3D printed turbine download

Turbine best 3D printer files・Cults

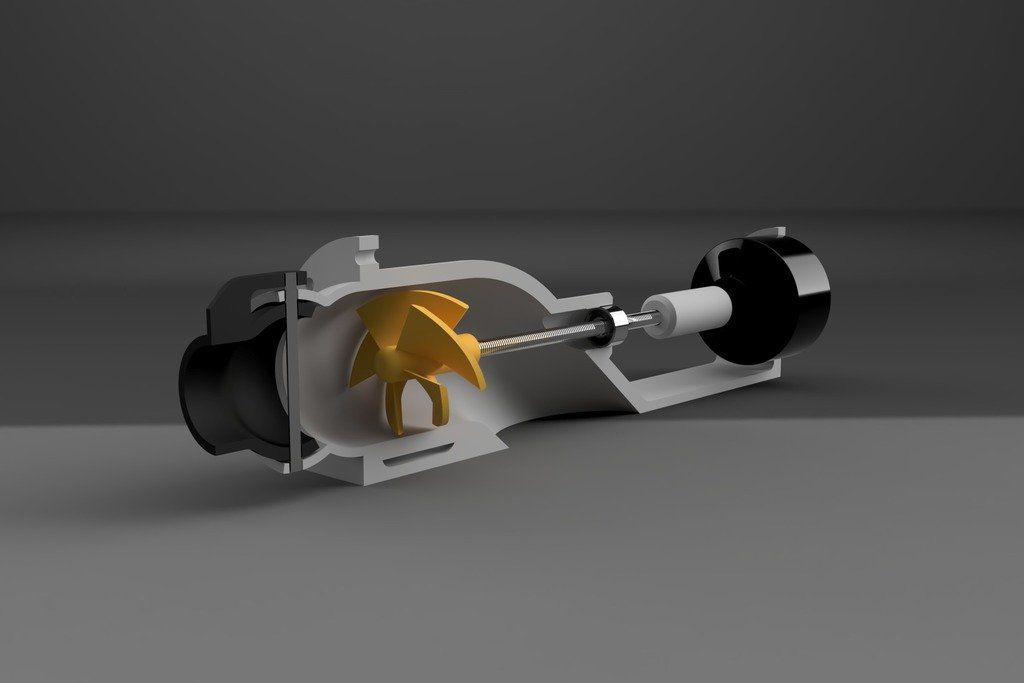

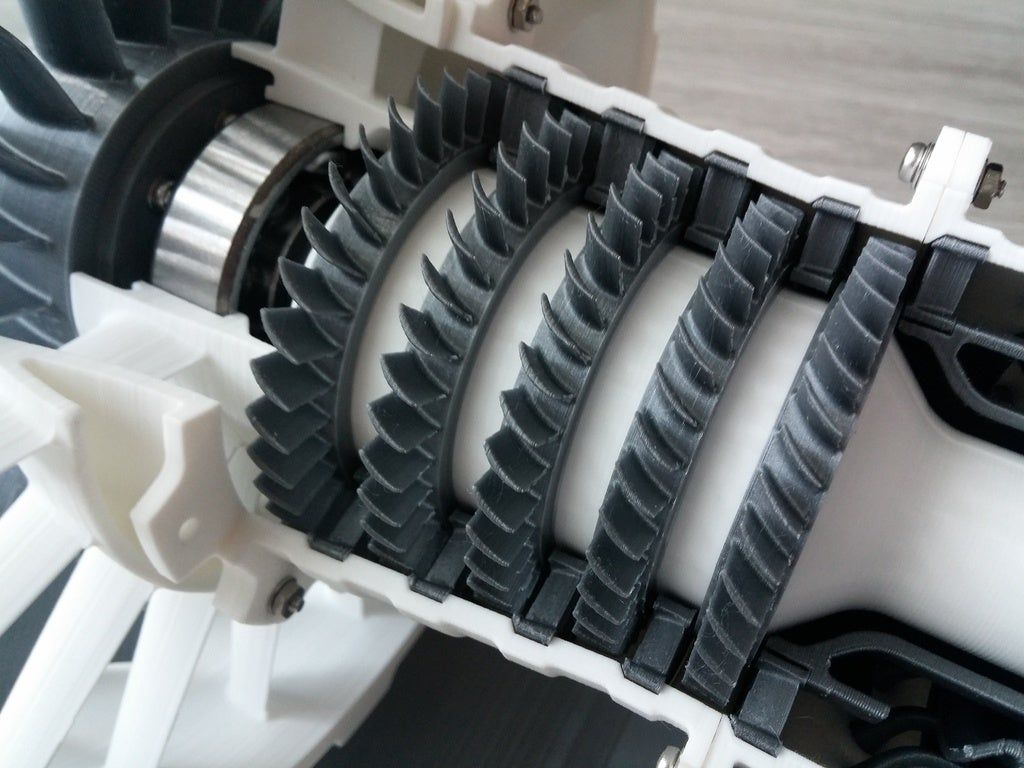

Turbine for RC boat

€6 -75% €1.50

Turbine ECU bracket Universal

€3.56

Jet Cat ECU Board Holder V12

€4.27

Vertical Turbine - Derived

Free

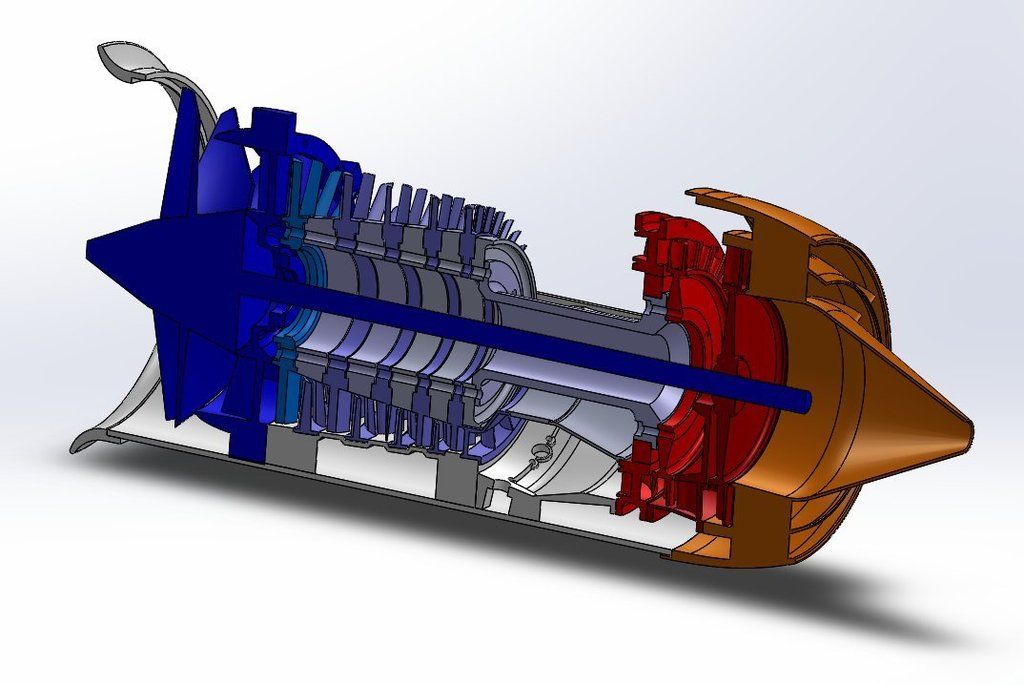

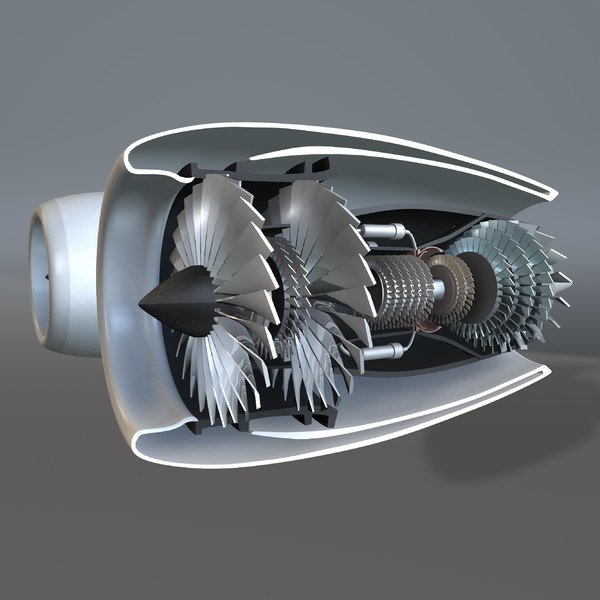

Turbojet Engine, 2nd Flight, 1941, Sir Whittle

€14.12

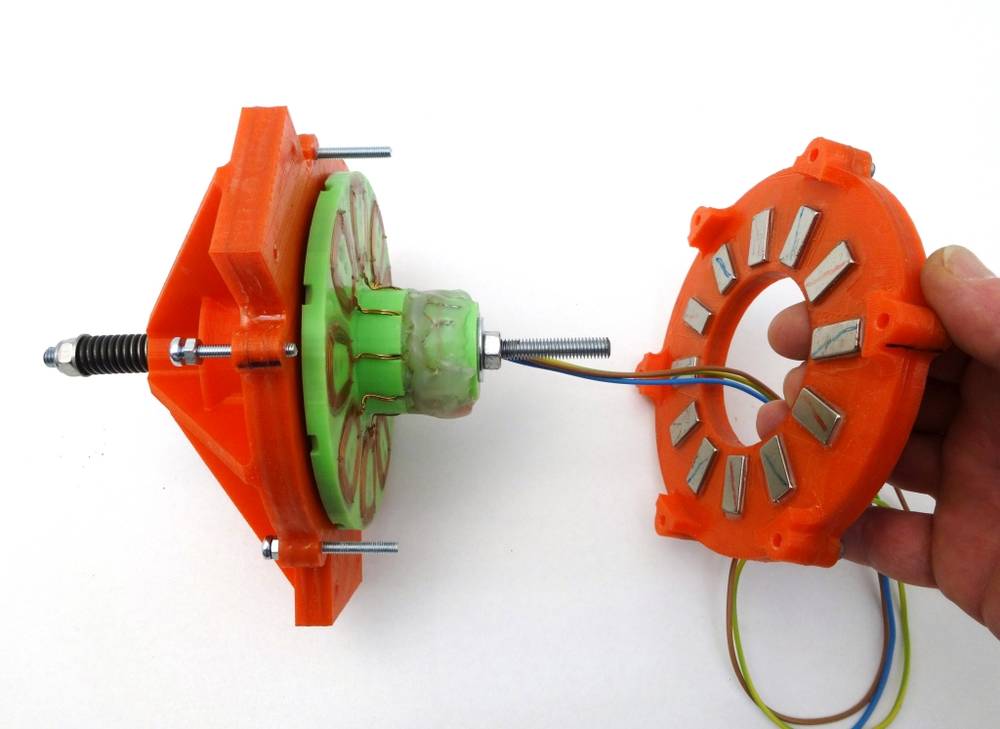

Modular vertical wind turbine electricity generator a simple and economical project to produce energy at home

€5 -25% €3.75

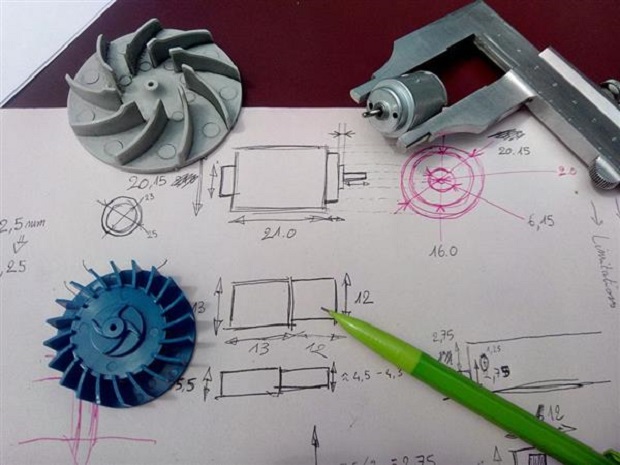

Turbocharger Small 3D Printed 25mm Turbine

€2

P51 mustang NEW Hight definition work Cockpit STL FILES ONLY

€25

Wind turbine, experiment on the effect of the number of rotor blades and their angle of attack on the performance.

Free

Turbine Water Jer

€0.54

SciFi Turbine

Free

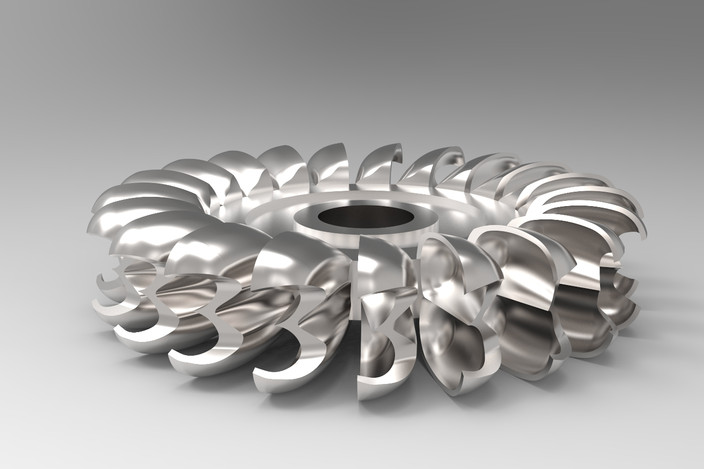

TURBO IMPELLER

Free

Motorized Wind Turbine

€5.25

A320 (IAE 2500) ENGINES PACK L&R

€2.50

Vertical Turbine

Free

'Water / Shower Powered "Turbine" Mods - Exhaust redirection, Connectors, Printing Improvements

Free

HANDPIECE BASE/ BASE FOR HANDPIECE AND MICROMOTOR

€9 -20% €7.20

1/24 78-81 Camaro Turbine Wheels

€5. 72

72

Rotary wind Spinner Toy

€1.88

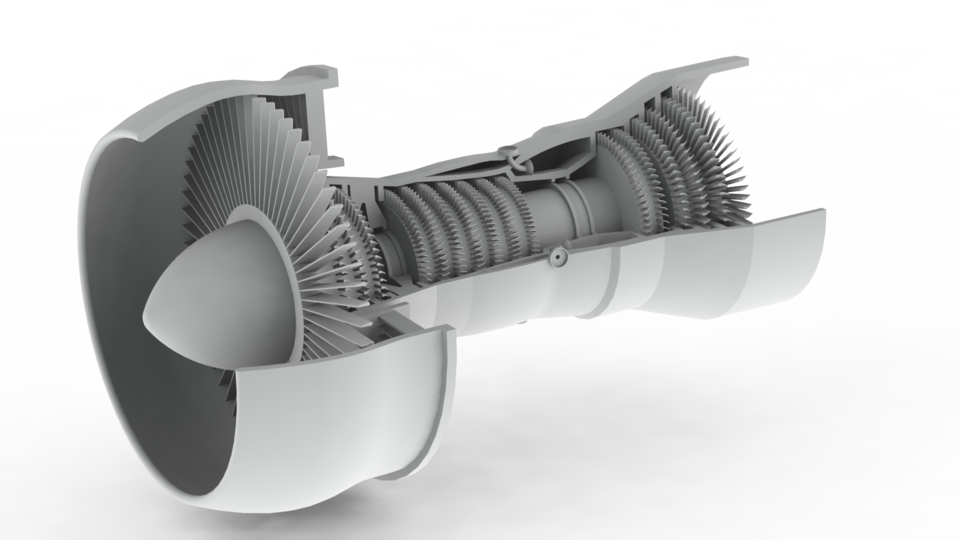

Airbus A320 Turbofan

Free

turbo guard

Free

Turbocharger inlet compressor

€8.95

epicyclic gear for vertical wind turbine

Free

Reactor

€3.96

Pump Impeller Fan

€1

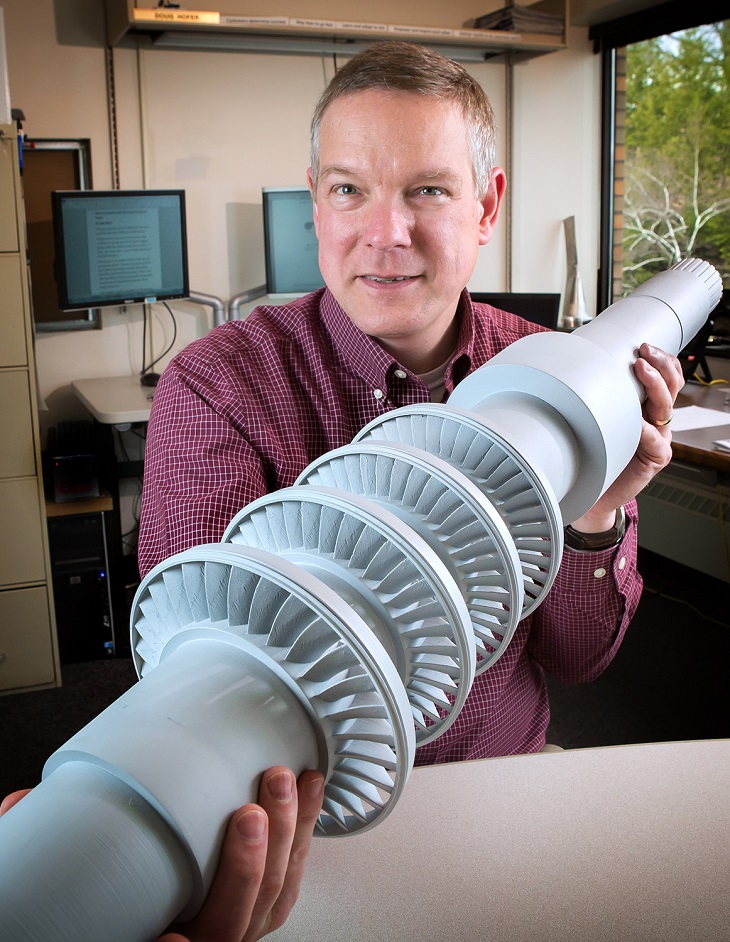

Sample Steam Turbine

Free

Jet Turbine Blades

Free

Hairdryer impeller 8 blades

€4

Hairdryer impeller 7 blades

€4

turbine thing

Free

Decorative VAWT

Free

3DSolutech Spool Wind Turbine

Free

A-10

€3

Air Pump

Free

Gyroscope Earrings

Free

1/24 Offroad wheels

€5

Vertical Helical Wind Turbine

€1. 38

38

SL_ST BALANCING STAND in progress

Free

Fan with chasing

€2.54

Impeller and pulley of the BOSCH ARM lawnmower motor

€14

Turbine Mug v2

€1

Turbine Blower for 380 sized Motor

Free

5015 turbine repair

Free

Impeller for engine salute

€2

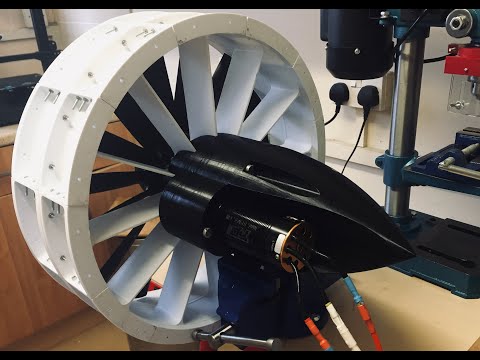

120mm ELectric Ducted Fan

Free

Turbine blade

€0.50

Kingtech Turbine FOD Mesh Holder

€2.85

Xicoy X45 pump bracket

Free

Lenz2 Helical Turbine Xl.

STL File for 3D Printing Digital

STL File for 3D Printing DigitalEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Click to zoom

725 sales |

4. 5 out of 5 stars

5 out of 5 stars HKD 23.82

Loading

Explore more related searches

Listed on Sep 10, 2022

One favorite

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

All categories

Craft Supplies & Tools

Best 3D Printing Files Turbina・Cults

Turbine for RC boat

6 € -75% 1.50 €

Bracket for turbine control unit Universal

3.56 €

ECU board holder Jet Cat V12

4.27 €

nine0002 Vertical turbine - derivativeFree

Turbojet engine, 2nd flight, 1941, Sir Whittle

14.12 €

Modular Vertical Wind Power Generator simple and economical home power generation project

5 € -25% 3. 75€

75€

Turbocharger Small 3D printed 25mm turbine

2 €

P51 mustang NEW High resolution cockpit operation STL FILES ONLY

25 €

Turbine water Jer

0.54 €

ENGINES A320 (IAE 2500) KIT L&R

2,50 €

Vertical turbine

Free

'Turbine' Water/Shower Powered Mods - Exhaust Redirection, Connectors, Print Improvement

Free

1/24 78-81 Camaro turbine wheels

5.72 €

Airbus A320 Turbofan

Free

nine0002 Turbine protectionFree

Turbocharger inlet compressor

8. 95 €

95 €

Epicyclic gear for vertical wind turbines

Free

Reactor

3.96 €

Sample steam turbine

Free

nine0002 turbinefree

Decorative VAWT

Free

Earrings with gyroscope

Free

1/24 off-road wheels

5 €

SL_ST BALANCE STANDARD in progress

Free

nine0002 Embossed fan2.54 €

Mug "Turbine" v2

1 €

Turbine fan for size 380 engine

Free

5015 Turbine repair

Free

120mm electric duct fan

Free

nine0002 Turbine blade 0. 50 €

50 €

Kingtech Turbine grid holder FOD

2.85 €

Pump bracket Xicoy X45

Free

Turbine dryer FAR SLEM 08

Free

Turbine Propeller Fan Generator v2

Free

nine0002 Single turbineFree

Turbine head v2

Free

Sci Fi flying drone 3D model Cyberpunk

3,76 €

Mate Aircraft Turbine V2.0

10.82 €

Best fpv drone propellers

4.02 €

nine0002 Hair dryer turbine1.73 €

Turbofan for RC

Free

Screw extractor centrifugal turbine

5 €

3D Hydro generator - hydraulic generator

18. 94 €

94 €

Eixo Propulsor Hidráulico - Estilo WaveJet

6.34 €

anemometer fan replacement (somfy)

1.50 €

Warhammer Epic Industrial Buildings (8mm)

Free

Electric vehicle hydrant

Free

MINI *turbo* BONG - Wiadro machine *eco smoking*

2,14 €

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product. nine0007

In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product. nine0007

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Available technologies and key differences

Currently, a huge number of 3D devices have appeared, from small desktops that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

FDM 3D printing

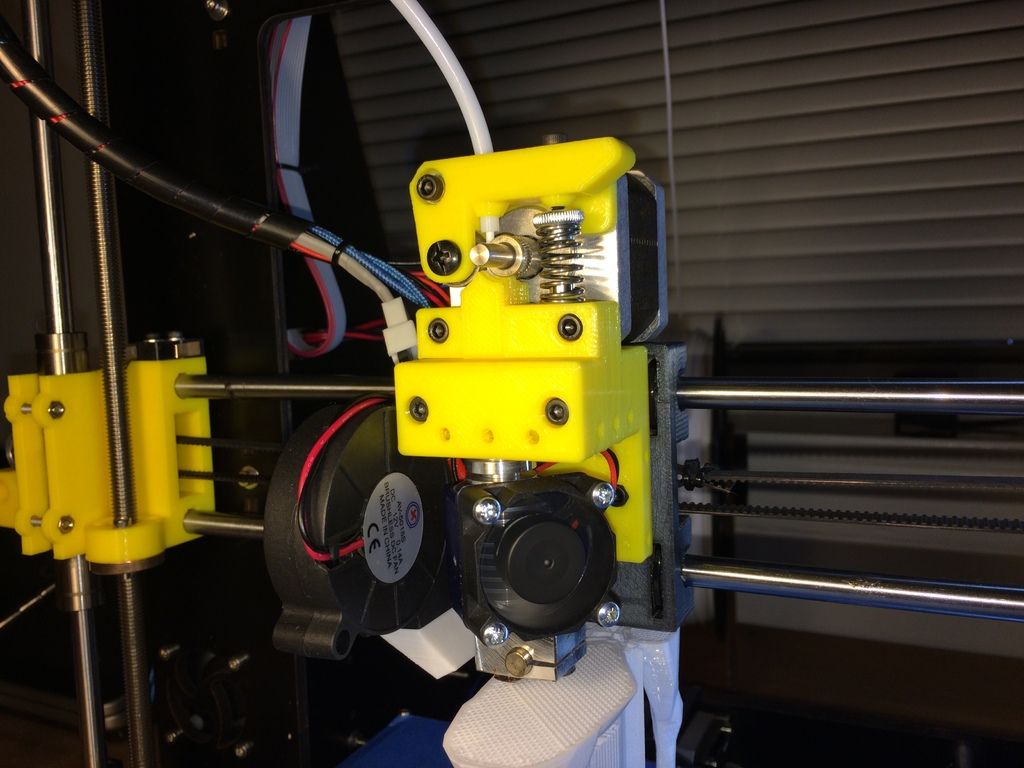

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

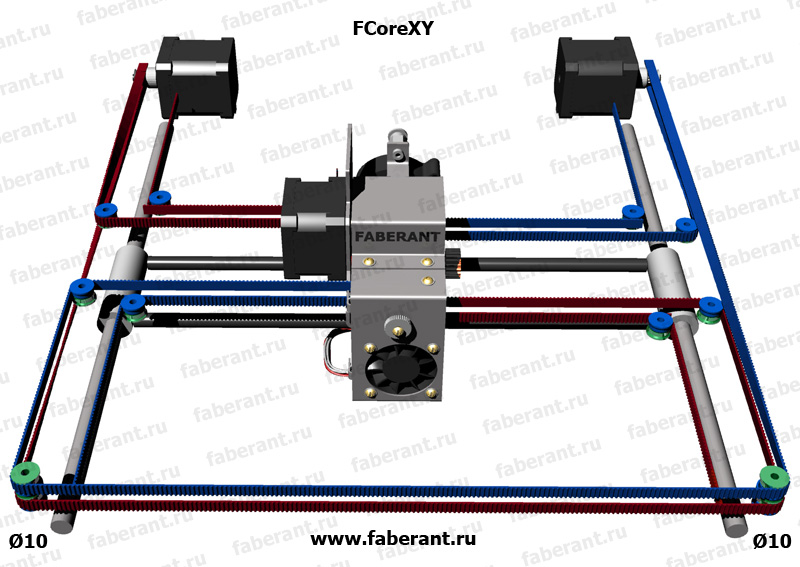

Schematic operation of FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc. nine0007

On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc. nine0007

Pros:

Cons:

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

Photopolymer printing

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details. nine0007

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

nine0258 -

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more. nine0007

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

nine0219 CreatBot F160-PEEK designed for use with refractory plastics

Photopolymer printers

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model. nine0007

Large Area Prismlab Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored. nine0007

Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored. nine0007

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support. nine0007

You can combine several materials at once - for example, for complex models, you can use wax as a support. nine0007

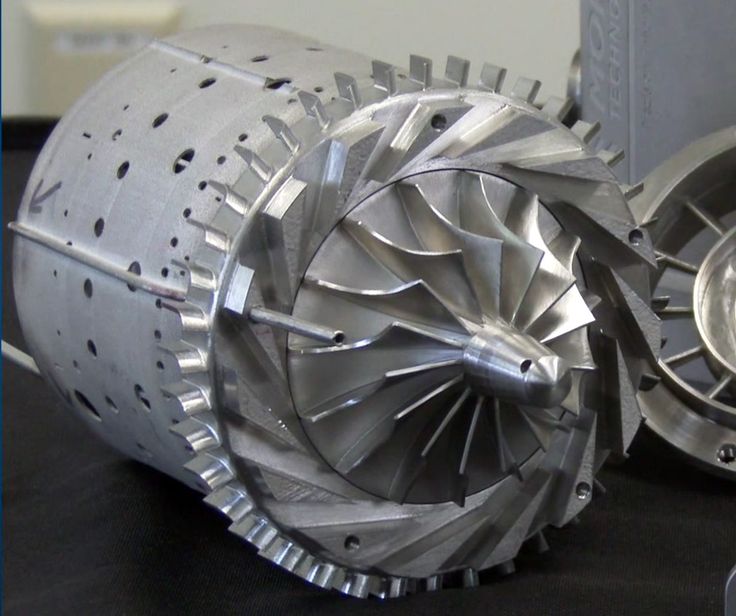

SLM

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

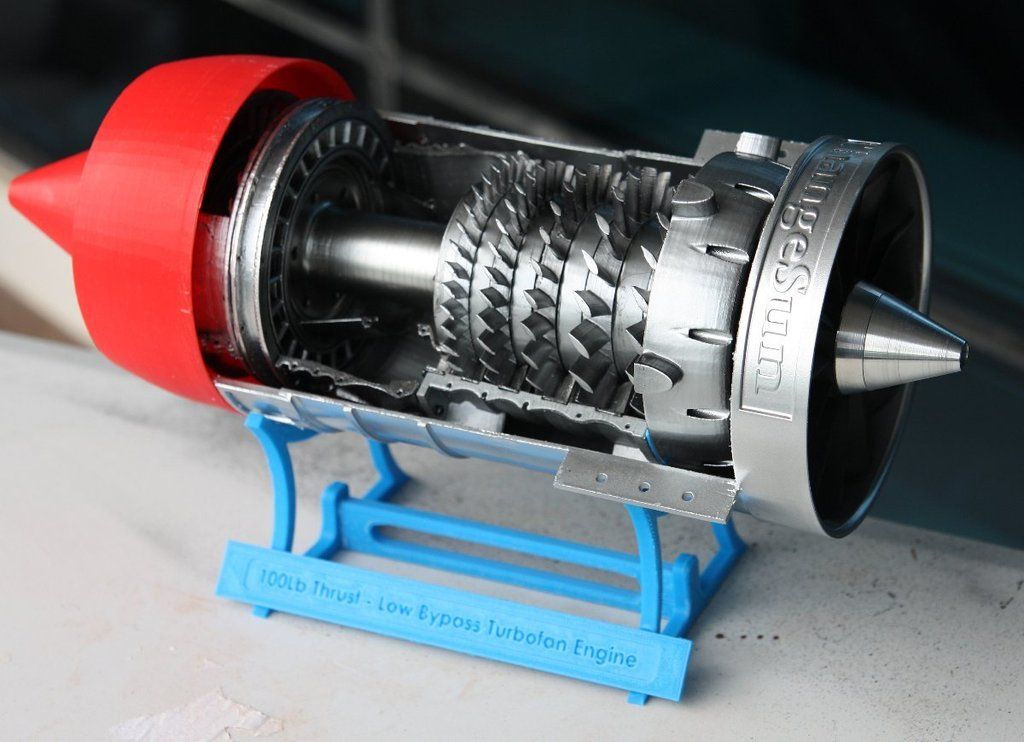

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc. nine0007

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.). nine0007

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder).

The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype. nine0007

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model. nine0007

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.

5 kg starts from 5900r and above.

5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin. nine0007

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull (quick release loop) for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles. nine0213

nine0213

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products). nine0007

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

nine0007

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

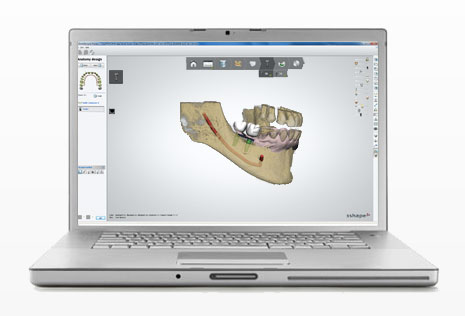

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product. nine0007

Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product. nine0007

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different. nine0007

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling.

Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make. nine0007

Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make. nine0007

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

nine0365What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer. For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D Printed Layout

Profitable to print on a 3D printer:

If the item is only sold as an assembly.

Learn more