3D print meat

Scientists Create First 3-D Printed Wagyu Beef | Smart News

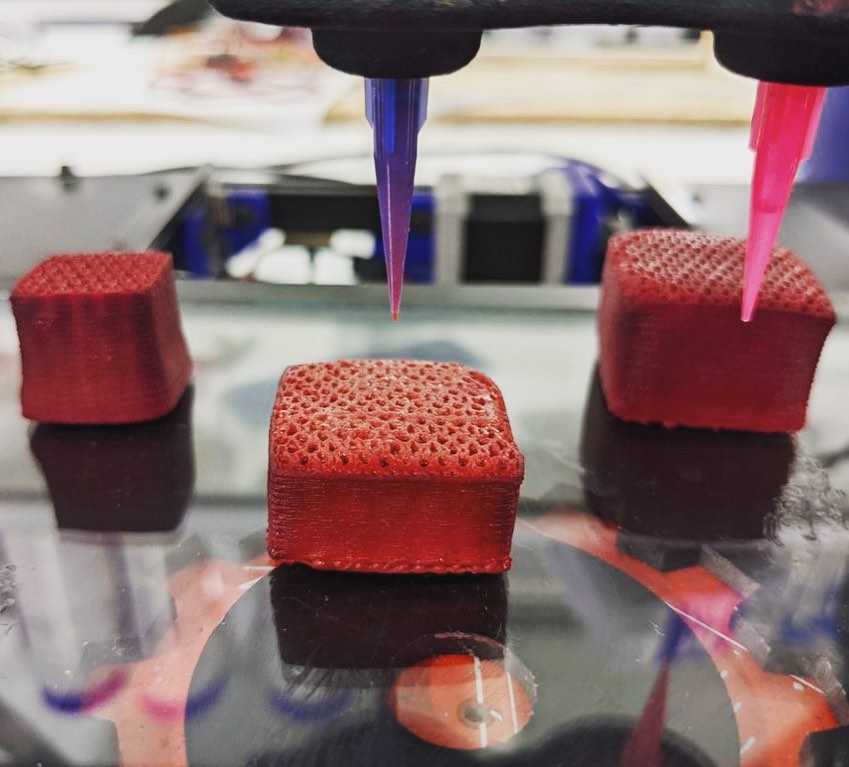

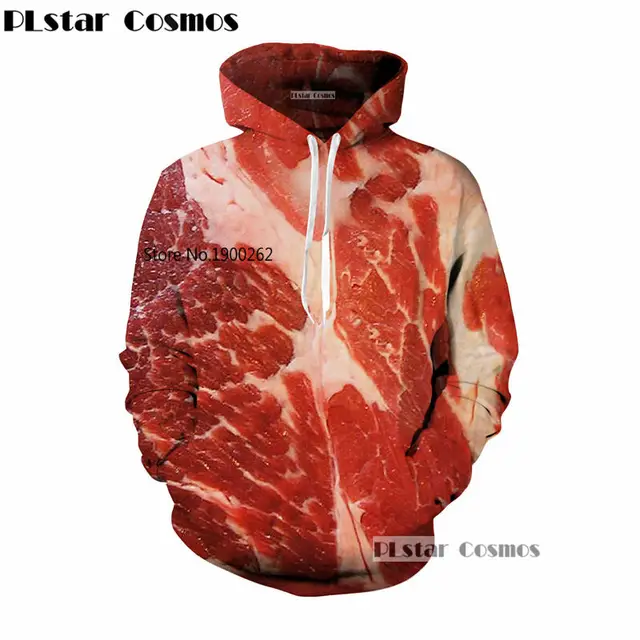

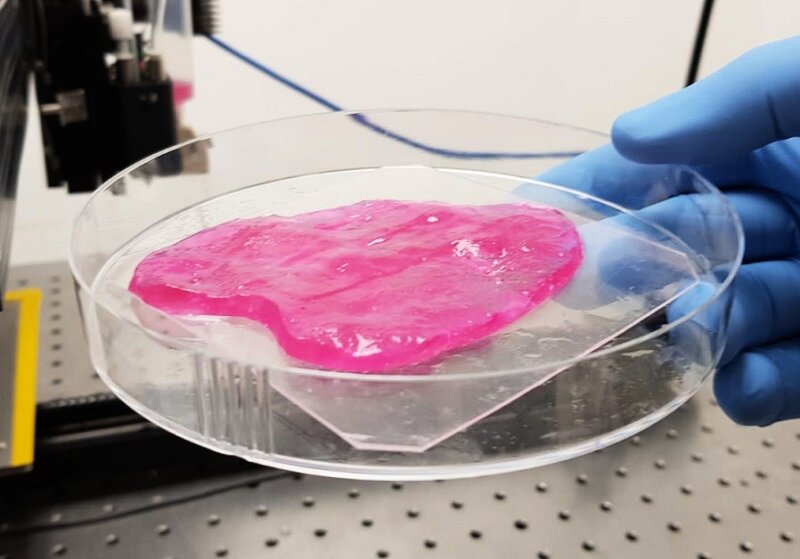

Scientists recreated the famous beef, which is prized for its fat marbling, or sashi. H. Alexander Talbot via Wikimedia Commons under [CC BY 2.0]Scientists in Japan successfully 3-D printed a cut of Wagyu beef that looks just like the real thing. The team at Osaka University in Japan used three dimenstional bioprinting to replicate the cut's specific arrangement of muscle, fat and blood vessels. They hope lab-grown meats could provide a more sustainable—and delicious—alternative to traditionally-raised beef.

“By improving this technology, it will be possible to not only reproduce complex meat structures, such as the beautiful sashi [or marbling] of Wagyu beef, but to also make subtle adjustments to the fat and muscle components,” study co-author Michiya Matsusaki said in a statement.

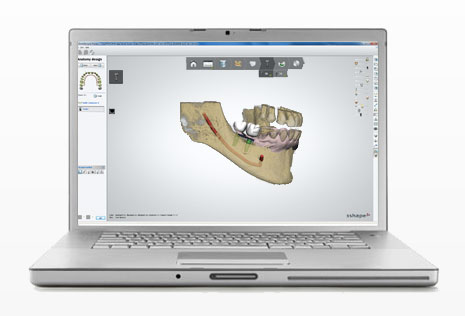

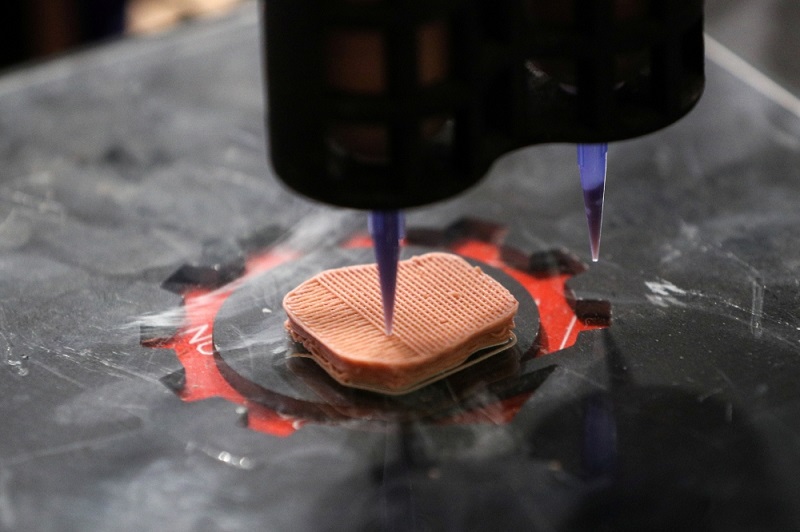

The study, published last month in Nature Communications, is the first to attempt bioprinting Wagyu beef—an expensive cut prized for its tenderness, flavor and delicate fat marbling. Like traditional 3-D printing, bioprinting uses a computer-generated model that deposits layers of material to create a final three-dimensional project. But unlike standard methods which use materials like plastic or metal, 3-D bioprinting stacks living cells to build complex structures like blood vessels and muscle tissue.

This new beef isn’t the first bioprinted cut of cow—an Israeli company unveiled their 3-D printed ribeye steak earlier this year—but Wagyu posed a specific challenge, according to Insider’s Cheryl Teh. The team needed to recreate the Wagyu's signature intramuscular fat content, known more commonly as fat marbling or sashi.

To create the manufactured meat, scientists used two types of stem cells from specific breeds of Waygu cows, reports Victor Tangermann for Futurism. By manipulating the stem cells, they could coax them into every type of cell needed to culture the meat. The individual fibers of muscle, fat and blood vessels were bio-printed in layers that replicated a perfect Waygu cut.

“Using the histological structure of Wagyu beef as a blueprint, we have developed a 3-D-printing method that can produce tailor-made complex structures, like muscle fibers, fat and blood vessels,” study co-author Dong-Hee Kang said in a statement.

No one has tasted the beef, so the meat’s flavor performance remains to be seen, reports Lauren Rouse for Gizmodo Australia. More studies are needed before anyone is green-lighting cooking or eating it. Because earlier experiments with cultured meats have grown largely unstructured cuts, the team hopes this high-controlled printing method can improve lab-grown meat texture, too. Theoretically, a customizable meat printing method means scientists could create tastier, more tender cuts of beef than exist today.

The scientists hope their 3-D printed meat will be an appealing option for those looking to reduce their reliance on livestock, which currently accounts for around 15 percent of U.S. greenhouse gas emissions. Though lab-made Wagyu beef could be a more sustainable alternative to traditionally raised meat, the high cost of production and limited regulatory oversight means it won’t be available on supermarket shelves any time soon.

Recommended Videos

What is 3D Meat, How is it Made, and What are its Benefits?

From pasta to chocolate and now 3D-printed meat, 3D-printed food is becoming increasingly popular. And while there is resistance against 3D-printed meat, the practice is here to stay.

With an increasing number of people adopting vegan, flexitarian, or vegetarian eating practices, coupled with the rising issues with livestock, alternative options that taste like meat are gaining in popularity.

In this guide, we’ll answer questions like what is 3D meat and explore the concept in greater depth.

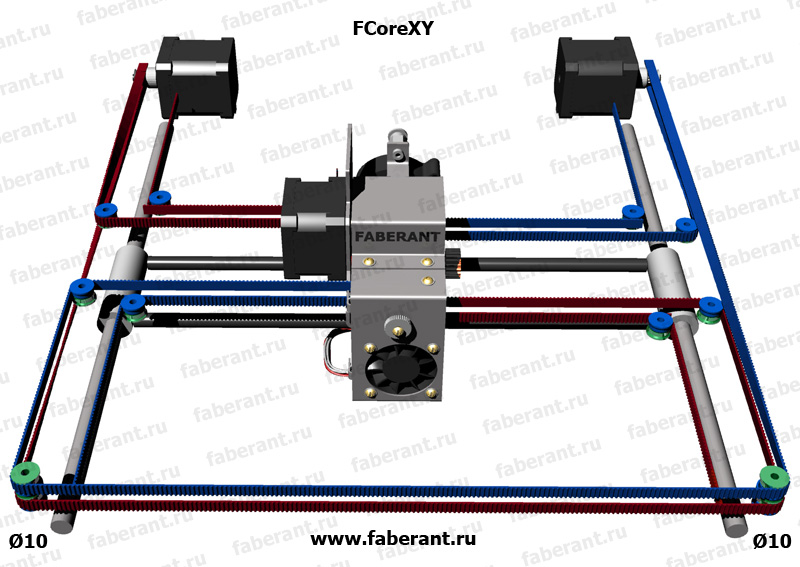

What Is 3D Meat?3D meat or 3D printed meat is a type of cultured or created meat made using 3D printers and additive manufacturing techniques, along with artificial intelligence and material science.

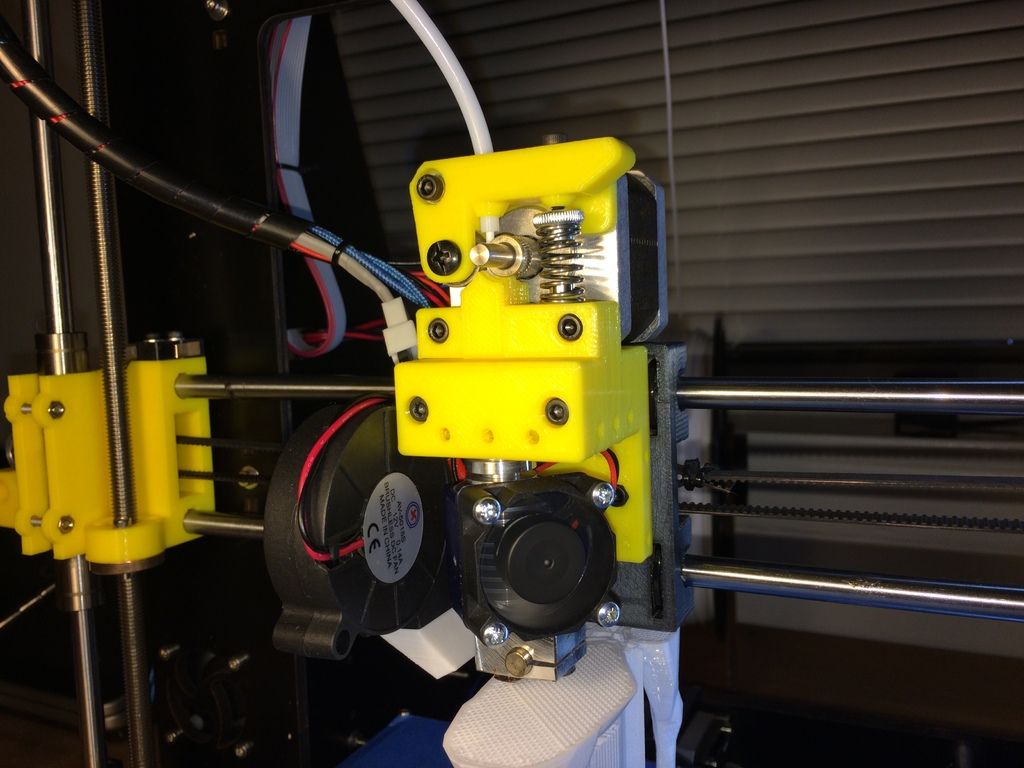

One approach involves feeding the printer cultured animal cells that are ‘printed’ into meat-like forms. Think of a regular printer, but instead of ink, you feed it a viscous consumable material, and you can eat the final product.

Note that 3D printed meat is only the process of producing the meat—it must still be cooked before it can be consumed. The 3D printing process only involves printing or projecting the material onto a surface in the desired shape.

Now that we’ve defined 3D meat, let’s see what 3D food and 3D meat are made from.

What Is 3D Food Made Of?3D food can be made using any ingredient as long as it adheres to the printing technique used. Some of these techniques include:

- Extrusion-based printing

- Selective laser sintering

- Hot-melt and room-temperature extrusion

- Inkjet printing

- Binder jetting

- Multi-printhead and multi-material printing

Most 3D food involves the following ingredients:

- Puree

- Mashed potatoes

- Jelly

- Cheese

- Frosting

- Chocolate

- Sugar

- Chocolate powder

- Protein powder

- Sauces (ketchup, pizza, hot sauce, mustard, etc.

)

) - Colored food ink

For 3D-printed meat, this list of ingredients can include plant-based ingredients such as peas, chickpeas, beetroot, etc., or cultured animal cells.

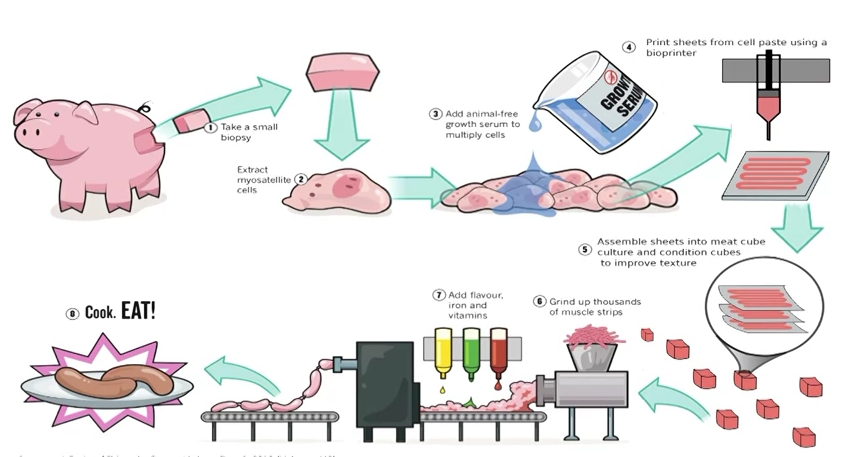

How Is 3D Printed Cultured Meat Made?Lab-grown cultured 3D meat is produced using bovine stem cells from a cow or chicken egg. Also known as starter cells, these are isolated and grown in a bioreactor to produce a large quantity of biomass. The cells are then differentiated into edible tissue of muscle and fat cells that are printed into the meat we know and enjoy. Consumers can rest assured that this is an entirely harmless procedure.

This process is further broken down into steps that may differ based on the technology and company producing it.

Is 3D-Printed Meat Vegan/Vegetarian?3D-printed meat may or may not be vegetarian, depending on the ingredients used to ‘print’ it.

Some 3D-printed meat is made using plant-based ingredients such as soy, pea protein, beetroot, chickpeas, and coconut fat. While other varieties of 3D meat — also known as cultured meat — are made using animal cells.

While other varieties of 3D meat — also known as cultured meat — are made using animal cells.

While there is technically no ethical violation in eating printed meat made using cultured animal cells, some vegans and vegetarians might disagree.

At present, there is limited regulatory oversight involved in 3D printing food. But with an increasing number of vegans and vegetarians adapting to the idea of 3D-printed meat or cultured meat, regulation will follow soon.

Is 3D Meat Healthy?Here are some of the health benefits of 3D meat when compared to consuming livestock-based meats:

- Lower risk of cardiovascular disease

- Lower risk of diabetes

- Lower risk of certain types of cancer

- And more.

Nutritious Content in 3D Meats

The best thing about 3D meat is that it can be found in various nutritional constituencies. Depending on health conditions or dietary requirements, 3D meat can be made to cater to people with celiac disease, obesity, hypertension, diabetes, and more.

Since 3D meat is made of plant-based ingredients or cultured cells, its nutritional value is typically much higher than regular meat. These alt-meats provide more nutritious supplements without any harmful content, like unhealthy fats.

3D Meat: The Expenses InvolvedAt present, 3D printing meat can involve high cost of production, which makes the resulting product prohibitively expensive.

Commercial-grade 3D printers cost thousands of dollars. Every element must be top-grade, from the materials and filaments to the machine itself. And with a relatively small scale of production, this can mean incredibly high production costs overall.

The filaments used in 3D printers also require quite a bit of processing to make them safe for food production. Add to that the time spent learning how to handle these devices properly, and this endeavor becomes even more resource-intensive.

Using cheaper alternatives comes with safety risks and machine troubles—two things that must be avoided.

Yes, 3D meat is eco-friendly.

3D printing uses fewer resources to produce a cultured lab-grown piece of steak than the complex processes needed to make the real thing. More importantly, it doesn’t require raising livestock, slaughtering, or processing meat.

The process of 3D printing also allows for the use of meat by-products to print a steak, thereby reducing the amount of waste that goes out of restaurants.

3D printing also has a lower impact on the environment than other forms of meat processing and production practices.

Currently, the practice of printing meat is one of the best eco-friendly alternatives in the industry. Although, more work is required to make the process affordable for all types of enterprises and customers all over the world. Manufacturers of 3D printers must also find ways to match the production requirements of current food production methods.

In time, these improvements will make the 3D printing process and products an affordable and more environmentally friendly alternative to traditional meat sources.

Companies and scientists making 3D-printed meats have claimed that their products taste just like the real thing. But little data backs up this claim since 3D printed meat is not yet accessible for large-scale consumption.

The technology used to create 3D meat aims to recreate the muscle fibers of real meat and its juiciness. This may be as close to getting the taste and texture right.

One recent study attempted to use 3D printing to replicate prized Wagyu beef, with a focus on mimicking the original product’s unique marbling, tenderness, texture, and flavor. While no taste reports are available, getting Wagyu right is sure to be an important milestone in the 3D printed meat industry.

There is also a reluctance to taste lab-grown meat among Gen-Z. This implies the taste of cultured meat is still mainly a matter of perception and will need some getting used to.

Types of Alt-Meat That Can Be Created Using 3D PrintingAs 3D meat printing techniques continue to develop, various types of meat can be created. The popular options available to consumers currently include:

The popular options available to consumers currently include:

- Ground beef

- Burgers

- Lamb

- Kebabs

- Sausages

- And more.

There’s no limit on the type of alternative meats that can be produced using 3D printing.

Reasons to Use 3D Printing to Produce FoodCustomization Options

One reason to use 3D printing to produce food is that you can customize the food preparations and alter its taste, flavor, texture, appearance, and more. This helps to ensure better consumer satisfaction, as personalization leads to satisfaction.

Nutritious

3D-printed food is also more nutritious than regular food, thanks to the nutritional control that can be exercised in its production.

From personalized dietary requirements to elderly nutrition, one can control how much protein, sugar, vitamins, minerals, and fats go into 3D-printed food. One can also make softer food products for older adults that fulfill their nutritional requirements.

One can also make softer food products for older adults that fulfill their nutritional requirements.

Sustainability

While plenty of food is being produced to feed everyone in the world, doing so requires a vast amount of natural resources. This has increased the need for sustainable solutions in food production.

One such solution lies in entomophagy, or the consumption of insects. For example, crickets have long been known for their high protein levels. Capturing and processing these insects for consumption requires very few resources, especially compared to other animal protein sources.

While eating crickets as they are might seem strange, 3D printing makes the process more palatable. Using crickets as material for 3D-printed meat will lead to a delicious and nutritious meat alternative. This is one way to explore the sustainable production of food for mass consumption.

When 3D-printed meat becomes more common, it will require little in the way of transportation—an element of food production and distribution that consumes a lot of resources and accounts for tons of greenhouse gas emissions.

Reduction of Food Waste

Leftovers, bruised fruit, meat off-cuts, perishables—there’s no shortage of food waste in every step of the food production and distribution process. Over 1.3 billion tons of food waste is generated every year.

By using 3D printing technology, one can put consumable ingredients to good use and finally solve the global food waste problem.

Reproducibility

With 3D printing technology, consistency is much easier to achieve. These machines are fed recipes that they turn into the ideal product, be it pancakes or burger patties.

Space Exploration

3D food printing is also a great way to provide astronauts with nutritious food alternatives. The customization options are especially useful—these explorers will be able to prepare the meals that they want.

3D-printed food also has a longer shelf life in comparison to freeze-dried food. This means scientists can design space exploration journeys for longer periods without worrying about how long food can last in space.

3D meat is a smart alternative to traditionally-raised livestock in many ways.

Less Reliance on Livestock

For starters, it’s an obvious solution for those looking to reduce their reliance on livestock. This takes the pressure off the planet by reducing greenhouse gas emissions.

With growing climate change concerns, this makes a good case for why you should consider 3D printing to produce meat.

Healthier

3D-printed meat is also much healthier than traditionally sourced meat. You can customize nutrition content, flavor, texture, and other elements to suit the preferences and needs of your consumers.

Vegan and Vegetarian-Friendly

Another huge benefit of producing meat using 3D printing is that it allows manufacturers and restaurants to offer vegan, flexitarian or vegetarian customers delicious meat alternatives.

Better yet, these meat products also live up to the expectations of meat lovers, despite being made with plant-based ingredients.

De-Animalization

Even meat lovers have limits. And some animal parts, while technically edible, are often just thrown away as offcuts.

The solution? De-animalization of meat such as heart, tongue, liver, kidney, intestines, etc.

Typically, these parts would be removed from the meat product. But with 3D printing, they can be used to make more aesthetically pleasing ingredients that taste just as delicious.

Wrapping Up 3D MeatPreviously just an experimental research field, 3D printing food is now reaching new heights and expanding in popularity. With 3D-printed meat, we’ll soon be resolving the myriad problems caused by the cultivation and slaughter of meat using traditional methods.

Share this article:

What risks and opportunities are fraught with 3D-printing of meat

It would seem, why invent, everything has already been invented. Take at least the delicacies according to the recipe "Just add water." They are even cooler than 3D printing, because they are extremely unpretentious. It does not require special equipment, detailed layouts, consumables, cleaning, maintenance. Splashed with boiling water, and the digestive foam unfolds in a matter of minutes, like a pontoon bridge from hunger to satiety.

Take at least the delicacies according to the recipe "Just add water." They are even cooler than 3D printing, because they are extremely unpretentious. It does not require special equipment, detailed layouts, consumables, cleaning, maintenance. Splashed with boiling water, and the digestive foam unfolds in a matter of minutes, like a pontoon bridge from hunger to satiety.

However, innovators do not stand still. They have developed a 3D Pandora's box and are slowly releasing printed food out of it. nine0003

Israeli startup Redefine Meat uses a 3D printer to create vegan steaks that mimic the texture, taste and appearance of beef. And Japanese scientists from Osaka University , using 3D printing technology, managed to get artificial marbled beef.

How is this different from anything that used to fill plates and stomachs?

What is alarming about the new technology

Relatively recently, about 10 years ago (12 to be exact) , no particular trouble was observed. Pioneers at MIT developed a "cooking printer" that printed edibles but didn't create them. Just serving, basically. Absolutely harmless technology.

Pioneers at MIT developed a "cooking printer" that printed edibles but didn't create them. Just serving, basically. Absolutely harmless technology.

Then it logically developed into more and more precise and complex mechanisms for creating masterpieces from chocolate, pasta - whatever. It was already possible to exquisitely decorate your edible fantasies, not yet swaying at the foundations of the universe. The golden age of portraits on cappuccino foam, witty figurines on wedding and divorce cakes (if you didn't know, it's an entire industry) . Everything went on cheerfully and carefree, as it should be on the eve of a big nix.

And then it began - the seal of meat. The man again pressed the button under the inscription "DO NOT PRESS!" I poked it several times at first, then fixed it with a toothpick so that it would not back out, and delved into innovations.

Unlike the first timid "cooking printers", now everything is serious.

First meat, and in January 2022, fish appeared. So, Israeli startup Plantish has created a 3D printed vegetable-based salmon fillet made from legume proteins and algae extract that mimics the original in texture and taste.

The meat is printed with high quality, you won't find fault with it. But the cost is still higher than that of a real slaughtered, from flayers and concentration camps for fish, which are delicately called nurseries. Only these ranks converge rapidly. Like railroad tracks in a sunny landscape. And we rush along them towards the beautiful distance, which is getting closer with every beat of our real unprinted hearts. nine0003

But come on! What is bad and disturbing here? On the contrary, a technology has finally appeared that will protect peaceful animals, fish, other fauna and even, by the way, flora. It will be possible to feed everyone without eating anyone - isn't that wonderful! The wolves are full, the sheep are safe.

Mankind is on the threshold of a new era - total abundance at no one's expense, as if by magic. A bit like "free" credit card rates. Banks teach us that a mousetrap can be with a deferred payment, but it will slam shut. Every grace period ends sooner or later. nine0003

What will 3D printing of meat and fish lead to? Including "greens", vegans and gourmets who joined them.

A truly heavenly time will come when almost any food will be available to everyone. Quality, the best. Nutrient-rich, aesthetically pleasing, fresh from the printer. And what is important, with pristine karma, including the conscience of cooks. nine0020

It must be a special feeling to chew a cutlet for which no one was killed. The vegans looked at each other knowingly, but the plants are exactly the same living creatures. There were experiments proving that they have memory and emotions. The fact that we are used to sprinkling them with vinegar and neatly laying them out on dishes in neat pieces speaks only of our attitude. In a different scenario with a salad, we could discuss the weather, and Mr. Pumpkin would have a construction blog.

In a different scenario with a salad, we could discuss the weather, and Mr. Pumpkin would have a construction blog.

However, talking would change nothing. You can play quite complex games with octopuses, fish and birds recognize people after a long separation. It doesn't really help them all. The Red Book is not by chance of this color. nine0003

The whole biosphere on the Earth lives due to the fact that some forms of life eat others. Microcosm, macrocosm. They say there were also dinosaurs, so they also ate be healthy, until the ancient Mask flew from Mars in a large flotilla on a friendly visit.

This world order is not exactly to my liking. The fact is that they have already tried to break the biological balance several times, and everything is somehow unsuccessful. Then sparrows will be killed in the Middle Kingdom, and then at least eat caterpillars and locusts instead of harvest, because (suddenly) something went wrong. That in Australia, rabbits were bred, and then they had to build the Great Australian Wall from them, which still did not really protect.

But these are all flowers.

Let's imagine that the printing of food is really established. Not in the form of exotic boutique fads, but massively and everywhere. Like electricity or the Internet. But this will inevitably happen. In 2013, artificial meat for a burger cost $325,000, after 5 years the amount dropped to $11. Now we are approaching the point where will be cheaper to print than to grow. As soon as this happens, after a short pause for awareness, the flayers will go under the knife.

Billions (not an exaggeration) of livestock units will turn out to be useless and unprofitable. Unfortunately, instead of starting to dance through the chamomile meadows, they will probably die very quickly and unpleasantly. They will try to sell their carcasses on the cheap before the new technology swept away the entire market. Like chamomile, as well as other fields. But this will not help anyone, and the farmers will follow after the pigs, cows, other primers. nine0003

nine0003

Entire industries will be sucked into the rapidly growing black hole. Almost all agriculture, various types of vodstva, at the same time the forestry will go there too. And also a lot of things from the processing industry, transport. Retail and wholesale trade will be hit hard. Even catering will get it.

Automation already threatens to create unemployment higher than ever. At the intersection of trends of AI, robots and 3D food printing, billions of "fired" animals will be added to 90,008 billions of people who were fired from work .

The consequences will be truly dramatic. Oddly enough, despite the abundance of leisure and creativity, it's not design or NFTs that the hungry, frantic crowds will get into. I don’t even want to think what kind of Apocalypse can begin.

But the Titanic would not be complete without the upper decks. Here they will come off not childishly. After all, you can print not only chicken or capelin. How about a menu from the same Red Book? Or Jurassic Park? Or even feasts by invitation without QR codes in large vaulted halls to the fascinating speeches of the lecturer Hannibal. nine0003

nine0003

Here the nerds get a little freaked out and, nervously adjusting their glasses, they start muttering that they meant something completely different, and in general they had good intentions. But they will be hard to hear over the roar of the crowd: “Chop! A couple more!"

Is there light in the ring tunnel

The problem is not technology, of course. It's bad that Neanderthals modernize clubs faster than they evolve themselves. In an ideal spherical world, cookery and even meat printers could indeed save many lives, feed and equip everyone.

Here it should be noted that according to the UN, in 2022 (yes, right now) about 45 million people are hungry or may be starving, which is not much better. In this context, any way to feed people looks not just tempting, but strictly necessary.

What do we say to quality standards in such a situation? That's right, somehow then . Yes, "green" technologies are no strangers to the fact that they only have a beautiful showcase. Production may no longer be very environmentally friendly, and even more so support. In artificial products, stimulants of taste, smell, color and consistency are asked by themselves. To make it not just cheaper, but spectacularly more profitable. nine0003

Production may no longer be very environmentally friendly, and even more so support. In artificial products, stimulants of taste, smell, color and consistency are asked by themselves. To make it not just cheaper, but spectacularly more profitable. nine0003

No matter how well-intentioned we are in an uncomfortably warm place with 3D vats. And not only those who were starving, but in general all or too many. After all, by and large it is difficult to say - do people own the technology or does it own us?

As the Strugatskys said: "Man is only an intermediate link in evolution, necessary to create the crown of nature's creation - a glass of cognac and a slice of lemon."

Well, or for something else that may appear at the intersection of neural networks, 3D printing and some other non-existent plasma generators. In the meantime, you can live a little the old fashioned way. In a terrible archaic way that will soon go out of fashion feet first. nine0003

nine0003

See also:

What does 3D printer steak taste like? - such a question is no longer from the category of fantasy. Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants. nine0003

Many companies produce artificial meat from soy and pea protein, coconut fat, sunflower oil, natural colors and flavors. But even if they taste like real minced meat, they lack the main thing: the texture and look of the steak. Redefine Meat founder Eshkhar Ben-Shitrit figured out what to do with it. His printer prints three types of voxels, or millimetric three-dimensional pixels. Some copy muscle, others fat, others blood. Each stake consists of an example of 3 million voxels. By changing the recipe and collecting them in different sequences and proportions, you can reproduce tenderloin, ribeye, picanha and other types of steaks. And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online. nine0003

By changing the recipe and collecting them in different sequences and proportions, you can reproduce tenderloin, ribeye, picanha and other types of steaks. And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online. nine0003

How Ben-Shitrit met cows

Ben-Shitrit grew up on a kibbutz where his mother ran a dairy farm. He loved meat since childhood. And at the age of 13, he learned how to cook the perfect steak when he went to work part-time at his uncle's restaurant in Tel Aviv in the summer.

He graduated with a law degree from the Hebrew University of Jerusalem, worked for a year and a half as a clerk of the Israeli Supreme Court, and in 2011 changed careers to become a product manager for Hewlett-Packard. Responsible for printing on cardboard boxes. His next job was at the Israeli company Highcon, specializing in cardboard packaging. In 2015–2017 he was its vice president of marketing. nine0003

Responsible for printing on cardboard boxes. His next job was at the Israeli company Highcon, specializing in cardboard packaging. In 2015–2017 he was its vice president of marketing. nine0003

So, Ben Shitrit loved meat. But when his first child was born, he was surprised to find that he could no longer eat beef. There were memories of his childhood on a dairy farm, where he saw firsthand how cows take care of their calves. Ben-Shitrit tried many meat substitutes, but none of them looked like a real steak. Then he had the idea to print meat on a printer to copy its texture. He quit and in February 2018 founded Jet-Eat, which was later renamed Redefine Meat. nine0003

“The company was engaged in R&D for almost two years before [in the fall of 2019] we first raised serious investments and recruited a team - in nine months the staff grew from 6 to 25 people,” Ben-Shitrit told Business Insider and last July . Now, judging by the information on the startup's website, it employs 36 people.

The startup developed its products in collaboration with scientists from the Israeli Technion Institute of Technology, using its laboratories for experiments. In September 2019The company received $6 million in seed funding from CPT Capital, a venture fund that also has stakes in other artificial meat producers, Impossible Foods and Beyond Meat. In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

1/5 cow per day

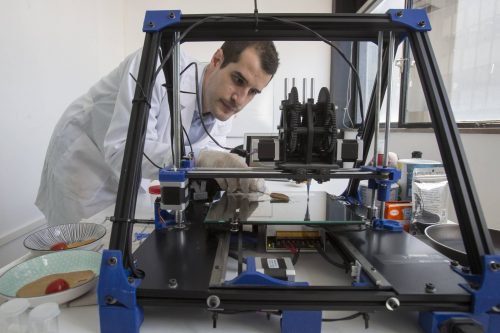

Redefine Meat already has something to boast about. Last June, the company officially unveiled the world's first plant-based industrial 3D printed steak, then began testing its product in high-end restaurants in Israel, and Ben-Shitrit became a hero in the Israeli media with the phrase "We print steaks on a 3D printer ". nine0003

True, the fastest printer at his disposal prints about 6 kg of meat per hour. With three cartridges to recharge (artificial meat, fat and blood) and maintain the machine, on good days it produces about 90 kg of meat per day. Beef cows can weigh about half a ton, but meat can account for 60–70% of the total weight.

Beef cows can weigh about half a ton, but meat can account for 60–70% of the total weight.

No meat in meat, no milk in chocolate

Not only meat becomes vegan. In mid-February, Nestle announced that it would launch the first vegan milk chocolate, called KitKat V. The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes. nine0003

The startup is currently completing the construction of the first production line, which will assemble a new printer model designed for 10 kg of meat per hour. “It’s not yet an industrial machine, we call it semi-industrial,” Ben-Shitrit told Business Insider.

“It’s not yet an industrial machine, we call it semi-industrial,” Ben-Shitrit told Business Insider.

Machines will be installed directly at customers' premises to enable them to sell fresh meat. The technology that Redefine Meat is developing could disrupt the global food supply chain, Ben-Shitrit shared his thoughts with The Times of Israel online edition. 3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said. nine0003

Redefine Meat was supposed to hit restaurants late last year, but the coronavirus got in the way. During the pandemic, Redefine Meat signed contracts with several organizations interested in introducing artificial meat into the assortment. For example, in January of this year, Redefine Meat announced a strategic agreement with Israeli meat distributor Best Meister. The partner will supply not only to restaurants in Israel, but also to butcher shops. The agreement was signed after a blind tasting of alternative meats in Tel Aviv (both companies claim that it was the largest in the world - it was attended by about 600 people), which showed that 90% of meat eaters like fake meat. The company wants to conduct the same test with chefs in other countries and is preparing to enter markets in Europe, Asia and North America later this year. “This is a step towards becoming the world's largest alternative meat company by 2030,” Ben-Shitrit told The Times of Israel.

The company wants to conduct the same test with chefs in other countries and is preparing to enter markets in Europe, Asia and North America later this year. “This is a step towards becoming the world's largest alternative meat company by 2030,” Ben-Shitrit told The Times of Israel.

What the startup hopes for

Ben-Shitrit is going to sell his meat at the price of the real one. He believes that now is the best time to bring the product to market - many large meat companies are investing in meat alternatives for vegans, flexitarists, etc.

According to Euromonitor, global sales of meat substitutes reached $19.5 billion in 2018. In 2019, investment bank UBS predicted that the plant-based meat market would reach $85 billion by 2030. And Barclays named meat substitutes as the fastest growing segment of the food industry and estimated their market by 2030 at $ 140 billion. A large contribution to its popularity is the demand from people concerned about healthy eating, animal cruelty and climate change.