HeatBreak; this tendency is actually often the cause of many clogs in poorly designed and manufactured HotEnds.

Whereas in an E3D V6, we carefully manage the transition zone by keeping it very short (2mm) and manufacturing the HeatBreak with an internal gloss-like surface finish, preventing the softened material from adhering to the walls of the HeatBreak.

As it so happens, the adherence of the filament is utilised by the HotEnd as a means of coaxing the molten polymer into the hotside and out the nozzle.

You see, as the filament enters the transition zone and softens, it also expands. This forms a soft rubbery plug between the gooey fluid on the hotside, and the solid brittle filament. This expanded plug creates a pressure seal which allows the solid filament to act like a piston and push the molten plastic out the nozzle, where this rubbery plug is the seal of the pistoné.

As it so happens, many users do not realise that this is a completely normal part of how a HotEnd functions, and upon removing filament from their HotEnd they are concerned to see the expanded tip on the end; they may fear the worst - when in reality everything is fine.

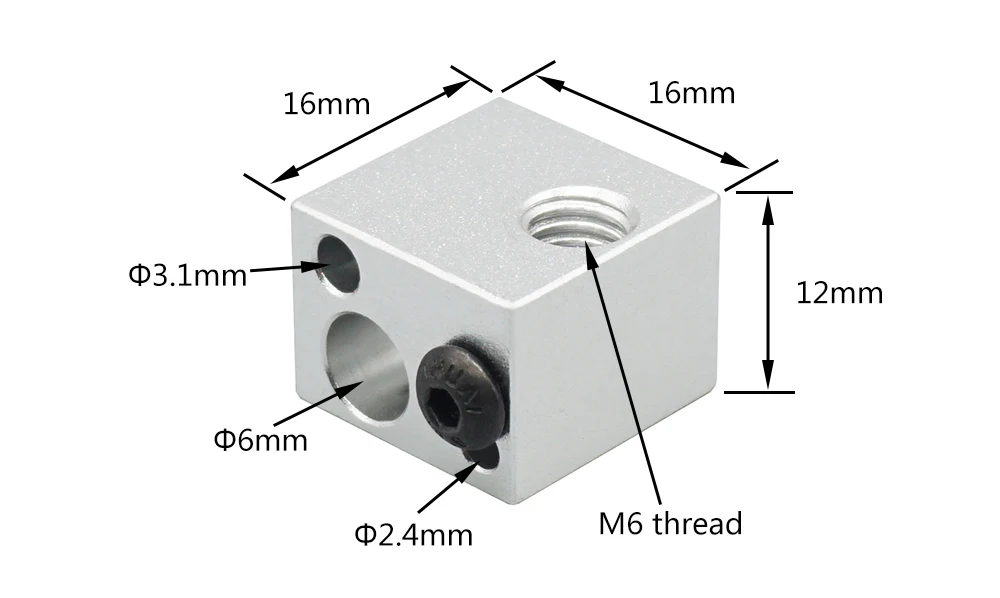

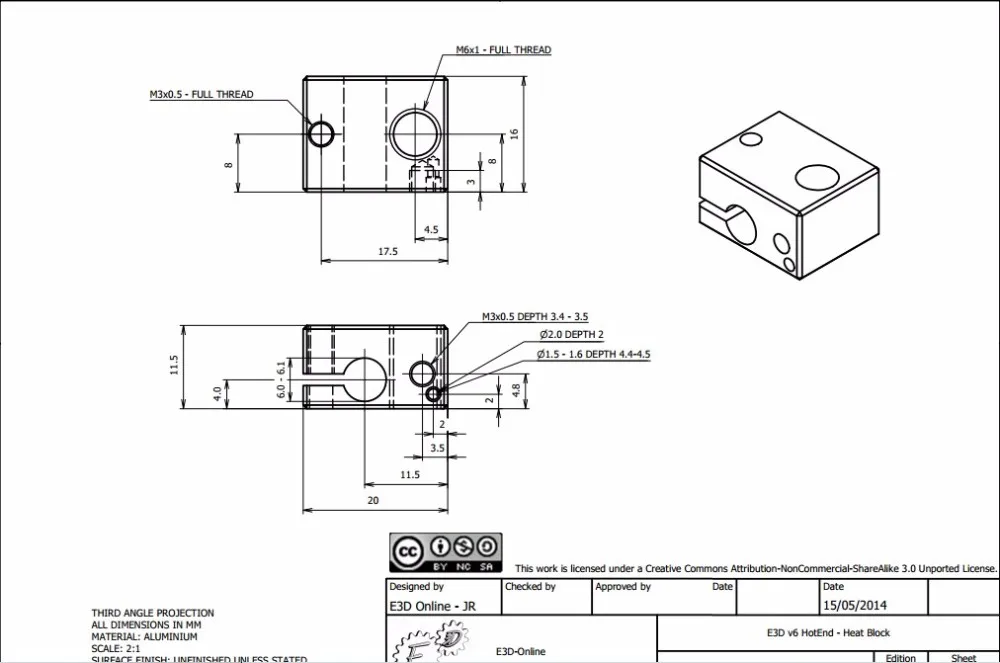

Serving a contrasting duty to the HeatBreak, the HeaterBlock is often made out of aluminium or copper - these being materials with high thermal conductivity. The HeaterBlock is responsible for mechanically and thermally coupling the heater, the sensor and the nozzle into a single collaborative system.

Perhaps more importantly, the HeaterBlock acts as a reservoir of heat for the nozzle to top up with, keeping its temperature stable and reducing thermal fluctuations.

The heater cartridge is an electrically-powered, tube-shaped device, embedded with a heating coil. Electricity cycles current through thin wires in the head of the heater cartridge. The tightness of the wire causes many collisions between the electrons and atoms within the wire which in turn generates heat. These wires are coiled into closely knit rings allowing heat between the individual coils to be shared and thus maximised.

Standard E3D heater cartridges have a power output of 30 watts which is tuned to allow the hotend to print at 300°C. We have intentionally chosen this wattage to maximise material potential of the HotEnd. Although printing above 300°C is possible with our standard heater cartridge, heating the aluminium block higher than 300°C causes it to soften and lose integrity; similarly the thermistor will also fail.

We have intentionally chosen this wattage to maximise material potential of the HotEnd. Although printing above 300°C is possible with our standard heater cartridge, heating the aluminium block higher than 300°C causes it to soften and lose integrity; similarly the thermistor will also fail.

Printing more advanced polymers (which require temperatures above 300°C) is easiest with the use of high temperature heater cartridges (65W). Printing at these heights requires the use of specialized plated copper HeaterBlocks to prevent the block softening. Our high temperature range allows users to print upwards of 500°C; which is more than enough for any polymer ever conceived.

The thermistor is a specific type of sensor responsible for detecting the temperature of the HeaterBlock. Based on the detected heat, the sensor sends a signal to the heater cartridge switching it on or off. This in turn cajoles the hotside into retaining an idealised temperature - in a process more commonly known as a control loop.

- If the block is below the desired temperature the signal switches on the heater cartridge

- If the block is above the desired temperature the heat sensor switches the heater cartridge off.

Some temperature sensors do their job better than standard thermistors. Those who want sharper results and faster reactions can upgrade to PT100s or even thermocouples - these use alternative methods at sensing temperatures which are more complicated yet more reliable than standard thermistors.

Bowden tubing is a more atypical part of the HotEnd as it is only required for certain HotEnds. Typically made from slippery materials like PTFE, bowden tubing serves the purpose of cleanly delivering filament into the top of the HeatSink. With this role in mind, bowden tubing is much more vital in printers utilising bowden setups, than those using direct drive.

- In a direct drive setup the extruder is mounted to the top of the HotEnd, feeding directly into the HeatSink.

- In bowden setups, the extruder is mounted elsewhere on the printer and feeds filament into bowden tubing. The other end of the tubing is inserted into the top of the printer’s HeatSink and is held in place with a collet clip.

The most effective bowden tubing has a well constrained, slippery filament path to prevent friction and backlash within the tube as represented on the below diagram.

Standard PTFE tubing vs. Capricorn PTFE tubing with it’s more constrained filament path.

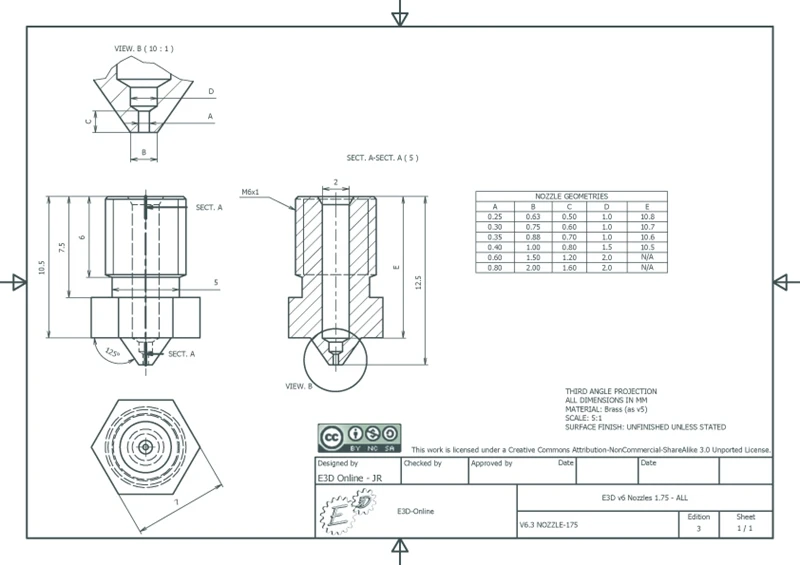

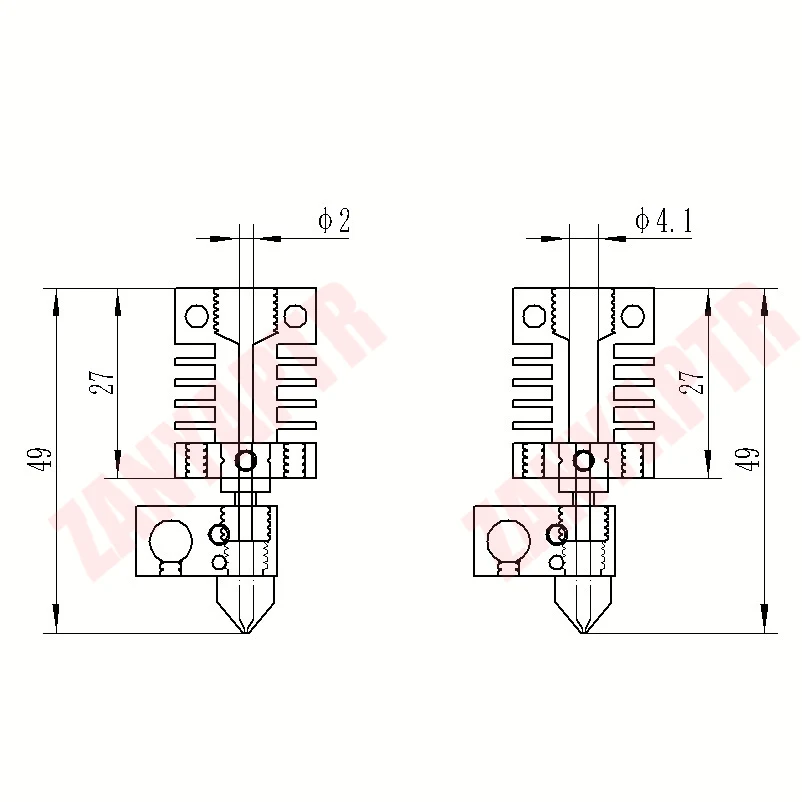

The nozzle is the final piece which completes our HotEnd puzzle, and perhaps the most important.

The internal geometries of a nozzle are precisely angled to allow optimal flow from its orifice and prevent clogs; its external geometries are also important. A well designed nozzle will have a flat tip surrounding its extrusion point which effectively ‘trowels down’ the layers of filament ejected from it. This flattening of layers is vital to ensure they bond to each other and the bed during the printing process.

As it turns out there is also an optimal ratio between the diameters of the hole and the flat tip, this ratio is something we employ in the production of every single nozzle we offer at E3D.

Nozzles are interchangeable and fit the user’s purpose. If the user wishes to print as rapidly as possible, they should opt for a nozzle with a large orifice diameter. Alternatively, if a user wishes to have a highly detailed print, they should use a nozzle with a tiny orifice diameter; the baseline size for most nozzles is a 0.4mm diameter.

In a similar vein, nozzle materials are also switched out to take advantage of the strengths each material possesses.

For instance, hardened steel nozzles excel when faced with abrasive filaments such as carbon fibre, which would otherwise tear up a brass nozzle’s internal geometries.

Whereas, plated copper nozzles stay robust when heated to high temperatures, which nozzles made of other materials would soften at; making them ideal for printing polymers with substantial glass transitions.

Nowadays, a well constructed, all-metal HotEnd can print essentially every polymer out there; so a better question might be - what is a polymer?

Plastic is a type of polymer, but not every polymer is a plastic. Thermoplastic is a specific type of plastic possessing a malleable and stringy nature when heated. Thermosetting plastics do not possess this nature, and instead blacken under heat. Some thermoplastics are also ‘resins’, meaning that they also contain any number of additives, colours or fillers which change their overall consistency and take them out of that stringy malleable nature essential for FDM 3D printing.

The first thermoplastics utilised by the industry were ABS and PLA, with PLA still being a fan favourite today due to how easy it is to print with. However, over the years HotEnds have grown to cope with a multitude of unique polymers such as PETG, Nylon, PVA and even PEEK.

“PLA is one of the hardest materials to thermodynamically manage.

..”

It may surprise you to know, but despite its popularity, PLA is one of the hardest polymers to thermodynamically manage. Makers enjoy PLA’s low printing temperature and its extremely sticky nature (with dreamlike interlayer adhesion) but this stickiness is ironically a common cause of HotEnds clogging. It was through iterative procedure that we eventually landed on the internal HotEnd geometries we have today, optimising flow rates and minimizing clogs from not only PLA, but other tenacious polymers.

Interestingly, a polymer tends to retain its cool and stiff, glass like state throughout the majority of a heating process. It is only when the polymer reaches a certain temperature (usually somewhere around 200°C), when the polymer suddenly becomes viscous and rubbery - this point is known as the polymer’s ‘glass transition’. Here the polymer may take on a whole host of other property changes that vary wildly dependent on which polymer you’re working with.

Polymers undergoing the ‘glass transition’ exhibit an interesting habit - they expand and build pressure. This pressure forces the nozzle to extrude filament, which in turn undergoes a phenomenon known as ‘die swell’. Die swell refers to how built up pressure in the polymer springs back to its original size when released. Die swell predominantly occurs as the polymer is ejected from the nozzle.

It is for this reason that nozzle size doesn’t quite parallel with extrusion width; tracks laid down by the HotEnd are often wider than the nozzle’s orifice size. Die swell leads to confusion in individuals who measure the width of the track with calipers.

HotEnds rely on the same pressure which causes die swell in order to function. Filament feeding into the HotEnd must stay back-pressured to keep the HeatBreak plugged and the viscous polymer beneath it flowing.

As a result of this, HotEnds experience something called ‘pressure delay’ - the appearance of less filament coming out the HotEnd than being fed into it.

Another common oversight made by makers is that they assume that when filament is extruded from the HotEnd, it is the same temperature as the nozzle. As previously detailed, the filament doesn’t spend enough time within the hotside to match its temperature. So naturally, the hotside is heated to an increased temperature to ensure the filament reaches a viscous state.

Ergo, although PLA ‘prints’ at 200°C, it really leaves the nozzle is around 150-160°C.

A large majority of clogs in poorly made HotEnds are caused by 'heatcreep'. Heatcreep is a plague on the function of HotEnds: heat will attempt to clamber its way up your HotEnd and cause the filament to liquify early, expanding above the designated transition zone of the HeatBreak. Heatcreep is a tenacious beast that will clog your HotEnd if you let it.

Thankfully, heatcreep can be tamed and prevented; all it takes it a precisely machined, temperature-balanced HotEnd. Care should be taken to ensure the cold side of the HotEnd dissipates enough heat to cope with the temperature of the hotside; but not too much cooling to prevent the hotside reaching its desired temperatures.

So in short, HotEnds are complicated - more complicated than they’re given credit for; and they’re difficult to manufacture well. At E3D we’ve spent been designing HotEnds since 2012 and have done all the worrying for you, ensuring ideal functionality with every piece. Keeping you printing and not have you worrying about: what on earth ‘glass transition’ is; whether or not your temperature is properly balanced or if you'll wake up to a failed print and a clogged nozzle the next morning.

Check out our range of HotEnds.

What are the parts that make up a hotend, and what do they do?

This varies by hotend design. The following is a list of components which you might find in a typical hotend, but note that different designs may integrate these components to some extent. For instance, on the J-head the heat block, nozzle and heatbreak are all one and the same component whereas on the E3D hotends these are all separate parts.

Nozzle: This is the part where the filament comes out.

It takes in the molten filament (typically as a bead of 1.75mm/3mm) and tapers down to the nozzle size (typically around 0.4mm). These are typically made of brass for its good heat conductivity, but brass is not suitable for printing abrasive materials (such as glow in the dark and metal-filled filaments) so sometimes (hardened) stainless steel is used.

It takes in the molten filament (typically as a bead of 1.75mm/3mm) and tapers down to the nozzle size (typically around 0.4mm). These are typically made of brass for its good heat conductivity, but brass is not suitable for printing abrasive materials (such as glow in the dark and metal-filled filaments) so sometimes (hardened) stainless steel is used.Heater Block: Usually made from aluminium, the heater block joins the nozzle to the heat break and holds the heater cartridge and thermistor.

Heater Cartridge: most hotends use a ceramic heater cartridge, though some older designs use power resistors or nichrome wire. This component is, as the name suggests, responsible for heating up the hotend. The heat block usually clamps around the heater cartridge to provide good contact.

Thermistor: This part senses the temperature of the heat block. It is usually a small glass bead with two wires attached (which are typically insulated with glass fiber or teflon).

For high-temperature printing, a thermocouple may be used in stead.

For high-temperature printing, a thermocouple may be used in stead.Heat Break: this is the part where hot meets cold. It usually takes the form of a thin tube and is made of stainless steel for its low thermal conductivity. The goal is generally to have the transition be as short as possible so as little of the filament is in a molten state as possible. It connects the heat block to the heat sink.

Heat Sink: the purpose of the heat sink is to cool down the cold side of the heat break. It is typically cooled with a fan. Most heat sinks also have a standard groove-mount for mounting to your printer. The heat sink usually has grooves to increase its surface area and cooling capability.

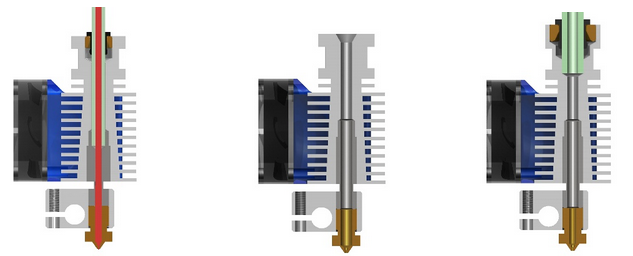

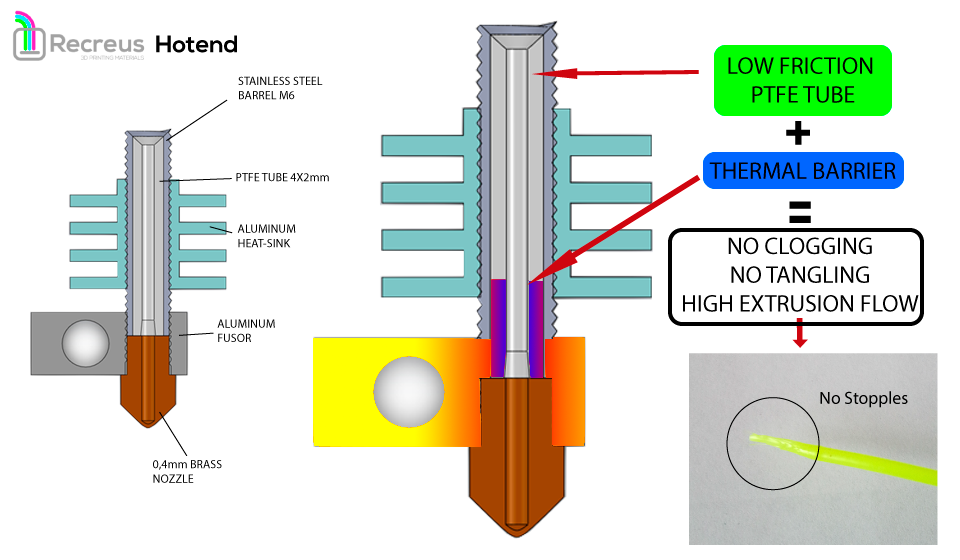

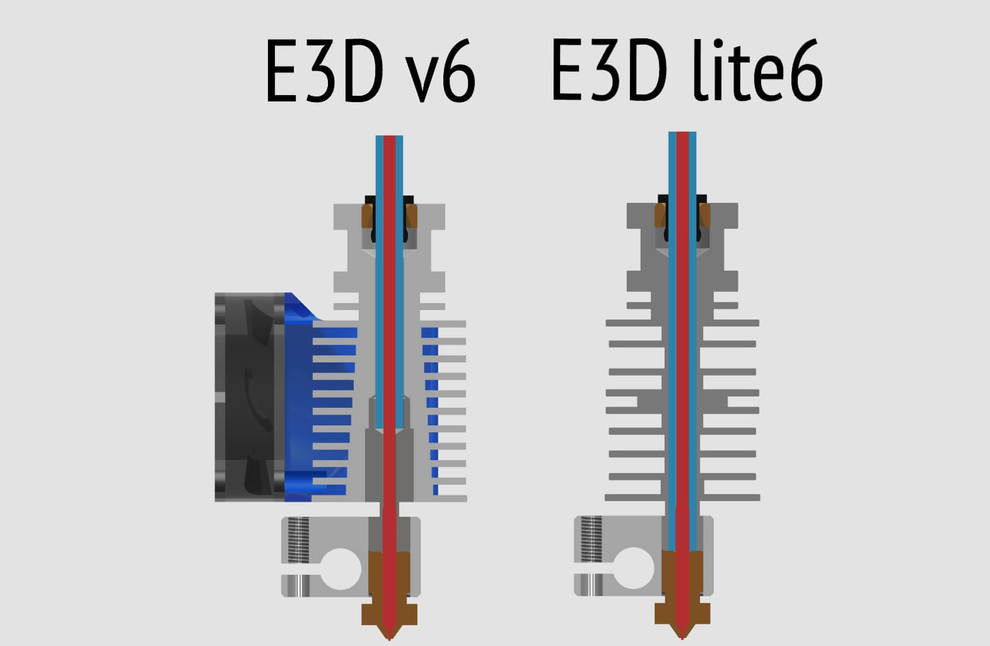

Teflon Liner: some hotends have a PTFE liner that guides the filament through the heat break into the nozzle. This makes it easier to print PLA, but compared to an all-metal hotend, limits the temperatures at which you can print (making it difficult to print PETG and impossible to print polycarbonate).

The ubis hotend you mentioned is a bit simpler than this, and simply uses a big chunk of PEEK in place of the heat break/sink. PEEK has very low thermal conductivity and thus passive cooling is sufficient. However, PEEK limits the temperatures at which you can print.

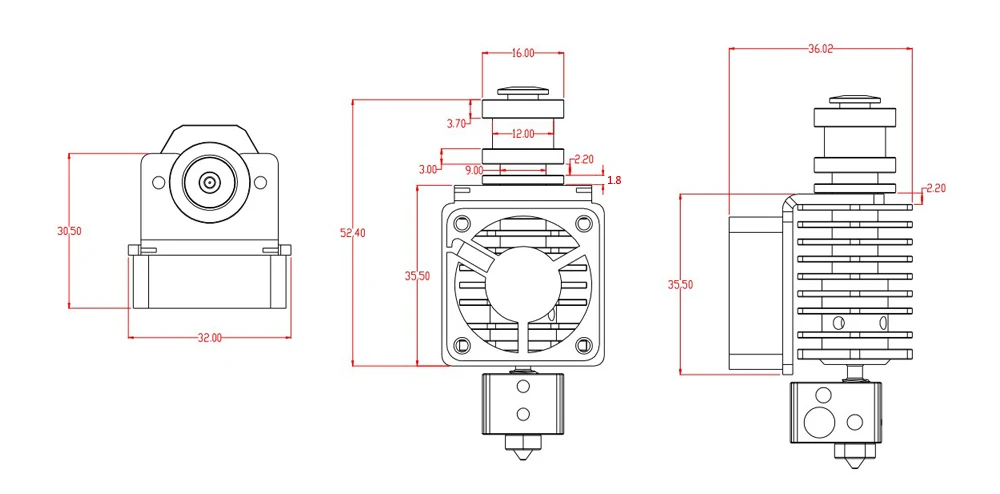

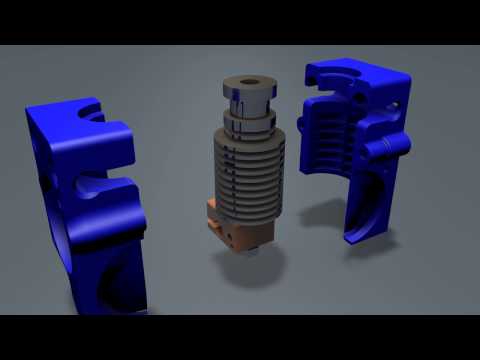

Here is an illustration outlining these components on an E3D V6 hotend:

Note that in this image the Teflon liner only goes into the heat sink, and not into the heat break or block. This means the maximum temperature is not limited by the Teflon, but if it did go all the way in (as is the case with, for instance, the Lite6) then it would be.

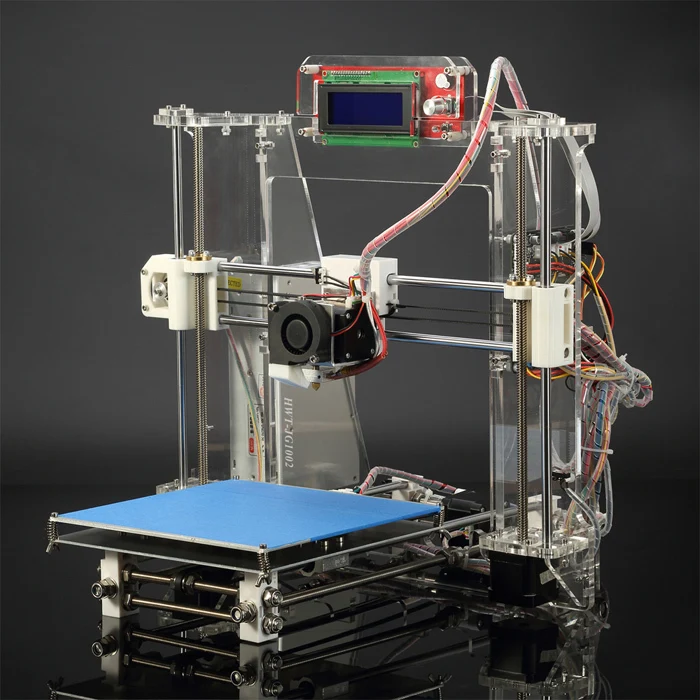

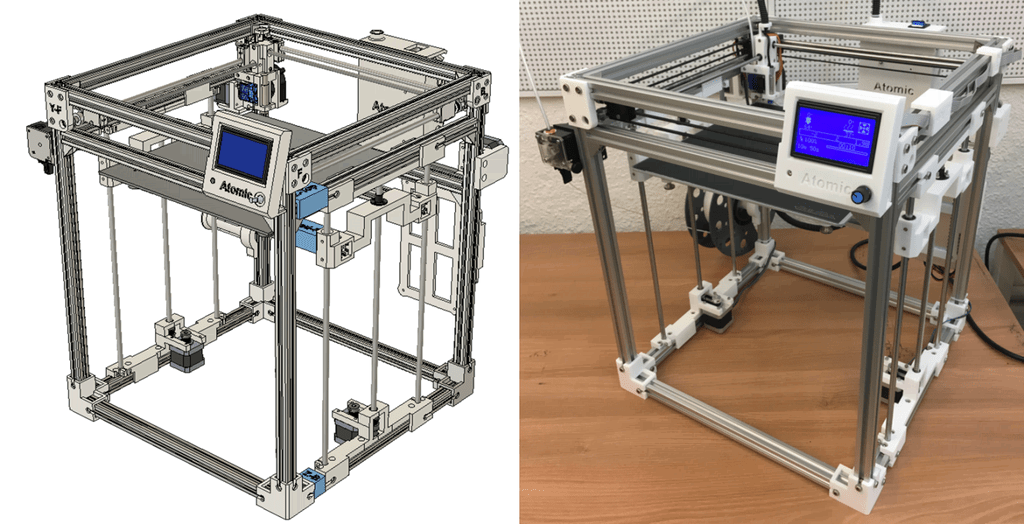

3D printing for the newest ones. From A to Z. Kinematics.

In this article, we will understand what 3D printing is and what the kinematics of 3D printers are.

1. 3D printing. What does she taste like?

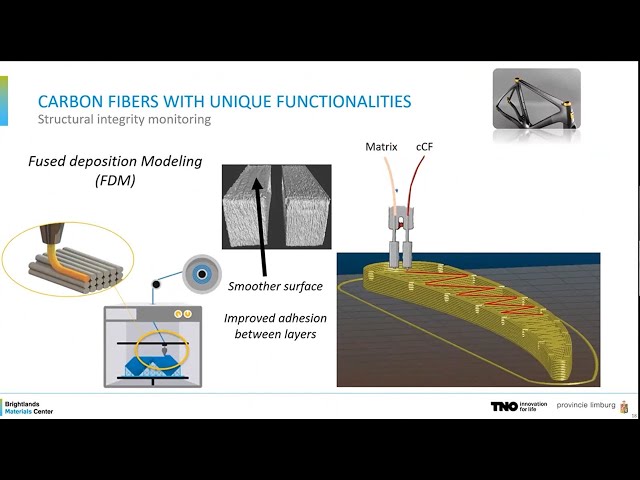

There are a lot of printing technologies, from FDM (FFF), which is used by more than 90% of printers on this portal, to SLA / DLP / LCD (with photopolymers) and SLS / SLM (powder sintering using powerful lasers)

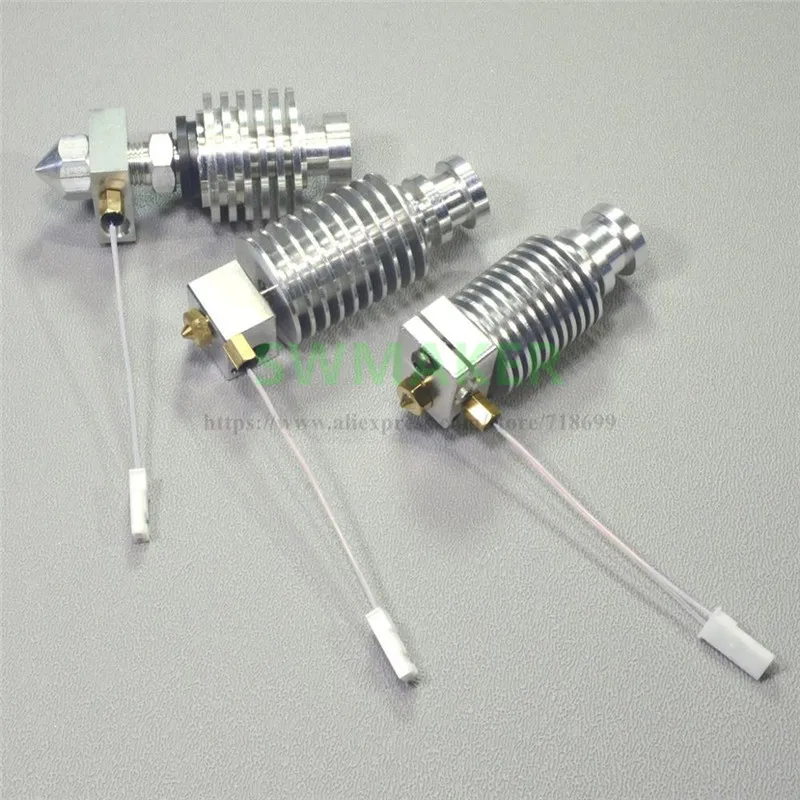

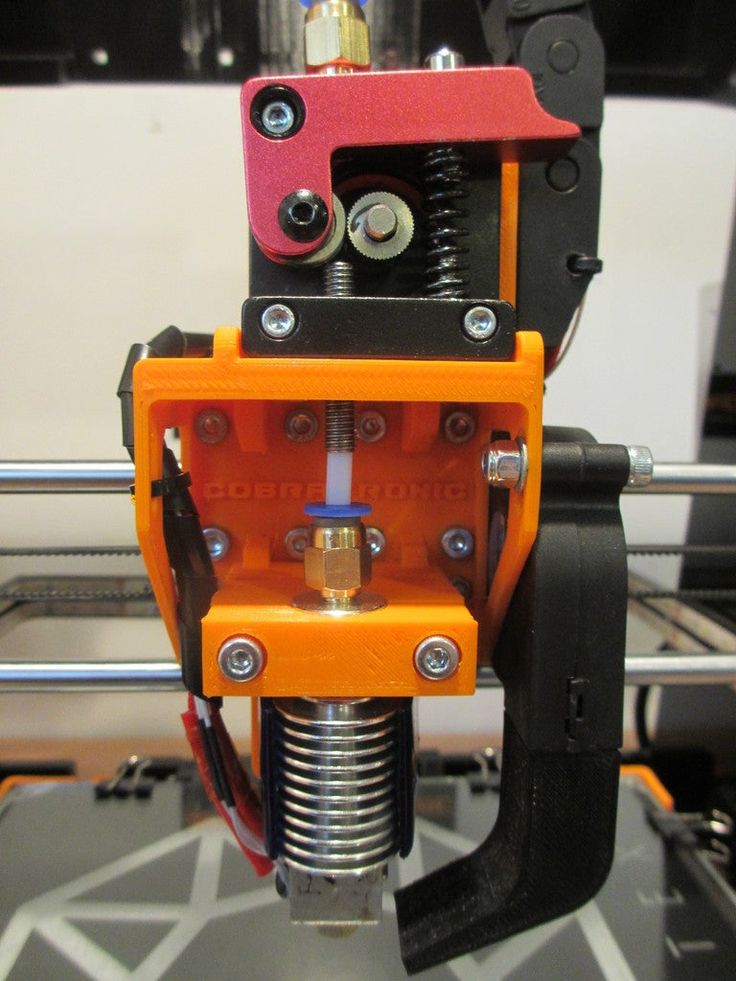

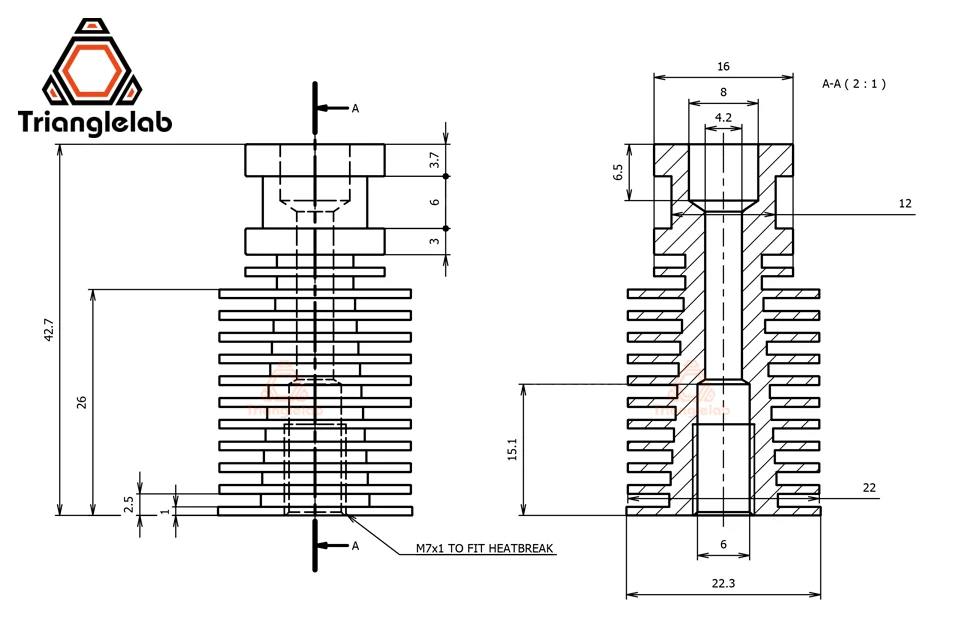

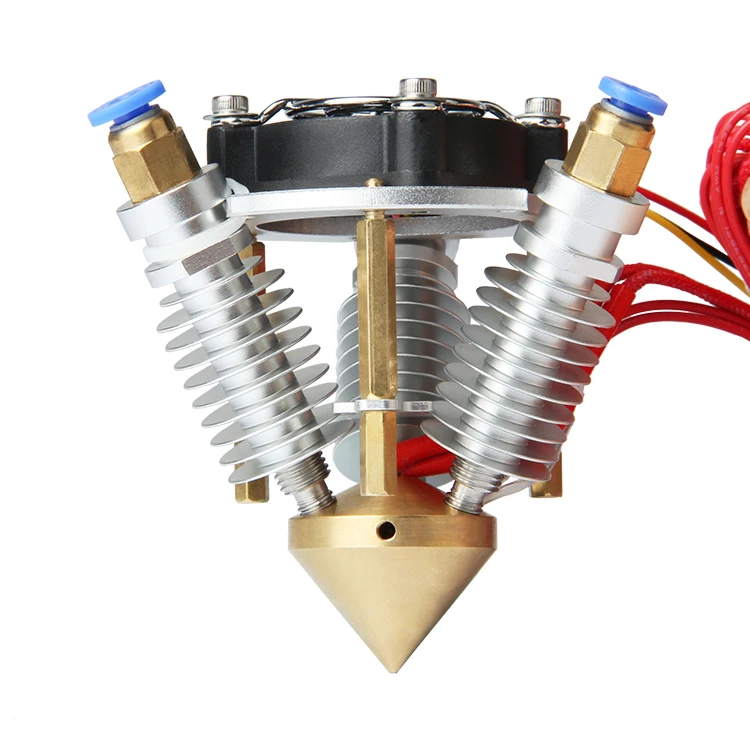

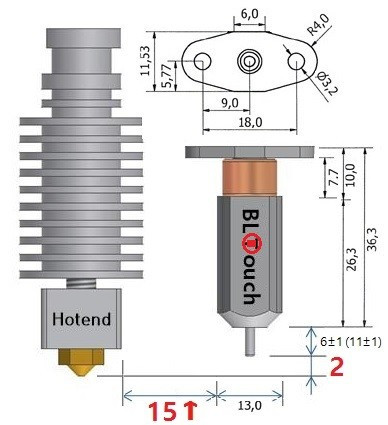

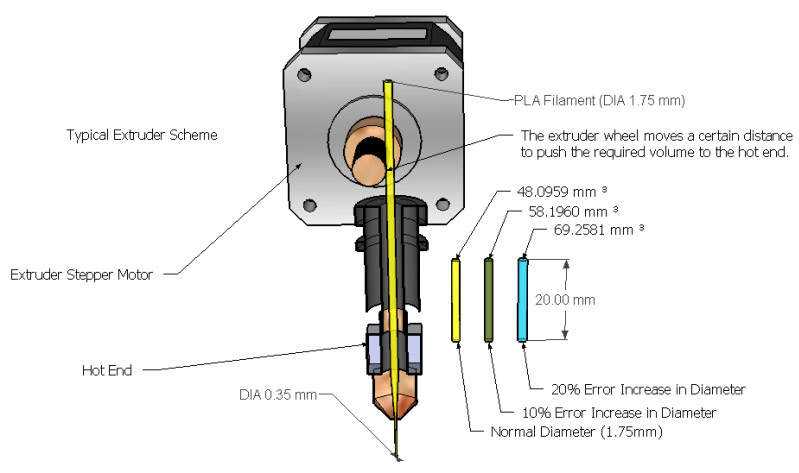

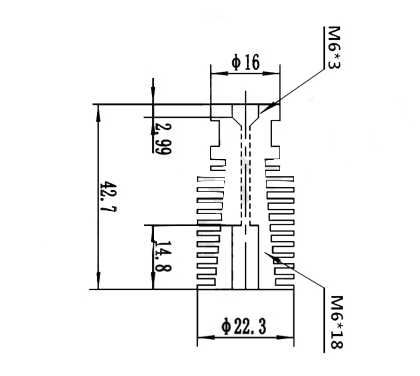

At the initial stage, we are interested in FDM - layer-by-layer deposition of a molten rod. The picture below shows the hot end (Hot end) - that part of the 3D printer extruder where the rod is melted. nine0003

The picture below shows the hot end (Hot end) - that part of the 3D printer extruder where the rod is melted. nine0003

The plastic rod is fed through the Teflon tube and radiator into the thermal barrier, and through it into the heating block. It melts there and exits through the nozzle. The nozzle has a certain diameter, which is marked on it.

It is often made of brass, as the material is inexpensive and easy to process. The accuracy of printing depends on the nozzle. The smaller the nozzle, the more threads fit into one mm.

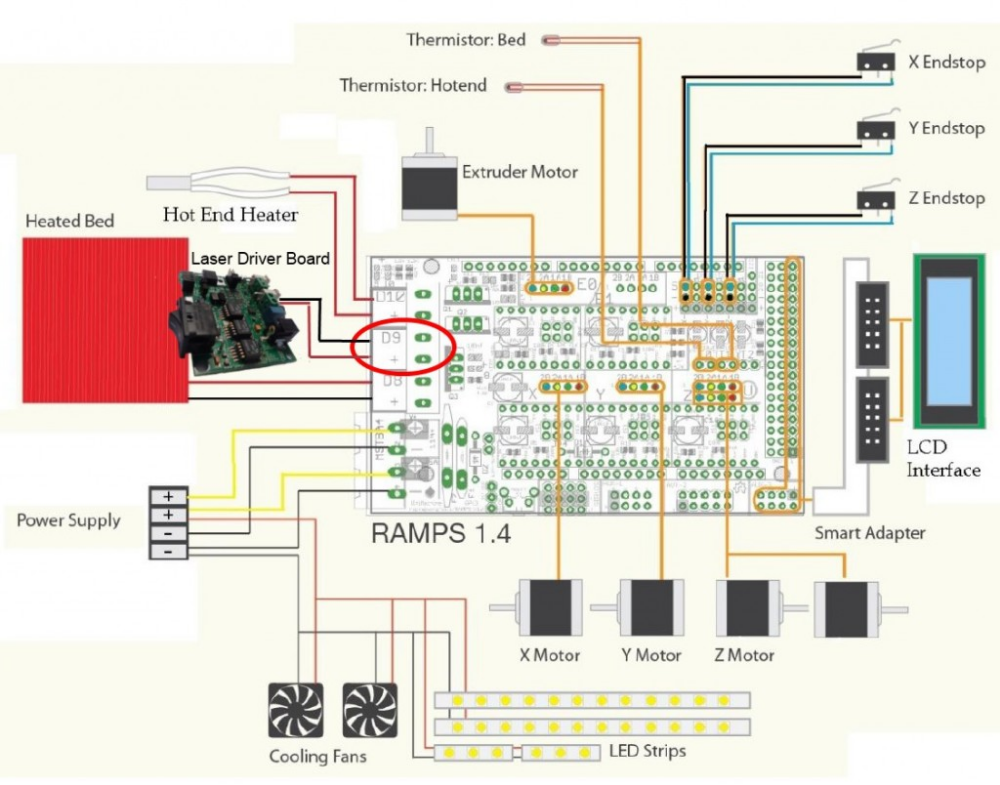

Heater and thermistor provide feedback for temperature control and regulation. That is, the voltage supply to the heater depends on what temperature the thermistor shows, and the processor compares it with the set one. nine0003

Next we see the heating block. A nozzle is screwed into it on one side, and a thermal barrier on the other.

The thermal barrier is used to minimize the heating of the plastic above the thermoblock.

[IMG]http://3d-makers.nethouse.ru/static/img/0000/0002/6151/26151635.2ofdbr37y8.W665.jpg[/IMG]

Most often made of stainless steel. It has a lower thermal conductivity than conventional, unalloyed steel. To prevent the rod from melting above the thermal block, a radiator is screwed on top of the thermal barrier and blown by a cooler. Everything is quite simple. nine0003

It is very common for melted plastic to leak through threads.

This means that the nozzle has not pressed the thermal barrier in the heater block. Therefore, when disassembling and assembling the hot end, we first screw the thermal barrier into the heating block, and then press it with a nozzle. If, when you twist the nozzle, there is a gap between the end of the nozzle and the heating block, then this is normal, the gap in order to press the thermal barrier with the nozzle.

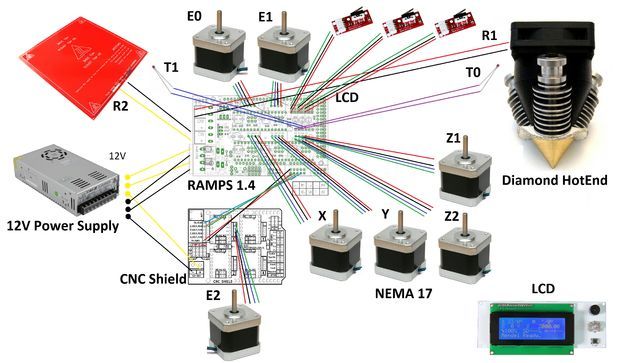

In order to feed the bar at the right time and in the right place, a feeder is needed, that is, a bar feeder. nine0003

Sometimes it is performed combined with a hot end, and then this type of extruder (this is all together a hot end + feeder) is called a direct (direct), that is, a direct feed, without tubes.

The same feeder is made separately, and the bar is fed through a fluoroplastic tube. Such a system is called bowden.

This is to lighten the moving part. As for the positive aspects and disadvantages - each design undoubtedly has them.

Direct extruder:

1. Advantages:

a) More reliable due to fewer plastic feed connections;

b) Less picky about the materials it prints on, in particular rubber-based rubber is problematic to print on bowden extruders;

2. Disadvantages:

a) Large weight, due to this, during acceleration / deceleration, small ripples can be observed on the surface of the part;

b) Dimensions. They greatly affect the plot area. Let's say, like in the picture above, a direct with 4 colors would be very huge. And for Bowden, this is just right. nine0003

They greatly affect the plot area. Let's say, like in the picture above, a direct with 4 colors would be very huge. And for Bowden, this is just right. nine0003

Bowden extruder:

1. Advantages:

b) The coil does not twitch after the model, otherwise, when the coil turns with the direct are entangled, we will get a skip of steps, since the carriage will pull the coil along with it.

2. Disadvantages:

a) Retract settings (pulling the rod back during idle movements so that the molten plastic does not ooze out of the nozzle while expanding) is more difficult, since the rod is smaller than the inner diameter of the tube, it tends to stretch; nine0003

b) It is more difficult than on direct to select all gaps in order to print with various flexible plastics. Everyone who says that printing on Bowden is impossible with flexible plastics is blatantly lying. I am typing. And quite successfully.

Now we go directly to the mechanics and its calibration.

Part 2. Mechanics. What, how and what pulls?

There is a very limited number of kinematic schemes for which the firmware is written, and which work out movements quite tolerably. nine0003

Consider everything, from the most common:

1. Design and kinematics from Joseph Pryusha (no need to read Prus, Prasha and so on, this is the name of a person, after all).

Movement along each of the axes is provided by its own independent motor. Movement along the Z axis (up and down) is provided with the help of 2 motors and with the help of a kinematic screw-nut pair. M5 studs are often used; recently, screws with trapezoidal threads have been increasingly installed. nine0003

Here is a trapezoidal screw. How studs with metric threads look I will not apply.

The only thing I will explain about moving along the studs and trapeziums is that for the production of trapeziums they take a calibrated rod and roll it between rollers at an angle. Get helical grooves. This method, a priori, gives better quality and step accuracy than building studs of far from the highest quality.

Get helical grooves. This method, a priori, gives better quality and step accuracy than building studs of far from the highest quality.

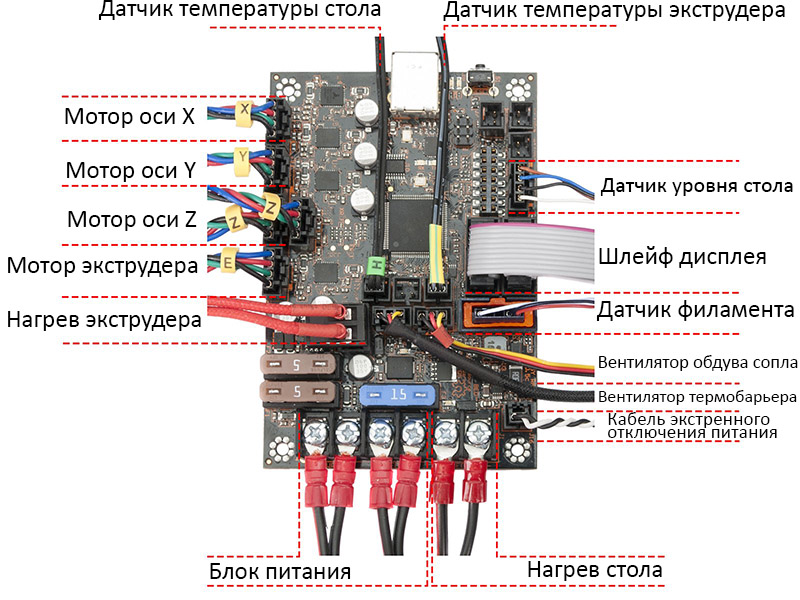

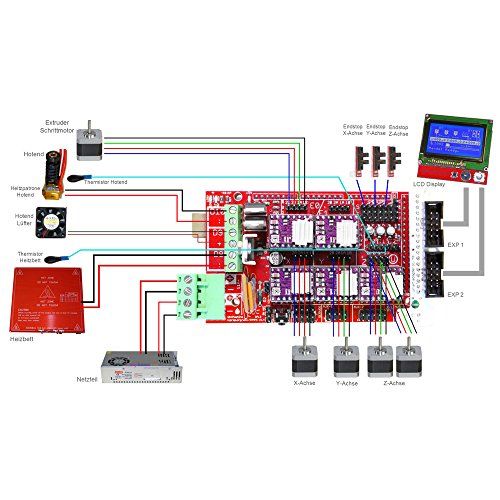

To connect 2 motors to one axle (and 1 connector) at the same time, the following scheme is used. nine0003

Connection in series, 2 wires soldered and the rest crimped. You can ignore the colors, the main thing is that the windings ring. A and B are windings, and 1 and 2 are terminals.

Advantages of this kinematics:

1) Independent movement of each axis. It is easy to catch to understand which axis skips steps. Kinematics migrated to printers from CNC milling, so many manufacturers make desktop milling machines on it, instead of an extruder they offer to install a laser for engraving or cutting, a spindle for milling boards, an extruder for chocolate or even dough to bake pancakes. nine0003

nine0003

Pictured above is a ZMorph printer. It can be used as a printer (with one or two extruders), as an engraver (Dremel machine), as an engraving laser, and so on. A small presentation video.

Milling machine with this kinematics. I note that for milling it is necessary to use a screw-nut pair to move, and not belts, they are not designed for such loads.

Chocolate and pancake printers according to your design. It is worth noting that it is not recommended to use chocolates like Alenka or Babaevsky, since they already contain cocoa butter and during processing (melting and hardening) the result is unpredictable. It is necessary to use chocolate in galettes, such as the Belgian Callebaut, as it does not contain cocoa butter, and must be added for the final filling. For this type of chocolate, each pack has a graph of its crystallization. It is desirable to take the oil in powder form. For more information, I recommend Google about tempering chocolate. nine0003

For this type of chocolate, each pack has a graph of its crystallization. It is desirable to take the oil in powder form. For more information, I recommend Google about tempering chocolate. nine0003

2) The kinematics are as easy as two fingers. Its very easy to assemble. Many even collect on old DVD drives.

3) Easily changed to suit your needs, the size of the extruder is also of little importance, as it protrudes forward and does not interfere with the movement of other parts. Many people put a second extruder, or make the nozzles swing so that the nozzles of one extruder do not remain on the part when printing with the second nozzle.

Therefore, for this kinematics, there are a huge number of extruder variations, for every taste, on a very famous site. nine0003

Disadvantages of this kinematics:

1) Complicated calibration. Yes, since the table 'jumps', it is difficult to print with high quality, because the part + table, with a sharp change in the direction of movement by inertia, tend to go further. Ugly print artifacts are obtained. And for high-quality printing, you need a small speed. In general, it all depends on the frame. My first printer was a Chinese pryusha. With acrylic frame.

Ugly print artifacts are obtained. And for high-quality printing, you need a small speed. In general, it all depends on the frame. My first printer was a Chinese pryusha. With acrylic frame.

Acrylic is not very hard. And as you know, the rigidity of the printer, like the CNC, is the most important thing. And it was possible to print more or less qualitatively at speeds of 40-50 mm / s. Then I transplanted it to a steel frame from MZTO. nine0003

And after that, without loss of print quality, I was able to print at speeds up to 100 mm / s.

2) Delamination. Due to the open case and the constantly moving platform, hot air, one might say, is constantly blown away, and by cooling the part excessively with drafts, we increase the already large shrinkage of nylons, abs and other capricious plastics. Someone sews a fur coat for a fabric printer, and someone is content with boxes.

But the goal, as always, is the same - to reduce the effect of drafts on the shrinkage of the part. nine0003

nine0003

Key points for correct calibration of printers with this kinematics:

1) Place the printer on a level surface. Preferably horizontal. This requires a bubble level. Next, set the level of the position of the X axis.

2) Transfer to the home position. It is done either in the printer menu with the Home / Home command, if you are printing from a computer, then either with the G28 command in the command line, or with special buttons with the house icon.

Next, tighten the table screw so that the nozzle touches the glass. It did not press on the glass, but touched. We look at the light and twist. After that, move the extruder to another corner with the arrows in + X, + Y from the PC, or through menu

Turn the screw in the same way until it touches the nozzle. And repeat the operation for the remaining points.

I will try to save you from mistakes. In the photo of the printer above, the glass on the table is fastened with as many as 8 clamps. And it is quite possible that there will be a hump in the center. To avoid such problems, the glass should be fixed with 3 clamps. The plane is built, as is known from descriptive geometry, by 3 points. And calibration will be easier in this case. Just tighten the screw over the limit switch in Z.

In the photo of the printer above, the glass on the table is fastened with as many as 8 clamps. And it is quite possible that there will be a hump in the center. To avoid such problems, the glass should be fixed with 3 clamps. The plane is built, as is known from descriptive geometry, by 3 points. And calibration will be easier in this case. Just tighten the screw over the limit switch in Z.

For the nozzle to touch the glass in the middle of the side with 1 clip. Then we distill the hot end into the corner where there is another clamp, tighten the table screw, and repeat the operation with another angle.

Regarding wobble.

All sorts of anti-wobble systems such as installing a bearing in the upper support do not work.

Just because putting 4 far from perfectly even cylinders in perfect parallel and in the same plane is an unrealistic task. Especially on a flimsy acrylic frame with printed details. Therefore, if we take the straightness of the shafts as a constant, and set them parallel on the frame (purely hypothetically), and release the screws (from below the coupling for attaching to the motor) and nuts for attaching the X axis. Due to their curvature, the screws will spin like a mixer, but on printing will not be affected. nine0003

Therefore, if we take the straightness of the shafts as a constant, and set them parallel on the frame (purely hypothetically), and release the screws (from below the coupling for attaching to the motor) and nuts for attaching the X axis. Due to their curvature, the screws will spin like a mixer, but on printing will not be affected. nine0003

Otherwise, the design will work on who will be stronger in terms of bending resistance. And it will turn out far from a flat wall. Do you need it?

2. Kinematic design of Felix printers.

There are many such printers, such ones are made by MZTO (mz3d.ru), already mentioned by Felix. In fact, the kinematics are the same as those of the Prusa. axes independent of each other. Only now the table does not travel along one axis, but along two at once. Along the Z axis, and along the Y axis.

The design of the table is something like this.

A platform rides on the Z shafts. The engine hangs at the back. The table moves along the rails with the help of a belt. The hotend moves only along one axis. The design is very funny, since the table weighs much more than the hotend, and they try to move it along 2 axes at once.

The engine hangs at the back. The table moves along the rails with the help of a belt. The hotend moves only along one axis. The design is very funny, since the table weighs much more than the hotend, and they try to move it along 2 axes at once.

Advantages of this kinematics:

1) There is no second motor along the Z axis. There is no notorious wobble simply because there are 2 shafts and 1 propeller. The screw should also not be fixed from above. If it's not a ball screw. nine0003

Ball screw is a separate issue. If we take a high-quality ball screw, say, from the same Hiwin, then it is manufactured according to at least the 7th accuracy class (if rolled, and if polished, then the class is even higher) and must be installed in bearing supports. On the drive side there are 2 back-to-back angular contact bearings, and on the other end a radial bearing with a loose fit to compensate for thermal expansion.

The purpose of mounting a ball screw is to ensure movement accuracy. If it is installed incorrectly, money is wasted, and the accuracy will not be higher than a screw-nut pair with a trapezoidal thread. For FDM, trapezoidal accuracy is more than enough. nine0003

If it is installed incorrectly, money is wasted, and the accuracy will not be higher than a screw-nut pair with a trapezoidal thread. For FDM, trapezoidal accuracy is more than enough. nine0003

2) Plenty of space for a direct extruder. As in the previous kinematics, there is room for creativity, to select the one and only extruder that you like.

3) Rigid frame. It is possible to make a normal frame. Rigid, durable. Yes, even cast iron. The guys from Felix decided not to bother their heads and sculpt from an aluminum profile. MZTO went further, bent the steel sheet. And the shelf for the installation of the table was milled from a sheet of aluminum.

4) If we take the design of Felix on the profile, then by replacing a pair of pieces of the profile and the Z screw, you can increase the print area. nine0003

Just be sure to add stiffness. And it will turn out like a miracle of design thought. Big, meaningless and merciless.

Kinematic disadvantages:

1) Undoubtedly large twitching masses. The table back and forth, and if you turn on the movement along Z during idle movements (Z-hope), then there will be a disco.

The table back and forth, and if you turn on the movement along Z during idle movements (Z-hope), then there will be a disco.

2) There is no way to make him a normal heat chamber. The table moves back and forth and the temperature gradient simply blows away. Hence the problems when printing with nylons or ABS. Small drafts in the room will easily show you where the crayfish hibernate, how the material shrinks. nine0003

The calibration of the table of this printer is similar to the calibration of the Prusa table, only slightly simpler. It is easier due to the fact that you do not need to level the X-axis, it is automatically set when assembling the frame. We bring the nozzle to the table and twist the lambs.

3. Ultimaker kinematics.

One of the most common variations of Cartesian kinematics.

There are not very many such printers, but they do exist. Variation from Zortrax deserves attention. A variant of the same Raise is closer to the classics. nine0003

nine0003

Zortrax has twin shafts, the reason is simple - they have a direct extruder with a full size Nema 17 motor. Raise Dual has a double direct extruder, so the classic 6 mm shafts are replaced by 8 mm. And the total weight of the 'head' is almost 900 grams.

Kinematics built entirely on shafts. They act both as guides and as pulleys. Kinematics also refers to Cartesian kinematics with independent movement along each axis by its own motor. Very picky about the straightness of the shafts. If you use curved shafts, you can get very funny artifacts on the walls of models. And they will be on all 3 coordinates. Most often it looks like a different thickness of the first layer and small waves along the walls. Therefore, all the salt and the high price of the original Ultimaker is only in high-quality components. Namely, in straight shafts. The belts are often used as ring belts, which simplifies their tensioning system, since it is important that all 4 belts are equally tensioned. nine0003

nine0003

Advantages of this kinematics:

1) The table only moves along one axis. vertical. And the temperature gradient in no way suffers from this. The table is cantilever, so it is desirable to provide stiffeners or take this into account with the thickness of the table.

The metal fold on the table acts as a stiffener.

Many Chinese clones are equipped with such stiffening ribs for the table.

2) Despite the seeming complexity of the kinematic scheme, it is simple and each axis moves with its own motor. nine0003

3) The body is closed, which protects against drafts, and therefore delamination. Some put an acrylic door to heighten the effect.

Disadvantages of kinematics:

1) For good printing, it is not enough to buy a pack of even rollers. Collecting all these shafts correctly together is another task. At the same time and buy good bearings. Not that, Chinese junk, which is often sold on Ali, but normal bearings. If the bearings that are placed in the housing rotate poorly, the print will be jerky and with a shift in the layers. The consequences can be asked from Vanya (Plastmaska). Also, when buying leopard bushings, brass bearings with graphite inserts, be prepared for the fact that they will play. And if there is a backlash, the whole structure will knock. nine0003

Not that, Chinese junk, which is often sold on Ali, but normal bearings. If the bearings that are placed in the housing rotate poorly, the print will be jerky and with a shift in the layers. The consequences can be asked from Vanya (Plastmaska). Also, when buying leopard bushings, brass bearings with graphite inserts, be prepared for the fact that they will play. And if there is a backlash, the whole structure will knock. nine0003

And also, the Chinese like to push brass instead of bronze. And with even wear of brass and graphite, there will be an oily sticky black film on the shafts, which will make the movements harder. Ilya (tiger) offers good bushings. He also wrote about these difficulties.

2) All shaft parallels must be set correctly. I suggest using this device.

4 shafts that go along the walls of the body automatically stand up correctly, but it is important to set the crosspiece correctly in order to get angles 90 degrees in the XY plane.

3) The design does not provide for an increase in the printable area with a couple of profile pieces, so the size of the hotend matters. Direct is difficult to put, but you can if you want.

Calibrating the table couldn't be easier. The table is often on 3 attachment points. Move the hot end by 3 points and turn the thumbs.

4. Kinematics used by Makerbot.

Also very widespread. In particular, printers from Makerbot, BQ, BCN3D, Magnum, magnum clone Zenit and quite tolerable makerbot replicas Flashforge and Hori work on this kinematic scheme. nine0003

In this case we have independent movement of each of the axes, with a Z table and all the resulting sides.

The main drawback is that the engine hangs on one side of the rolling beam, creating a kind of imbalance. This shortcoming was compensated in a two-extruder version - BCN3D Sigma. There, each bowden head has its own engine to move along the beam. And they are installed at the edges of the beam and balance each other. For uniform movement of each of the edges of the beam, 2 shafts, pulleys and belts are used. Belts must be tensioned equally. nine0003

For uniform movement of each of the edges of the beam, 2 shafts, pulleys and belts are used. Belts must be tensioned equally. nine0003

Advantages of kinematics:

1) Independent movement of each axis.

2) Z-moving table. The temperature gradient does not suffer from 'blowing'.

3) Enclosed body. If not closed, then there is a quite normal chance from the point of view of aesthetics to close it.

4) Scalable kinematics possible. Various BigREPs and others with 1m print areas use exactly this kinematics, as various H-bot/CoreXYs will ring like hell due to the presence of 4-5m belts and their stretching during accelerations. nine0003

Disadvantages of kinematics:

1) Unbalanced masses on the moving beam, hence the maximum print speed, with acceptable quality no more than 60-80 mm/s. Some manage to balance them and it is not so noticeable.

2) Bulky structures on the shafts to avoid unbalance during movements.

3) Make sure that the belt tensions on the right and left are the same.

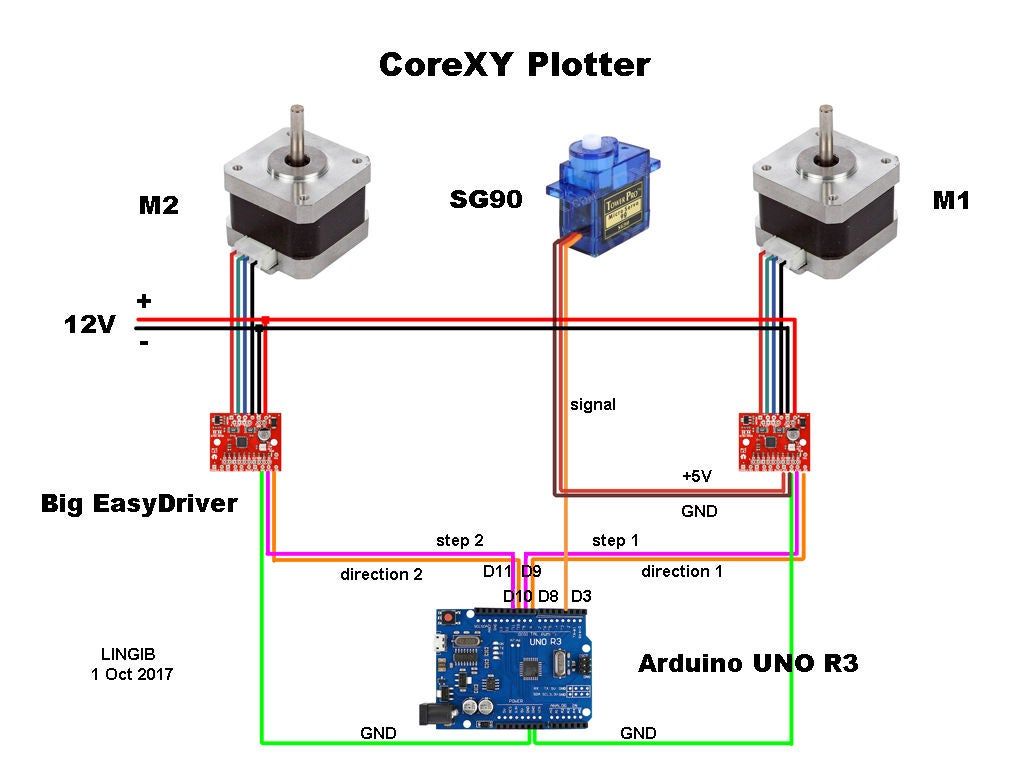

4. H-bot/CoreXY kinematics.

Next in distribution. Also Cartesian. Two motors are stationary, but move the carriage along the rails with one long piece of belt, or with two, but shorter. The math is more complicated than the previous ones, as it is necessary to synchronize the rotation of both motor rotors. That is, to move along each axis, you need to rotate both motors, and to move diagonally, only 1.

[IMG]http://www.doublejumpelectric.com/projects/core_xy/pics/hbot.svg[/IMG]

In fact, the mathematics for rotating motors is the same, but the implementation in mechanics is different. One of the biggest disadvantages of the H-bot over the CoreXY is that the belt tends to rotate the beam as it moves.

In the picture on the left, this is noticeable, the forces on the right and the forces on the left create a torque. Therefore, to implement this kinematics, the rigidity of the kinematic scheme is necessary. Most often it is implemented in rails. nine0003

Most often it is implemented in rails. nine0003

With rigid beam. Some do, of course, on the shafts, but in the end - this is not a fountain.

And then they realize this and move to the rails.

For they are both easier to assemble and set up, and it is not necessary to invent carriages so that the shafts do not need to be fixed well.

CoreXY, unlike the H-bot, is driven by two belts.

And so, for ease of understanding, I will describe the positive and negative aspects of each variation of this kinematics. nine0003

H-bot.

Advantages:

1) Only one belt is needed, and the scheme provides for its operation without twisting.

2) It is more convenient to tension one belt than 2, so only one normal tensioner is needed in this scheme.

Even so.

Disadvantages:

1) The belt tends to stretch over time, and since the amount of stretching directly depends on the length, it is necessary to monitor its tension. Otherwise, you will get ugly waves on the surface before the stops. nine0003

With a loose belt tension, the carriage will have this play.

2) It is necessary to set the rollers strictly perpendicular to the XY plane, since if the roller is slightly skewed, the belt will be eaten against the roller shoulders. And we will get such a bullshit.

Tested in the skin and ZAV printer. Therefore, I always recommend that the rollers be fixed normally, and not cantilevered, in order to avoid bending the roller axis from belt tension.

3) Complicated mathematics, due to which at speeds above 100 mm/s there may be problems with the lack of resources of 8 bit boards. nine0003

CoreXY.

Advantages:

1) Two short pieces of belt. They are easier to find than one long one.

2) The forces balance the beam, but do not tend to turn it, so these kinematics can also be assembled on shafts.

Disadvantages:

1) There are schemes with belt twisting and belt transition from one level to another - this is not very pleasant for a belt. Especially when one belt rubs against another. This moment is on video. nine0003

:{}

2) The difficulty of tightening the belts. They must be tensioned equally, otherwise the tension forces will tend to turn the carriage.

3) Complexity of assembly and development. It is necessary to maintain the verticality of the rollers, relative to the horizontality of the platform for installing motors and rails. A slight misalignment of the rollers will cause the belt to tend to slide down the roller, and if it rests against the shoulder of the roller, it will creak, if the shoulder is large, and if it is small, it will try to drive into it, as in the photo from the description of h-bot . nine0003

nine0003

The general disadvantage of kinematics is poor scalability. That is, it is very problematic to set such a kinematics for a print area larger than 300 * 300 simply because of the elongation of the belt during printing. For small printers with high print speeds - one of the best kinematics.

5. Delta kinematics.

The kinematics are based on the movements of the delta robot.

Only the hot end is installed instead of grips. It has its own set-up problems, but it can take a very long time to print. It is rare when direct extruders are installed, since the effector (a platform for installing a hot end) is often mounted on magnets and it is necessary to unload it as much as possible. But in order to reduce the length of the tube (more specifically, the effect of the length of the tube on the print quality due to the correct adjustment of the retracts (pulling the plastic rod back to reduce its leakage from the expansion)) on the print quality, the extruder is hung on the same carriages, but on separate hangers. This reduces the length of the bowden tube and increases print quality. nine0003

This reduces the length of the bowden tube and increases print quality. nine0003

Advantages:

1) Easy to customize. To increase the height, it is enough to buy 3 pieces of a longer profile, and increase the maximum height in the settings.

2) Takes up little space. It is more often high than bulky in length and width, due to this compactness.

3) If you make a light effector (carriage on which the hot end is installed), then you can achieve high speeds without losing print quality.

4) Vertical movement is the same as XY movement. Thus, there is no sticking of linear bearings on the table crossings, as in Cartesian printers, no extra motors rolling on the beam...

5) The absence of protrusions makes it possible to close the housing and stiffen the frame.

6) The aesthetic part - it's more interesting to stick to the work of the delta.

Disadvantages:

1) Difficult mathematics of movements, it is recommended to install 32-bit boards at once.

2) Complicated setting. A common problem in tuning is to remove the so-called 'lens', because each rod rotates with a radius, and if the tuning is incorrect, your printed plane will be either a convex or concave lens. nine0003

3) It is difficult and expensive to make a rigid frame, so that it would not dangle from the constant jerking of the carriages.

4) Difficulty installing a direct extruder. It turns out to be heavy, and since many deltas are made on magnets, it will not be possible to accelerate. Although, there is one neat and easy solution - installing a ready-made direct extruder with a gearbox. Like E3D Titan Aero or Bondtech BMG.

5) Parts precision problems - any unevenness and misalignment will be visible even if they are on the same axis. And they add up along the axes. nine0003

To sum up , do you want a small printer (not larger than 300*300 mm) with nimble kinematics? Then you should go to Ultimaker or H-bot/CoreXY. Need a printer with a large printable area or 2 independent extruders? Then to Makerbot. If you print vases, hookahs and sufficiently high details - delta. For everything else, there is a classic - Prusa. Experiments with double carriages, chocolate, engravings? Yes, anything. And most importantly - cheap.

Need a printer with a large printable area or 2 independent extruders? Then to Makerbot. If you print vases, hookahs and sufficiently high details - delta. For everything else, there is a classic - Prusa. Experiments with double carriages, chocolate, engravings? Yes, anything. And most importantly - cheap.

You can even screw on 4 colors. nine0003

3D Printer Extruder - Complete Manual Heatle

Learn the basics of direct drive and Bowden extruders, hot and cold ends, nozzle sizes and materials, and find the best 3D printer cartridge for your needs.

The 3D printing process can be briefly described as follows: a filament of plastic material is fed into a heated metal block with a nozzle, where it is melted and extruded in a given form. This path is repeated, gradually building up until a solid three-dimensional object is formed. nine0003

nine0003

The entire business task of handling the material, melting it and exiting for printing takes place in a block called 3D printer extruder .

In this article, we will look at the main sections of the 3D printer extruder, the options and advantages of different styles of extruders, popular models on the market, as well as cartridge heaters for 3D printers and other items.

What is an extruder

The 3D printer extruder is a set of parts that together process and move plastic filament. nine0003

Some consider the extruder to be just the motor and associated parts that push and pull the filament, others the entire assembly including the heated part that melts and deposits the filament.

For simplicity, this article treats the entire assembly as an extruder. To begin with, while explaining the key components of a 3D printer extruder, we will divide it into two elements: a cold zone and a hot zone.

Cold zone

As the name implies, the cold zone is exactly that - cold. It's The top of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print bed.

It's The top of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print bed.

The appearance and location of the cold zone on your 3D printer depends on whether it is a direct drive or Bowden drive extruder (both of which are detailed below).

There is no filament heating here. The cold zone consists of the extruder motor and gear train, which are usually mounted either on the printer frame or on the print head itself, depending on the type of extruder, and a PTFE tube to smoothly guide the filament into the hot end. nine0003

What happens in the cold zone?

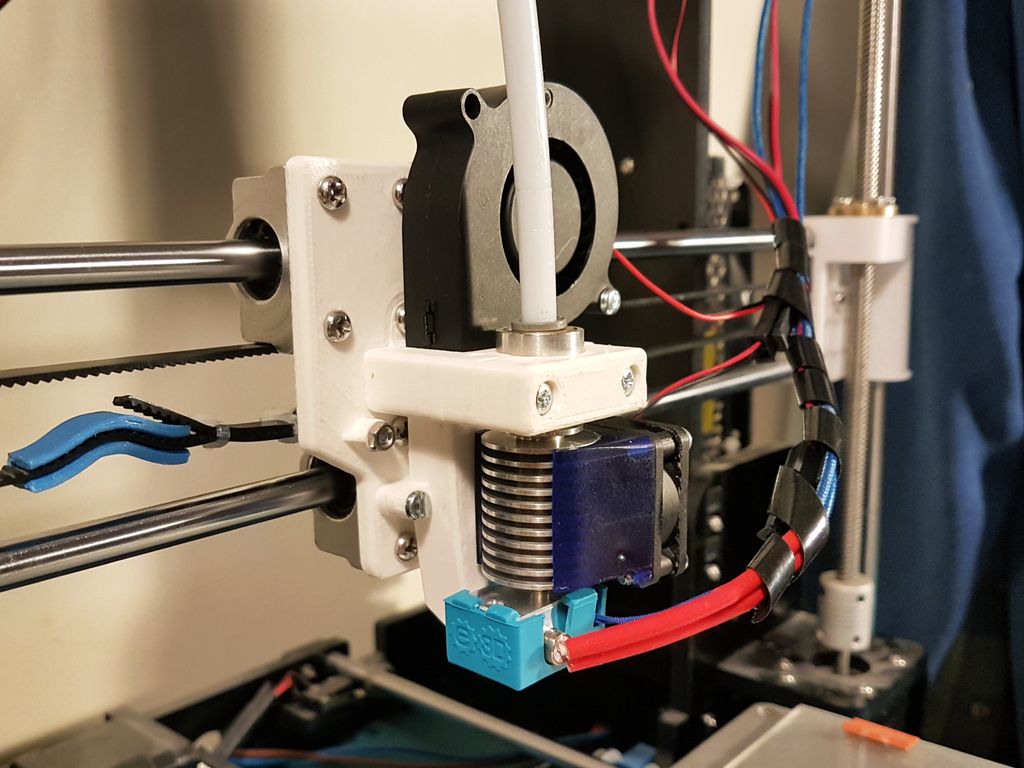

With the heatsink removed on this e3D Titan Aero, we can see the inner workings of the 3D printer's extruder.

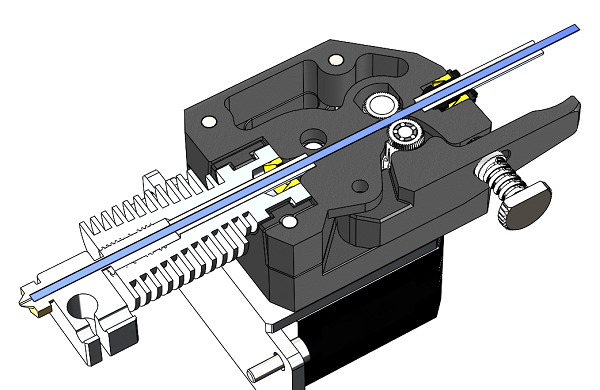

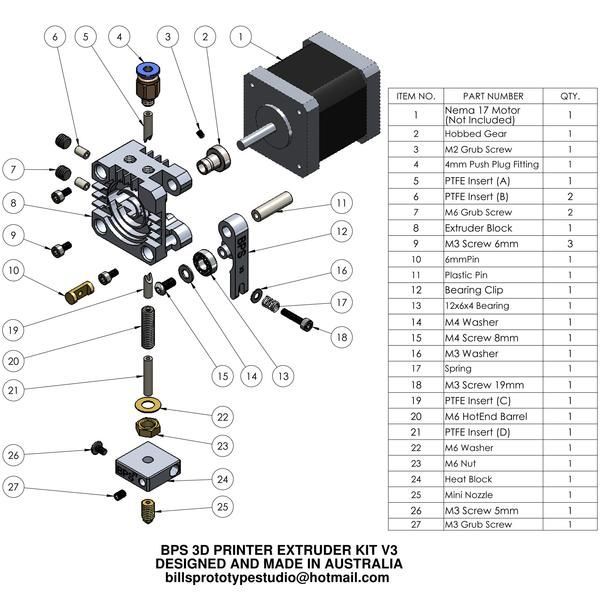

Essentially, the cold zone consists of a stepper motor, some form of gear, a toothed bolt or gear, a spring-loaded idler (usually a bearing of some kind) to hold the filament, and then a PTFE tube to guide the filament.

A humble stepper motor with a metal gear required for a 3D printer's extruder drives the filament extrusion in most if not all modern desktop 3D printers.

However, one stepper motor is not enough to feed the filament to the hot end. The parts attached to and operating the stepper motor drive shaft must physically grab the filament and push it on its way to the hot end.

In this cutaway view of a 3D printer extruder, we see a metal gear and a plastic gear with a toothed shaft. nine0046

This usually uses a combination of toothed gears and toothed bolts or shafts (in the image above we see a metal gear and a plastic gear with a toothed shaft) serving as a pressure wheel along with a bearing or other rigid frictionless material.

Here we see a plastic lever with an integrated bearing, an extension spring and a plastic gear with a toothed shaft. Together they apply pressure to the filament and force it through the extruder. nine0046

nine0046

Alternatively, there are versions of the cold end of the 3D printer extruder that use a slightly different arrangement of parts to feed the filament. Such deviations are often claimed to provide increased traction and yarn delivery.

Here we see both sides of the Prusa i3 Mk3 cold end, including the Bondtech extruder gear train.

As mentioned, there are varieties of 3D printer extruder that use these parts in slightly different layouts. Each has its pros and cons. Next, we will look at what is the difference between a direct drive 3D printer extruder and a Bowden 3D printer. nine0003

Direct drive extruders

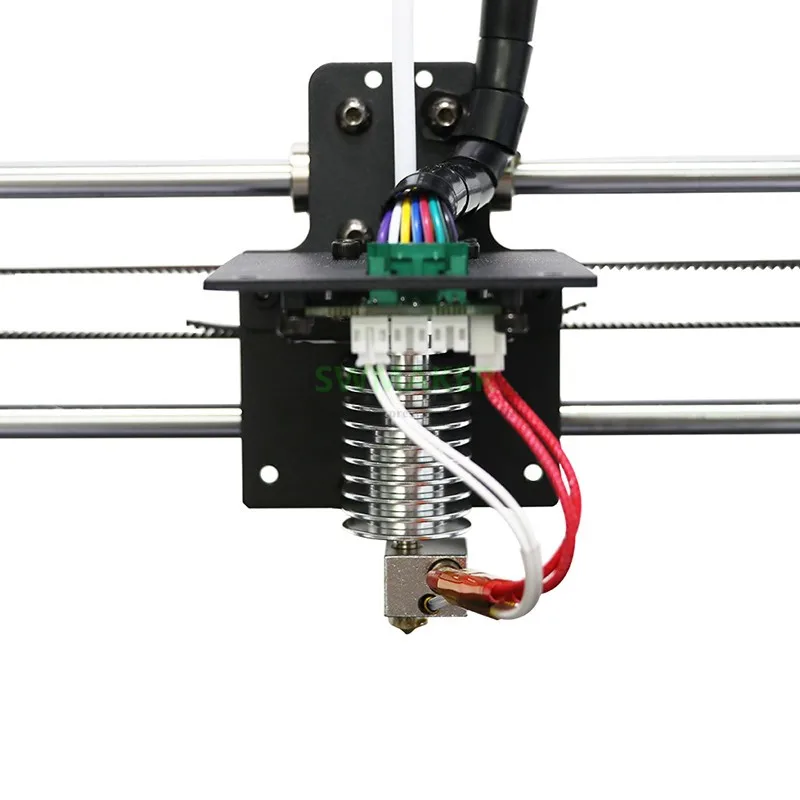

The Direct Drive 3D Printer Extruder is different in that it places the extruder motor directly above the heating unit. This arrangement minimizes the travel distance of the filament to the hot end and can enable more reliable 3D printing of flexible filaments.

The advantage of using direct drive is more precise retraction control. Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure. nine0003

Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure. nine0003

Bowden extruders

Bowden Style 3D Printer Extruder The does not mount directly on the top of the hotend like a direct drive 3D printer extruder, but the motor and gear assembly mounts on the frame of the printer. This gives this type of extruder an advantage over its head-mounted direct drive brother: speed.

By placing the mass of the 3D printer's extruder on the frame instead, the printhead is freed up to print at higher speeds without sacrificing print quality. nine0003

A side effect of placing the 3D printer's extruder this way is that the filament now has to travel a long way in a tube that's a fraction wider than it is. There should be enough room along the entire length of the tube for a slight bend in the thread. When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings. nine0003

When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings. nine0003

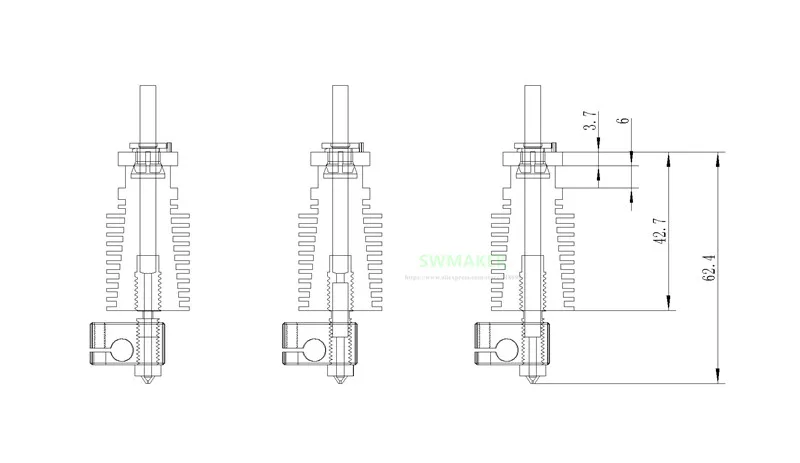

Heating block (Hotend)

Inside the knot, known as the hot end, the filament passes into a heated chamber where it changes from solid to liquid. Sounds simple, and mostly it is. Although there is a lot more to make the filament silky extrude onto the build plate.

What happens in the heating zone?

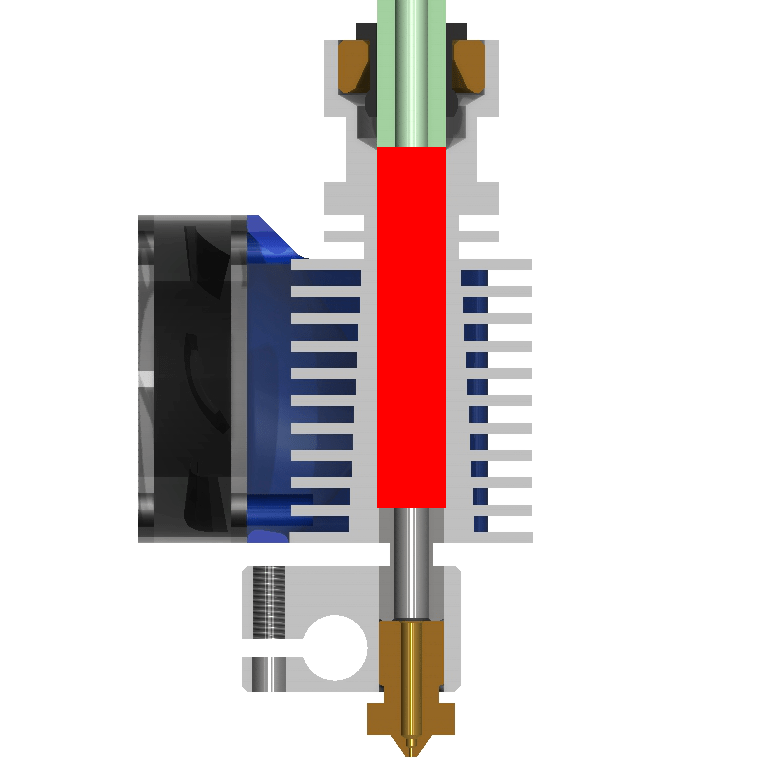

The E3D Titan Aero combines a heating block and an extruder in one compact unit. The hot end usually only has the central parts of this image: the heatsink (and fan), the heating element (micro cartridge heater), the heater block, the thermistor, and the nozzle. nine0046

A typical 3D printer hotend consists of a specific sequence of parts. There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

First, it is a filament supply tube. In both a Bowden 3D printer extruder and a direct drive extruder, it will just be a PTFE tube coming from your cold filament feeder. nine0003

You can sometimes find direct drive 3D printer extruders where the filament runs straight into the print head.

On a Bowden 3D printer's extruder, this feed tube inserts the filament directly into the thermal barrier via a heatsink. The thermal barrier that is screwed into the heatsink is often a threaded stainless steel (or other non-conductive metal such as titanium) tube.

Split in two (note the two separate threads in the image below - longer for the heatsink, shorter for the heater block) and machined on the inside, the thermal break allows the filament to pass freely into the extrusion nozzle. nine0003

Clockwise from bottom left: steel thermal barrier, aluminum heating block and brass nozzle.

But since we're dealing with precision and a material that liquefies for rapid recooling, the 's temperature management is critical. The thermal barrier, in combination with the heat sink, maintains a certain limit at which the filament is exposed to high temperatures. nine0003

The top, which is actively cooled by a heatsink and dedicated fan, prevents heat from escaping from the hot end and weakening the filament before it is where it needs to be for extrusion. This unwanted phenomenon is known as thermal creep.

The lower part of the thermal barrier is located inside the heater block together with the cartridge heater, the temperature switch thermistor and the nozzle.

The heater block, usually made of aluminum, ensures a smooth transition of the filament from the open end of the thermal break tube to the nozzle. nine0003

The temperature to melt the filament has to come from somewhere, and this is where the cartridge heater comes into play.