20Th century fox 3d print

Free STL file 20th Century Fox Logo・3D print design to download・Cults

Anycubic Mono Resin Angled Corner Drip

Free

Improved DJI Mavic Mini Landing Gear

Free

Hydra Base for MicroSwiss Direct Drive for Ender 5 / Plus

Free

Anycubic Mono VAT Cover

Free

DJI Mavic Mini Battery Retention Clip

Free

DJI Mavic Mini Clip Mount for Ulanzi Drone LED

Free

DJI Mavic Mini Phone Ulanzi Holder

Free

Insta360 One X Improved GoPro Mount

Free

Best 3D printer files of the Game category

Truss bridge for OS-Railway - Fully 3D-printable railway system

Free

Peach princess lowpoly

€2. 50

Cheese Boxed Mouse

€3.76

IAI Nesher/Dagger

€1

VW Scirocco MK1 (Stanced wheels)

Free

Another Gold Hoarder Skull

€3.79

Sherlock Holmes bubble pipe

€1.20

Best sellers of the category Game

SM Healer Conversion Kit

€6

Snake and Rattlesnake

€3.76

Imperial Heavy Weapons & Regimental Flags [PRESUPPORTED]

€3

Off-Road Car

€2

Chopper Motorcycle Print-In-Place

€1

Beaky Boyz Builder: PF_MK-Six

€11. 79

79

Nice Flexi Unicorn

€1.05

WARFORGED VOIDWALKER EXOSUITS UPGRADE KIT

€9.43

CRAMER Truggy RC 4x4 Full 3D Printed

€7.50

Dugtrio Funny 3D print model

€8.49

Flexi Flying Unicorn

€1.77

USS EnterSurprise - Print-in-place Playset Container for Tiny F14 Jet Fighters

€3.76

Octopus 2.0

€3.76

Nice Flexi Dragon

€1.77

Eldstokkr Steel-Master & E-ROXs

€9.43

Articulated Dragon

€3.76

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ 20th century fox television logo 3d models 【 STLFinder 】

20th Century Fox Logo

thingiverse

20th Century Fox For kids I made the 2 and 0 separate so they can play with it. ... Have fun!

20th century fox logo 3D model

cgtrader

this is a detail 20th century fox television title or logo made in blender and editable also exported for other 3d formats

20th century fox logo 3D model

cgtrader

This 3D model was originally created with Sketchup 13 and then converted to all other 3D formats. ...Native format is .skp 3dsmax scene is 3ds Max 2016 version, rendered with Vray 3.00 Fox Studios Logo seen at the beginning of all of their movies

...Native format is .skp 3dsmax scene is 3ds Max 2016 version, rendered with Vray 3.00 Fox Studios Logo seen at the beginning of all of their movies

20th Century Fox 1994 Logo Update Remake

sketchfab

Made Sonic Yt The Logo remaker

20th century fox television

thingiverse

20th Century Fox Logo

sketchfab

No description provided.

20th Century Fox

sketchfab

CENTURY FOX

20th Century Fox

thingiverse

Twentieth Century Fox Film Corporation with support less Let's print it 3D :)

20th Century Fox Television (TEST)

sketchfab

No description provided.

20th Century Fox Television V2

sketchfab

No description provided.

20th Century Fox Movie Logo Replica 3D model

cgtrader

A Replica Of A Twentieth Century Fox Logo All Redone In Blender Render.

20th Century Fox 1994 logo remake Part 16

sketchfab

CENTURY FOX 16

20th Century Fox 2009 Logo 3D Recreation 3D model

cgtrader

. .. copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favor of fair use. All Rights By Disney/20th Century Fox/Studios. If Used In Commercials,School Projects E.T.C,Please Credit Me. ...

.. copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favor of fair use. All Rights By Disney/20th Century Fox/Studios. If Used In Commercials,School Projects E.T.C,Please Credit Me. ...

20th century fox 3d model.

grabcad

20th century fox 3d model.

20th Century Fox Logo 1977

sketchfab

Made In Blender.

20th Century Fox Logo Remake

sketchfab

Credit to TP Percival for the model. ...I am not stealing this, It’s for testing.

...I am not stealing this, It’s for testing.

20th century fox 3D print model

cgtrader

20th century fox

20th century studios 2020 logo

sketchfab

20th century studios 2020 logo

20th Century Fox 1994 Remake V4

sketchfab

20th Century Fox 1994 Remake V4 sorry for lag

20th Century Fox 2009 Remake Rebuild

sketchfab

my own rebuild on 20th century fox 2009 remake

20th Century Fox Logo 1994 Remake V6

sketchfab

No description provided.

20th Century Fox Logo 2010 Remake

sketchfab

you’re not a good person but you are not a Livestream E you

20th Century Fox Logo 1994 V5 FINAL

sketchfab

Credit to Eyertory!

20th Century Fox Logo 1994 Remake V3

sketchfab

Credit to Eyertory!

20th Century Fox Logo 1994 Remake (realistic)

sketchfab

Ethan James Titlon

20th Century Fox Logo By Borreguito Remake

sketchfab

I reuploaded it.

20th Century Fox 1994 logo prototype remake

sketchfab

No description provided.

20th Century Fox 1994 Logo Remake V7

sketchfab

No description provided.

20th Century Fox Logo (Mandy Variant) Remake

sketchfab

so I c T U R E I c T U R E I have a Ne in g major chorded and friends

3D printable 20th Century Fox logo

pinshape

Model dimensions: - height - 79 mm - width – 62 mm - thickness – 62 mm Designed in Solid Works 2012, rendered in Keyshot 5. 0.99.

0.99.

Free STL file 20th century fox・Object for download and 3D printing・Cults

Naruto Headband

Free

Pikachu

Free

Blastoise

Free

Drumsticks

Free

nine0003 DogFree

Disney Castle

Free

Skateboard

Free

Ford Mustang

Free

Best Files for 3D Printers in the Art Category

3 grenade granadas

2.45 €

Steampunk taxidermy stand

Free

Flexi Skeleton Pink Soldier - Squid Play

0,93 €

C Galaxy Trooper P1 Helmet Fan Art

8,47 €

Stretch print In Place Creepy Spider

2,50 €

nine0003 Floating worktop V. 2

2 Free

Ice cream play set for children

4,55 €

Folding Roberto

3.76 €

Art category bestsellers

Item

7 € -fifty% 3.50€

Baby Crystalwing, Cinderwing3D, articulating Flexi Wiggle Pet, print on site, fantasy

3,76 €

Triceratops on flexi printer

2,78 €

Cute skeleton with flexi print

2.78 €

Cute sloth with flexi print

2.78 €

☃️ Monster Snowman - XMAS TREE ORNAMENT☃️

2,50 €

Flexi print-in-place Phoenix

3,72 €

Cute frog with flexi print

1. 84 €

84 €

Jointed toy "Python snake", body with prints, head with latches, cute flexi

3,72 €

Pink Dragon, Valentine's Day, Articulating Animal Flexi Wiggle, Print on the Spot, Fantasy

3.82€

FLEXIBLE STANDING STANDING YETI

2,78 €

Cute little fox with flexi print

2,35 €

Bearded Dragon Articulated Toy, Imprinted Body, Snap Head, Cute Flexi

3.28 €

Cute elf with flexi print

1.84 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2,78 €

Elf on shelf in carbonite

€8.47 -fifty% 4. 24 €

24 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads. nine0006

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology. nine0006

nine0006

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers. nine0006

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc. ), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied. nine0006

), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied. nine0006

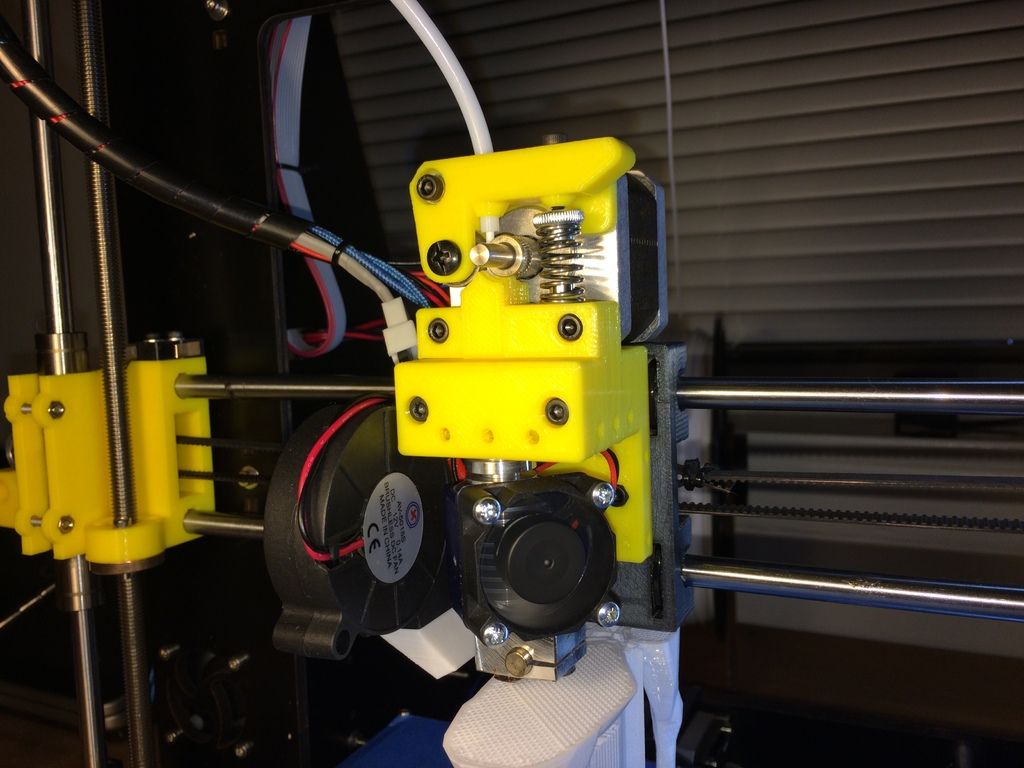

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers. nine0006

Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers. nine0006

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

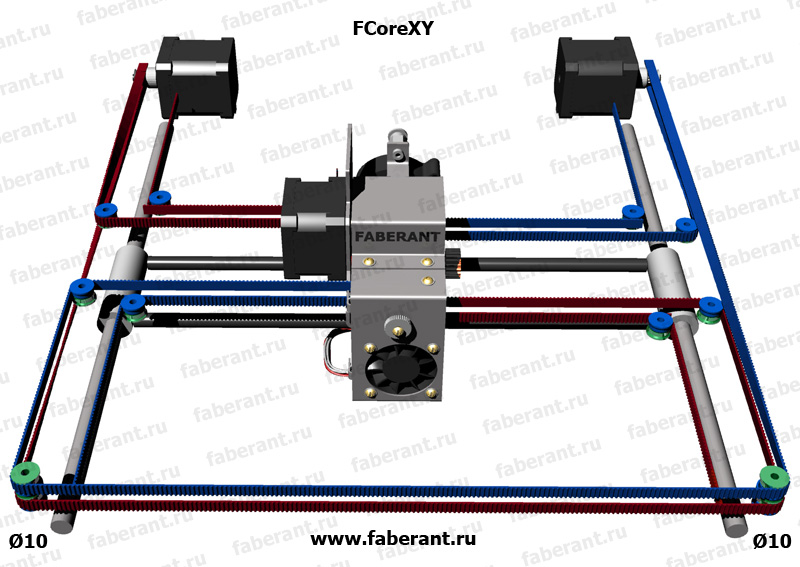

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer operating on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain. nine0006

driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain. nine0006

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible. nine0006

The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible. nine0006

First of all, it is worth mentioning the company MakerBot, which started as a startup, took the ideas of RepRap as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes. nine0006

This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes. nine0006

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend. nine0006

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials. nine0006

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal). nine0006

3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal). nine0006

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) . nine0006

All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) . nine0006

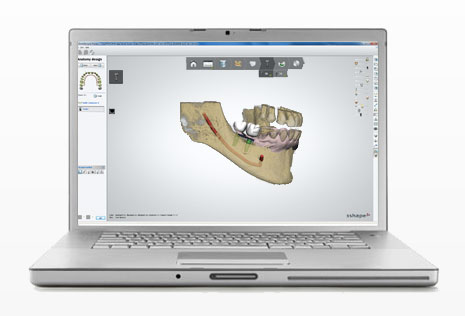

In addition to the "classic" scope of 3D printing, today you can increasingly see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages. nine0188 With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells. nine0006

nine0188 With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells. nine0006

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).