3D printer fast

7 Fastest 3D Printers 2022 In Every Price Range

One of the major gripes with 3D printing is many consider it to be slow. However, over time both the speeds of FDM and resin printers have crept up — and there are now some super-fast options for both technologies.

For industrial printing, there are printers now reaching speeds competitive with traditional manufacturing, aiming to displace injection molding.

But what are the other fastest 3D printers in the world?

We have listed the world’s fastest 3D printers in every price range below, for both FDM and resin printers – but first, let’s explain the factors that affect the speed of 3D printing.

Do Bigger 3D Printers Print Faster?

A bigger resin 3D printer does indeed print faster, but this is more in the sense of being more productive. A resin printer cures an entire layer on the XY axes, regardless of size, in one go. This means that the larger the printer, the more productive the printer is.

However, this isn’t the case for FDM printers, which need to deposit filament across the entire layer before moving on to the next.

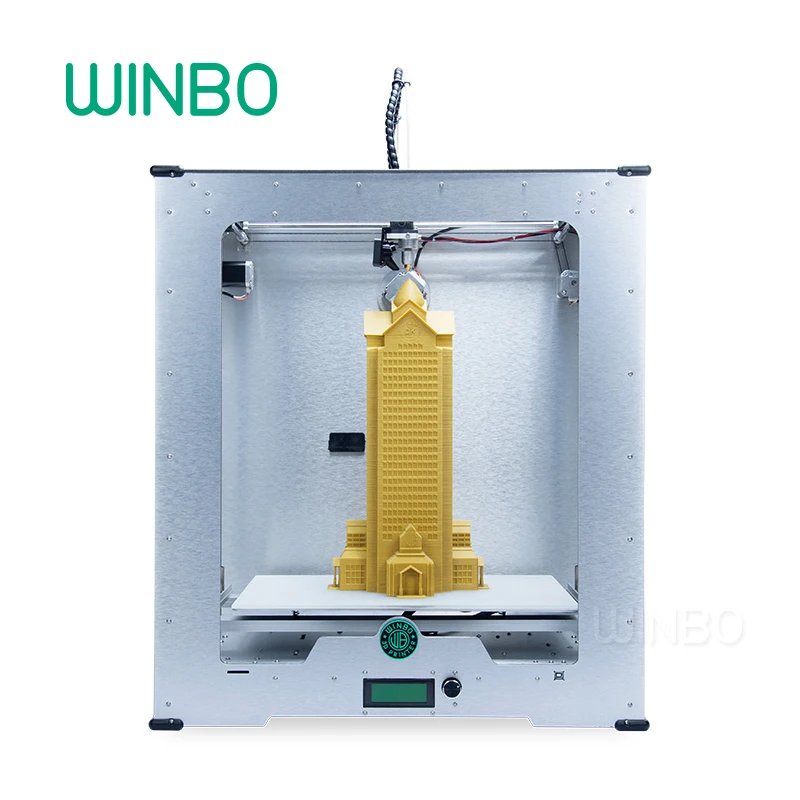

FAST FDM PICK

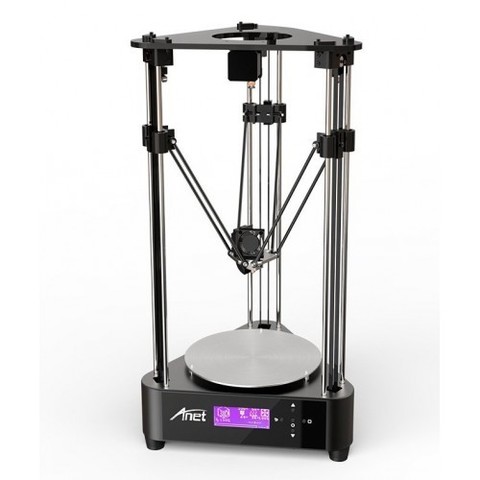

Flsun Super Racer200mm/s makes it one of the fastest FDM printers around

Comes 95% pre-assembled

Available at Amazon here

FAST RESIN PICK

Anycubic Photon M3 PlusSuper-fast 100mm/h speed

Larger resin build area for scalable minis prints or larger resin models

Available at Anycubic here Amazon here

SUPER-FAST PICK

Phrozen Sonic Mega 8KExtremely high-res 8K LCD screen

Enormous build area and 70mm/h speed

Available At Phrozen here Amazon here

How Fast is a 3D Printer?

As for the technologies and 3D printers we have now, simply stating the fastest possible 3D printing speeds is difficult.

That’s because – and I know it’s frustrating to read this – it depends on several factors:

Resolution of the 3D printed part: before you start printing, you need to slice your model into layers on a 3D slicer. The more layers, and the thinner each layer, the longer the part will take to print at the same speed. A part printed with 50-micron layers will have twice as many layers as the same part printed with 100-micron layers, and take twice as long at the same speed.

- We also have a guide to high resolution 3D printers.

Quality of print: theoretically you could run a budget 3D printer at an extremely high speed, and it would still print. But the results wouldn’t be anything like how it looked on your slicer. It would be a mess of filament hairs and blobs, because the speed settings were set too fast. Some 3D printers can handle high-speed 3D printing, some cannot.

3D printing technology: how fast a 3D printer prints depends on the technology. Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Material: some materials are easier to print than others, putting less demand on the printer and leading to a slightly faster print.

Complexity of the model: You will be able to print a cube block far quicker than an intricate 3D printed jewelry piece. This is because you can print larger layers and at a faster print speed without a notable loss of quality, since the cube is a very simple shape with no details.

Size of print: fairly obvious, but a larger print will take far longer than a small one. A full-size vase will take around 12 hours to print in normal detail on most FDM 3D printers, but a small statue may take under an hour.

Nozzle size: for FDM 3D printing, smaller nozzles mean more intricate details can be printed more accurately, but larger nozzles can potentially print faster.

Will 3D printers get faster?

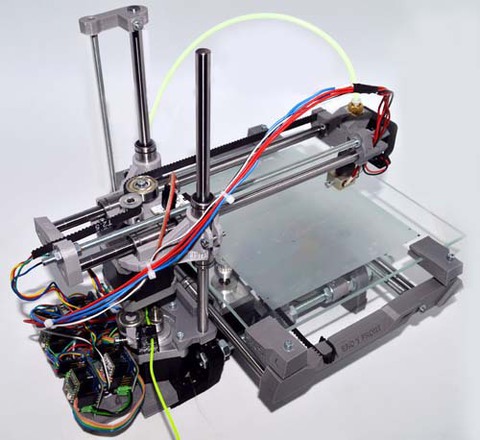

Almost certainly. We’ve already seen a number of major innovations that make 3D printers faster in the last decade. In 2012, the first delta 3D printers started to appear, which print significantly faster than previous Cartesian 3D printers.

Then, new resin 3D printer innovations such as Carbon 3D’s CLIP, and Uniz’s UDP technologies made SLA and DLP faster. Other significant speed innovations include HP’s Multi Jet Fusion technology, and also the huge advances being made in many metal 3D printers such as those by Desktop Metal and Markforged.

The Fastest 3D printers 2022 in Every Price Range

| Name and brand | Build volume (mm) | Max speed | Price | Where to buy |

|---|---|---|---|---|

| Flsun Super Racer | 260 x 260 x 330 | 200mm/s | $499 | Amazon here |

| Anycubic Photon M3 Plus | 197 x 122 x 245 | 100mm/h | $699 | Anycubic here |

| Anycubic Photon M3 Max | 298 x 164 x 300 | 60mm/h | $1099 | Anycubic here |

| Phrozen Sonic Mega 8K | 330 x 185 x 400 | 70mm/h | $2199 | Phrozen here |

| Uniz Slash UDP | 293 x 122 x 200 | 600mm/h | $1,999 | Matterhackers here |

| WASP 2040 Pro Turbo | 200 x 200 x 400 | 500mm/s | $3,400 | Amazon here |

| HP Jet Fusion 5200 | 380 x 284 x 380 | 4115cm3/h | Quote |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

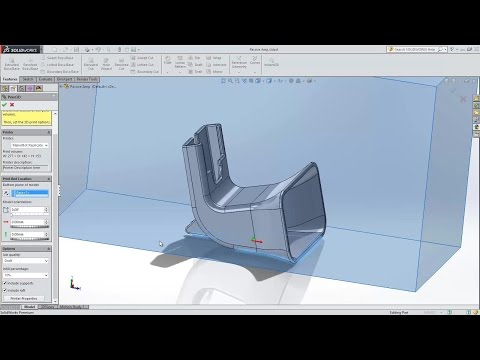

Flsun Super Racer – Fastest FDM 3D Printer Under $500

- Price — Check latest price at Amazon here

- Technology: FDM Delta

- Max Print Speed: 200 mm/h

- Build Volume: 260 x 260 x 330 mm

True to its speedy name, the Flsun Super Racer is a Delta FDM printer that absolutely gallops with a top print speed of 200 mm/h. It’s an upgraded version of Flsun’s QQ-S, which after some one-on-one time we found to be a competent, worthwhile printer for large projects.

Delta printers are known for offering higher speeds than their Cartesian brothers, but Flsun is pushing the boat out to new extremes with the Super Racer. Most standard FDM printers perform best at a comfortable 50-60 mm/h, while the Super Racer delivers solid quality prints at four times that.

With a decently-sized 260 x 260 x 330 mm build volume, the Super Racer is also big on vertical print capacity, ideal for those towering prints that exceed the dimensions of budget FDM printers. Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Now, all this speed does come with a trade-off. Delta printers, the Flsun Super Racer included, lack the accuracy and consistent print quality offered by Cartesian 3D printers. The difference is relatively negligible, but it’s a point to consider before buying for makers that favor quality over speed.

On the filament front, the Flsun Super Racer’s Bowden extruder setup works great for PLA but coughs up the usual Bowden-related jamming and clogging issues with flexibles. For example, if you’re working with TPU, you’re better off sticking to a classic Cartesian printer – ideally with a direct drive extruder.

Anycubic Photon M3 Plus/Max – Fastest Resin 3D Printers Under $1,000

- Price: $699 / $1,099 — M3 Plus Available here / M3 Max Available here

- Technology: MSLA Resin

- Max Print Speed: 100 mm/h / 60 mm/h

- Build Volume: 197 x 122 x 245 mm / 298 x 164 x 300 mm

More than simply an update to the long-running Photon series, the Anycubic Photon M3 machines are turning more than a few heads as the fastest resin 3D printer range around.

In particular, the Anycubic Photon M3 Plus proposes a top print speed of 100 mm/h. The beauty of resin printers is that they cure in layers, regardless of how much space on the build plate that layer takes. Those 100 mm/h apply whether you’re printing a single small miniature or a batch of twelve, which makes the Anycubic Photon M3 Plus exponentially more productive.

The Anycubic Photon M3 Max is no slouch either, offering a respectable 60 mm/h, but does this across a massive 298 x 164 x 300 mm. That’s the largest of any Anycubic resin printer and among the highest capacities found on consumer-grade printers, rubbing shoulders with the hulking Elegoo Jupiter and Phrozen Sonic Mega 8K.

Elsewhere, the Photon M3 duo stands out for offering excellent detail with 34 microns XY resolution on the Plus and 46 microns on the Max. The Max has a 7K LCD, one of the highest pixel counts on the market, while the Plus pushes a 6K LCD – higher than the standard 4K found on comparable printers. Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Read the full comparison: Anycubic Photon M3 vs M3 Plus vs M3 Max

Phrozen Sonic Mega 8K – Fastest High-Quality Resin 3D Printer

- Price: $2,199 — Available at Phrozen official here

- Technology: MSLA Resin

- Max Print Speed: 70 mm/h

- Build Volume: 330 x 185 x 400 mm

With the Phrozen Sonic Mega 8K, size and speed combine into arguably one of the most impressive mid-range professional resin printers on the market.

The 330 x 185 x 400 mm build volume is the largest available in this price range, and the Sonic Mega 8K darts across this printing expanse at a nippy 70 mm/h. No other printers manage to weave in such a large build volume with such high speeds; it’s always been one or the other.

The Phrozen Sonic Mega 8K allows makers to hone in on all the fine features and intricacies of even the most detailed models and minis thanks to a 43-micron resolution, propped up by a pixel-rich 15’’ 8K LCD. It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

The build plate comes pre-calibrated, allowing you to print without delay once the Mega 8K lands on your doorstep. A clever dual linear rail design ensures the printer behaves and delivers those sharp details even high up into the upper reaches of the build area.

If you need a mammoth-format printer at a reasonable price to power a small business where time is of the essence, there’s little else out there that comes close to the Phrozen Sonic Mega 8K. If the build volume exceeds what you’ll conceivably ever need, a lower-cost resin printer such as the Anycubic Photon M3 Plus or even the standard M3 is likely a better use of your money. The Phrozen Sonic Mega 8K is a jumbo printer and will be far too much for most amateur makers.

Uniz Slash Plus UDP — Fastest desktop 3D printer

- Max print volume: 293 x 122 x 200 mm

- Price: $1,999 — Available on Matterhackers here

- Fastest 3D printer speed: 600mm/hour in UDP mode

Uniz have made a big impact since their original Kickstarter campaign that raised over $500,000 to produce super-fast resin 3D printers at consumer prices. This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

When not in UDP mode the maximum 3D printer speed is 200mm/hour, but this is still super fast. This is because not all parts are compatible, for example, any parts with cross sections, or fully enclosed parts cannot be printed in UDP mode; and no parts with solid infill can be printed either. You are also restricted as very tall prints cannot be printed in UDP mode, but if your part qualifies then you can print extremely quickly!

Not only is it an extremely fast 3D printer, but it’s also accurate. This SLA 3D printer has an XY resolution of 75 microns, and a minimum layer of thickness of just 10 microns. As a result, parts have very good surface finish and look almost like they have no layers at all. The printer can also calibrate itself, can be operated via your phone or table on the mobile app, and weighs just 12kg. It’s certainly one of the best speedy 3D printers for the price.

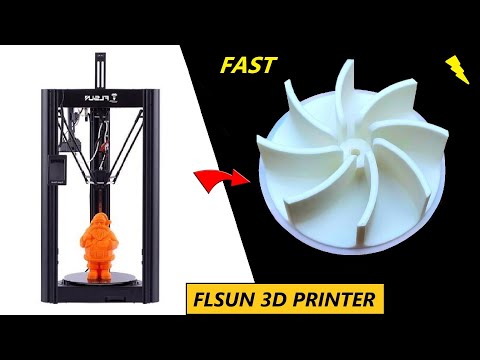

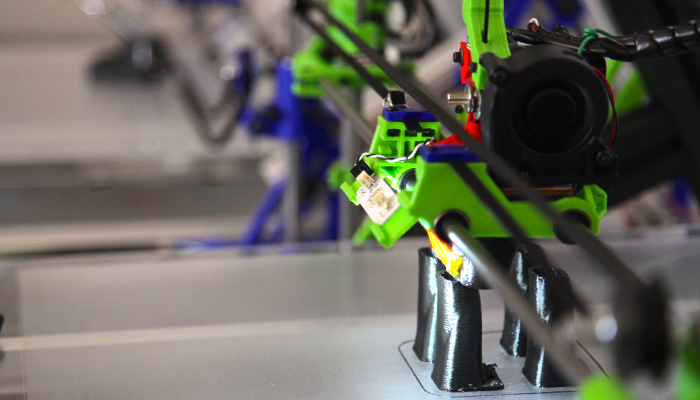

WASP 2040 PRO Turbo — Fastest 3D printer in the world

- Price: $3,400 — Available on Amazon here

- Max print volume: 200 x 200 x 400 mm

- Fastest 3D printer speed: 500mm/s recommend (some say it can print even faster!)

Delta 3D printers are known for their speed, and are the fastest FDM 3D printers in the world. The WASP 2040 PRO Turbo is a delta printer that is not only incredibly fast – at up to a recommend 500mm/s – but is also extremely accurate for an FDM printer. The resolution of up to 50 microns means very accurate and low cost prototypes and parts can be produced, and in record time. WASP claim they make the fastest 3D printers in the world for FDM.

WASP 3D printers are known for their reliability, with the Italian company ensuring the printers operate with workhorse-like consistency. It can print 3D printer filaments including ABS, PLA, PETG and Nylon, so if you want to print stronger parts from one of the tougher plastics you still can, and you can use third party filaments if you prefer – the WASP allows for these. and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

Unlike most RepRap 3D printer deltas, the WASP 2040 Turbo comes fully assembled, so those who aren’t masters of DIY do not need to worry. You can also choose to order it either as a single or dual extruder 3D printer based on your printing needs.

It’s the world’s fastest 3D printer for FDM, and also accurate and reliable – what more could you want for under $5,000!

- It also has a variation designed specifically as a clay 3D printer.

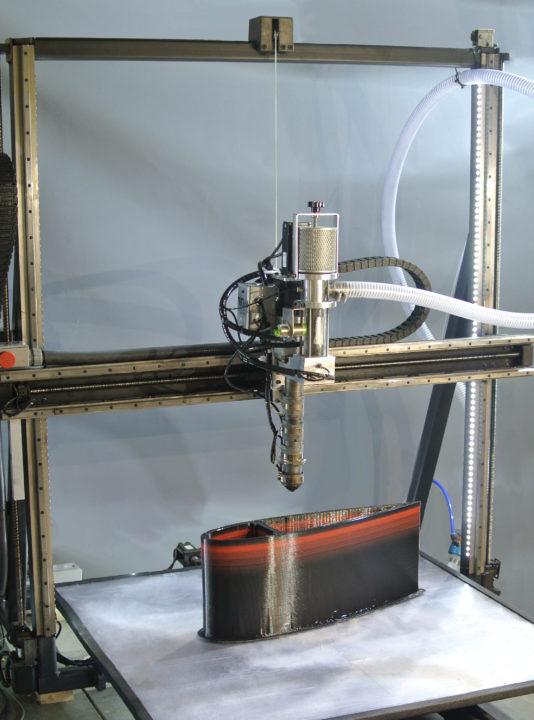

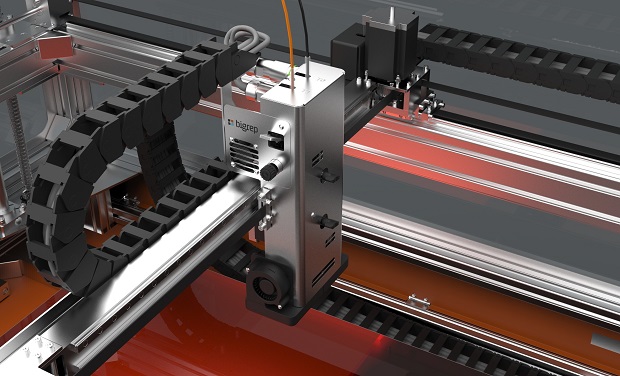

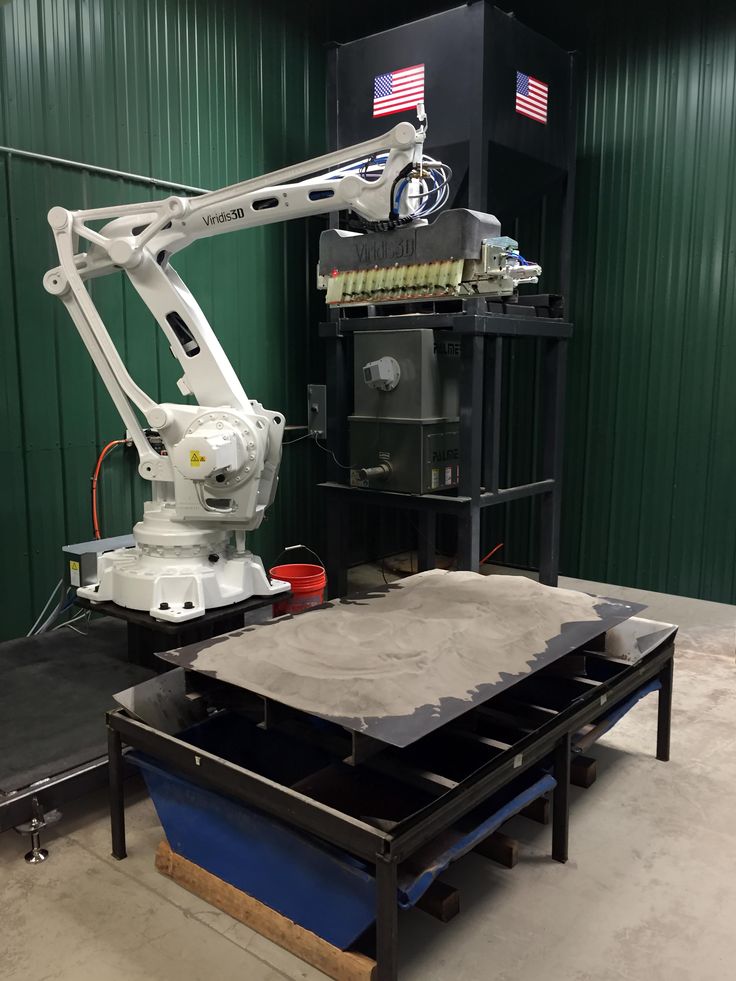

HP 3D Jet Fusion 5200 — Fastest Industrial 3D printer

- Price: Requires a quote

- Max print volume: 380 x 284 x 380 mm

- Fastest 3D printer speed: 4115cm3/hour

HP have only been actively involved in the 3D printing industry for the last few years, but have brought such technological advantages in that short space of time. The Jet Fusion 5200 epitomizes this, marking uncharted territory for 3D printing where it is now considered viable for mid-range production.

Multi Jet Fusion has always been known for its fast 3D printing speed, but the Jet Fusion is even faster than its predecessors. With speeds up to 4115cm3/hour, it’s faster than the Jet Fusion 4200 (4000cm3) and the 3200 (2800cm3) – and these were already some of the fastest 3D printers in the world. The high-quality 1200dpi print head resolution allows for extremely accurate parts with smooth surface finishes and crisp, sharp edges.

The Jet Fusion 5200 combines this astonishing speed with low part cost and scalability. Whole layers can be printed at once, rather than tracing each layer as with Selective Laser Sintering, meaning multiple parts can be printed at once without a drop off in productivity. Multi Jet Fusion isn’t known for its versatility of materials, but PA12, PA11 Nylons and TPU are strong materials with good properties for a variety of industries. It’s extremely fast, extraordinarily accurate, and a rare example of 3D printers being competitive in mid-volume part production – very exciting.

Do you really need a fast 3D printer?

Speed is always useful; nobody chooses to wait in a queue longer than they need to. However, with the quickest 3D printers, there are some cases where you can’t take advantage of this speed.

For FDM 3D printers, some materials become volatile and print with imperfections if you don’t slow right down, like PEEK, PC, and others. Printing at 150mm/s+ would just ruin your prints, so the speed is useless here.

Also, if you are printing a very simple object like a cube, speed becomes less useful as you can just use very large layer heights and print quickly anyway.

However, if your business depends on quick production, then absolutely go for a printer that can either print objects very quickly, or multiple objects simultaneously. The ability to rapidly prototype new designs and innovate quicker is invaluable, and other industries like 3D printed jewelry production or hearing aids need to be able to print custom designs at the highest speeds possible.

So, it depends. For hobbyists, speed is great for quality of life and printing all the cool things and useful 3D prints you can. For industry it can be more necessary, and businesses often opt for an industrial 3D printer than can meet their production speed requirements.

How Fast Can PLA Be 3D Printed?

The fastest FDM printers, such as the Flsun Super Racer, can print PLA up to 200 mm/h. However, the most common 3D printers, such as the Ender 3, can print PLA at around 50 to 80 mm/h without sacrificing print quality.

Related articles:

- Best large resin 3D printers (bigger = faster!)

- Best delta FDM 3D printers

- Best FDM 3D printers

7 Fastest FDM & Resin 3D Printers In 2022

- Last Updated: December 8, 2022

- Pat Nathaniel

3D printers are a great way to get your part, but if you’re impatient, then you want the fastest on the market. At the same time, you don’t want to waste money or compromise on quality.

At the same time, you don’t want to waste money or compromise on quality.

Don’t worry; this extensive list has you covered.

We will dive into the fastest FDM printers, then take a look at some resin options. Afterward, we’ll take a look at what print speed is good for a normal printer and why printers can’t go faster.

Let’s take a look at some of the fastest 3D printers available for you to buy today.

Creality Ender 7

Build volume: 250 x 250 x 300 mm

Get Discount Now

Check Latest Price

FLSUN Super Race (SR)

Build volume: 260 x 260 x 330 mm

Click For Official Website

Check Latest Price

Original Prusa SL1S

Build volume: 127 x 80 x 150 mm

Check Latest Price

Table of Contents

- FDM 3D Printers

- 1. Creality Ender 7

- 2.

FLSUN Super Racer (SR)

FLSUN Super Racer (SR) - 3. Qidi Tech iFast

- Resin 3D Printers

- 4. Original Prusa SL1S

- 5. Phrozen Sonic Mini 4K

- 6. Elegoo Mars 3 Pro

- 7. Anycubic Photon M3 Plus

- What is a Good Print Speed for 3D Printers?

- Relationship Between Speed and Quality

- Limiting Factors for Speed

- Cooling the Plastic

- Tiny Motors Driving the Motion

- 3-Axis Setup

- How to Make a 3D Printer Faster

- Conclusion

7 Fastest & Quickest 3D Printers At A Glance

FDM 3D Printers

1. Creality Ender 7 (Best Value)

2. FLSUN Super Race (SR) (Best Choice)

3. Qidi Tech iFast

Resin 3D Printers:

4. Original Prusa SL1S (Premium Choice)

5. Phrozen Sonic Mini 4K

6. Elegoo Mars 3 Pro

7. Anycubic Photon M3 Plus

FDM 3D Printers

1. Creality Ender 7

3D Printer Type: FDM | Materials: PLA, ABS, TPU & PETG | Build Volume: 250 x 250 x 300 mm | Max Print Speed: 250 mm/s

Folks, this is Avengers: Endergame. Creality is known for putting out affordable and high-performance printers (most notably its Ender series) and this one is its fastest yet.

Creality is known for putting out affordable and high-performance printers (most notably its Ender series) and this one is its fastest yet.

If you’re looking for a fast FDM printer for production, look no further. It literally can’t get better than the Ender 7.

This is a heavy printer at 17 kg — so you might want to enlist some help when moving it around. (Your spine will thank you.)

This weight is for two main reasons:

- Fast printing speed requires heavier and more robust stepper motors, and;

- More weight equals less vibration, so your printer doesn’t wobble around like a washing machine at top speed

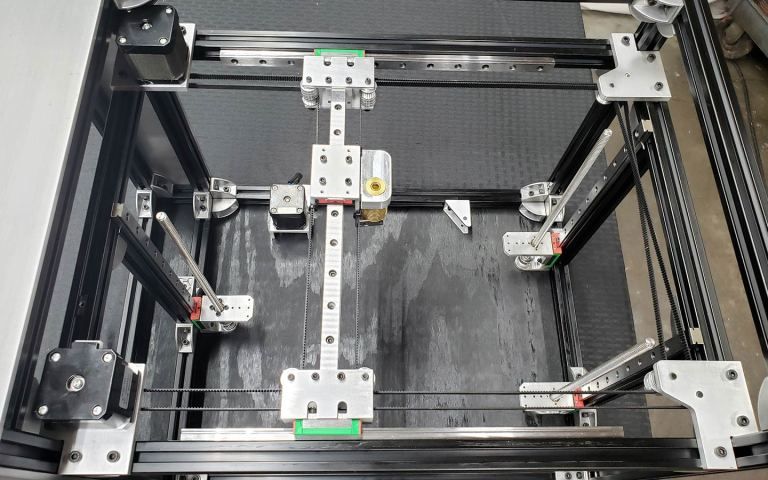

This is a CoreXY printer. The CoreXY structure differs from your typical run-of-the-mill Cartesian printer in that it distributes weight on the printhead rather than on the X and Y axes.

This makes it print much faster than standard 3D printers.

In fact, the Ender 7 is up to 80% faster than the Ender 3 — and this difference is especially noticeable in big prints. It has an INSANE speed of 250 mm/s, which… speaks for itself, pretty much.

It has an INSANE speed of 250 mm/s, which… speaks for itself, pretty much.

This heavyweight champ also offers a huge build volume of 250 x 250 x 300 mm. For home users and hobbyists (anyone who isn’t building giant space robots), this is more than ample printing space.

Our only gripe with this printer: when you’re printing fast, it’s bound to get noisy. But hey, for these results we’ll excuse it. After all, what racecar is ever silent?

- Remarkably shorter printing time than most printers in its range

- Ability to print large objects

- Built very solidly to last

- Can get noisy

Get Discount (Official Store)

Check Latest Price

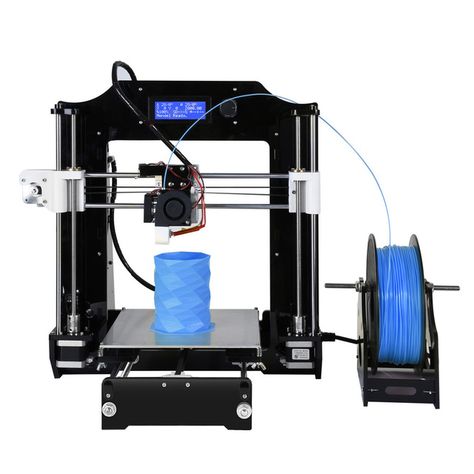

2.

FLSUN Super Racer (SR)

FLSUN Super Racer (SR) 3D Printer Type: FDM | Materials: PLA, ABS, PETG & Flexibles | Build Volume: 260 x 260 x 330 mm | Max Print Speed: 150-200 mm/s

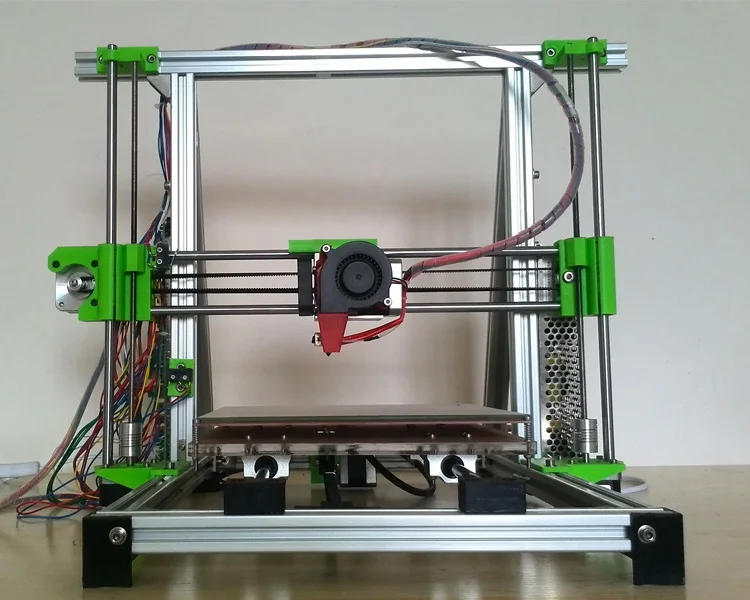

We’re in the Grand Prix of 3D printers, and our next contestant is the FLSUN Super Racer!

If you’re looking for a fast and accurate printer, this one’s for you.

With a print speed of 200mm/s, the FLSUN offers super precise detailing and accuracy. It’s a Delta-style printer that uses a sturdy linear rail to give the printer stability and keep your eardrums from exploding!

The Racer gives you a roomy 260 x 260 x 330 mm build volume for large vases, giant ducks, cosplay masks, and so on.

The FLSUN Super Racer comes with automatic bed leveling, which is a nice plus. It also has safety features built in place — which are really important for a printer.

You’ve got the resume print function so you don’t lose your print in a power outage (insert gif of Grandpa Simpson yelling at a power grid). Then you’ve got the filament detection feature so the Racer warns you when you’re soon to run out.

Then you’ve got the filament detection feature so the Racer warns you when you’re soon to run out.

The FLSUN comes with a removable print bed — no need to struggle anymore with removing your prints. Here’s a neat trick: you can actually pop the print bed into the freezer for a few hours (with your printed part) for easier removal.

This printer has a 0.4mm nozzle that can support 1.75 mm filaments of PLA, ABS, and PETG. Sorry TPU folks, This Printer is not for U!

Layer thicknesses range from 5 microns to 30 microns — this printer really puts an emphasis on detail. Case in point, it’s got an accuracy of just 10 microns. Wow. You can achieve breathtakingly fine details!

- Fine detail and small layer thicknesses

- 200 mm/s

- Printing safety features

- Delta printer may have an initial learning curve due to different setup

Click For Official Website

Check Latest Price

3.

Qidi Tech iFast

Qidi Tech iFast 3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, PVA, Carbon Fiber, Nylon & PC | Build Volume: 330 x 250 x 320 mm | Max Print Speed: 150 mm/s

Speed? Check. Dual extrusion? Check again!

The Qidi Tech iFast is an FDM printer that gives you industrial-grade precision and speed at an affordable price tag. So if you want fast printing AND dual extrusion, this printer is perfect for you!

The iFast lives up to its name with a print speed of 150 mm/s. It also has a roomy build volume of 330 x 250 x 320 mm where you can cook up larger prints.

And with its multiple extruders, the iFast can print PLA, ABS, TPU, PETG, Nylon, carbon fiber, and water-soluble PVA.

It also has a heated enclosure for better printing of high-temp filaments — and built-in air filters to keep your printing space clean.

Removing our printed parts was a breeze with this printer — all we had to do was remove the flexible print bed, bend it a little, and the print popped right off in one piece!

The only thing we didn’t like was the noise coming from the stepper drivers when the iFast was in use. But if that isn’t a dealbreaker for you, this printer is perfect for speedy printing!

But if that isn’t a dealbreaker for you, this printer is perfect for speedy printing!

- High printing speed

- Dual extrusion

- Easy part removal

- Large build volume

- Noisy stepper motors

Check Latest Price

Resin 3D Printers

4. Original Prusa SL1S

3D Printer Type: MSLA | Materials: 405 nm UV Resins | Build Volume: 127 x 80 x 150 mm | Max Print Speed: 1.4 s/layer

Highly detailed prints at a faster speed… The most coveted combination in 3D printing. Can anyone pull it off?

Can anyone pull it off?

Well, Prusa has! With MSLA (masked stereolithography) technology and a high-res monochrome LCD panel, the SL1S provides amazingly detailed prints at 80 mm/hr.

Before you balk at this seemingly low speed (compared to FDM), the SL1S is markedly faster than the average resin printer speed of 30-60 mm/hr.

So if you want the sublime clarity and detail of resin prints at a comparatively faster speed, the SL1S is for you.

MSLA works by curing UV resin using an LCD to mask each layer’s cross-section. The SL1S comes with an 8 UV LED array to cure resin with amazingly sharp detail. It also uses a 2560 x 1620p monochrome LCD with a pixel size of just 49 microns.

This is an amazingly well-built printer (par for the course with Prusa), sporting a robust aluminum body with a 127 x 80 X 150 mm build volume. Perfect for smaller objects! And with a minimum layer thickness of 25 microns, you can easily capture fine details.

And, in typical Prusa fashion, it comes with a thorough manual to guide you through everything step-by-step, including potential printing problems. We loved the detailed and clear documentation — it truly sets a standard for other 3D printer companies.

This printer comes fully assembled — and as it’s a resin printer, you have the choice to buy it with a Cure & Wash station for post-processing of your prints.

The printer comes with a half kg of Prusament resin — though since it’s open-source, you can use virtually any resin you want.

- Amazing detail at relatively fast speed

- Sturdy and reliable aluminum build

- Very clear and helpful documentation

- Smaller build volume

Check Latest Price

5.

Phrozen Sonic Mini 4K

Phrozen Sonic Mini 4K 3D Printer Type: LCD | Materials: 405nm UV Resins | Build Volume: 134 x 75 x 130 mm | Max Print Speed: 80 mm/h

Looking for a lightweight resin printer that can print fast with amazingly crisp details quality? Do you want to print a snowman? Well, now you can “Let It Go” with the Phrozen Sonic Mini 4K! (See what we did there?)

The Phrozen Sonic Mini 4K offers a 4K resolution LCD screen that makes it 4x faster than traditional resin printers at a speed of 80 mm/hour.

This Mini contender offers a 134 x 75 x 130 mm build volume and weighs just 5kg! It’s perfect for printing in a smaller workspace.

Let’s talk about detail — this printer offers an XY resolution of just 35 microns with 722 PI (pixels per inch) — the highest among commercial-grade printers. It offers layer thicknesses of 10 to 30 microns.

As to software, the Mini 4K comes with Chitubox version 1. 6.5. Chitubox is considered the best slicer available for resin printers, and it’s packed with features usually only present in paid software.

6.5. Chitubox is considered the best slicer available for resin printers, and it’s packed with features usually only present in paid software.

The Mini 4K offers multi-resin compatibility, which is really neat if you like working with different resin brands.

On purchase of this printer you get 1 year warranty except on the LCD and FEP film of the printer. It comes with a 2.8″ touch panel for easy navigation and prints via USB connection.

- XY resolution of 35 microns

- Touchscreen capability

- Multi-resin compatibility

- Doesn't offer Wifi option

Get Discount (Official Store)

Check Latest Price

6.

Elegoo Mars 3 Pro

Elegoo Mars 3 Pro 3D Printer Type: MSLA | Materials: 405nm UV Resins | Build Volume: 143 x 90 x 175 mm | Max Print Speed: 30-50 mm/h

Are you looking for an affordable yet still fast and precise resin printer that can print big objects?

The Elegoo Mars 3 Pro is your answer.

It uses a light source of a whopping 36 UV LED lights and a Fresnel lens to produce a 405 nm wavelength. This combination yields high-quality prints with a smooth surface finish that you’ll love staring at and showing off to people.

As some other printers already mentioned, it uses a 4K monochrome LCD. It’s a 6.66″ screen that comes with anti-scratch glass of 9H hardness.

It’s like a screen protector for your printer’s LCD, which is very handy in the event of a resin spill. That way, if some resin does end up being where it shouldn’t, you’ll only have to replace the glass and not the whole LCD.

The light source and glass protector are both new features from the Elegoo Saturn S and Saturn 2, so this truly makes the Mars 3 a “Pro” machine.

It’s got a large build volume of 143 x 90 x 175 mm and, being a robustly built and reliable machine, is perfect for round-the-clock printing. It comes with a carbon filter for resin fumes and odor, as well as a powerful and efficient cooling fan. However, we could still feel the remnants of some odors when printing.

Let’s talk software — the Mars 3 Pro can be used with Chitubox or Lychee Slicer 3.0. Both are viable choices of software. You have to pay extra for a Chitubox Pro subscription, though.

It prints with a pixel size of an amazing 35 microns and takes about 2.2 seconds to print a layer.

- Large build volume

- Affordable

- High-quality printing

- Carbon filter not 100% functional

- Have to pay extra for Chitubox Pro

Get Discount (Official Store)

Check Latest Price

7.

Anycubic Photon M3 Plus

Anycubic Photon M3 Plus 3D Printer Type: MSLA | Materials: 405nm UV Resins | Build Volume: 245 x 197 x 122 mm | Max Print Speed: 100 mm/h

Are you looking for a resin printer that can make some super high-definition and smooth-surfaced amazing prints?

It’s still at an experimental stage in some ways, but the Anycubic Photon M3 Plus comes with some impressive features.

It’s got a 9.25″ 6K monochrome screen where its predecessor, the Photon M3, has a screen of 7.6″.

Using the Anycubic LighTurbo, which consists of 40 LED beads in a parallel matrix (Where are you, Keanu?), you can get a pixel size of just 34 microns, which is pretty impressive for an MSLA printer.

It has a pretty large build volume of 245 x 197 x 122 mm. It’s equipped with an aluminum alloy build plate with superb adhesion — in fact, too superb. We had a bit of trouble getting our prints off it. For a printer of this size, it’s better to just use a flexible build plate.

For a printer of this size, it’s better to just use a flexible build plate.

This printer is advertised as having a speed of 100 mm/h, but in reality it comes with a speed of 20 mm/h for 50 micron layers.

It’s got a smart resin filling feature that’s more of a burden than a solution, since it sometimes overfills the vat with resin and then you have to pour it out. Yep, not so great … we’d recommend turning this feature off.

This printer does come with a camera that’s connected to Anycubic Cloud, a cloud service that also connects to your slicer, and the Anycubic Cloud app on your phone (the website doesn’t work).

The slicer for this printer is Photon Workshop, which is in many ways similar to Chitubox.

The Photon M3 has a responsive 5″ touchscreen, so that’s a nice . . . touch.

It comes with an anti-scratch glass on the LCD in case of resin spills (we thought that a very wise addition). The printer comes with a tool set, as well as a scraper, masks, and gloves.

- Amazingly detailed prints

- Large build volume

- Camera for remote monitoring of prints

- Vat autofill feature unnecessary

- Can only use this printer with phone app

- Slower than advertised

Get Discount (Official Store)

Check Latest Price

What is a Good Print Speed for 3D Printers?

Source: Youtube The Technology ManA good print speed really depends on what you’re using your printer for, and it’s all about personal preference.

For a recreational printer that you’re just using for fun, realistically nothing’s wrong with 1 mm/s – it’s just going to take a lot of patience.

3D printer manufacturers know that we aren’t patient, so they upped that number a lot.

As you look around the market, you’ll find that a lot of commercial printers can hit 40-60 mm/s comfortably.

For a little more money, you can hit 100 mm/s on a commercial printer. The higher-end units will run around 150 mm/s.

Manufacturers suggest running at 60% of the max speed so you get a higher quality.

But how is quality related to speed?

Relationship Between Speed and Quality

Speed and quality seem to be related in every industry – if your mechanic is the fastest in the world, you’re going to be sitting on the side of the road a lot.

3D printers are the same in this sense, but for a technical reason.

The actual speed of a printer moving in a straight line doesn’t affect the print a ton. It’s the change in speed that does.

It’s the change in speed that does.

When you’re in a car and you stomp on the gas or brake pedal hard, your body will lurch. When a 3D printer suddenly accelerates or slows down, the same thing happens.

When the 3D printer lurches, the print quality suffers. You’ll get stringers, wobbly sections, fuzzy exterior walls, and an inconsistent build.

A ton of effort has to go into ramping the printer up to speed and decelerating it without hurting the print.

There are other reasons why the speed can hurt the quality of print.

Limiting Factors for Speed

Don’t let this list fool you, a majority of printers on the market are painstakingly slow in comparison.

So what slows down 3D printers? Let’s look at the answer in terms of FDM printers.

If you recall, FDM printers work by laying down hot plastic from an extruder head that moves on a 3-axis setup, driven by tiny motors. Every step of this process limits how fast you can print

Cooling the Plastic

The first thing that limits how fast you print is how long it takes the hot plastic to cool.

Since you’re building on top of previous layers, the first layer has to be solidified enough before adding the second layer.

Imagine you’re painting a wall, but you don’t wait for the primer to dry before applying the first coat of paint. The result is similar to 3D printers.

The layers will drag, deform, and might get caught on the extruder nozzle. In other words, your final print will be unrecognizable.

Tiny Motors Driving the Motion

If you want a 3D printer to be small, quiet, and inexpensive, you need tiny motors to run the operation.

- Check out our review of the smallest 3D printers here

This is fine because the extruder isn’t heavy either, so you don’t need a lot of power.

If you want the printer to move faster, you need bigger, heavier, stronger motors. This would call for a complete redesign of how 3D printers look, and the added weight would be a huge problem.

The tiny motors are another limiting factor to the speed.

3-Axis Setup

The 3-axis setup (or gantry) is the final big hurdle.

It’s tough to understand how this limits speed without a deep explanation, but it works for the same reason that trains run on a single track.

Single-axis motion is really easy to speed up and predict the outcome. When you add the y- and z-axes, things become more unpredictable, and more vibration affects the process.

Your 3D printer relies on predictability and few vibrations. That’s the secret sauce to get good quality on your final print.

That’s why the printers have to take it slow on a 3-axis gantry, so the final prints turn out good.

Let’s see what can be done to make 3D printing faster.

How to Make a 3D Printer Faster

3D printers can be faster by getting rid of the limiting factors described above.

- Get rid of the jerk associated with quickly getting up to speed and slowing down.

- Use materials that cool a lot quicker or don’t require cooling.

- Step away from the tiny motors used to drive 3-axis printers.

- Lastly, get rid of the 3-axis setup altogether.

The way printing companies achieve this is by getting away from FDM altogether. They’ll opt for SLA, GDP, or MJF technologies which eliminate one or all of these limiting factors for speed.

Unfortunately, the way to make a 3D printer faster is to get away from FDM printers and move to another technology of printer.

Conclusion

If you want to print quickly, there aren’t a lot of printers that can do so without hurting the final print quality. This shortlist of printers can manage to do it successfully, but it comes at a price.

You’ll be shelling out more cash and potentially getting a smaller build volume. You have to consider which is the most important for your application and go from there.

When it comes to true speed, the printers on this list stand in a league of their own.

Related Articles:

- Best DIY 3D Printer Kit Review

- Best 3D Printer Under 200 Review

- Best 3D Printers Under 300 Review

- Best Resin 3D Printers

- Best Delta 3D Printers

Pat Nathaniel

Pat is the editor-in-chief at Printing Atoms. He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

3D printer speed: how to set it up correctly?

3DPrintStory 3D printing process 3D printer speed: how to set it up correctly?

3D printing is often referred to as "rapid prototyping". The irony is that the creation of individual models can take up to several hours. Fortunately, 3D printing speed can be adjusted to reduce production time, but setting the speed incorrectly can also lead to defects and 3D printing failures. nine0005

In this article, we will introduce you to the general speed settings of a 3D printer. By the end of this guide, you'll know how to find the perfect balance between print speed and quality. Please be aware that different 3D printers, slicing software and materials may behave differently and retesting may be required.

By the end of this guide, you'll know how to find the perfect balance between print speed and quality. Please be aware that different 3D printers, slicing software and materials may behave differently and retesting may be required.

Well, run the slicing software and let's get started!

3D Print Speed

3D Print Speed is the main setting that affects the printing of your 3D model. As the name suggests, print speed determines how fast your printer's motors move. This includes the motors that control the X and Y axes, as well as the motor(s) of the extruder. nine0005

To test your 3D printing speed, download the test model to determine the optimal print speed above. The description of this 3D model also contains recommendations for speed settings. In essence, the experiment is that the same model will be printed, but at a gradually increasing speed, which will allow you to visually determine the optimal speed setting.

Too low a 3D print speed can cause deformation due to the nozzle being on the plastic for too long. If too fast, other overheating artifacts may appear, caused by insufficient cooling, as well as extrusion and poor adhesion of the layers. The optimal speed should be as fast as possible for your 3D printer without compromising print quality too much. This 3D model will help you determine what speed will be optimal for your particular case. nine0005

If too fast, other overheating artifacts may appear, caused by insufficient cooling, as well as extrusion and poor adhesion of the layers. The optimal speed should be as fast as possible for your 3D printer without compromising print quality too much. This 3D model will help you determine what speed will be optimal for your particular case. nine0005

To optimize print speed, this parameter is usually divided into several sub-parameters:

- Outer Wall/Shell 3D Print Speed : This parameter adjusts the print speed of the outer perimeter of the model. Usually it is slightly reduced to improve the surface quality.

- Inner Wall/Shell 3D Print Speed : This parameter controls the print speed of the inner perimeter(s) of the model. It is usually the same as the overall print speed to reduce print time while maintaining durability. nine0028

- Infill 3D Print Speed : This parameter controls the infill print speed of the model. This is usually the same as the overall print speed to reduce 3D printing time while maintaining strength.

- Top/Bottom 3D Print Speed : This setting adjusts the print speed of the top and bottom of the model. Usually it is slightly reduced to improve the surface quality.

Travel speed (idle)

Travel speed controls how fast the print head moves when it is not extruding plastic. Increasing the movement speed can save a lot of 3D printing time, but increasing it too much can lead to many defects, including misaligned layers (and therefore 3D printing failure). nine0005

To determine the optimal idle travel speed for your printer, print this test pattern at various travel speeds, starting at 100 mm/s and working up in increments of 5 mm/s. Continue to increase the speed if the surface quality is acceptable, and decrease if the 3D print quality is deteriorating. Pay attention to defects such as mismatched layers.

Retract Speed

Retract Speed controls how fast the 3D printer pulls material back before moving. This setting is critical for reducing material waste and improving 3D print quality. Too slow and you may be left with unsightly threads and blemishes on your models. Too fast and you can get excessive material wear on the extruder drive gear, resulting in voids. nine0005

This setting is critical for reducing material waste and improving 3D print quality. Too slow and you may be left with unsightly threads and blemishes on your models. Too fast and you can get excessive material wear on the extruder drive gear, resulting in voids. nine0005

To determine the optimal retract speed for your 3D printer, print this test model at various retract speeds, starting at 25mm/s and adjusting in 5mm/s increments. Pay attention to the remnants of plastic in the form of a web, stretched between the spikes of the model. The ideal retract speed should be the maximum value that minimizes these artifacts without deforming the material in the feed mechanism.

To better tune the retract speed, this parameter is usually divided into two additional parameters:

Retraction Retract Speed : This parameter controls how fast the retraction (actually pulling the thread back) occurs. This is usually the same as your overall retract speed and is set the same way.

Retraction Prime Speed: This setting controls how fast the filament is re-feeded after the initial retraction in preparation for further printing. Increasing this speed will result in shorter 3D printing times and fewer defects due to prolonged exposure to heat on the plastic. However, increasing it too much can also cause the newly fed media to not heat up enough before printing resumes. For most cases, this setting should be left the same as Retraction Retract Speed. nine0005

To learn more about reducing retract speed defects, see our separate retract speed tuning guide.

Walls, infill and layer height

The speed of your 3D printer is not only affected by "speed". It is also significantly affected by how much and how thick plastic is extruded onto each layer of the 3D model. These settings are incredibly detailed, so we'll only cover general information about how each of them affects 3D print speed. nine0005

- Walls : The wall setting specifies how many perimeters of plastic are extruded to form the outline of your part.

Increasing the number of layers increases the strength of the part, but also increases the 3D printing time.

Increasing the number of layers increases the strength of the part, but also increases the 3D printing time. - Infill : Infill is an internal structure designed to save material when 3D printing the interior of 3D models. The infill pattern will slightly affect the speed of 3D printing, while the density of the infill will significantly change the print time. Higher infill density increases part strength, but also increases print time. nine0028

- Layer Height : The layer height greatly affects the speed at which your parts print. The higher the layer height, the thicker each layer of your 3D models and therefore the faster they will be completed. Adjust this depending on what print resolution you need.

In search of the holy grail or how to find the maximum speed of 3D printing.

How to do a quick extruder performance test? How to find the maximum print speed on an FDM printer? What is the best print speed? How to find the optimal print speed? Why is the extruder throat clogged, did I put everything together correctly? How to quickly print on a 3D printer? Why is the filament wrinkled in Bowden? Why does the extruder chew on the filament? nine0005

About the main thing

Only three parameters are responsible for the maximum print speed on an FDM printer:

- The technical characteristics of the printer are how fast it can move the printing machine.

You can learn them from the user manual, so the study of mechanics is not considered here - your printer will not be able to move the print head faster than it is physically capable of.

You can learn them from the user manual, so the study of mechanics is not considered here - your printer will not be able to move the print head faster than it is physically capable of. - Extruder performance - whether the extruder is able to melt enough plastic to produce a line of a given height and width at a given print speed. This is an important parameter that depends on the design of the heating block, the standard E3D V6 melts less plastic than VOLCANO, but, as practice shows, there are no problems in the vast majority of cases, since on standard nozzles with a diameter of 0.2 to 0.6 mm you you will encounter another main reason for not being able to increase the print speed, namely:

- Maximum nozzle output!

Yes, the most critical point on the way to print speeds is precisely the performance of the nozzle - the amount of plastic that it is able to pass through itself without damaging the thread, without clogging the extruder, etc.

It is the nozzle output that is the overall output of the entire extruder, which affects the maximum line speed.

So, the output of the extruder is equal to the output of the installed nozzle. nine0005

How does it work? (short retelling, no details)

For those who are more interested in watching and listening - here is the video.

For those who are not interested in the details and who want more action immediately, without reading the abbreviations - a link to an Excel spreadsheet.

- Pre-set the flow (number of motor steps per mm), there are a lot of instructions on the Internet, I won’t write here - let’s assume that you have the flow set up.

- Uploading an excel spreadsheet. nine0028

- Enter the diameter of your nozzle, the diameter of the filament used, the height of the print layer in the fields marked in yellow (do not touch anything else!).

- In the table below you get the speed of feeding the filament into the extruder and the length of the extruded filament sufficient to print a line with a given width and height for 3 minutes at the specified print speed.

- Heat the extruder to the required temperature, and extrude the resulting length of the filament through the slicer at the selected feed rate (it is the feed rate, not the print speed, do not confuse!). nine0028

Extruder sticking? Filament does not gnaw? Is the diameter of the extruded thread equal to the diameter of the nozzle? Throat not clogged? Does the filament wrinkle in the Bowden tube? Does the heating unit successfully melt plastic? Does the diameter of the extruded filament match the diameter of the nozzle?

Excellent! Go to the next line of the table and extrude the plastic at the next feed rate. As soon as the problems start - you have reached the performance limit, print at the speed that was successfully tested last, for example, if the plastic bites at a print speed of 70 mm / sec, but everything was fine at a speed of 60 mm / sec - print at a speed of 60 mm \sec. You have found the maximum possible print speed with your nozzle, on your plastic, with your print temperature and your layer height. nine0005

You have found the maximum possible print speed with your nozzle, on your plastic, with your print temperature and your layer height. nine0005

That's all, if you did everything right, it means that I helped you. You can leave thanks in the comments and / or donate using the details on the profile page, I won’t be offended :).

But what does not need to do is send me curses without reading the article to the end if something did not work out.

If you have read, but do not understand - I'm waiting for your questions in the comments, I'll try to answer.

If you have read and understood, but have your own opinion - also write constructive criticism in the comments, it will be useful to everyone. nine0005

How does it work?

And here are the details of the study, for people interested in the details.

To print at a given speed, we need the volume of filament of a given diameter (1.75 mm or 3 mm) supplied to be equal to the required volume of the printed line . We know that a certain amount of plastic is required to build a line, equal to Volume of extruded plastic (OP) = line height (HL) * line width (SL) * line length (DL) , where Line Width (WL) is the diameter of the nozzle used, and Line Height (LH) is the height of the printed layer. The volume of extruded plastic (OP) is a tabular value and is constant regardless of the material used, it is determined only by the height, length and width of the printed line, for ease of use, these data are dynamically calculated in the Excel table attached at the link at the end of the article.

We know that a certain amount of plastic is required to build a line, equal to Volume of extruded plastic (OP) = line height (HL) * line width (SL) * line length (DL) , where Line Width (WL) is the diameter of the nozzle used, and Line Height (LH) is the height of the printed layer. The volume of extruded plastic (OP) is a tabular value and is constant regardless of the material used, it is determined only by the height, length and width of the printed line, for ease of use, these data are dynamically calculated in the Excel table attached at the link at the end of the article.

Knowing the volume of plastic (OP) per second of time 93 filaments per second of time, which is equal to a filament feed rate of 3.3 mm/sec.

If the nozzle copes with the extrusion of a given volume of filament, no excess pressure is created in it, no excess plastic is ejected from the melt zone into the throat (there is no plug in the barrier), there is no jamming or jamming of the filament, and the thread squeezed out by the nozzle does not deviates from the specified diameter, which means that the selected maximum print speed (as well as the filament supply to the extruder) can be used in printing. nine0005

nine0005

Actually, this is the answer to the question of what maximum print speed your extruder can support, on a given type of plastic, height and line width, at a given temperature.

The nozzle is the bottleneck of the whole system, even if the heating block is able to melt a lot of plastic - you will not be able to successfully extrude it if the nozzle does not allow it.

Many problems and questions may arise, but there is only one answer - the extrusion speed is greater than the throughput of the nozzle - it is necessary to experimentally (using the table) determine the allowable maximum printing speed and not exceed it. nine0005

The test can be carried out for each type of plastic you print with - their physical properties are approximately the same from type to type. I indicated at the very beginning how to use the table at the link at the end of the article - use it. I hope this helped you.

Important: if you experiment with different layer heights without changing the nozzle diameter, you will find the following: The change in layer height is inversely proportional to the print speed.

And it's true, how many times you reduced the height of the layer - so many times you can increase the speed of printing! This is a consequence of the fact that the maximum allowable volume of extruded plastic does not change. Unfortunately, another conclusion follows from this - as the layer height increases, you will be forced to reduce the speed. nine0005

Important: If the filament is extruded with a larger diameter than the nozzle, reduce the print speed, do not try to reduce the flow rate in the slicer!

The slicer initially sets the amount of extruded filament required to print the line, and changing the setting will create underextrusion. Forget about slicer flow control (the topic of a separate article) - slicer flow control is necessary in exceptional cases, and believe me, your case is not exceptional, since the flow is perfectly controlled by the feed rate and setting the number of microsteps of the extruder motor (if the flow is configured incorrectly).