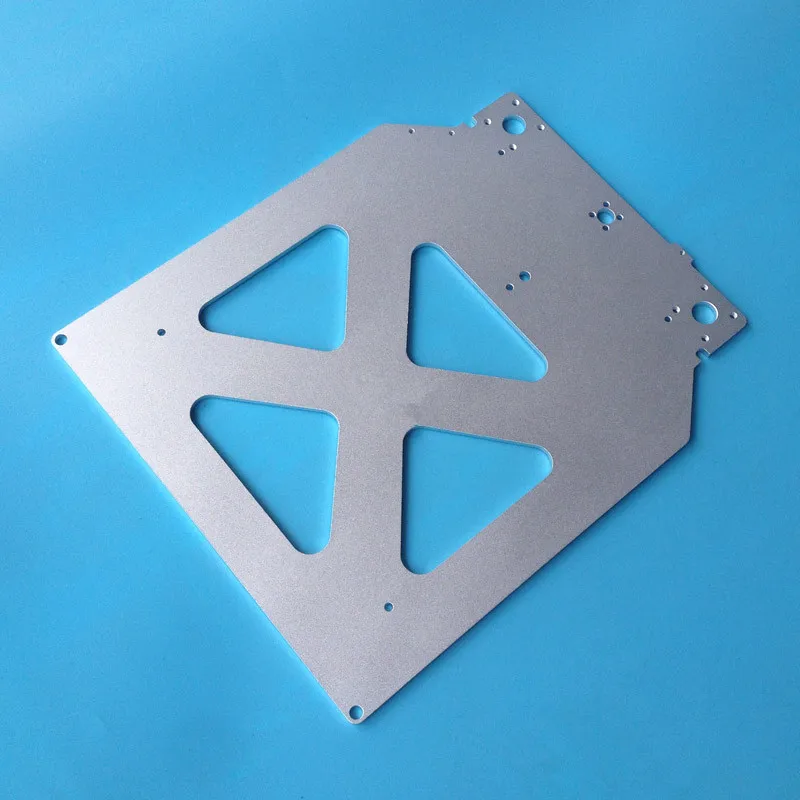

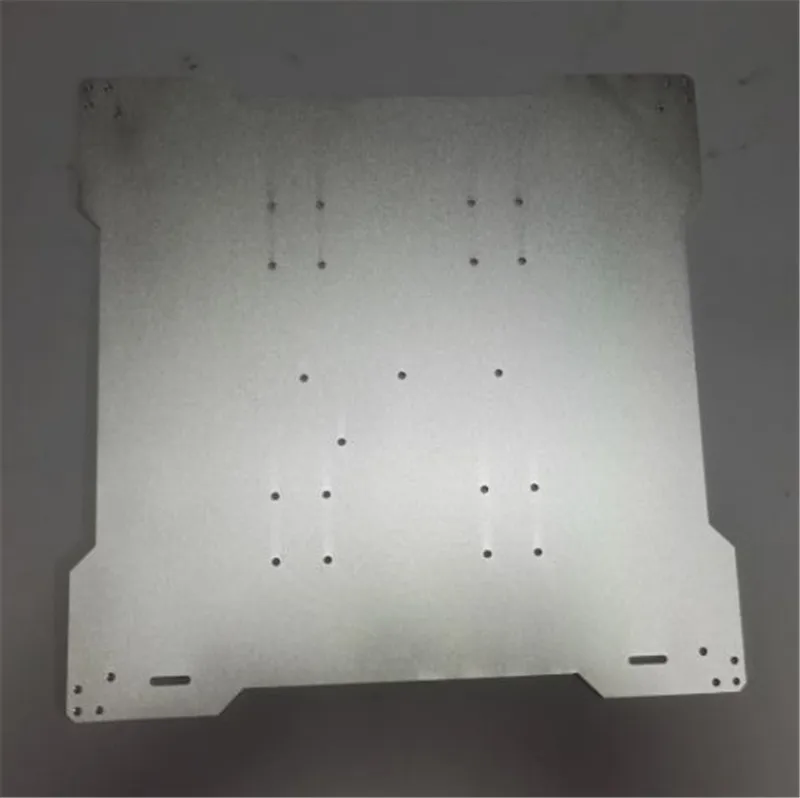

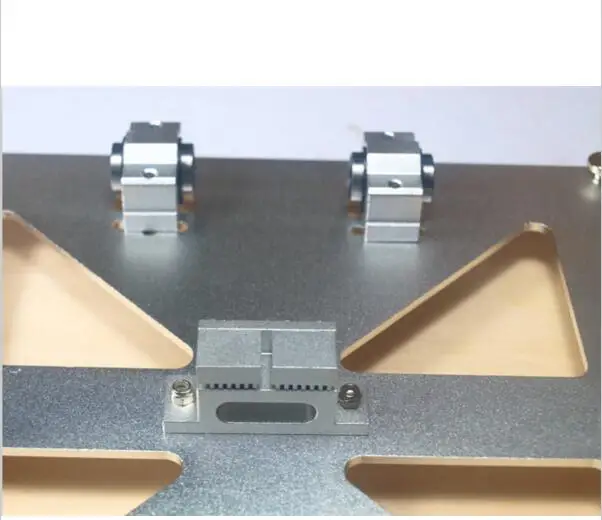

3D printer bed plate

Stick Stick 3D Printer Bed Adhesion

MatterHackers' Stick Stick 3D printer bed adhesive is a great solution for ensuring that you get the best results for all your 3D printed parts. Stick Stick 3D printer bed adhesive works with a variety of 3D printing materials, like PLA filament, PETG filament, PRO Series Ryno filament, and a variety of advanced 3D printing materials.

3D Printer Build Surfaces

LayerLock Build Surfaces

The best solution for 3D printing with Nylon, advanced materials, and resin.

BuildTak Build Surfaces

Build surfaces with the perfect amount of texture to grip the first layer of most filaments.

Wham Bam Build Surfaces

The innovative print surface for your FFF & Resin 3D Printer.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

LayerLock 3D Printer Build Surfaces

- Home

- Store

- 3D Printer Accessories

- Build Surfaces

- LayerLock Build Surfaces

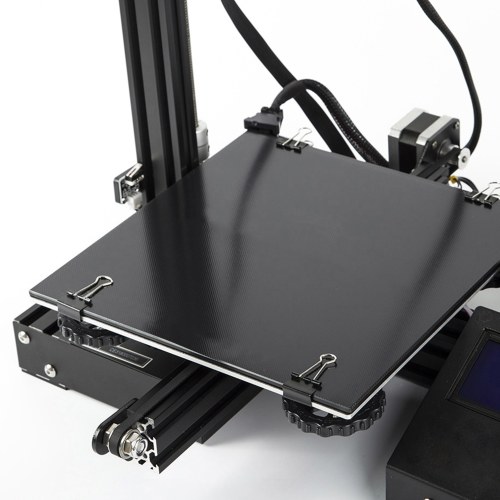

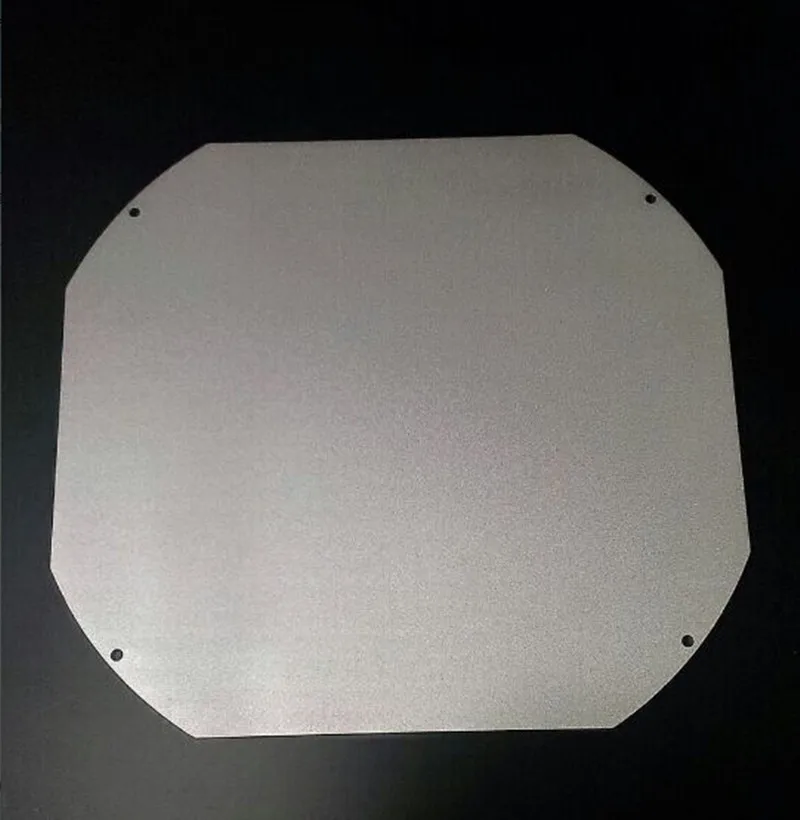

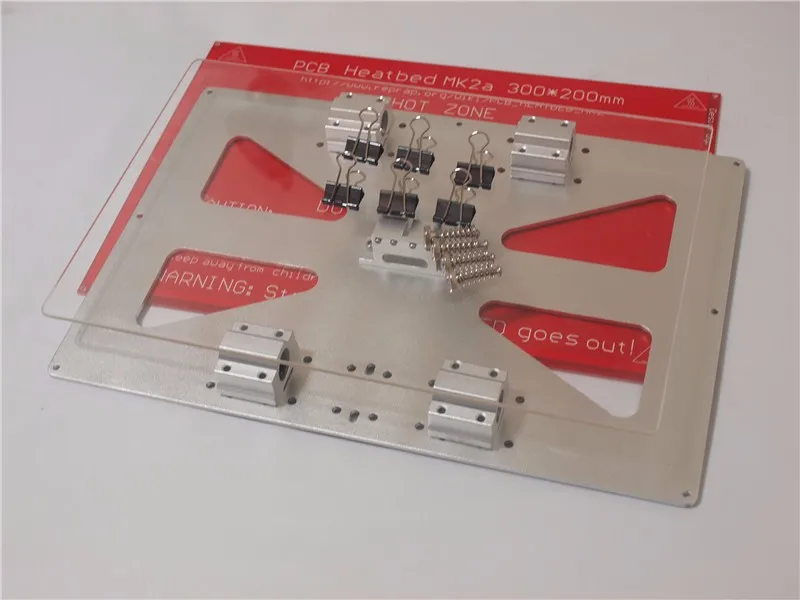

LayerLock provides a variety of build surfaces and build plates designed for stronger bed adhesion for both advanced and standard materials. With LayerLock Garolite Build Surfaces, successfully printing warp-free parts out of NylonX, NylonG, and other nylon filaments will be a breeze. This type of surface also successfully prints standard filaments such as PLA, PETG, TPU and more for a plethora of material compatibility. With LayerLock Powder Coated PEI Build Plates, users have a reliable alternative bed surface for successfully printing standard filaments such as PLA, ABS, PETG and flexibles. Both types of bed surfaces are durable, dependable, and require little to no maintenance so strong bed adhesion is attainable without the huge hassle. Take your 3D printing to the next level with these advanced build surfaces that will help you successfully achieve warp-free projects for a lifetime.

Both types of bed surfaces are durable, dependable, and require little to no maintenance so strong bed adhesion is attainable without the huge hassle. Take your 3D printing to the next level with these advanced build surfaces that will help you successfully achieve warp-free projects for a lifetime.

LayerLock Build Surfaces Collections

All LayerLock Build Surfaces 3D Printer Build Surfaces

Technical Specifications

- Material Surfaces Available: Garolite, PEI, Surface for Polypropylene, Surface for SLA

- Available in various sizes—check individual products for guaranteed printer compatibility

- Material compatibility for Garolite: NylonX, NylonG, Nylon, PLA, PETG, TPU, and more

- Material compatibility for PEI: PLA, ABS, PETG, and flexibles such as TPU and TPE

- Material compatibility for Surface for Polypropylene: Polypropylene and OBC

- Material compatibility for Surface for SLA: Most LCD / MSLA, Laser, and DLP resins

LayerLock Build Surfaces

LayerLock Garolite Build Surfaces

Superior bed adhesion to Nylon based materials like NylonG

LayerLock Build Surfaces for Polypropylene

Get the best first layer with polypropylene and OBC filament

LayerLock Powder Coated PEI Build Plates

Great first layers and easy part removal with this flexible build plate

LayerLock SLA Resin 3D Printing Build Surface

Achieve strong bed adhesion in SLA printing with this surface

LayerLock MagBase

Easily add a magnetic base to your 3D printer for interchangeable surfaces

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

LayerLock 3D Printer Build Surfaces strengthen the bond between the print bed and both advanced and standard materials. LayerLock Garolite Build Surfaces are made out of linen-based phenolic sheets, allowing for just enough texture on the surface to provide a sturdy grip for prints to hold onto while still having a fairly smooth finishing surface. Alternatively, LayerLock Powder Coated PEI Build Plates have PEI powder coated onto a flexible spring steel sheet which leaves behind a bumpy surface on the plate and produces a charming, rugged finishing texture on the bottom of prints. Both types of bed surfaces are engineered for easy installation and to withstand thousands of print jobs. Successfully achieve warp-free prints with zero hassle using LayerLock 3D Printer Build Surfaces.

LayerLock Garolite Build Surfaces are made out of linen-based phenolic sheets, allowing for just enough texture on the surface to provide a sturdy grip for prints to hold onto while still having a fairly smooth finishing surface. Alternatively, LayerLock Powder Coated PEI Build Plates have PEI powder coated onto a flexible spring steel sheet which leaves behind a bumpy surface on the plate and produces a charming, rugged finishing texture on the bottom of prints. Both types of bed surfaces are engineered for easy installation and to withstand thousands of print jobs. Successfully achieve warp-free prints with zero hassle using LayerLock 3D Printer Build Surfaces.

📱 Best 3D Printable STL Files for Phone Holder・Cults

📱 Best 3D Printable STL Files for Phone Holder

Download 3D Files for Phone Holders

Discover our collection of 3D files of designer phone holders, very useful and beautifully printable in 3D. No matter what you want to use the phone holder for (music, charging, jewelry, car. ..), in this collection you will find something to print in 3D. nine0007

..), in this collection you will find something to print in 3D. nine0007

flexible turtle

Free

Mechanical quick release phone stand

Free

Mobile phone holder in socket

Free

flexible mammoth

free

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?! nine0009

Free

flexible bear

free

Universal phone holder _ Samsung galaxy / Xiaomi Redmi

Free

phone holder - candice

Free

Modular mounting system

Free of charge

nine0008 phone stand1 €

Cell Phone and Tablet Stand

Free

Universal phone stand

Free

Multi-angle phone stand

Free

Amplifier for iPhone

Free

nine0008 Mobile phone stand-2Free of charge

Phone Amplifier Hex

Free

Bat Smarphone Stand

Free

Stand Holder Tool for iPhone iPad

Free

Phone Stand with Cable Routing

Free

Geometric phone holder

Free

Piggy Phone Stand Keychain

Free

Support phone 2 positions

Free

Parametric Folding Phone Stand

Free

Kitty Phone Holder

Free

Sticky Note!?

Free

Customizable Bike Mount for Modular Mounting System

Free

Phone holder for charging

Free

Tortoise Keychain / Smartphone Stand

Free

nine0008 Octopus Tablet / Phone StandFree

iPhone 6, 6S and 6 plus Amp Dock

Free

Telephone Support

€0. 50

50

Post It Phone Stand - Stand Phone

0,50 €

Multi Angle Phone Stand

Free

nine0008 Charging shelfFree

iphone 5/5S/SE car holder

Free

Cell phone stand-4

Free of charge

Smartphone Hugger

Free

Phone Stand project by Mayku

Free

nine0008 Elephant diver Portable stand and pencil cup2,90 €

Cat Phone Stand

Free

Textured column phone stand

Free

Foldable tilting tablet/phone stand

Free

mobile support

Free

Phone Mount for Car Vent

Free

Funny Phone Stand

Free

Universal Stand for Mobile Phone and Tablet

Free

GRAMiPhone Fixed - iPhone 6 Gramophone Horn

Free

nine0008 Support phoneFree

flexible turtle

phone holder - candice

flexible bear

Stand Holder Tool for iPhone iPad

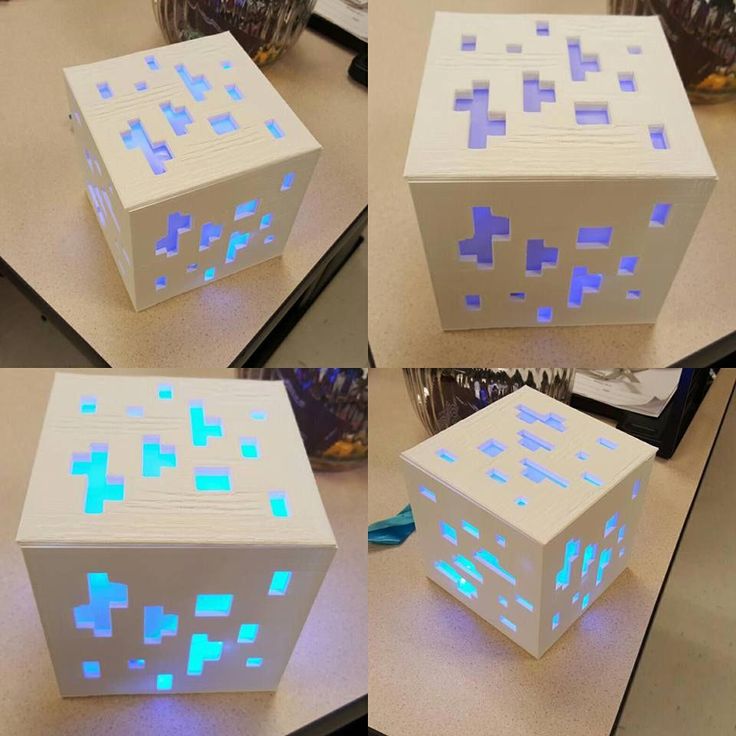

Here is our selection of best files for 3D printer holders for phones and smartphones , all these creations are created on STL file platform Cults and are perfectly 3D printable .

This collection includes free and premium 3D files of phone holders created by our community designers. There is something for every taste and every need. Indeed, you'll find designer phone holders with sleek shapes that are almost invisible and leave your phone as the only visible graphic element on your desktop. There are also much more technical coasters with 3D-printed mechanisms , allowing, for example, to block them. Some cradles are designed so that the phone can be plugged into a power outlet so that it remains visible and accessible while the batteries are being charged.

In addition to the appearance, there is also a utility: some stands allow to amplify the music in a passive way . Thus, without wasting energy, you can listen to your favorite songs to your friends in the evening, on the beach or in the office. These phone stands are in most cases are very useful and handy for 3D printed models . Therefore, new owners of 3D printers are very fond of these items. And when you change your phone, you don't need to buy a new holder, just print another one that fits the size.

Therefore, new owners of 3D printers are very fond of these items. And when you change your phone, you don't need to buy a new holder, just print another one that fits the size.

The 3D designers who offer their creations on the Cults 3D upload platform really competed in ingenuity and creativity to make all of these iPhone or Samsung holders 3D printable , if you download them, don't forget to post pictures of the result!

smartphone holder and tripod model

Smartphone users often try to place their mobile device in a way that is convenient to use: watch movies, take pictures, communicate via video calls. Holders and tripods for smartphones are widely sold, but these are mass-produced models. If you want a holder that no one else has, you need to print it on a 3D printer.

- Printing a phone stand on a 3D printer

- Mistakes when printing a phone stand and how to avoid them

Printing a phone stand on a 3D printer

Mobile phone stands and tripods can be printed on a 3D printer. Such products will not only perform a utilitarian function, but will also be a unique object of interior decoration. The main thing is to be patient, choose the right design, create a digital model or download it on the Internet and send it to print. And this article will tell you which filament is suitable for the job and how to avoid common mistakes. nine0007

Such products will not only perform a utilitarian function, but will also be a unique object of interior decoration. The main thing is to be patient, choose the right design, create a digital model or download it on the Internet and send it to print. And this article will tell you which filament is suitable for the job and how to avoid common mistakes. nine0007

Which model do you prefer?

The choice of model is determined by the purpose of use:

- The phone is needed for making conversations, making video calls, but the hands are busy with some kind of work. In such cases, the mobile device is placed vertically and the stand is a simple case-like design with a support.

- The screen is used to view video content. For convenience, the phone is placed horizontally. Such a tripod is structurally similar to the previous model, only it will be oriented in a horizontal position. nine0253

- If occasional adjustment of the display position is required, the stand has a console swivel mechanism.

Important! If the holder will be used as a tripod to keep the phone stationary during shooting, this design will be the most optimal. Changing the position of the smartphone camera will be very convenient.

- The phone holder will be used as an interior design element. Such stands are the most unusual: in the form of fantastic animals, cases of retro telephones, surrealistic objects, flower buds - everything that the wild imagination of the smartphone owner will tell you. nine0253

The most difficult to print models are those with an adjustable console. This is a prefabricated object, to create it, several parts are printed and connected to each other.

Which material should I choose?

PLA, PETG, ABS, Nylon are suitable for smartphone holder 3D printing. Models with a large number of small elements are preferably printed in PLA - this material provides the best detail. In terms of the quality of the resulting volumetric objects, PETG is not inferior to it. Both plastics do not require special printer settings, the parts from them are obtained with a given accuracy. nine0007

Both plastics do not require special printer settings, the parts from them are obtained with a given accuracy. nine0007

Important! When printing prefabricated models, the dimensions of the individual elements are required. Otherwise, without mechanical refinement, it will not be possible to mount the stand so that the rotary mechanisms work normally.

Decorative holders can be printed with ABS. Post-processing the model in an acetone bath will give the effect of varnishing, and solvent vapors will increase the adhesion of the layers.

Nylon is a capricious material. Large shrinkage and high extrusion temperatures are intimidating for 3D printer users, especially beginners. But products from it are extremely durable, and thin walls remain flexible. In addition, nylon shows a minimum coefficient of friction, which means that all parts of the adjustable consoles will rotate easily and their wear will be minimal. nine0007

How do I print a tripod or phone holder?

The easiest way is to choose a finished 3D model and download the STL file on the Internet. If you have the skills to work in programs for creating digital spatial objects, you can create a stand from scratch: come up with a design, calculate the dimensions, prepare a file of the required format.

If you have the skills to work in programs for creating digital spatial objects, you can create a stand from scratch: come up with a design, calculate the dimensions, prepare a file of the required format.

Further, the order of work will be the same for both the downloaded model and the one created by yourself:

- The object is sent to the slicer program. nine0273 Attention! Depending on the material that will be used for printing, settings are set, in particular, scaling the model with the expectation of filament shrinkage.

- The G-code file is loaded into the 3D printer to start the printing process. It is better to print several small details separately, and not to place everything at once on one desktop. Simultaneous printing of many elements requires a very fine adjustment of the retract, otherwise post-processing will require a lot of effort. nine0253

- The finished base is sanded and painted if it is provided by the design idea, assembled if it is printed from several parts.

Important! Not always printing the stand as a whole can be called an easier option. The complex geometry of the object will require the creation of supports and their subsequent removal. It may be preferable for some to print a few simple-shaped parts and then assemble a finished tripod from them.

Mistakes when printing a phone stand and how to avoid them

Common mistakes that are most often made when printing spatial models prevent you from getting the expected result:

- Incorrect printer settings will lead to distortion of the shape and size of the product. These include the inconsistency of requirements with the capabilities of the printer, the wrong choice of layer thickness, print speed, extruder and table temperatures.

Solution to the problem: When specifying the printing parameters in the slicer, one should take into account the potential of the printing device, the type of filament, the shape of the future object and set the appropriate settings. nine0253

nine0253 - An unsuitable filament was selected, the detailing of the model is insufficient, the geometry of the part is violated.

Solution: for each specific model, a material with specified properties is needed. High-precision products are printed from PLA and PETG.Attention! When giving preference to one or another filament, first of all they find out if the printer can work with this material.

- The printed parts cannot be put together because the dimensions do not match. Possible reasons for this are plastic shrinkage or incorrect modeling. nine0331 Solution: choose another filament for printing with minimal shrinkage, try to “play” with the slicer settings to compensate for the change in size when the plastic cools down. If mistakes are made in the process of creating a digital model, you will have to check all the dimensions of the drawings, correct inaccuracies and re-create the STL file.

The main principle to avoid mistakes is to study the theory and fundamentals of 3D printing and apply them in practice.