3D printed car accessories

🚗 Best STL files 3D printed for cars・Cults

🚗 Best STL files 3D printed for cars

Download 3D files of accessories for your car

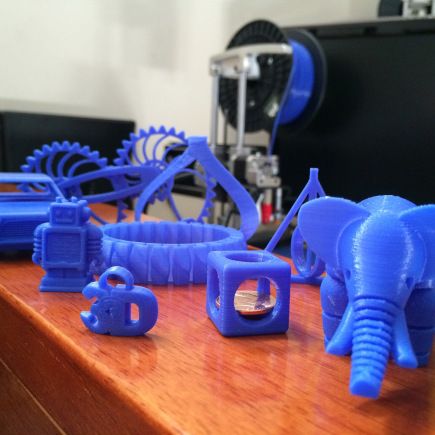

Discover our selection of 3D printable STL models to repair or improve many small parts and details of your car. So you can make your car more efficient, useful or pretty, just plug in the 3D printer and print these great creations downloadable in STL.

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?!

Free

iphone 5/5S/SE car holder

Free

Phone Mount for Car Vent

Free

Universal Phone Car Mount

Free

Simple Ice Scraper

Free

Car phone holder

Free

Mobile Car Holder

Free

Cup holder for car headrest

Free

Brompton logo tap

Free

Car phone holder (IPHONE 5)

Free

replacement car window crank

Free

Embellecedor llanta de automobil

Free

Headrest Mount for iPad Holder

Free

Renault Senic 4 - S4 phone holder with protection

Free

Tablet holder for car

Free

Support smartphone S5 pour mercedes classe B

Free

Renault Clio 4 - phone carrier shell with S4

Free

Gear knob Gear lever

Free

Smaller simple car phone holder

Free

Smaller simple car phone holder

Free

Gear knob Golf 5

Free

Car Cup Holder iPhone 7/8 Dock

Free

Remote buttons, Peugeot 107 fit also toyota aygo and citroen C1

Free

Blocko Brick Stud Center Wheel Cap

Free

Renault clip mat / clip for floor mats

Free

universal antitheft bolt cover peugeot

Free

Peugeot 205 Key

Free

Audi A5 Fuel Gas Tank Cap Cover Rubber

Free

Mate 20 Pro stand for Renault and Dasia cars

Free

Mustang 2.

Free

DIY Car Radio replacement 2

Free

Colorado Seat-back Hanger

Free

Recycled Gift Card Scraper

Free

Car phone holder (HUAWEI P8 2017)

€1

Safety belt block for babies, children or disabled persons

Free

Coin Holder for Norwegian Kroner (NOK)

Free

E-Tool (Car Emergency Tool)

Free

Mokka DIY - Central Air Vents Phone Support - iPhone 7

Free

Mokka DIY - Central Air Vents Phone Support - iPhone 7

Free

Audi Dope Centercap

Free

Car Alfa Romeo 159 - gear knob

Free

Peugeot 307 Can and bottle holder

Free

hood / bonnet Rod holder Renault clio 2 II fase 2 II

€0. 50

50

BMW E30 Cup Holder

€2.50

DIY Car radio replacement

Free

DOOR GOBLETS

Free

remote key button peugeot 307

Free

Dodge Wheel Center Cap

Free

CİTROEN C5 BARDAKLIK ( CUP HOLDERS) DESIGN IS RENEWED

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?!

Smartphone holder for Peugeot 308

Car phone holder (HUAWEI P8 2017)

Here is our selection of the best STL files to repair or improve your car, all these accessories come from the 3D file site Cults and are perfectly printable in 3D.

This collection contains free 3D files** of accessories for your vehicle. There is everything to make your car even more practical, beautiful and pleasant during your trips. For example, you can find excellent support for smartphone (iPhone, Android, Samsung) or for your GPS so that you can consult it while keeping your hands free. There is also something to improve the look of your car with gear levers, front grille logo, 3D printed car tuning elements**.

There is everything to make your car even more practical, beautiful and pleasant during your trips. For example, you can find excellent support for smartphone (iPhone, Android, Samsung) or for your GPS so that you can consult it while keeping your hands free. There is also something to improve the look of your car with gear levers, front grille logo, 3D printed car tuning elements**.

The 3D designers who offer their creations on the 3D file download platform Cults have also vied with each other in ingenuity to come up with little tricks to make your interior more usable for both you and your passengers. There are, for example, improved pocket dividers, cup holders or even screen mounts in the back of your seat.

There are also spare parts of all kinds to repair small broken plastic parts in your car. This is for example a tyre valve, a door handle or a piece of a rear-view mirror. For fans of vintage cars, the 3D printing makes it possible to repair vintage cars, because many parts that are no longer available can be made with a 3D printer.

3d Printed Car Parts - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

3D auto printer - perspectives of 3D technologies in the automotive industry

3D auto printer

The phrase "car is not a luxury, but a vehicle" may soon become a reality for almost everyone. All this thanks to the development of 3D technologies and 3D printing. In order to become the owner of a new car, it will be enough to press a few buttons on your 3D printer.

All this thanks to the development of 3D technologies and 3D printing. In order to become the owner of a new car, it will be enough to press a few buttons on your 3D printer.

Many large automotive companies are already using 3D printing technology in the production of modern cars. Increasingly, there is information about the release of cars printed on a 3D printer. The technology of 3D printing of cars has very broad prospects. Such major automotive companies as Local Motors, Peugeut, Audi, Ford and Chevrolet have already presented their cars printed on 3D printers to the world. nine0004

Auto 3D Printer

Local Motors is planning to produce a range of cars in the near future, created using direct digital manufacturing (DDM), part of which is 3D printing.

3D car printer

And China has developed 3D printing of a car from a cheap composite material. This material is as strong as metal, but much lighter. According to experts, the main advantage of 3D printing of cars is that each client will be able to create his own car. nine0004

nine0004

Car makers want to refute the notion that 3D printing is too slow and too expensive for mass production. But while 3D printing of cars is still in its infancy, the opportunity to buy or print auto parts is much closer.

Auto 3D printer

Very soon it will be possible to buy auto parts for BMW, Ford, Audi and other car brands created using 3D printing technology. 3D technology will enable automakers and ordinary car enthusiasts to update their cars faster and cheaper. If you wish, you can print and replace a broken or worn part of your car yourself. Or just use a 3D printed part to make your car more creative. nine0004

Auto 3D printer

Automotive analysts predict that 3D printing will revolutionize the automotive industry. Perhaps very soon everyone will be able to easily print at home a copy of their favorite car, which they had only dreamed of before.

3D printer auto

Don't be afraid to dream, make your dreams come true! And our online store will help you with this. Here you will find a large selection of 3D printers, 3D pens, 3D scanners, spare parts, accessories and consumables for 3D printing. Our staff will help you decide on the choice of a 3D printer, as well as advise on any issue of interest to you. But if you are not ready to buy a 3D printer yet, you can order 3D printing from us. Contact us, we will be glad to cooperate! nine0004

Here you will find a large selection of 3D printers, 3D pens, 3D scanners, spare parts, accessories and consumables for 3D printing. Our staff will help you decide on the choice of a 3D printer, as well as advise on any issue of interest to you. But if you are not ready to buy a 3D printer yet, you can order 3D printing from us. Contact us, we will be glad to cooperate! nine0004

Auto 3D printer

Back to main page Some production steps or tasks often have to be outsourced. Customization processes can take weeks or sometimes months, resulting in significant production costs. And the desire of many customers to produce ever more individual and personalized products poses additional challenges for car manufacturers. 3D printing helps solve many problems. nine0004

Customization processes can take weeks or sometimes months, resulting in significant production costs. And the desire of many customers to produce ever more individual and personalized products poses additional challenges for car manufacturers. 3D printing helps solve many problems. nine0004

Faster, cheaper, more creative

Creating unique products is never an easy task. Businesses must create new designs and high-quality parts that set them apart from the competition, while balancing the costs of design, testing, and custom-made products.

Ringbrothers creates award-winning custom cars and a line of high quality, unique accessories. The Ring brothers have introduced 3D printing into their production for both prototyping and final parts. So with the help of 3D printing, a prototype door handle was created for the redesign of the Chevrolet 19 car.71 years for its subsequent manufacture. It was printed with a special fast printing resin, DraftResin, so the whole process didn't take long. And to mount the mechanism inside the rear-view mirrors, they simply printed the desired mount on the printer. If the mount were made in a standard way, then the costs would be enormous.

And to mount the mechanism inside the rear-view mirrors, they simply printed the desired mount on the printer. If the mount were made in a standard way, then the costs would be enormous.

The main benefit of 3D printing is the space for experimentation and design improvement. All you need is any 3D modeling software based on your specific preferences. 3D printing speeds up the process between iterations - just a couple of mouse clicks and the design is adjusted. Prototypes printed on a printer are several times cheaper than those produced in a standard way, and rapid iteration leads to a faster time to market for the finished product. nine0004

3 D Printing is the engine of the automotive industry

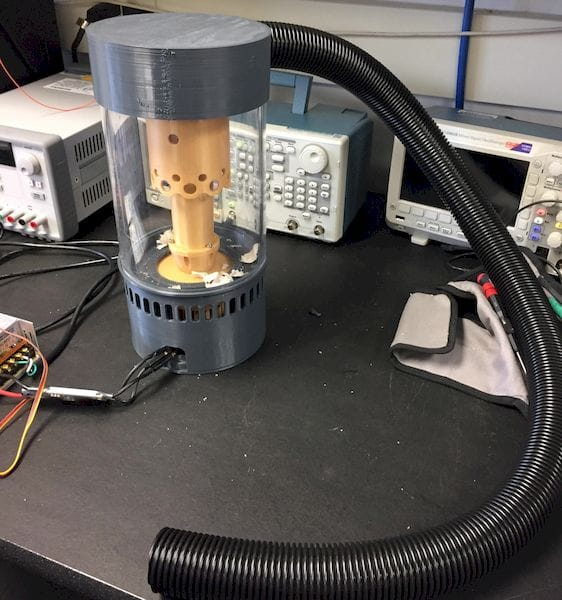

Major companies are already actively using 3D printing in manufacturing, as is one of Germany's most innovative companies, Brose. This company is one of the largest Tier 1 family car suppliers, working with 80 car brands, over 40 suppliers and 50 motorcycle manufacturers. Every second new car worldwide is equipped with at least one Brose product, including various mechatronic components and systems. nine0004

Every second new car worldwide is equipped with at least one Brose product, including various mechatronic components and systems. nine0004

The company started introducing 3D printing 10 years ago. Brose's printer fleet is now equipped with a variety of SLS printing systems, from small desktop machines to the largest traditional industrial printers. They recently purchased a Formlabs floorstanding printer to expand their capabilities. The use of an SLS printer allowed them to achieve amazing part accuracy, they were able to print hundreds of parts with minimal post-processing, and as a result, parts printed on this printer were more affordable than similar ones printed on large machines. The company used the printer to produce smaller parts for car door interiors, opening and closing mechanisms, which must be rigid and resistant to stress, as a large number of parts can fit in one print run. The printer proved to be very easy to operate compared to the large industrial machines that Brose uses to print already large parts. nine0004

nine0004

Saving money, not quality

Metal 3D printers are now popular, but for the most part they remain expensive, exotic, and extremely complex. However, resin 3D printers can sometimes do a much better job of producing metal parts. One of the easiest and highest quality ways to get metal parts out of a polymer 3D printer is electroplating (an electrochemical process in which metal ions are deposited in a thin layer on the surface of a part), an approach that our partners Volkswagen and Autodesk used to create a beautiful set of tire covers . The hubcaps were printed on a Formlabs SLA desktop 3D printer and then electroplated with a 0.004" thick nickel layer. The production of such a part in a standard way or on a metal printer would cost the company several times more. In addition, galvanized surfaces significantly strengthen the base parts and increase the material's resistance to wear, UV and corrosion. nine0004

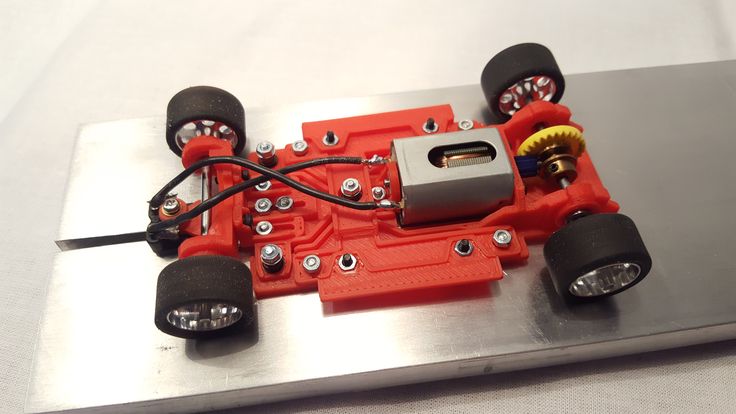

Investing in education

3D printers are increasingly being used in universities as well. For example, students at TUBerlin have printed injection molds for carbon fiber parts and printed over 30 final parts for a racing car. Universities often do not have expensive equipment in their arsenals, and in this case SLA printing was a one-stop solution. The presence of 3D printers in universities helps students develop creative thinking and provides indispensable experience in working with various materials. Formlabs, for example, has over 25 different plastic-like materials in its arsenal, allowing for a lot of experimentation and invention. nine0004

For example, students at TUBerlin have printed injection molds for carbon fiber parts and printed over 30 final parts for a racing car. Universities often do not have expensive equipment in their arsenals, and in this case SLA printing was a one-stop solution. The presence of 3D printers in universities helps students develop creative thinking and provides indispensable experience in working with various materials. Formlabs, for example, has over 25 different plastic-like materials in its arsenal, allowing for a lot of experimentation and invention. nine0004

Custom parts made easy

Automotive manufacturers and OEMs use a wide range of custom tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs. Some of them are now printable. This is how in-house printing helped Pankl Racing Systems, which specializes in the design and manufacture of engine and transmission components for racing cars, performance vehicles and aerospace, reduce production by weeks. nine0004

nine0004

They printed custom parts for the production line instead of ordering them from a supplier and waiting weeks for an order. For example, special clamps for the production of motorcycle equipment or special grippers for transferring a part from one machine to another. The parts turned out to be even more resistant to stress and friction than the originals, so the company basically replaced some of the tooling for the production line with 3D-printed products. nine0004

Spare parts are no longer a problem

3D printing also helps to partially solve the problem with the availability of spare parts for cars and their production. Vehicles are made up of thousands of parts, from tiny sensors to large body components. For many car companies, spare parts have historically been a problem. Demand for them is inherently unpredictable, so the cost of producing spare parts is sometimes a contentious financial decision. nine0004

Now a 3D printer only needs a scan of the desired part and access to various materials.