3D printer for clay

3D Potter - Real Clay 3D Ceramic Printers

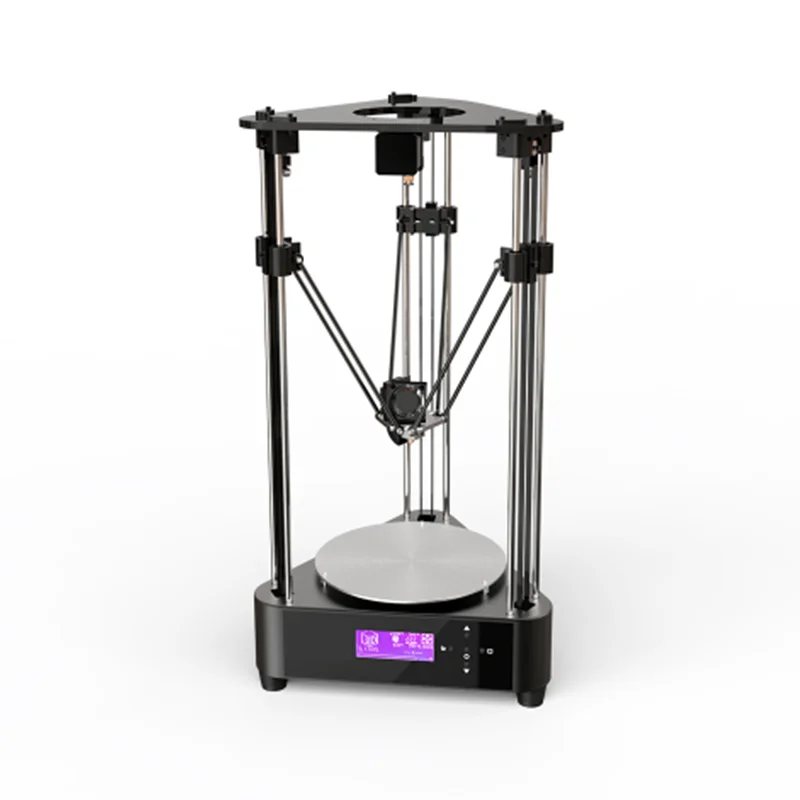

Our line of 3D Clay printers have some unique features when compared to other 3D printers. We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.

3D Printing Cement is here! We have combined our Scara Elite and Small 50 pump with Sikacrete® 3D printer cement developed by Sika USA. This is a versatile and convenient way of printing large-scale architecture and structures.

The Scara Elite is the first viable large-scale ceramic 3D printer using 3D printing material. It is capable of printing multiple objects non-stop. The Elite with the Small 50 can pump up to 3.5 gallons of material per minute through 85 feet of 1″ hose.

They work together so well, we decided to make them a package.

The possibilities are endless!

PR Articles/Videos

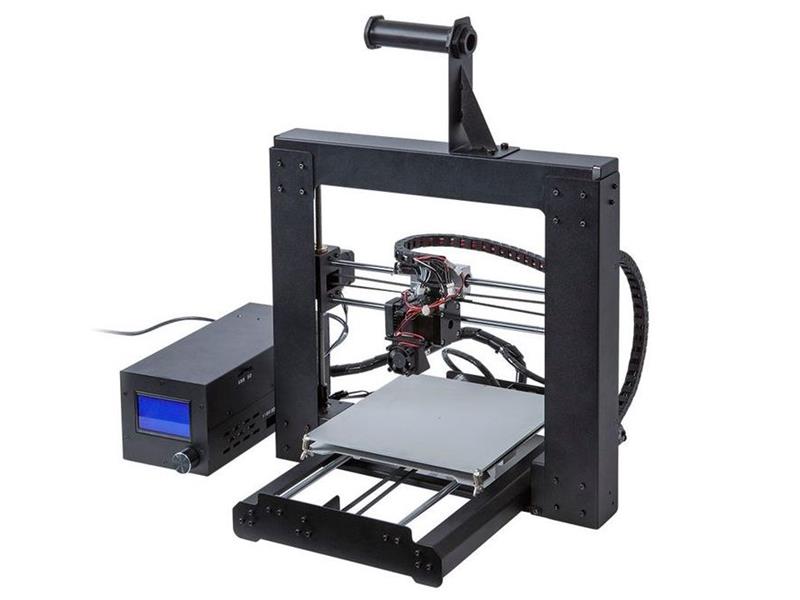

Great entry-level printer

More info

10 Proreliable and accurate

More info

Full size, Full control

More info

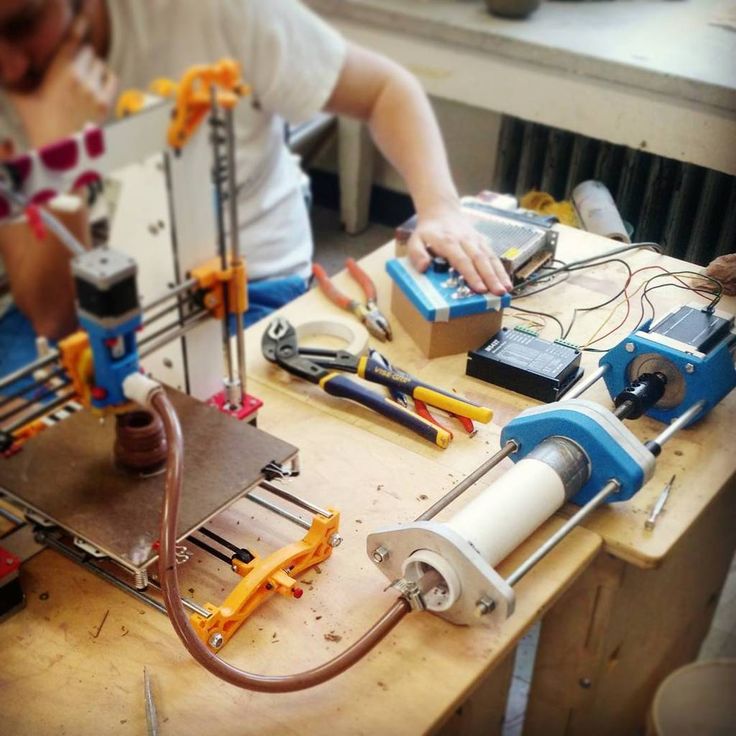

View this post on Instagram

A post shared by Hybrid Objects (@hybrid.obj) featuring non-planar printing.

View this post on Instagram

A post shared by Arina Erdélyi (@arinaerdeyli) featuring a print taken to new heights.

View this post on Instagram

A post shared by Atlas of Lost Finds (@atlas_of_lost_finds) featuring large-scale printing.

See More

3D Potter is proud to offer assembly tutorials and troubleshooting videos for our printers. Our printers can be used with Potterware, a beginner-friendly program to design pots and vases of all shapes, sizes, and patterns.Check out our Youtube channels to see our videos!Assembly Videos

Main Channel

3D Potter accepts payment of Bitcoin (BTC) for our products. If you wish to pay by BTC, please contact us.bitcoincash:qr5wmqhnylzr0hcewfrla852xxy9zhp94uugrxy9ay

Here at 3D Potter, we like forward-thinking and preserving the environment. Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles.

Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles. https://www.tesla.com/referral/dan47410

3D Potterbot Scara V4 Ceramic 3D Clay Printer — Real Clay 3D Ceramic Printer

The Scara V4 is the first viable large-scale ceramic 3D printer using real clay. The advanced design and substantial construction can take on board loads like the 3D Potter 4000ml clay extruder.

What's included:1. Scara v4

2. Closed loop stepper on X, Y, Z, extruder

3. Extruder size of your choice.

4. 5 anodized aluminum nozzles (standard sizes: 3, 4, 5, 6, and 8mm when extruder is purchased)

5. Parts Box: Alan key set, grease, Acme driver tool, tie wraps, extra screws

6. Power Supply

Power Supply

Printing Envelope:

X/Y- 72" Diameter Circle (1829mm)

Z- 45” (1143mm)

Minimum Printing Envelope:

X/Y- 22" Diameter Circle (558mm)

Printer size:

W-34” L-18” H-44”

Normal operational space needed: W-40” L-36” H-~70”

Maximum operational space needed: W-88” L-88” H-~84”

Height to the top of the extruder fully extended is H~84” (2134mm)

Weight with extruder: 90 lbs. (41kg)

Average speed: 1.2’’ to 3.9’’/s (30 to 100 mm/s)

Power Supply: Output - 24V ~15 amps, Input - 110-220V, 50-60 Hertz.

Power consumption: 24V ~8 amps, ~192 Watt

Main controller board running Duet3D with Atmel SAM4E8E: 120MHz ARM Cortex-M4

Full control through web interface, no apps or software installation. Non-WiFi versions are available, please contact us if you would like this type of connection (Ethernet connection).

* http://www.igus.com

Some components may be re-manufactured

** https://en. wikipedia.org/wiki/Harmonic_drive

wikipedia.org/wiki/Harmonic_drive

Duet Web Control is a fully developed UI for the Scara. Opened in a web browser, it can be used on your laptop, tablet, phone, or other WiFi capable device.

Print StatusOnce a print is started, it shows information about the model being printed. Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

G-Code FilesThe G-Code Files page allows g-code files for printing to be uploaded, edited, or downloaded. A summary of the file is given such as size, layer height, and what the file was generated by.

Software requirementsNone! The only requirements is a web browser interface.

For object generation, the Scara V4 is similar to the rest of the 3D Potter line ceramic printers. It's is just like any other 3D printer which requires an STL file to be sliced by a third-party program. We recommend Simplify3D or Cura, and then loading the file to the SD card in the printer, which can be done over WiFi.

Build envelope

The build envelope diagrams represent the 45 in Z height. We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

The Scara V4 build envelope is quite unique because it's capable of printing 360 degrees with continuous rotation. This means you can create a huge vessel with the printer initially residing inside the vessel or structure. This opens up a whole another opportunity to print small habitat structures (houses). Larger printers are available for this potential habitat project.

Another unique ability is printing multiple objects within the specified envelope in a sequential mode. For instance you could print a particular vessel starting on the far left side and continue to print these vessels until there is no more space left.

The Scara V4 is capable of extreme speeds however speed is relative when it comes to ceramic 3D printing. Realistically you probably don't want to exceed 130 mm/s. There are many factors which determine the speed like nozzle size, layer height, and achieving a good adhesion on interlayer of the clay.

The Scara V4 is very quiet, so it can be operated in any area without disturbing the surrounding environment.

Construction and designWe were able to achieve high precision and accuracy with this large Scara arm robot only through diligent design and robust construction techniques. The majority of this structure is out of heavy aircraft grade 6061 aluminum utilizing CNC and welded components for maximum strength and rigidity. The main rail components are from IGUS* which is one of the leading German manufacturers of precision guide rails. The drive motors consist of very sophisticated hybrid closed-loop stepper motors. These have on-board computers with telemetry that continually update their position for zero error positioning.

These have on-board computers with telemetry that continually update their position for zero error positioning.

This is no souped-up 3D printer, this is a dedicated heavy duty purpose-built robot. The main drives are sophisticated harmonic drive units**. These are the same drives used on large industrial robots similar to the ones that are now in most of the large manufacturing facilities. These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

Space needed for setupThe real advantage is this machine can be positioned on a substantial table top and you can start printing right away within a limited envelope area. Or you can give it its own dedicated space for partial or full envelope.

The space needed is really determined by the end-user and how much of the print envelope they choose to use. Whether on the table top or on the floor, the Scara V4 will require direct mounting for maximum stability. This is achieved with multiple screws to secure the printer to the surface it is on. If you choose to use a tabletop it must be of substantial construction, the minimum is 1.5" thick heavy plywood or wood construction. If a inadequate table is used, the results from the printer will be diminished depending on the build envelope and speed at which the prints are created with.

Whether on the table top or on the floor, the Scara V4 will require direct mounting for maximum stability. This is achieved with multiple screws to secure the printer to the surface it is on. If you choose to use a tabletop it must be of substantial construction, the minimum is 1.5" thick heavy plywood or wood construction. If a inadequate table is used, the results from the printer will be diminished depending on the build envelope and speed at which the prints are created with.

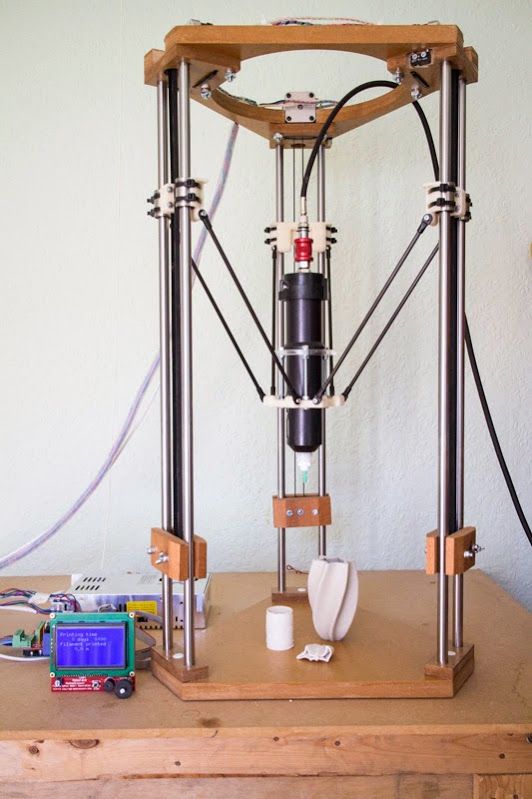

Clay 3D printer Most likely, you will think about plastic. Someone might have heard about metal powders, gypsum, wax... It was a discovery for me that clay can be used for 3D printing.

1487 views

In fact, this is not a new invention, more than one company is engaged in the production of 3D printers for printing from clay. Here I want to talk about the Cerambot Eazao printer from Cerambot. I found this project on the Kickstarter crowdfunding platform.

Retrieved from https://www. kickstarter.com/

kickstarter.com/

Why clay?

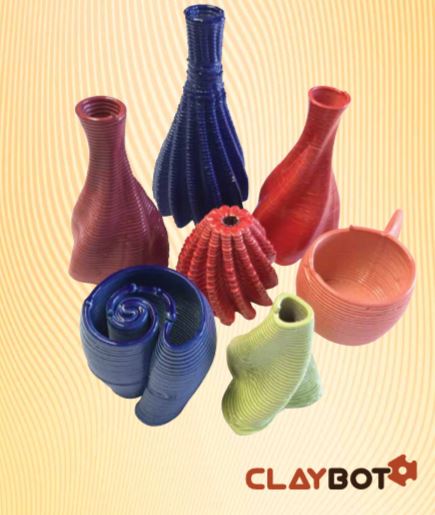

Clay is an environmentally friendly, accessible and cheap material. Sculptures, pots, dishes are made from it. Unlike plastic, clay does not pollute the environment and is safe for health. Clay products are easy to recycle and reuse, just soak the product in water.

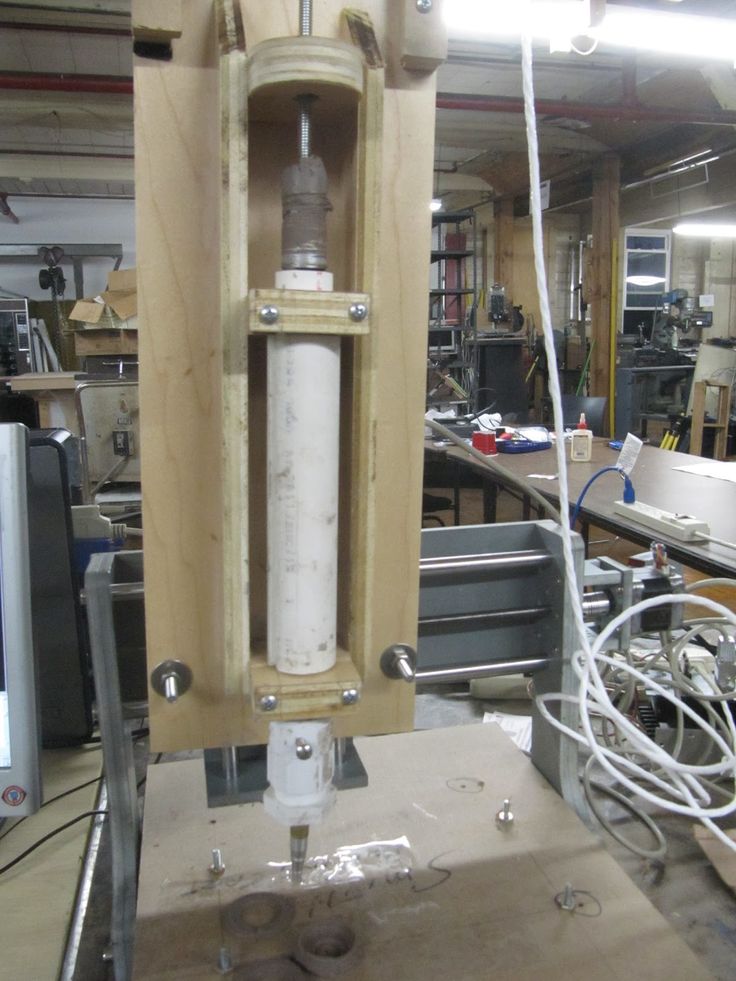

In order for the printed product to be of good quality, it is important to achieve the correct consistency when kneading the clay. Clay should be elastic, not too hard and not too soft. It should not stick to your hands and crack when squeezed.

Source https://cute4home.ru

About the printer

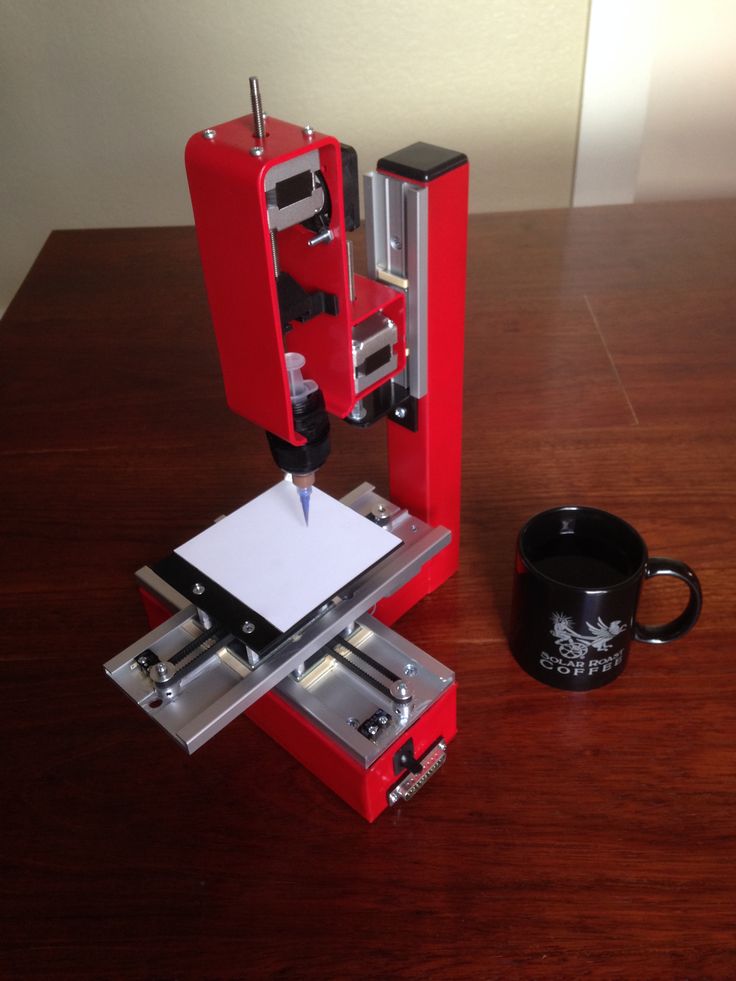

Cerambot Eazao is designed for home use. It comes pre-assembled, so it's ready to go right out of the box. All you need to do is fill the cartridge with clay and start printing.

Retrieved from https://www.kickstarter.com/

The maximum printing speed of Cerambot Eazao is 40 mm/s. The thickness of the layers is set by different nozzles and varies from 0.8 to 2 mm. After printing, the clay remains soft and pliable for some time, so you can correct the shape of the product and eliminate imperfections.

The thickness of the layers is set by different nozzles and varies from 0.8 to 2 mm. After printing, the clay remains soft and pliable for some time, so you can correct the shape of the product and eliminate imperfections.

This is the second model of a 3D printer from Cerambot. The first project raised $286,000 on Kickstarter from 1,000 sponsors.

In the second model, the developers took into account the wishes of users, improved their product and added a clay kiln to the kit.

The furnace allows you to fire products at high temperatures at home without the use of specialized furnaces. It consists of a heat-resistant heat-insulating material - ceramic fiber and a high-temperature absorbing material - silicon carbide. Inside there is a cavity for the finished product.

Retrieved from https://www.eazao.com

Kiln principle

The firing process takes 35 minutes. It is necessary to place the oven with the product inside in a household microwave oven with a power of 1500 W and turn it on at maximum power.

Microwaves penetrate alumina and silica ceramic fiber. Silicon carbide absorbs microwaves and converts them into heat. The temperature in the cavity of the furnace, where the product is located, rises. Since silicon carbide is insulated and resistant to high temperatures, the temperature continues to rise and reaches the firing temperature of handmade ceramics.

After firing, wait until the oven has cooled down before removing the finished product.

Price

The price of the printer depends on the configuration. For one printer, manufacturers ask for $450, for a set with an oven - more than $500. In my opinion, this is a pretty high price for a home 3D printer. What do you think?

Other interesting Kickstarter finds:

First 3D printed clay house / Sudo Null IT News0001

Bright_Translate

RUVDS. com company blog Design Gadgets Popular science 3D printers Original author: Jenny Brewer

com company blog Design Gadgets Popular science 3D printers Original author: Jenny Brewer

Several printers printed this house from local soil in 200 hours. As a result, no waste and the need to deliver building materials.

Mario Cucinella Architects, together with Wasp, the leading Italian 3D printing company, have completed the first clay house. This process, called Tecla (technology and clay), is sustainable and does not harm the environment, since the production leaves no waste and does not require the delivery of materials to the construction site. It took several industrial printers just 200 hours to build this 60 square meter prototype in Ravenna, Italy.

In terms of design, the house is an organic cave-like form that looks like an ancient creation created by nature itself, looking at which you will never think that high technology is behind it. This is a natural feature of the "humanistic" architecture of Mario Cucinella, which arises at the intersection of the world of simplicity with the world of high-tech. "The aesthetics of this house was born as a result of technical and material efforts." - says Mario - "Moreover, the approach was based not only on aesthetics, but also contained the openness and sincerity of the form."

"The aesthetics of this house was born as a result of technical and material efforts." - says Mario - "Moreover, the approach was based not only on aesthetics, but also contained the openness and sincerity of the form."

The project began with a development that Cucinella and Wasp founder Massimo Moretti started with the School of Sustainability, an organization that is exploring the possibility of building sustainable homes with minimal environmental impact - that is, from local materials without having to ship them to building sites. The result is Tecla technology, which is a nearly zero-emission, low-carbon process. "Tecla shows that a beautiful, healthy and sustainable home can be built with a machine." Moretti adds.

The architect studied how the form of a building can affect its efficiency depending on the climate and geographic latitude, and also realized the composition of the material, taking into account insulation and ventilation. At the same time, the shape and external protrusions of the house additionally ensure its stability.