3D printed thumb

Dani Clode's 3D Printed Prosthetic "The Third Thumb"

Dani Clode takes the meaning of prosthesis quite literally: rather than fixing or replacing, the Latin word's original meaning is to add something. With “The Third Thumb,” Clode has designed an attachable 3D printed thumb controlled by the feet–and challenges our perception of prosthetics.

Watch the video to learn how “The Third Thumb” works and how it extends the wearer’s abilities.

Her graduation project at the Royal College of Art in London combines a seemingly simple design with refined technology. 3D printing enabled the young designer to achieve the level of precision required for the prosthetic on an accessible machine and with a quick turnaround.

Clode’s design work is centered around the body and making human augmentation aesthetically appealing and approachable. Her previous work ranges from an experimental bone knitter, currently exhibited at the Vienna Biennale, to a prosthetic arm for the disabled model Kelly Knox.

“The Third Thumb” has been featured in various press outlets, including The Verge, Dezeen, and NBC News.

How did you get the idea for designing a 3D printed prosthetic?

The idea started when I was working on my dissertation at Royal College of Arts in London. I started to research prosthetics and became fascinated with them as a product. I came across the origin of the word “prosthesis” and found that it meant “in addition to.” This really inspired me to look into reframing prosthetics as extensions, rather than anything that “fixes” or “replaces.”

Prosthetics are such unique products; it’s a product relationship that is unlike any other, and I wanted to really explore this connection that develops between the wearer and the limb. I wanted the design to be able to be experienced by anyone.

How does 3D printing fit into your design process?

I utilize the Form 2 to prototype and realize final models. I don’t like to work on a design in 3D virtual space for too long. I usually create my first prototype, print it, and then return to Rhino to update the model. I can go back and forth like this up to five or six times before I am happy with my final print.

I don’t like to work on a design in 3D virtual space for too long. I usually create my first prototype, print it, and then return to Rhino to update the model. I can go back and forth like this up to five or six times before I am happy with my final print.

I think when you work in a virtual space too long, you start to lose the tangibility of the design, especially when it comes to designs that attach to the body. So it’s great that we now have the facilities as designers to be able to very quickly work in both physical and virtual space almost simultaneously.

What are special requirements or attributes of the designs you’re 3D printing?

Feeling finished was a big part of it. With so many 3D printed parts, you can tell right away how it was printed, but with the Form 2, after sanding and a little bit of oil, it looks like a finished part.

I also had some very tight tolerances with “The Third Thumb.” There are pipes running through the hand piece that house the teflon tubing for the wires; I was working with a tolerance of about ±0. 2 mm.

2 mm.

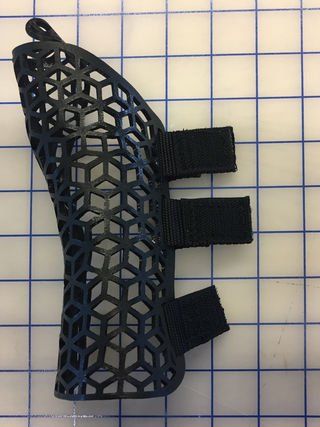

The hand cover and servo wrist piece on “The Third Thumb” are both produced with Formlabs Grey Resin. The jewelry thumb, shown on the left, is a version of“The Third Thumb” reimagined in a kinetic jewelry setting, and is printed with Formlabs Black Resin.Dani Clode used Formlabs Grey Resin for “The Third Thumb” prosthesis. Request a free sample part.

What specific aspects of the design and workflow were made possible by 3D printing?

The fast turnaround helped enormously. I also really appreciate not having to paint the prints for them to look good, I think that saved me the most time in my process.

The biggest challenge was definitely the internal pipes in my design. It was such a tight tolerance, and the Form 2 performed great with the tolerances I provided.

“The Third Thumb” uses Bluetooth connectivity and a motor in a 3D printed wrist to a pressure sensor attached to the shoe sole.Your project got quite a bit of press coverage.

How do you explain the hype?

How do you explain the hype?I think it catches your eye online. It’s a bit weird, but it makes you think about the possibilities.

Balancing glasses with an extra digit.Human augmentation is also a big topic at the moment, and I think “The Third Thumb” slots into that conversation perfectly. That was really what this project was about, having conversation about ability and prosthetics.

The goal of “The Third Thumb” is to create a catalyst for society to consider human extension, framed in an approachable, accessible design. It is a tool, an experience, and a form of self-expression. When we start to extend our abilities, and when we reframe prosthetics as extensions, then we start to shift the focus from “fixing” disability, to extending ability.

What projects are on the horizon for you? Will you continue to do 3D printing and prosthetics?

I have already used the Form 2 with another project, as part of a prosthetic arm. 3D printing is the perfect medium for prosthetic projects. It enables quick prototyping, customized designs for various body sizes, and one-off production. I will definitely continue to use Form 2 resin in my work, it is a great material and the quality is to hard to beat.

It enables quick prototyping, customized designs for various body sizes, and one-off production. I will definitely continue to use Form 2 resin in my work, it is a great material and the quality is to hard to beat.

Manufacturing Affordable Custom Prosthetics

Inspired by Dani Clode’s project? Learn how 3D printing empowered a Virginia startup to challenge the prosthetics industry and manufacture affordable custom prosthetic hands.

Need an Extra Thumb? The Third Thumb Project Uses 3D Printing to Change Perceptions of Prosthetics - 3DPrint.com

Many people have, at one time or another, wished for an extra set of hands to do everything they need to get done, or to carry loads of items. Royal College of Art graduate Dani Clode might not be able to fulfill that wish, but she can give you the next best thing – an extra thumb. No, there’s no questionable genetic engineering at work here – just good old-fashioned 3D printing. (Okay, maybe 3D printing isn’t old-fashioned yet, but anyway.) For her graduate degree in design, Clode engineered a prosthetic thumb that gives wearers a bit of extra reach and dexterity.

(Okay, maybe 3D printing isn’t old-fashioned yet, but anyway.) For her graduate degree in design, Clode engineered a prosthetic thumb that gives wearers a bit of extra reach and dexterity.

Part of the idea of the Third Thumb Project, explains Clode, is to redefine what the word “prosthetic” means. We typically think of a prosthetic device as something that replaces a body part that has been lost, but that’s not always the case – a prosthetic can also be used to augment or expand.

“The Third Thumb investigates the relationship between the body and prosthetic technology in new ways,” she says. “It is part tool, part experience, and part self-expression; a model by which we better understand human response to artificial extensions. It instigates necessary conversation about the definition of ‘ability.’ The origin of the word ‘prosthesis’ meant ‘to add, put onto;’ so not to fix or replace, but to extend. The Third Thumb is inspired by this word origin, exploring human augmentation and aiming to reframe prosthetics as extensions of the body.

”

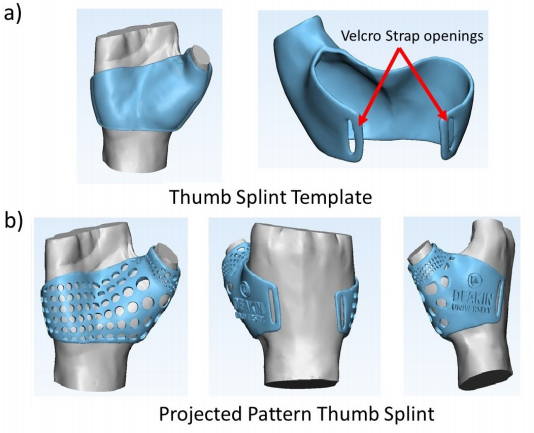

The Third Thumb is a 3D printed device that wraps around the hand and attaches to a wristband, providing an actual third thumb on the opposite side of the hand from the natural thumb. The design of the thumb itself is based on live hinges, 3D printed from Ninjaflex filament, while the hand and wrist components – both of which contain motors – are 3D printed from Formlabs grey resin. The parts are connected by a bowden cable system made of teflon tubing and wire, similar to a bicycle brake.

“The human thumb has a really dynamic movement, the opposing movements working together to make the thumb more functional than a single finger,” says Clode. “The Third Thumb replicates these movements by using two motors pulling against the natural tension of a flexible 3d printed material…3d printing is the perfect medium for this project, as it enables quick prototyping, customised designs for various hand sizes and one-off production.”

The movement of the Third Thumb is actually controlled by the feet. Two pressure sensors are placed into the wearer’s shoes and connected to the thumb through a Bluetooth connection. With an extra thumb, wearers can extend their musical instrument-playing abilities, more easily grasp objects, or just improve their dexterity overall.

Two pressure sensors are placed into the wearer’s shoes and connected to the thumb through a Bluetooth connection. With an extra thumb, wearers can extend their musical instrument-playing abilities, more easily grasp objects, or just improve their dexterity overall.

The design is currently in the working prototype stage, and Clode envisions two possible design aesthetics for the device. The “tool aesthetic” is designed to look functional, with a design that combines the look of a watch, a power tool and a fitness tracker. The “kinetic jewelry aesthetic” is a more designer look, inspired by the appearance of a tattoo – it looks more like jewelry, yet still serves the same function.

“The Third Thumb aims to challenge the perception of prosthetics,” Clode continues. “By extending the body I see it creating a similar trajectory for prosthetics as glasses or plastic surgery. Creating a shift from medical device to positive body image statement…When we start to extend our abilities, and when we reframe prosthetics as extensions, then we start to shift the focus from fixing disability, to extending ability.

”

The design recently won the Royal College of Art’s Helen Hamlyn Award for Creativity, for which she and the other five HHA winners were each awarded £2,000 to help in further project development. Discuss in the Third Thumb forum at 3DPB.com.

[Sources/Images: Dani Clode Design, Dezeen]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed prosthetic • 3d printed prosthetic device • 3d printed prosthetic devices • 3d printed prosthetics • 3D printed thumb • Dani Clode • formlabs resin • ninjaflex • Royal College of Art • Third Thumb Project

Please enable JavaScript to view the comments powered by Disqus.

Free 3D File Thumb M3・3D Printed Model for Download・Cults

usb micro sd

free

The best files for 3D printers in the Tools category

Anet A8 Spool holder - reuse Anet parts

Free

cookie cutter Masha and the bear

0. 93 €

93 €

Action protection cover for Canon SX230 HS

Free

Pumpkin cookie cutter - size 10cm

6,50 €

Tim's Test Train (calibration and test models to help reduce plastic waste)

Free

SD-Card Organizer

Free

Hole / Column Test Print (Customizable)

Free

Nasa space wrench Kit

Free

Bestsellers in the Tools category

ENDER 3 S1/PRO SPRITE, HOTEND 4020 OR 5015 FAN PROBE NO Y OFFSET

€2.28 -twenty% 1.82€

209 Flash Bang / Ukrainian Hot Potato

0,94 €

Shrek Pooping Toothpaste Topper

2. 82 €

82 €

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED COIL

€2.13 -twenty% 1.70€

PRECISION CALIPER 3D PRINT DIY

3,11 €

telephone ring holder

0,90 €

Ender 3 S1 Duct for stock fan

€1.20 -10% 1.08 €

1.04 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.81 €

Quick Print Paint Bottle Rack (6 sizes)

2. 86 €

86 €

Bit holder Spartan 4 mm Hex

1,80 €

nine0003 Paint stand with scissors5.19 €

Armadillo - flexible wire conduit

1.67 €

Ratchet holders - magnetic - holders for tool box organization

2,67 €

3D printed wave transmission (harmonic drive)

4.99 €

nine0003 Cooling system Minimus Hotend2.33 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

Antibacterial plastics

References :

1. Ziegler-Graham, K.; MacKenzie, E.J.; Ephraim, P. L.; Travison, T. G.; Brookmeyer, R. Estimating the prevalence of limb loss in the United States: 2005 to 2050. Arch. Phys. Med. Rehabil. 2008, 89, 422-429. [CrossRef] [PubMed]

2. VA Office of Inspector General. Helathcare Inspection Prosthetic Limb Care in VA Facilities; VA Office of Inspector General: Washington, DC, USA, 2011.

3. Kuret, Z.; Burger, H.; Vidmar, G.; Maver, T. Adjustment to finger amputation and silicone finger prosthesis use. Disabil. Rehabil. 2018.1-6. [CrossRef] [PubMed]

4. Biddiss, E.A.; Chau, T.T. Upper limb prosthesis use and abandonment: A survey of the last 25 years. Prosthet. Orthot. Int. 2007, 31, 236-257. [CrossRef] [PubMed]

5. Butkus, J.; Dennison, C; Orr, A.; Laurent, M.S. Occupational Therapy with the Military Upper Extremity Amputee: Advances and Research Implications. nine0152 Curr. Phys. Med. Rehabil. Rep. 2014.2.255-262. [CrossRef]

6. Routhier, E; Vincent, C; Morissette, M.J.; Desaulniers, L. Clinical results of an investigation of pediatric upper limb myoelectric prosthesis fitting at the Quebec Rehabilitation Institute. Prosthet. Orthot. Int. 2001, 25,119-131. [CrossRef] [PubMed]

7. Bosnians, J.; Geertzen, J.; Dijkstra, P.U. Consumer satisfaction with the services of prosthetics and orthotics facilities. Prosthet. Orthot. Int. nine0153 2009, 33, 69-77. [CrossRef] [PubMed]

Prosthet. Orthot. Int. nine0153 2009, 33, 69-77. [CrossRef] [PubMed]

8. Shim, J.-H.; Lee, Y.-H.; Lee, J.-M.; Park, J.M.; Moon, J.-H. Wrist-driven prehension prosthesis for amputee patients with disarticulation of the thumb and index finger. Arch. Phys. Med. Rehabil. 1998, 79, 877-878. [CrossRef]

9. Nallegowda, M.; Singh, U.; Khanna, M.; Babbar, A. Temporary Upper Limb ALIMS Prostheses—A New Design. Indian J. Phys. Med. Rehabil. 2010, 21, 1-4.

10. Bowker, J.H.; Michael, J. W.; Surgeons, A.A.O.O. Atlas of Limb Prosthetics: Surgical, Prosthetic, and Rehabilitation Principles; Mosby Year Book: Maryland Heights, MO, USA, 1992.

11. Godymchuk, A.; Frolov, G.; Gusev, A.; Zakharova, O.; Yunda, E.; Kuznetsov, D.; Kolesnikov, E. Antibacterial Properties of Copper Nanoparticle Dispersions: Influence of Synthesis Conditions and Physicochemical Characteristics. IOP Conf. Ser. mater. Sc. Eng. 2015, 98, 012033. [CrossRef]

Eng. 2015, 98, 012033. [CrossRef]

12. Palza, H. Antimicrobial polymers with metal nanoparticles. Int. J. Mol. sci. 2015, 16, 2099-2116. [CrossRef] [PubMed]

13. Muwaffak, Z.; Goyanes, A.; Clark, V.; Basit, A. W.; Hilton, S.T.; Gaisford, S. Patient-specific 3D scanned and 3D printed antimicrobial polycaprolactone wound dressings. Int. J Pharm. 2017,527,161-170. [CrossRef] [PubMed]

14. Gadi, B.; Jeffrey, G. Copper as a Biocidal Tool. nine0152 Curr. Med. Chem. 2005, 12, 2163-2175. [CrossRef]

15. Liu, Y.; He, L.; Mustapha, A.; Li, H.; Hu, Z.Q.; Lin, M. Antibacterial activities of zinc oxide nanoparticles against Escherichia coli 0157:H7. J.Appl. microbiol. 2009, 107, 1193-1201. [CrossRef] [PubMed]

16. Zuniga, J.M.; Katsavelis, D.; Peck, J.; Stollberg, J.; Petrykowski, M.; Carson, A.; Fernandez, C. Cyborg beast: A low-cost 3d-printed prosthetic hand for children with upper-limb differences. nine0152 BMC Res. Notes 2015, 8 , 10. [CrossRef] [PubMed]

nine0152 BMC Res. Notes 2015, 8 , 10. [CrossRef] [PubMed]

17. Zuniga, J.M.; Carson, A. M.; Peck, J.M.; Kalina, T; Srivastava, R.M.; Peck, K. The development of a low-cost three-dimensional printed shoulder, arm, and hand prostheses for children. Prosthet. Orthot. Int. 2016, 41, 205-209. [CrossRef] [PubMed]

18. Zuniga, J.M.; Peck, J.; Srivastava, R.; Katsavelis, D.; Carson, A. An Open Source 3D-Printed Transitional Hand Prosthesis for Children. nine0152}. Prosthet. Orthot. 2016, 28, 103-108. [CrossRef]

19. Zuniga, J.M.; Peck, J. L.; Srivastava, R.; Pierce, J.E.; Dudley, D.R.; Than, N.A.; Stergiou, N. Functional changes through the usage of 3D-printed transitional prostheses in children. Disabil. Rehabil. assist. Technol. 2017.1-7. [CrossRef] [PubMed]

20. Mathiowetz, V.; Volland, G.; Kashman, N.; Weber, K. Adult norms for the Box and Block Test of manual dexterity. nine0152 Am. J. Occup. Ther. off. Publ. Am. Occup. Ther. Assoc. 1985, 39, 386-391. [CrossRef]

J. Occup. Ther. off. Publ. Am. Occup. Ther. Assoc. 1985, 39, 386-391. [CrossRef]

21. Mathiowetz, V; Wiemer, D.M.; Federman, S.M. Grip and pinch strength: Norms for 6- to 19-year-olds. Am. J. Occup. Ther. off. Publ. Am. Occup. Ther. Assoc. 1986, 40, 705-711. [CrossRef]

22. Dromerick, A.W.; Schabowsky, C.N.; Holley, R.J.; Monroe, B.; Markotic, A.; Lum, P.S. Effect of training on upper-extremity prosthetic performance and motor learning: A single-case study. nine0152 Arch. Phys. Med. Rehabil. 2008, 89, 1199-1204. [CrossRef] [PubMed]

23. Demers, L.; Weiss-Lambrou, R.; Ska, B. Item analysis of the Quebec User Evaluation of Satisfaction with Assistive Technology (QUEST). Assist. Technol. off. }. RESNA 2000, 12, 96-105. [CrossRef] [PubMed]

24. Patemo, L.; Ibrahimi, M.; Gruppioni, E.; Menciassi, A.; Ricotti, L. Sockets for Limb Prostheses: A Review of Existing Technologies and Open Challenges. nine0152 IEEE Trans. Biomed. Eng. 2018, 65, 1996-2010. [CrossRef] [PubMed]

nine0152 IEEE Trans. Biomed. Eng. 2018, 65, 1996-2010. [CrossRef] [PubMed]

25. Yamada, R.; Nozaki, K.; Horiuchi, N.; Yamashita, K.; Nemoto, R.; Miura, H.; Nagai, A. Ag nanoparticle-coated zirconia for antibacterial prosthesis. Mater. sci. Eng. cmater. Boil. Appl. 2017, 78, 1054-1060. [CrossRef] [PubMed]

26. Brenner, C.D.; Brenner, J.K. The Use of Preparatory/Evaluation/Training Prostheses in Developing Evidenced-Based Practice in Upper Limb Prosthetics. nine0152}. Prosthet. Orthot. 2008, 20, 70-82. [CrossRef]

27. Bryant, M.H.; Donahue, J.R.; Sweigart, J. F.; Hunter, J.M. A prosthesis to restore opposition in children with congenital absence of the hand. Assoc. child. Prosthet.-Orthot. Clin. 1979, 17.5-10.

28. Rankin, T.M.; Giovinco, N.A.; Cucher, D.J.; Watts, G.; Hurwitz, B.; Armstrong, D.G. Three-dimensional printing surgical instruments: Are we there yet? J.

Learn more