3D printer filament spool

Spool best 3D printer files・Cults

Side spool holder for Reprap Prism

Free

cardboard spool dissposable air filter

Free

Spacer 35mm for 608 bearing shafts

Free

Ender3 Direct Drive Spool Holder Bracket

Free

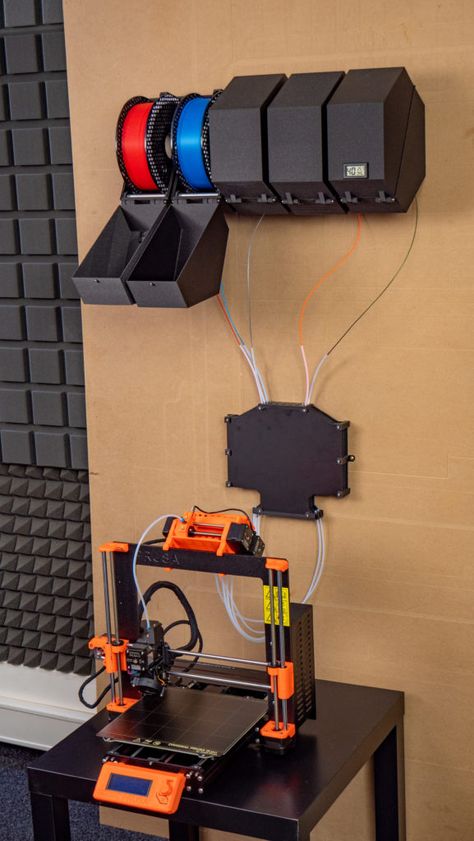

Prusa i3 MMU Retraction Management / Hanging Spool Holder

Free

T-slot spool holder

Free

Top Spool Mount, Anycubic Linear Kossel

Free

Spool Holder Free Standing

Free

Universal Spool Holder

Free

S-Hook Filament Hanger

Free

Spool Holder - Unwinder

€1

Filament Spool Keychain

Free

Filament Spool Wall Bracket

Free

PORTAROLLO ECOFILA

Free

Manual starter for generator (cord winding coil)

€2. 20

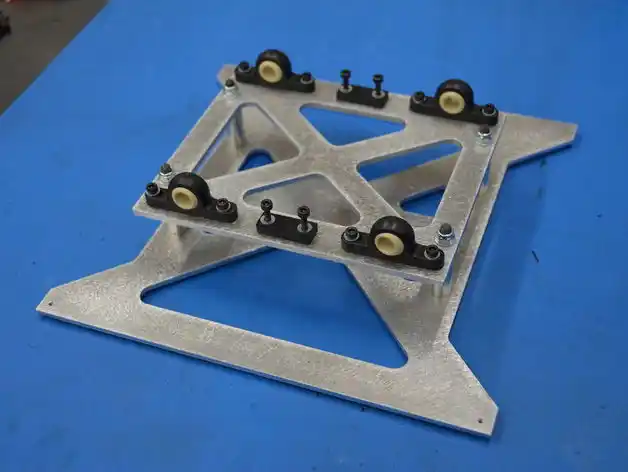

Filament spool holder (with bearings) for 20x20 T-slot

Free

Low friction spool holder

Free

Filament Spools

Free

Organizer, box, holder from Azure filament empty spool

€1

holder for trumpet mouthpieces

Free

Ender 3 spool holder ball bearing

€1.25 -25% €0.94

Ender 3 Top Mounted Spool Holder Replacement

Free

Filament spool holder/stand with 625 bearings

Free

Filament Spool Holder - Robust | Optional Side Bracket | 1KG/5KG

Free

TUSH for the Alfawise U20

Free

Ender 3 Pro spool holder adapter

Free

3/4 PVC pipe wall hanger

Free

Edison Ender 3 "Zen Set up Kit" v1

Free

Filament Spool Drawer

€3. -50% €1.75 50

50

Spool fidget

Free

Mini Spool

Free

Filament guide for floor, wall, or ceiling mounted spool

€1.41

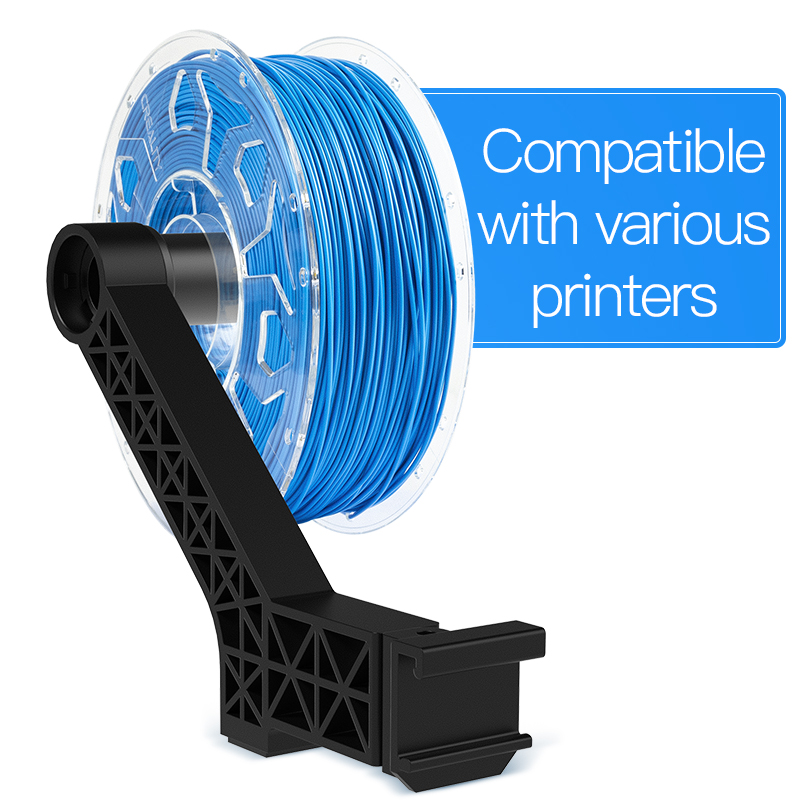

Befenybay Top Mount Spool holder 2020 frame

Free

Side Spool Mount Bambu X1 / X1C

€1.14

Fishing line spool

Free

Cable Spool Dispenser

€0.94

Cable Spool

Free

97_New Frictionless Spool Holder With Metal Shaft

Free

Support bobine vertical / Vertical spool holder

Free

Dual spool holder for Volumic 3D printer

Free

Filament Server System Mark II

Free

Filament Server System

Free

Filament Guide Single

Free

Filament Spool Scale

Free

Lulzbot Mini filament spool bushing w/ flange, 38mm spools

Free

Artillery Sidewinder X1 and X2 roll holder - Artillery Sidewinder X1 and X2 roll holder

Free

Mount anywhere spool holder

Free

5 Kg Spool Roller

Free

5KG PLA 3D Printer Filament

$89. 95 - $94.95

95 - $94.95

(78 reviews) Write a Review

5KG Texas Size Spool PLA 3D Printer Filament 1.75 mm 11 lbs

Rating Required Select Rating1 star (worst)2 stars3 stars (average)4 stars5 stars (best)

Name

Email Required

Review Subject Required

Comments Required

- PLA filament is an affordable 3D printing filament meant for every maker.

ZYLtech PLA filament is formulated to highlight the best attributes of the material, like reliability and ease to print. Each 5kg (11 lb) spool is perfect for bulk or long printing projects that require quality and dependable parts.

ZYLtech PLA filament is formulated to highlight the best attributes of the material, like reliability and ease to print. Each 5kg (11 lb) spool is perfect for bulk or long printing projects that require quality and dependable parts. - Tagged: 5kg Filament, 3D Printer Filament, PLA Filament,

- SKU:

- FMT-PLA-5KG

- Easy to Print?:

- Easy

- Description

- Full Specs

- Print Tips

- Why Choose ZYLtech?

- Warranty Information

Black/White/Gray/Silver/Panhandle Khaki PLA - 5 Kg Spool

Go Texas Size and Save!

Our 5kg Texas size spools will save you around 12% and improve cost effectiveness by about 50% compared with 5 individual spools!

Why ZYLtech PLA 5kg Rolls?

ZYLtech 5kg rolls are ideal for:

- Stress-free Long Prints

- No more worrying about running out of or having to change filament when you’re printing those large format or long print jobs!

- Perfect for bulk or continuous product manufacturing

- Ideal for continuous manufacturing, print farms.

- Waste Reduction

- Reduce Spool waste by over 25% with one 5kg spool vs five 1kg spools.

- Time Efficiency

- Time efficiency is key during production! No more changing out those 1kg spools!

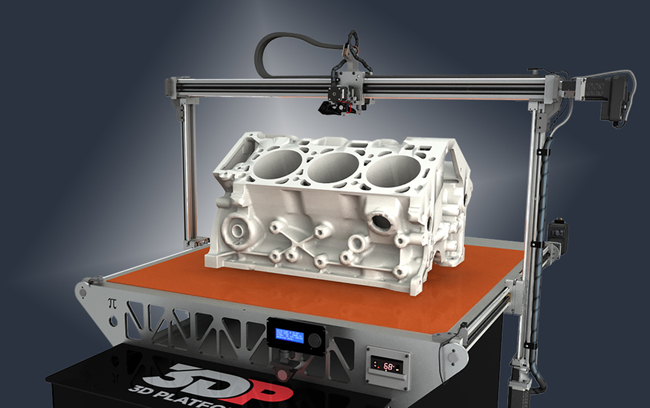

*Utilize our 5kg Spool Holder for smooth and controllable pull from your 5kg Spools.

Technical Specifications:

- Filament:

- Diameter: 1.75mm

- Tolerance: ±.05mm

- Density: 1.27 g/cm³

- Appx Length on Spool: 1,635 meters

- Spool Dimensions:

- Outer Dimension of Spool: 11.

5" x 6"

5" x 6" - Inner Hole Diameter: 32mm

- Recommended Temps:

- Print Temperature: 205±10°C

- Recommended Bed Temperature: Not needed, but if printer has heated bed, 40±15 °C

- Recommended Build Surface:

- PEI

- Microporous Coated Glass

- Painters Tape

- Glue Stick or Hairspray on Glass (use caution with adhesives as PLA may adhere very well)

Pro Tips from the ZYLtech Print Lab:

- Leveling for PLA filament:

- If you use the paper method to level, we usually suggest leveling as you would for PLA then setting a Z offset of +.5-1mm.

- PLA does not like to “squish.”

- First Layer Adherence:

- We have found that 0% fan for the first 2 layers gives the best chance to avoid curling/warping.

- Layer Adhesion:

- PLA 3d printer filament will adhere to itself more efficiently when printed with little to no parts cooling fan. If you are working with fine detail or bridging, you will have to experiment with parts cooling fan settings for best results.

- Stringing and retraction:

- You will typically need to increase the retraction distance and retraction speed vs printing with PLA. You will need to experiment with stringing and retraction test models to dial in your machine’s settings.

Why Choose ZYLtech?

- Affordable Quality

- ZYLtech strives to provide our customers with the highest quality 3d printer filament at the most affordable price.

- Fast US Based Shipping

- All of your products are packaged and shipped directly to you from our facility in Houston, Tx.

- Amazing In House Customer Support

- You'll experience great sales, customer service and technical support directly from our in house team. We truly care about our customers and appreciate each of you! We're here 5 days a week and are ready to help you any way we can!

- All of ZYLtech's products are supported by our friendly, in-house team based in Houston, Tx. If you ever have questions about products or need support on a project, the ZYLtech family is here to help!

- Single Source Manufacturing

- All of ZYLtech's 3d printer filament is sourced from a single manufacturing facility so you can expect consistency and reliability roll after roll.

All of our 3D printing filaments are backed by our 30 Day 100% Customer Satisfaction Guarantee. If you need to return an item, please Contact Us with your order number and details about the product you would like to return. We will respond quickly with instructions for how to return items from your order.

We will respond quickly with instructions for how to return items from your order.

78 Reviews Hide Reviews Show Reviews

- 5

5 kg Spool

Posted by Rick Welcher on Dec 13th 2022

Works great on the Kobra Max, took a few prints to get it dialed in. New spool holder is printed and is working just fine. Wife likes the color and said it looks fancy and not a "baby" spool. Printable spool holder available upon request to clear the Kobra gantry

- 5

My go to filament

Posted by Malachi on Nov 10th 2022

Have purchased this several times and will continue to purchase time and time again!

- 5

5kg kaki green

Posted by ron wells on Oct 21st 2022

It would be great if you would produce a 5 kg spool of marble filament PLA

- 5

5K Spool

Posted by Jared Choate on Sep 17th 2022

It’s a great deal.

Buy in bulk. Just beware this is massive. Your regular spool holders won’t work with this. You will need special accommodations. Definitely worth it though

Buy in bulk. Just beware this is massive. Your regular spool holders won’t work with this. You will need special accommodations. Definitely worth it though

- Related Products

- Customers Also Viewed

How to avoid wasting empty spools of thread

Author Kirill Sokolov Reading 8 min. 88 views Posted by

3D printing can be inherently waste-generating, but in recent years, 3D printing professionals have embraced more environmentally friendly methods. Through the use of biodegradable plastic and the recycling of waste prints to make a new filament, a concerted effort has been made to reduce solid waste from 3D printing. However, there is another type of waste that has yet to be completely eliminated - empty spools of thread. nine0005

nine0005

Disposal of empty spools of filament has been a constant problem in 3D printing. It's not unusual for a 3D printing firm to end up with hundreds of empty spools a month. What can we do to keep these coils out of the landfill?

Contents

- 1. Buy cardboard spools

- 2. 3D print your own spool

- 3. Make new filament with the

- filament extruder 4. Use them in various ways

- 5. Return them to the manufacturer

- Final Thoughts

1. Buy cardboard spools

An easy way to avoid To deal with plastic empty spools, you need to buy spools that are not made of plastic. Some brands offer this option, such as Proto-Pasta and SainSmart. Although the cardboard used in reels may not be fully biodegradable due to inks and wax coatings, most local cardboard recycling facilities should be able to accept and process cardboard reels. nine0005

Also there is the fact that the cardboard is made from sustainable sources. It may seem hypocritical if you are buying what is essentially a whole roll of filament made from unstable plastic. However, every little thing matters. Both of us can be held accountable for how we use our plastic filaments and for reducing solid waste from empty spools.

It may seem hypocritical if you are buying what is essentially a whole roll of filament made from unstable plastic. However, every little thing matters. Both of us can be held accountable for how we use our plastic filaments and for reducing solid waste from empty spools.

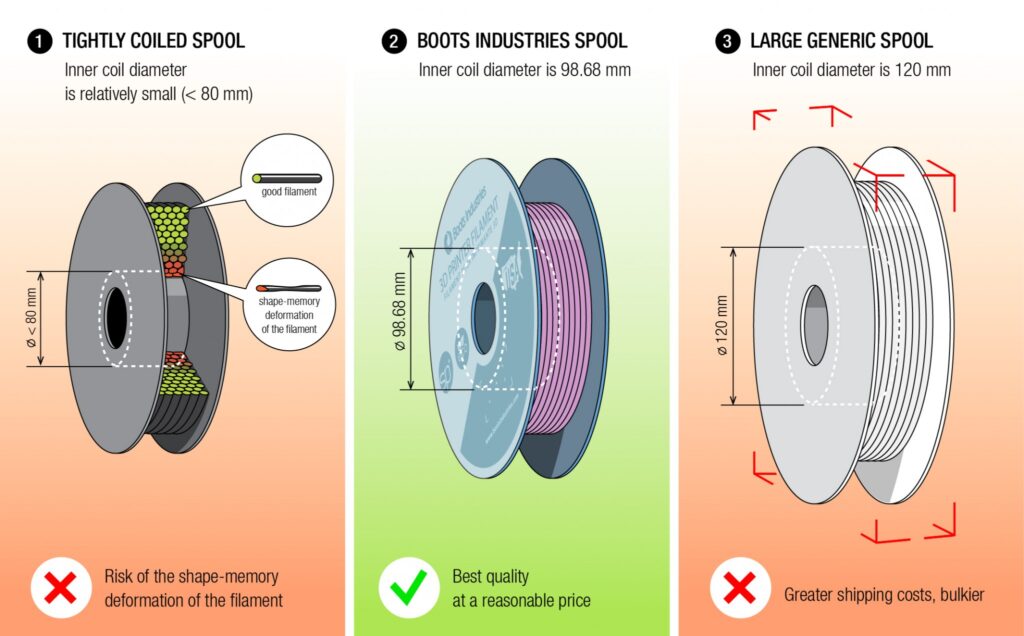

If cardboard reels are so good why aren't more brands using them? It all comes down to durability and customer preference. Even with the corrugated design of Proto-Pasta cardboard spools of filament, they are still much easier to deform than their plastic counterparts. Spool warping can be a major problem as it can prevent the spool from turning when mounted on a spool holder. nine0005

This is also a matter of consumer preference. Many customers feel left out when they receive a roll of filament on a cardboard spool. This is especially true of Proto-Pasta because the brand sells fibers that are a bit more expensive than usual.

Despite the lack of a unanimously positive customer reaction, using cardboard spools seems to be the best way to make 3D printing sustainable at the moment. With improvements in materials and construction, the use of cardboard spools may become the standard. nine0005

With improvements in materials and construction, the use of cardboard spools may become the standard. nine0005

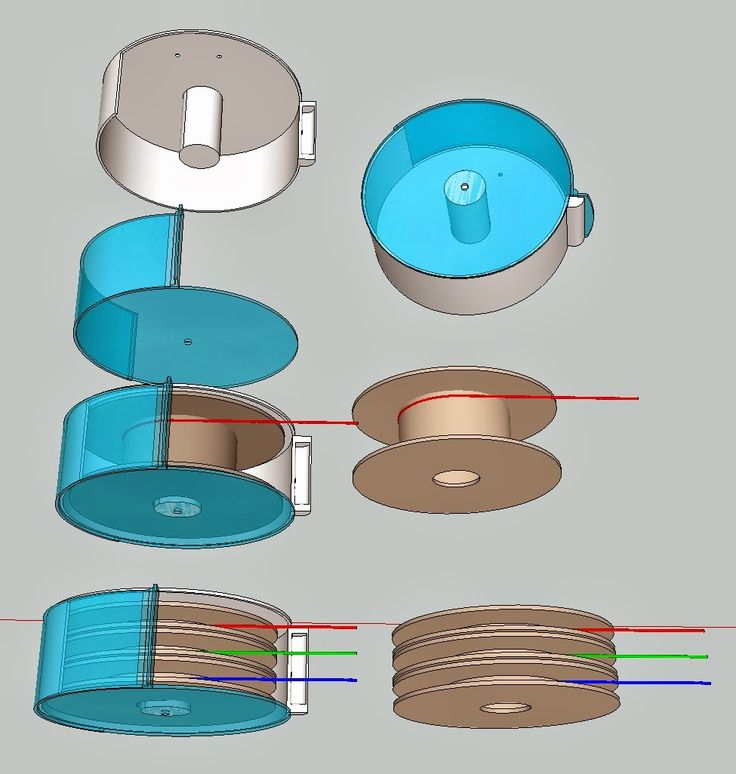

2. 3D print your own spool

Back in 2016, the Master Spool concept first gained popularity. The Master Spool can be 3D printed and opens up and can be used to load filament. The Master Spool design has gone through several iterations and updates over the years, but it is still a free download from Thingiverse. coils. This allows for reusable spools so that old spools no longer need to be thrown away. nine0005

In response to this movement, several brands (eg 3D Solutech and FilaCube) have begun selling their filaments in shapes compatible with the Master Spool design. If you're not going to 3D print your own main spool, there are also filaments that come with the main spool included, which you can then reuse for your next orders.

Although there are many of them. Despite the merits of the Master Spool idea, many users and manufacturers have not fully embraced the idea. 3D printer users who like to have a variety of filaments to choose from didn't want to print a new spool every time they had to order a new filament. This is especially true of people who are into 3D printing as a business, they would rather spend their time 3D printing products they sell than an endless supply of empty spools! nine0005

3D printer users who like to have a variety of filaments to choose from didn't want to print a new spool every time they had to order a new filament. This is especially true of people who are into 3D printing as a business, they would rather spend their time 3D printing products they sell than an endless supply of empty spools! nine0005

In theory, filaments without spools should not be sold. help manufacturers by reducing material and shipping costs. However, most people tend to overlook the fact that the filament manufacturing process needs to be revised to allow "no spool" filaments to be used. New winding equipment must be introduced, and the threads must be packed with ties. All of these additional costs dwarfed any savings made by not shipping fibers with plastic spools. nine0005

According to a survey conducted by the Filamentive brand, almost two-thirds of their customer base still prefers to buy plastic spool fibers. cardboard spools compared to using master spools. The inconvenience of printing your own spool and installing filament yourself probably plays a huge role in this user reaction.

3. Make new filament with a filament extruder

If you know what material an empty spool is made of, it should theoretically be possible to cut it into small pieces and make recycled filament from it with a filament extruder. This is only possible if the coil is made from a thermoplastic such as ABS. nine0005

Unfortunately, making thread from an empty spool is easier than doing it. It's not just a matter of cutting the coil into pieces, melting them and squeezing them out through a nozzle. Most filament fiber extruders are built using plastic pellets as raw material because they are more uniform in shape and weight. There is also the fact that empty spools of filaments can contain dyes, glues and other additives that make them difficult or impossible to recycle.

The idea is correct, but we haven't heard anyone demonstrate it. with success. This may be due to the fact that fiber extruders are not very common in the first place due to their cost and complexity.

coils for winding them.

4. Use them in many ways

If you're not a heavy 3D printer user, you probably won't have to deal with hundreds of empty spools. One or two empty spools a month isn't much of a problem with a little creativity. The good news is that there is no shortage of creative ways to use blank reels online. nine0005

If you have anything to wind up like electrical wires, ethernet cables, etc. Christmas lights - then you might even be glad to have empty spools of thread lying around. This is probably the least creative of these proposals, but the most reasonable one.

A project posted on Thingiverse uses an empty spool of thread as a desktop organizer. All you have to do is 3D print these curved boxes that fit perfectly into the blank space of the reel. The product looks great, although there may only be so many of these "reel boxes" that you can use. nine0005

Empty spools of thread have been used to make chandeliers, paint organizers, car remote control wheels, clocks, laptop stands, lamps and table fans. There aren't really any recommendations on what you can do with these coils - if you have any other ideas, we'd love to hear them!

There aren't really any recommendations on what you can do with these coils - if you have any other ideas, we'd love to hear them!

5. Return them to the manufacturer

Some companies that still sell fibers for plastic spools have instead created programs to allow customers to return empty spools. Recognizing that it takes some work on the part of the buyer to recognize these reels, they also encourage this behavior by offering incentives. nine0005

Filamentive spearheaded this movement back in 2017 when they offered a 20% discount on anyone who returns empty spools. The brand has since switched to using cardboard reels, so the program is no longer relevant. Another brand, Azure Film, supported this initiative and offered a free 1kg PETG spool to anyone who returns 10 empty spools of their 1kg filament.

You may have noticed that the major brands in the filament industry do not have these empty spool return programs. The truth is that such an initiative is very difficult to be economical. The company can lose a lot of money if they bear the cost of shipping empty spools. Naturally, they also cannot expect buyers to bear the shipping costs. nine0005

The company can lose a lot of money if they bear the cost of shipping empty spools. Naturally, they also cannot expect buyers to bear the shipping costs. nine0005

Unless the logistical hurdles are removed, we are unlikely to see the return of empty spools to manufacturers become standard practice.

Final Thoughts

As 3D printing continues to gain popularity, dealing with empty spools of filament will also become more of a problem. to do with empty spools of thread, appear every week. The creative use of spools of filament is great, but let's face it, you can only make so many desk organizers and lamps out of empty spools of thread before your home looks like a hideout in an apocalyptic wasteland. nine0005

Today, 3D printing is considered a niche manufacturing process or hobby. Without any attention from regulators, plastic waste generated from 3D printing has been neglected. This led to attempts at self-regulation. Indeed, attempts to use cardboard spools or design the Master Spool have been spearheaded either by filament manufacturers or individual 3D printing professionals.

More and more people are asking what they can do with an empty thread. coils, it is clear that the effort was not enough. To effectively manage plastic waste in 3D printing, an industry-wide standard is needed. Any meaningful change will require a concerted effort between filament manufacturers, 3D printer manufacturers, large 3D printing companies, and individual users. nine0005

Attention! Never leave 3D printers unattended. They can pose a fire safety hazard.

how to change, insert and eject

Modern 3D printing allows you to create objects and models of amazing complexity. However, the process requires experience and knowledge. Improper maintenance of the equipment, including changing the filament if necessary, may damage the device or result in loss of quality when printing products. In order to avoid such a problem, it is necessary to carefully study the nuances of the procedure before proceeding to change the filament. As a rule, for home 3D printing, plastic is used, which manufacturers have shaped into a filament, supplied in spools. It is about the replacement of this type of material that will be discussed in our article. nine0005

It is about the replacement of this type of material that will be discussed in our article. nine0005

How do I prepare my 3D printer for plastic replacement?

Since refilling is one of the most difficult tasks in 3D printing, it deserves more attention.

A key task for a user who needs to change the bobbin filament in their 3D printer is device preparation. Printer preparation must be carried out in a strictly defined order:

- First of all, make sure that the device is connected to the computer with a USB cable. It is necessary to check how tightly the cord is inserted into the input jacks, and then check the operation of the device and its “visibility” to the system. nine0014

- Use the control panel of the 3D printer to start warming up the device to operating temperature. It is almost impossible to remove the old filament from an unheated printer without damaging the mechanism.

- After the printer is sufficiently warm, inspect the extruder outlet for visible damage and excessive drips, and prepare the necessary materials and tools for changing the spool.

How to remove the plastic? nine0027

When changing the filament, most of the breakdowns occur when the remnants of the old plastic filament are removed from the working head of the extruder.

IMPORTANT! Do not remove filament residue until the printer has warmed up sufficiently. Otherwise, the operating mechanism may be damaged and print quality may be noticeably reduced.

In order to remove the filament from the extruder, you will need:

- Turn on the heat of the 3D printer. nine0014

- Wait for the desired temperature to be reached. The temperature regime parameters must be set based on the characteristics of the replaced and refilled materials. For example, ABS and PLA plastics have different melting points, so replacement must be done as quickly as possible. When exposed to elevated temperatures, PLA deforms quickly and can clog the nozzle.

- Next, if the installed software supports the reverse function, you must enable this option and wait for the thread to exit from the corresponding hole.

nine0014

nine0014 - If the software does not have a reverse function, you must manually clean the channel, cutting the old thread as close as possible to the outlet and inserting a new one.

- During the run, the plastic from the old spool will gradually come out of the extruder nozzle and the new filament will take its place.

IMPORTANT! When old material is replaced by new material during a run, it is recommended to adjust the head heating temperature based on the characteristics of the new plastic. nine0005

Replacing plastic

In order to replace the old plastic filament in the extruder with new material, you must:

- Remove the remnants of the old filament.

- Set the extruder head to Maintenance mode.

- Remove the duct tube by pulling it up.

- Pull the filament rod out of the extruder head by pressing down on the presser and gently pulling the plastic filament up.

- Thread the end of the filament from the new spool by releasing the clamping mechanism and gently pushing the end of the rod. nine0014

- When new filament is threaded into the feeder, the channel tube must be returned to the extruder.

- The final stage is the drawing of the filament. It is recommended to eject 30 to 50 units of material by warming up the printer to the required temperature and immediately removing the ejected material. You can perform this action from the control panel by selecting a command.

- The signal that the replacement of the plastic filament in the 3D printer was successful will be the uniformity of the emitted material and the absence of streaks in the process. nine0014

Resuming work

In order to resume work after changing the filament spool, the 3D printer must be returned to its original position. To do this, you will need to reuse the RepetierHost control panel section and the Home command.

In the event that all actions have been performed correctly, printing can be resumed.