3D printed latches

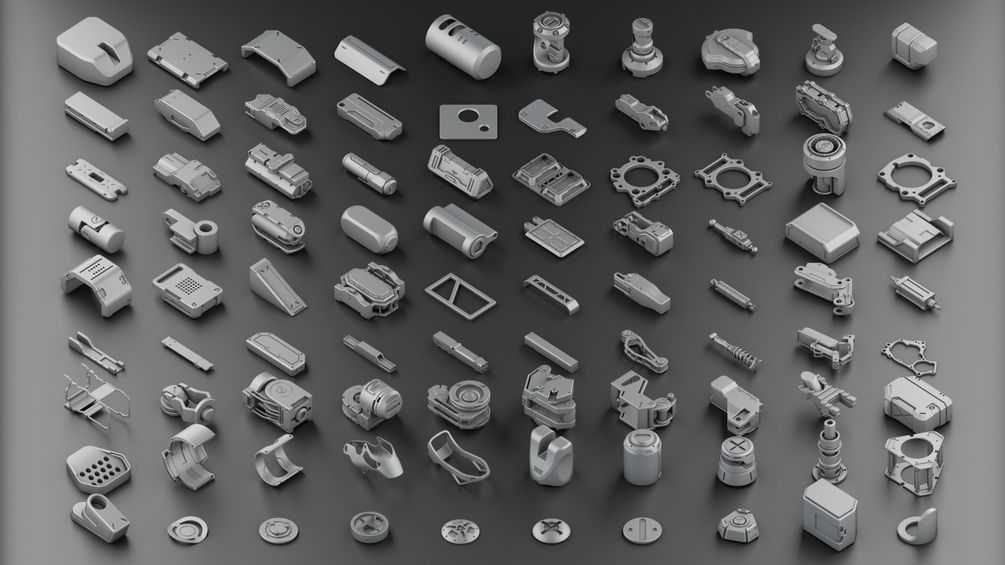

Latch best STL files for 3D printer・Cults

Volvo clip 8678600

€3

Mehari door striker / latch (old model)

Free

Mehari door striker / latch SPACERS (old model)

Free

AR-15 Latch Plate Reinforced

Free

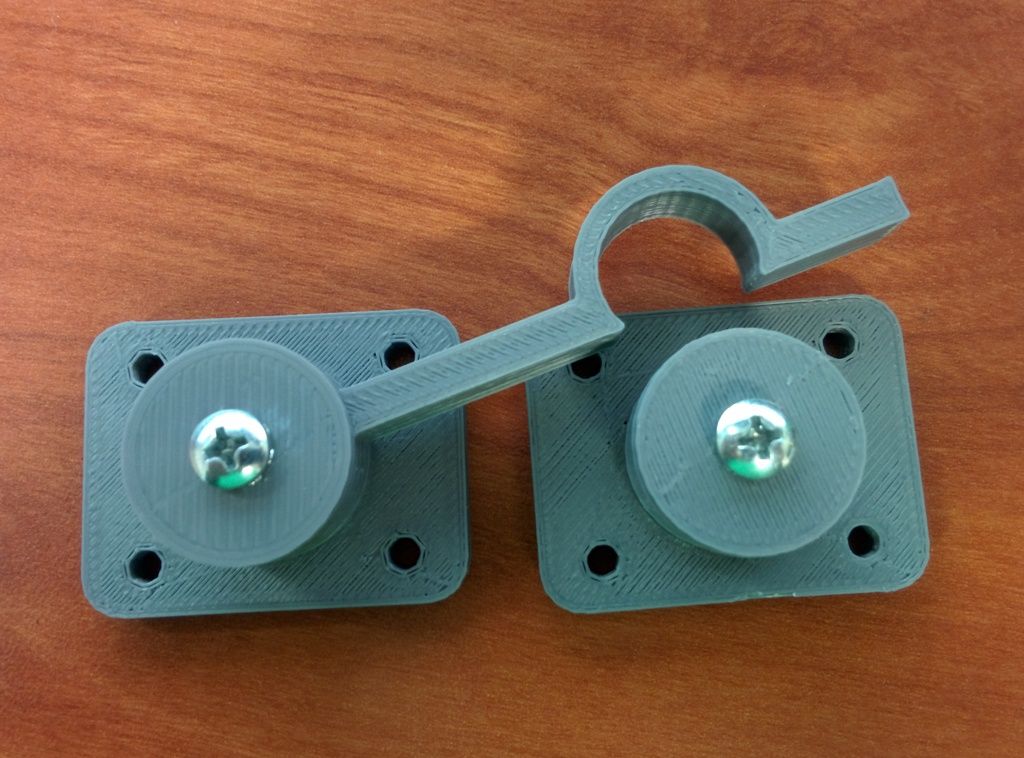

Double Magnetic Latch

Free

Magnetic Latch

Free

latch loquet

Free

Door Latch

Free

Window Latch Keeper

Free

Magnet mount

Free

Pocket Pill Box with Latch

€0.63

Cosplay Armor Helpers

Free

AR Charging Handle Latch

Free

3DV Mini Rafts - Round Panel Latches

€4

Window Holder Window Lock Window Lever Window Latch

€1

Westinghouse Microwave Latch Spare part (WMF4102SA)

€6. 22

the Addalock

Free

Magnetic drawer Child lock

Free

Part of Rear Trunk Lid Lock Latch Mercedes-Benz A6387430488

€9

NISSAN PRIMERA P12 Armrest Latch

€9

sliding window latch

Free

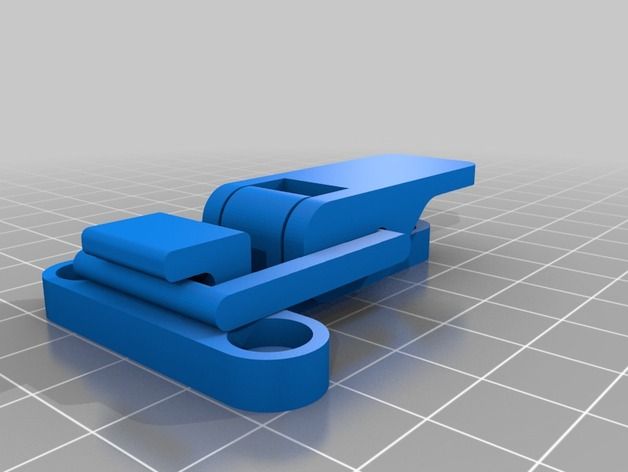

rotating stop latch

Free

Latch.

€4.70

Quick Release Shelf Latch

Free

Carlson Baby/Pet Latch (Top Release)

Free

Rigid Shop Vacuum / Shopvac Drum Latch

Free

Waeco lid check clip

Free

Toaster hook / clip

€0. 53

53

Silica Gel Box Clip

Free

VOLKSWAGEN ARMREST LATCH

€5.62

rear bumper latch F0rd Skorpio

€3

Honda Civic 92-95 Armrest Arm Rest Latch

Free

Tefal snack collection latch/lock

Free

Electrolux Fridge Lock/Latch

Free

RV Designer h325 Concealed Positive Cabinet Latch

Free

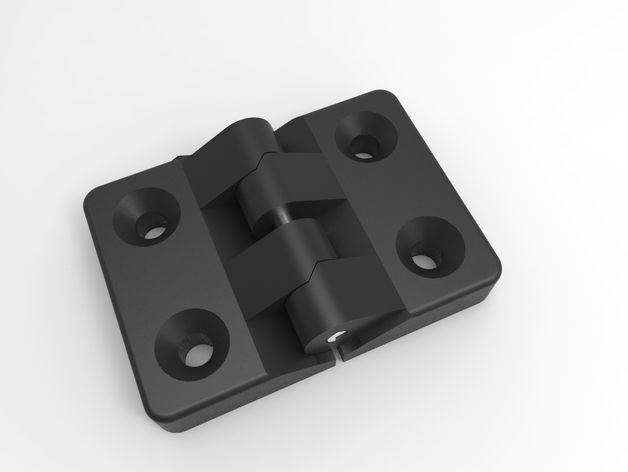

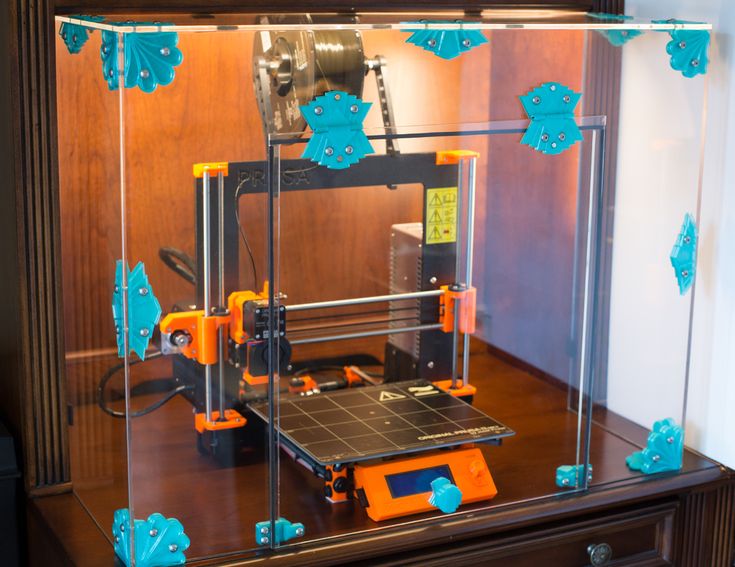

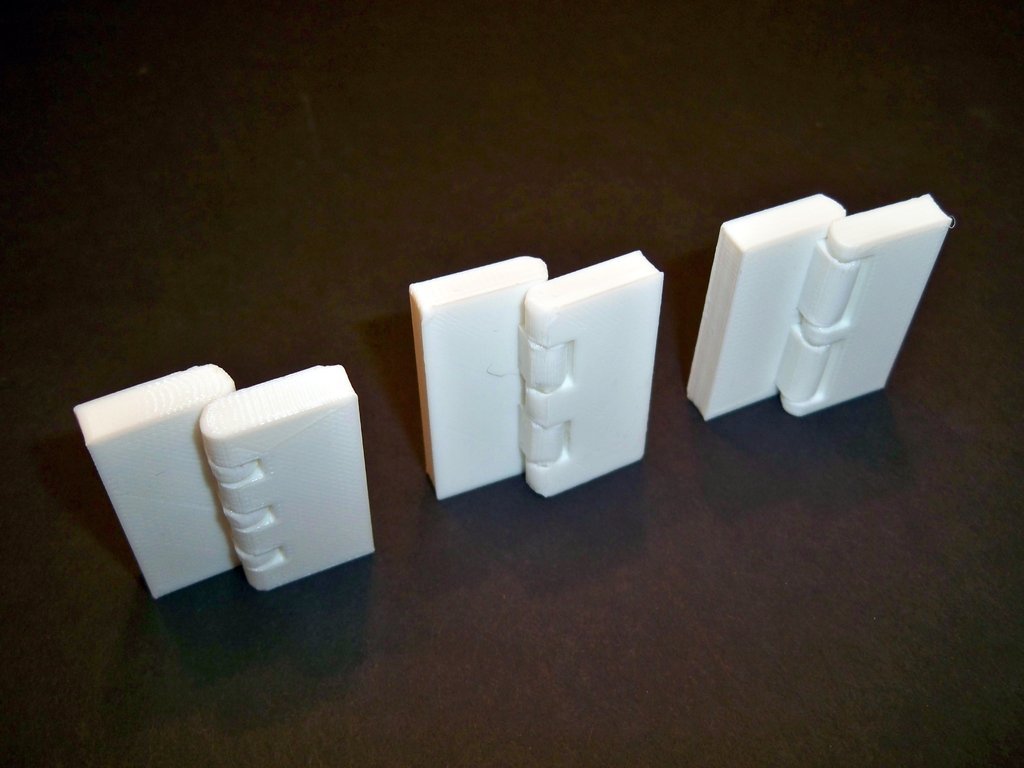

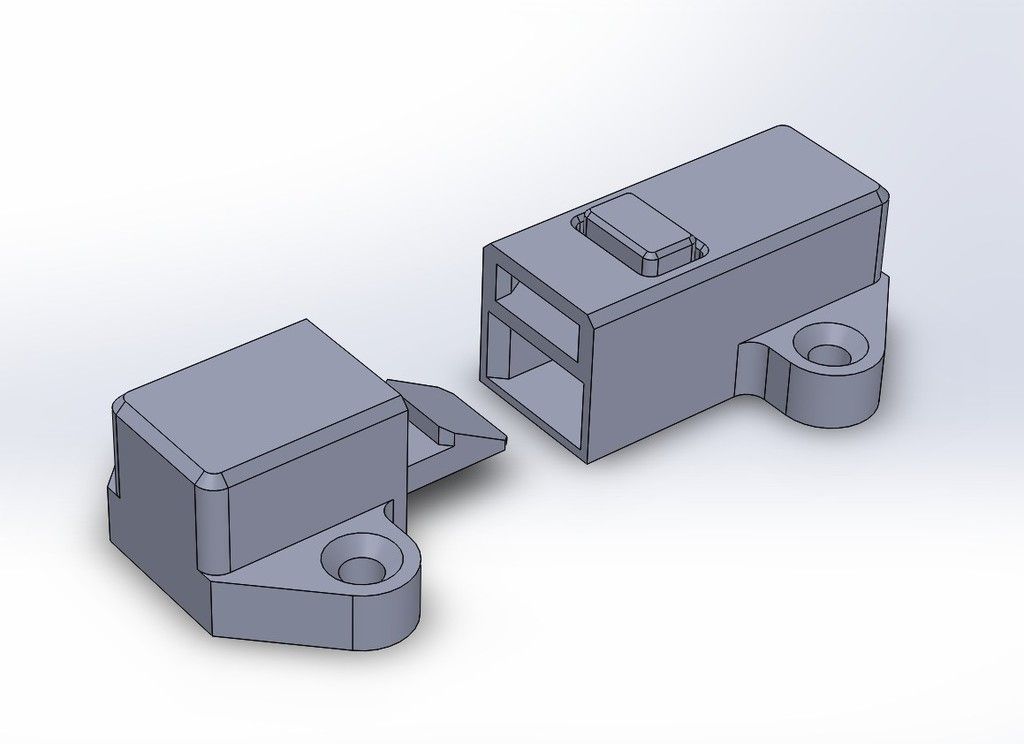

Cerniere e chiusura per cassetta degli attrezzi (Hinges and latches to toolbox)

Free

used metal lock - latch scale 1/1 and 1/32

€2.50

Microwave door latch

€0. 93

93

10 mm watch strap and buckle

Free

20 mm watch strap and buckle

Free

Door latch door

€4.91

Ford Bronco Dash Latch

€2.35 -50% €1.18

Replacement latch for an old vacuum

Free

Screen door latch

Free

Mailbox latch and retainer clip (Top only)

Free

Gopro Hero3 case latch

Free

E-Z Track connection latch

Free

Philips Sonicare Toothbrush Print In Place Travel Case

€1. 99

99

How do you design snap-fit joints for 3D printing?

What are snap-fit joints and how do they work? This in-depth guide discusses the benefits of 3D printing snap-fit connectors and clips and gives design and material recommendations for designing custom parts with snap-fit joints.

Snap-fit joints are a quick and easy way to connect two 3D-printed components by using interlocking features. Not only are they a low-cost and time-saving connection method, but they can also reduce the number of parts needed in an assembly. Plus, they offer the possibility of rapid assembly and disassembly.

This article covers the basics of snap-fit joints (also called connectors and clips) for 3D printing , what to consider when designing snap-fits with plastics and thermoplastics and which 3D printing process is optimal for manufacturing the best snap-fits.

Does Hubs have a snap-fit tutorial?

Before (or after) diving into this comprehensive guide, check out this nifty tutorial on designing snap-fit joints for 3D printing.

What are snap-fit joints (or connectors/clips)?

A snap-fit joint is a cost-effective and relatively simple method of attaching two 3d-printed plastic components. Also known as a connector or clip, a snap-fit generally consists of a small and bendable protrusion, like a bead, stud, or hook, and a mating depression that deflects and catches the protruding feature. The two features clicking into place create a robust interlocking connection.

Once the features have clicked into place, an undercut holds the two components of the snap-fit together. Depending on the shape of this integral undercut, snap-fit assemblies can also be designed to make the interlocking connection permanent. A well-designed snap-fit joint with the right material can be used quite a number of times without any noticeable mechanical fatigue.

There are plenty of types of snap-fit types and geometries that follow the basic principles of two interlocking components.

Common types of snap-fits: cantilever and annular joints

The two most widely used and commonly effective types of snap-fit connectors are cantilever and annular joints. Let’s break these down.

Cantilever snap-fit joints

The most common snap-fit joint is the cantilever, consisting of a protrusion (some type of bead or hook) on one end of the component and a structural support feature at the other end. This protrusion is placed into an opening and bends back to lock the connection into place.

Cantilever snap-fits are easy to design and intuitive when it comes to assembly and disassembly. For many applications and cases, cantilevers are the most cost-effective way to connect to components.

A cantilever snap-fit on a 3D-printed enclosureAnnular snap-fit joints

Annular snap-fit joints use a hoop strain to hold a pressed part in place. Common examples of annular snap-fits are bottle and pen caps. With annular snap-fits, it’s possible to create a waterproof seal around the joint.

Common examples of annular snap-fits are bottle and pen caps. With annular snap-fits, it’s possible to create a waterproof seal around the joint.

What are the advantages of snap-fitting with 3D printing?

While injection molding is often seen as the more robust way to produce snap-fit joints, 3D printing is a viable alternative (and even a go-to) with the right design and materials.

3D-printed snap-fits don’t have any of the design limitations associated with injection molding—for instance, draft angles, separation lines, wall thickness and undercuts—and can be designed and altered with ease. This makes them ideal for rapid prototyping, where clearance and fit are critical. This is why designers generally use 3D printing for snap-fits in enclosures .

Snap-fit construction for a DIY loudspeakerWhat materials are used for 3D printing snap-fit joints?

Every 3D printing process has its pluses and minuses when it comes to producing parts with snap-fit connectors. This is due in part to the materials used with each of the major additive manufacturing technologies.

This is due in part to the materials used with each of the major additive manufacturing technologies.

FDM is the most cost-efficient way to manufacture snap-fit connectors. While it’s definitely effective, the process has lower accuracy than other printing methods. If you choose FDM, we recommend using strain-resistant materials, such as ABS, Nylon and TPU.

SLA resins are also a viable option for making snap-fit joints, but they are relatively brittle. Using resins may increase the chances of the snap-fit breaking after repeated use. We recommend durable SLA resin if you print snap-fits with this technology.

SLS is more suitable than FDM and SLA for printing functional snap-fit prototypes and end-use parts that will be opened and closed many times. The best material for maximum tear resistance is SLS Nylon.

Similar to SLS, MJF is optimal for manufacturing snap-fit connectors. MJF produces robust parts from Nylon PA 12 and a few other nylon and polypropylene options. What’s important to remember with MJF is that there are several design guidelines to follow to achieve the best results. For instance, we recommend a minimum thickness of 1 mm at the base of the cantilever and a minimum common overhang depth of at least 1 mm.

MJF produces robust parts from Nylon PA 12 and a few other nylon and polypropylene options. What’s important to remember with MJF is that there are several design guidelines to follow to achieve the best results. For instance, we recommend a minimum thickness of 1 mm at the base of the cantilever and a minimum common overhang depth of at least 1 mm.

Explore pricing options for every 3D printing process

FDM SLS MJF SLA

Designing snap-fit clips isn’t the same for all technologies, materials and applications. Engineers faced with snap-fit design for 3D printing often encounter a few key challenges. Here we cover the main ones.

-

Sharp corners in the design may add stress to a cantilever, which may raise the probability of the joint breaking off.

-

Constant stress on plastics and thermoplastics tends to cause creeping (deformation). Creep will eventually weaken the snap-fit or even compromise it entirely.

-

Misplaced gaps on parts will cause tolerance issues, in turn making it harder for components to fit together.

-

The more you assemble and disassemble snap-fit joints, the more likely you are to come across fatigue failure.

In general, snap-fits will encounter the most stress during attachment and should return to their neutral position once the joining process is completed. Depending on the shape of the undercut, snap-fit assemblies can also be designed to make them permanent. A well-designed snap-fit with suitable material can be used many times without any noticeable fatigue.

What are the right tolerances for snap-fit joints?

3D printing properties can vary quite a bit, from printer calibration and materials to the printer technology itself. Because of these varying factors, there are no strict tolerancing rules for printing snap-fit joints and connectors.

While there are no set rules, we do recommend the following optimal tolerances for different types of 3D printers.

-

For FDM (fused deposition modeling): 0.5mm

-

For SLA (stereolithography), SLS (selective laser sintering) and MJF (Multi Jet Fusion): 0.3mm

When designing snap-fit joints for 3D printed parts, it is important to consider features that will reduce stress and strain on the snap-fit assembly. Here are some of our best practices for designing snap-fit joints for 3D printing.

Taper the design

A snap-fit cantilever with a constant cross-section has an uneven distribution of strain. We recommend reducing the cross-section of the cantilever beam over its length. This uses less material and results in more even distribution of strain across the entire cantilever.

This uses less material and results in more even distribution of strain across the entire cantilever.

Fillet the base of the cantilever:

Adding a fillet at the base of a cantilever will help distribute stress over a broader area, resulting in a stronger connection between snap-fit components. The radius of the fillet should be at least 0.5 times the thickness of the cantilever’s base.

Increase the width:

Increasing the width of the clip, if it’s feasible given any design constraints, makes the design stronger. You may need to iterate several times to get the right part stiffness, and remember that the clip should be at least 5mm wide.

Deflect during assembly:

To help reduce stress and improve the strength of the connection, make sure that the snap-fit cantilever is only deflected during assembly rather than when the components are connected.

Consider build direction:

If possible, avoid designing snap-fit cantilevers that are built up vertically (in the z-direction). These are inherently weaker due to the anisotropic nature of 3D printing.

These are inherently weaker due to the anisotropic nature of 3D printing.

Add lugs:

Consider adding lugs to your assembly to assist with the alignment of components and to transfer some of the shear load your snap-fit clips may be subjected to.

-

Sound design principles can make or break your snap-fit joints. Remember to implement good design practices that reduce stress (fillets, build direction and locating lugs) and strain (tapered profiles and cantilever width).

-

Choose the right tolerances for different 3D printers. Use 0.5mm tolerances for FDM snap-fit connectors and 0.3mm for all other 3D printing processes.

-

Do your materials homework beforehand. Prototyping plastics are ideal for design confirmation, but they are typically weaker than SLS or material jetting materials.

Think about functional or end-use materials for applications where the connector will be opened and closed repeatedly.

Think about functional or end-use materials for applications where the connector will be opened and closed repeatedly.

To explore 3D printing further, check out our full guide for a comprehensive overview and detailed design and manufacturing tips.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteFree STL file housing latch・3D printed object for download・Cults

Fly protection can lid

Free

Fly protection can lids

Free

Pool Skimmer Basket

Free

Pool skimmer basket

Free

nine0003 Roomba tireFree

End for bed post

Free of charge

Tenlog D3 Filament Guide

Free

Tool rack

Free

Best 3D Printer Files in the Miscellaneous Category

nine0003 Tortoise Keychain / Smartphone StandFree

Miner with side cart

28. 18 €

18 €

Homelander - The Boys

10 €

Nerf Worker PDW Stock Cheekrest

Free

Crushinator from Futurama!

Free

nine0003 Crater Lake TopoFree

Saichoro or the great patriarch

Free

GRENADA ARCANA

2,50 €

Bestsellers in Miscellaneous category

Key holder for middle finger

1 €

ItsLitho "Pure" Personalized Lithophane Christmas Ball

€1.90

Predator-inspired movable mask

€6.20 -fifteen% 5. 27 €

27 €

ItsLitho "Creamy" personalized Lithophane Christmas ball

1,90 €

HAND OF THE ADDAMS FAMILY

5 €

flexible volute

2 €

Bunch of Christmas balls ItsLitho

5,70 €

ItsLitho "Drop" personalized lithophane Christmas ball

1,90 €

4th planet Fighting pre-Olympic god

12 €

nine0003 Articulated Raykuaza Flexible Dragon Pokémon1 €

Speeder-Pad support on FLSUN V400 and FLSUN SuperRacer

3 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2 €

hinged shenron

3 €

CHRISTMAS TREE v2

1. 50 €

50 €

Item

8 €

M2 Browning Cal.50 American heavy machine gun 3D printed 1/35 and 1/16

14.99 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here. nine0006

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Free STL file Latch for tool box・3D printing template to download・Cults

Vase with broken skull

Free

Mazda 9 coolant reservoir connection0004

Free

box clip

free

osterrig magnetic fastener

free

Calibration focus ring #2 21*86

Free

Cardboard reducer

Free

Calibration focus ring #1 72.

6*13.9

6*13.9 Free

armrest hook for Nissan Almera classic 2006

Free

The best files for 3D printers in the Tools category

Mobile Berry Harvester 3D print V2, berry picker, garden hacks 3D printed

15 €

Custom Dual Color Filament Printing Coil

Free

COVID-19 Mask/Respirator

Free

DIY Mug

Free

Water-cooled radial engine, 1910s

23.70 €

Small Animal House (rats/mice/hamster)

Free

nine0003 Watering BottleFree

Cell Phone and Tablet Stand

Free

Bestsellers in the Tools category

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang.

CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing 1.55 €

nine0003 3D printed wave transmission (harmonic drive)4.99 €

Display holder FLSUN v400

€9.99 -fifty% 4.99 €

SUPERBOX

1,50 €

PRECISION CALIPER 3D PRINT DIY

3.11 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.72 €

Ratchet holders - magnetic - holders for tool box organization

2,67 €

Quick Print Paint Bottle Rack (6 sizes)

2. 86 €

86 €

15 €

Bit holder Spartan 4 mm Hex

1,80 €

Paint stand with scissors

5.19 €

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED COIL

€2.13 nine0087 -twenty% 1.70 €

Phone holder

2.44 €

Armadillo - flexible wire conduit

1.67 €

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020, LED strip

€2.69 -twenty% 2.