Leap motion as 3d scanner

Could the leap motion scan 3d objects? - Pimax 8K Series - OpenMR

aesopfabled

#1

Looking to see if it would be useful for vr level design.

1 Like

kw23

#2

Technically, yes. It’s the same tech as the Kinect, which people hacked to make 3D scans. Though… you might be better off with a used Kinect and a turn table.

1 Like

aesopfabled

#3

What about scanning a room? I was guessing the leap motion 2. 0 was higher res than Kinect

1 Like

kw23

#4

You used to be able to use smart phone pictures to do this, but a lot of the tools don’t work anymore… might have to purchase photogrammetry tools.

1 Like

aesopfabled

#5

Photogrammetry is absurdly convoluted process. I haven’t seen any software that will just put it together and export in a useful format like fbx and fix meshes elsewhere.

1 Like

kw23

#6

Only other thing I’ve seen reviews on for room & scene scanning are portable lidar + EO cameras. I think they are $60k each, but the cost was high enough I mentally filed it under “not bloody worth pursuing.”

I think they are $60k each, but the cost was high enough I mentally filed it under “not bloody worth pursuing.”

1 Like

aesopfabled

#7

Photogrammetry would be great if someone made a software that wasn’t made for experts.

1 Like

kw23

#8

Are you familiar with any of those?

aesopfabled

#9

All the ones that don’t need external hardware, yea.

MR-Alex

#10

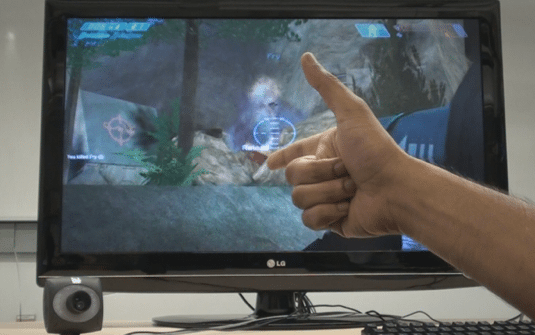

Sorry but Kinect used a different technologies. Kinect 360 used structured infrared laser light for depth and Kinect V2 used time of flight infrared lasers for depth calculation. Leap motion uses 2 infrared cameras for depth calculation. So its more similar to ZED and ZED mini which use also dual cameras. In theory you should be able to scan objects with Leap Motion using the raw image feed and tracking data of the headset. However you likely won’t get a scan with good resolution and the textures would be off, since you have only black and white images to work with.

2 Likes

Heliosurge

#11

Not sure but kinect xb360 can but xb1 reported a lot nicer. (Volumetric scanning) @lukeb posted xb1 kinnect long ago.

(Volumetric scanning) @lukeb posted xb1 kinnect long ago.

Heliosurge

#12

Not sure of leap res. 360 kinect is 720 & xb1 is 1080.

Digital worlds that feel human

Explore use cases Speak to the team

We remove boundaries between physical and digital worlds - for anyone, anywhere.

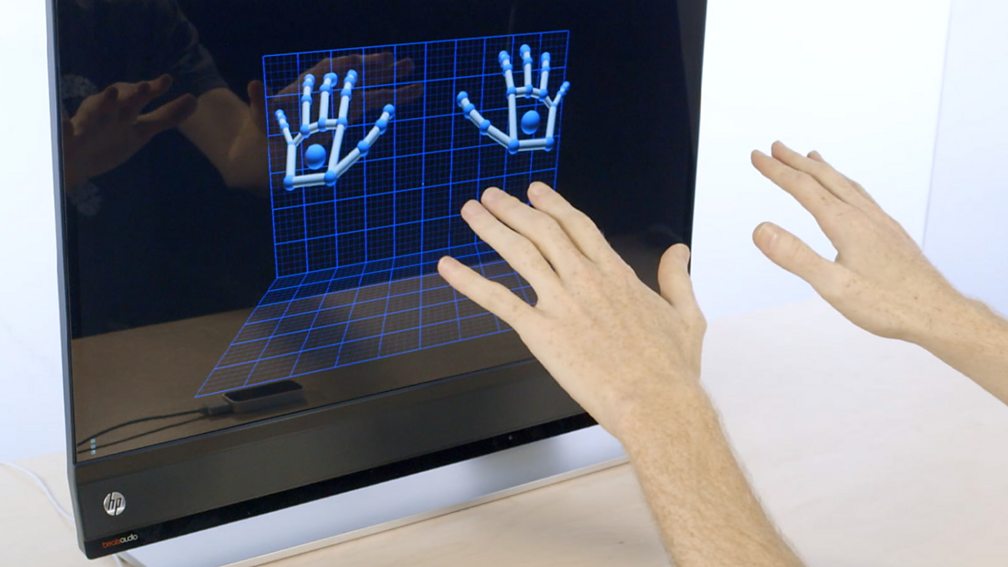

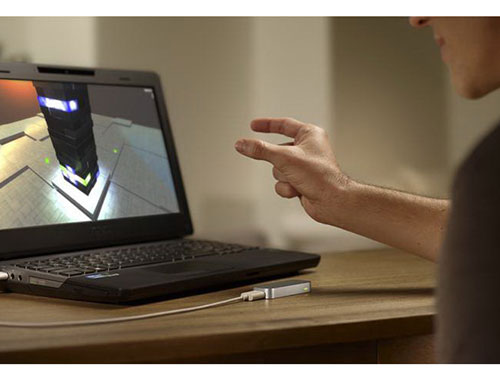

Say goodbye to hardware… Say hello to human technology.

Our hand tracking and haptics are powering the next wave of human potential. No controllers. No wearables. No touchscreens. Just natural interaction.

HAND TRACKING ACCESSORY

Pico Neo 3 Pro

Add Ultraleap hand tracking to the Pico Neo 3 Pro or Pico Neo 3 Pro Eye to unlock high-value use cases and bring in new users of all ages and levels of technical competency.

Where to buyLearn more

Touchless interaction

Ultraleap 3Di

The Ultraleap 3Di is a ruggedized hand tracking camera designed for connection to public interactive screens. DOOH, retail, museums, theme parks, and more.

Where to buyLearn more

XR HARDWARE, SOFTWARE & DEVELOPER TOOLING

Reach beyond controllers

To fully realize its potential, XR needs to remove the last barrier to entry: the user interface. Our advanced hand tracking solutions open up a bigger, more diverse community of users.

Explore solutions

TOUCHLESS INTERACTIVE KIOSKS

TouchFree: From easy retrofits to new touchless interfaces

Turn any existing touchscreen touchless with our TouchFree Application. Or, use TouchFree Tooling to integrate gesture control into applications as a native feature.

Learn more about TouchFree

Hand Tracking

The world’s most advanced hand tracking

Your hands are intricate and nuanced. Our software is too. Ultraleap’s world-leading hand tracking captures all the subtlety and complexity of natural hand movements. Real interaction, in real time.

Our software is too. Ultraleap’s world-leading hand tracking captures all the subtlety and complexity of natural hand movements. Real interaction, in real time.

Learn more about hand tracking

Haptics

The next wave of technology is one you can feel

Touch is going virtual. Our groundbreaking haptic technology uses ultrasound waves to create tactile sensations in mid-air.

Learn more about haptics

Making headlines.

See all our latest news, stories, and case studies.

Events

Meet the Ultraleap team at AES – Booth 906

Read more

Press Release

Consumer aversion to touchscreen germs here to stay

Read more

Blog

Future of retail technology: Touchscreens or Touchless?

Read more

Resources

Consumer report: Post-pandemic attitudes

Read more

Press Release

Ultraleap’s touchless tech available on BrightSign platform

Read more

Blog

What is VR training?

Read more

Developers

Let’s build a new reality, together

Join our community of over 350,000 developers worldwide – and let’s create a future where anything’s possible.

Learn more

Be the first to know

Get the latest curated news on haptics, tracking, and next-generation interfaces – straight to your inbox.

By signing up, you are agreeing to our privacy policy.

Product

- Ultraleap Stereo IR 170

- Leap Motion Controller

- Leap Motion VR Developer Mount

- Ultrahaptics STRATOS Explore

- Ultrahaptics STRATOS Inspire

Company

- About

- Careers | Work at Ultraleap

- Academic

- News

- Press

- Legal

Ultraleap

- logo_instagram_glyph-iconinstagram

- logo_youtube_192px_clryoutube

Contact us

- Privacy Policy

04/16/2021

Content

-

- What is 3D scan and why it is used by

- How 3D scanner

- 3D scan technologies

- Methods 3D

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners according to the principle of use

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

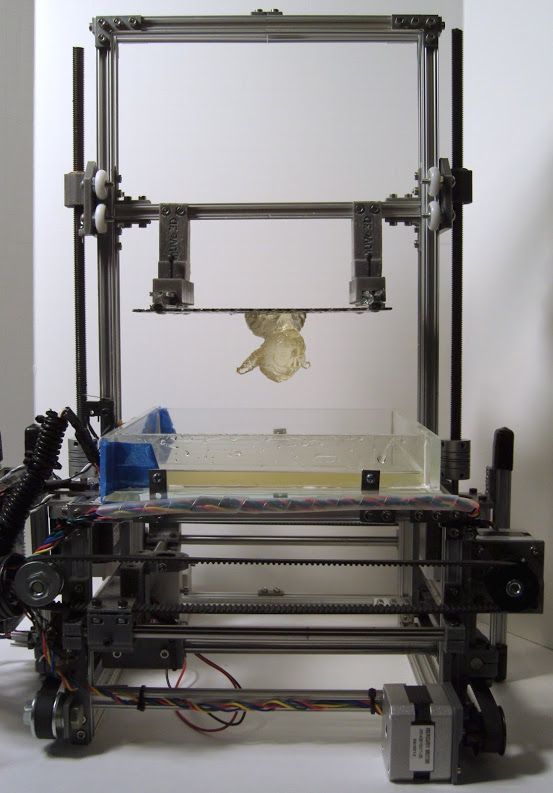

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more.

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers.

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

How a 3D scanner works

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos.

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object.

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object.

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details.

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and light-transmitting surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable.

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype.

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting.

They are similar in principle to a video camera and may require the use of additional devices for better lighting.

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image.

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

-

Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices.

-

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected.

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams.

Among other things, its undoubted advantage is its low weight, only 900 grams.

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages.

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes.

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required.

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment.

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

What to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner.

This is one of the most important features. It needs to be targeted first.

This is one of the most important features. It needs to be targeted first. -

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session.

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.).

-

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself.

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

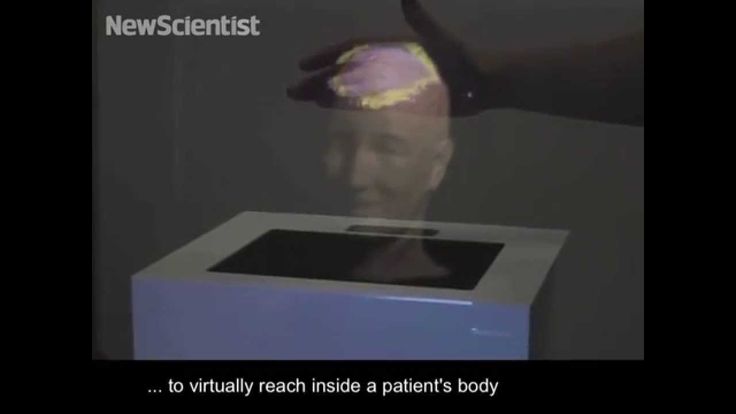

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable.

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning.

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

3D scanning of a person with Peel 3D budget scanner

Powerful tool for high-quality digitization of the human body

Order test scan

- Branches

- Scanning step by step

- 3D model examples

- Hardware and software

- Where to buy?

3D human scan with peel 3D scanner

- Fast and accurate acquisition of individual body images in color, taking into account all the features of the figure and clothing texture

- Efficiently create 3D models of a full-length human or a separate body part for implants in medicine, fashion design, entertainment, fashion, and 3D printing of souvenirs and advertising layouts

- Refinement of the 3D model in the embedded software, easy removal / addition of individual elements for further printing of the object

If you need to perform a human scan, you can order it from our specialists.

Applications

Medicine

- creation of individual prostheses, orthoses, surgical templates, implants

- visualization and modeling of the result of transplantation, prosthetics and plastic surgery

Souvenirs

- 3D printed figurines of real people

- manufacture of personalized accessories and jewelery

- digitization of mini-copies of real objects, sculptures, busts

Entertainment, fashion

- creation of digital models of real people for computer games and other programs

- 3D clothing modeling, sizing improvement

- use of 3D models for trying on clothes on sites

Project examples

Scanning the human body

Human body (whole)

Man in winter clothes

Saint Alphonse Liguori

More cases in different industries

Test the scanner for free and see how it performs for your needs Test scan

Body Scan Guidelines

Do you want to test the 3D scanner?

Order a scan in our office or make an appointment

for an online demo.

3D Human Scanning Solutions

3D scanner peel 3d Scanning a person is fast, easy and safe!

The compact peel 2, peel 2 CAD, Go!SCAN 20 scanners are professional solutions for digitizing objects up to 3 m with an accuracy of 0.1 mm and the ability to capture texture and color.

Go to catalog

Software Unleash your creativity with this powerful 3D modeling software!

The peel 3d software product allows you to solve all the main tasks when processing scanned data.

Go to catalog

Why order

solutions from iQB Technologies

Exclusive distributor of peel 3d in Russia

Professional

3D scanners at the price of budget counterparts

Free test

3D scan of your part

Demo hall in Moscow: more than 10 scanners and 3D printers

Services for the implementation, maintenance and repair of 3D equipment

Training in the use of 3D scanners in prof. activities

activities

3D scanning services based on our own fleet of equipment

About

Rules for 3D human scanning

For the greatest similarity of the resulting 3D copy with the original object and the successful implementation of the process of digitizing a human figure, several important rules must be observed.

By adhering to these recommendations, you can always achieve the highest quality and realistic results. Order a peel 3d scanner from iQB Technologies and you will be able to make a high-precision 3D model of yourself or any other person, and then print it using 3D printing.

All scanner models are in stock in our warehouse.

- Scan each body part once, especially when scanning a human face. If you scan the face several times in a row, the program will recreate the model as something in between all the received 3D scans.

As a result, you will get an option that is completely different from the original face of the person being scanned.

As a result, you will get an option that is completely different from the original face of the person being scanned. - In the process of work, the person being scanned must absolutely not move - otherwise, any movement, whether it be tilting, turning the head or stepping from foot to foot, can lead to image deformation. It is advisable to freeze in one position for a while and remain motionless until the very end of the procedure.

- If you want to create a figurine using 3D scanning, then you do not need to use additional light. To get a high-quality 3D figurine, LED flashes are enough.

- When using a turntable, its speed must be made as slow as possible. Thus, a 3D scan of a person will be much more accurate, and difficult places such as palms or ears will be much easier to scan.

The process of scanning a person with a 3D scanner

If you need to scan a person, you can order a scan of any part of the body from us at a bargain price.

The process of 3D scanning and modeling in software generally takes from 10 minutes to several hours.

The obtained data of 3D scanning of the human body is processed in specialized software: errors are corrected, problem areas are eliminated. The finished 3D model with an accurate texture and a clear rendering of the smallest details, if necessary, is sent for 3D printing. At the same time, a high-precision copy of a person can be obtained on a 3D printer, which in the future can become a memorable gift or souvenir. It is possible to scan with the transfer of the color of the object.

Also, the finished model can be used to create individual products that are ideally suited to the human figure.

It should be mentioned that 3D human scanning is completely safe, painless and does not harm the human body.

Scanner options

3D scanners for scanning a person are divided into:

-

Optical:

Optical 3D scanning technology uses a lamp flash designed to take measurements with the highest accuracy.

Projection distortions of the object are recorded by the scanner's video cameras, thereby allowing to determine the shape and dimensions of the scanned object, and then transferred to a specialized PC program for further processing.

Projection distortions of the object are recorded by the scanner's video cameras, thereby allowing to determine the shape and dimensions of the scanned object, and then transferred to a specialized PC program for further processing. Optical 3D scanners are fast, allowing you to scan people even in motion and in full growth.

Scanning a person with a 3D scanner using this technology takes from two minutes when using a special cell and up to 20 minutes when using a handheld scanner.

Most optical handheld devices are capable of color scanning and texture reproduction of the original model and various details, including jewelry and clothing.

-

Laser:

Traditional laser scanners, as a rule, are developed for the tasks of metrological measurements, and therefore require special reflective marks to be fixed on or near the object, the position of which is read by the device for precise positioning.

Learn more