How can 3d printing help business

3D Printing Applications for Business

- 3D printing can help your business with prototyping or low-volume manufacturing. It also has applications in design, biomedical devices and mechanical parts.

- You should guarantee your supply chain and product quality to protect against unlicensed 3D printing. You should also hire only people with skills and experience relevant to your 3D printing projects.

- Your small business could benefit from a 3D printer, such as the Original Prusa MINI, Ultimaker S3 or Anycubic Vyper.

- This article is for small business owners who manufacture products and are interested in 3D printing.

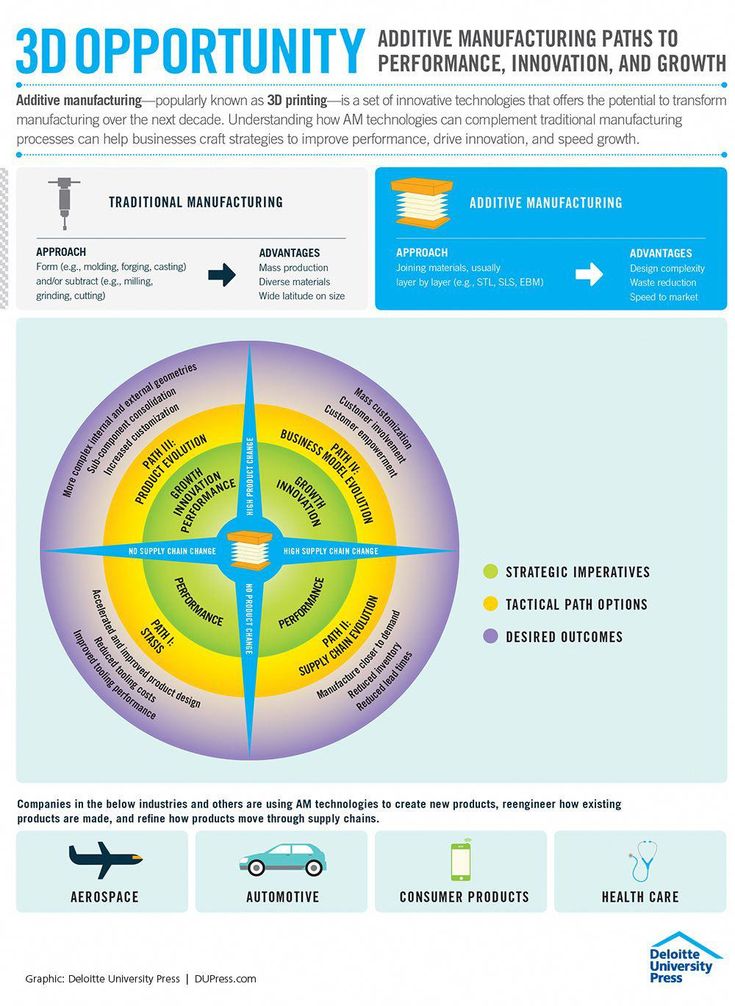

Manufacturing plays an essential role in the lives of many entrepreneurs and small business owners. As technology continues to improve, new methods of manufacturing continue to emerge as viable methods for small- and mid-scale production. Among these is 3D printing, and its widespread use in manufacturing has grown in recent years.

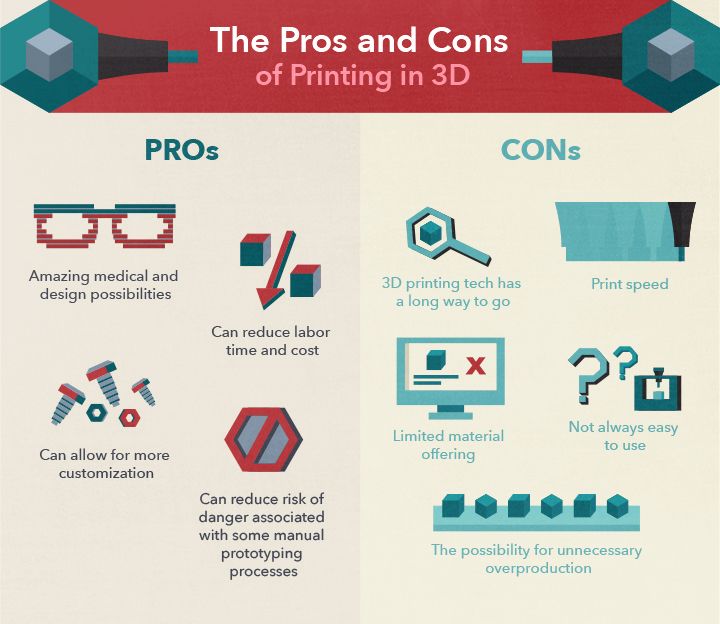

Just because 3D printing is an exciting way to manufacture doesn’t mean it makes sense for your business. There are still issues regarding cost and speed. In addition to the drawbacks, rumors constantly pop up discussing “the next big thing” in 3D printing.

With a lot of misinformation surrounding the future of 3D printing, we turned to experts to develop a clear picture of how 3D printing can help your business and determine what the future of 3D printing holds.

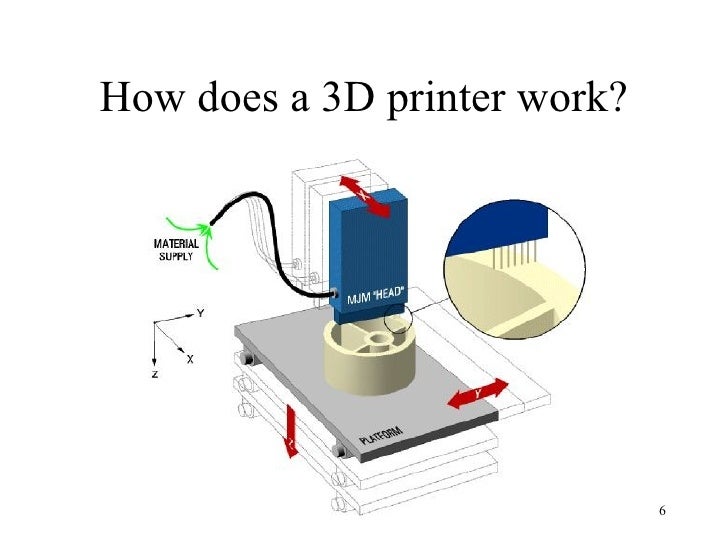

What is 3D printing?

3D printing is the process by which three-dimensional digital models are made into physical objects. Working in tandem with computer software, the 3D printer reads a digital STS file on a computer and then uses a filament or a resin to render the digital representation in tangible material, layer by layer.

3D printers employ a variety of materials, including plastics and polymers, steel, titanium, gold, and ceramic. This versatility means 3D-printed models can be used for various objects, including artistic sculptures and airplane components. Some 3D printers can even print proteins and chemicals, enabling the devices to create foods and medicines.

Some 3D printers can even print proteins and chemicals, enabling the devices to create foods and medicines.

“I don’t think there’s a component made today that won’t somehow be touched by 3D printing in some fashion or another, whether directly or indirectly,” said Mark Cola, former CEO of 3D printing company Sigma Labs.

Developments in the industry continue to arise. In fact, Statista projects the global 3D printing industry to reach $37.2 billion in 2026. That’s more than double the 2022 projection of $17.4 billion. Still, 3D printing is predominantly used for just a handful of project types.

Did you know? The 3D printing industry could more than double in size by 2026, according to market projections.

Applications for 3D printers

Prototyping

One of the oldest uses for 3D printers is the quick and efficient creation of prototypes. Since the printers were invented in 1983, companies have employed 3D printing to create a workable model of their desired end product, either to test the concept or present it to future investors.

“Before we called it ‘3D printing,’ it was called ‘rapid prototyping,'” said Greg Paulsen, director of applications engineering for third-party manufacturer Xometry. “It was seen as a way to get close enough to a functional model.”

Now that’s changing. While entrepreneurs still gladly use 3D printing for prototyping, the technology has become more accessible and adaptable, leading to new applications.

“The main development I’d summarize is moving from a primarily prototyping solution, currently the killer [application] for 3D printing, to end-part production,” said Filemon Schoffer, co-founder and CCO of online manufacturing platform Hubs. “This is already happening but will continue to accelerate.” [Related: How to Test a Business Idea]

Low-volume manufacturing

Though 3D printers can be slow, they’re adept at fulfilling low-volume production needs. Much like with prototyping, if an entrepreneur is ready to launch a new product and isn’t certain of the demand, they can print a small amount to test the waters. Low-volume production is also common for medical devices, for example, as manufacturers create, test and redesign their products for optimization.

Low-volume production is also common for medical devices, for example, as manufacturers create, test and redesign their products for optimization.

While low-volume manufacturing suits the capabilities of 3D printing, advances in technology make 3D printing a viable option of higher-volume production. Small businesses should consider the potential value of 3D printing in the mass customization of goods.

“Currently, 3D printing is mostly used in industries and applications with low-volume, high-unit cost and the need for customization, where costs of 3D printing are outweighed by the benefits,” said J. Scott Schiller, global head of customer and market development for HP Inc.’s 3D printing business. “However, [technological] improvement has been pushing the limits of the technology and unlocking its use in mass production applications. In the next five years, we’ll see part design become more function- and volume-oriented, and 3D printing will begin to fit into production systems across industries. ”

”

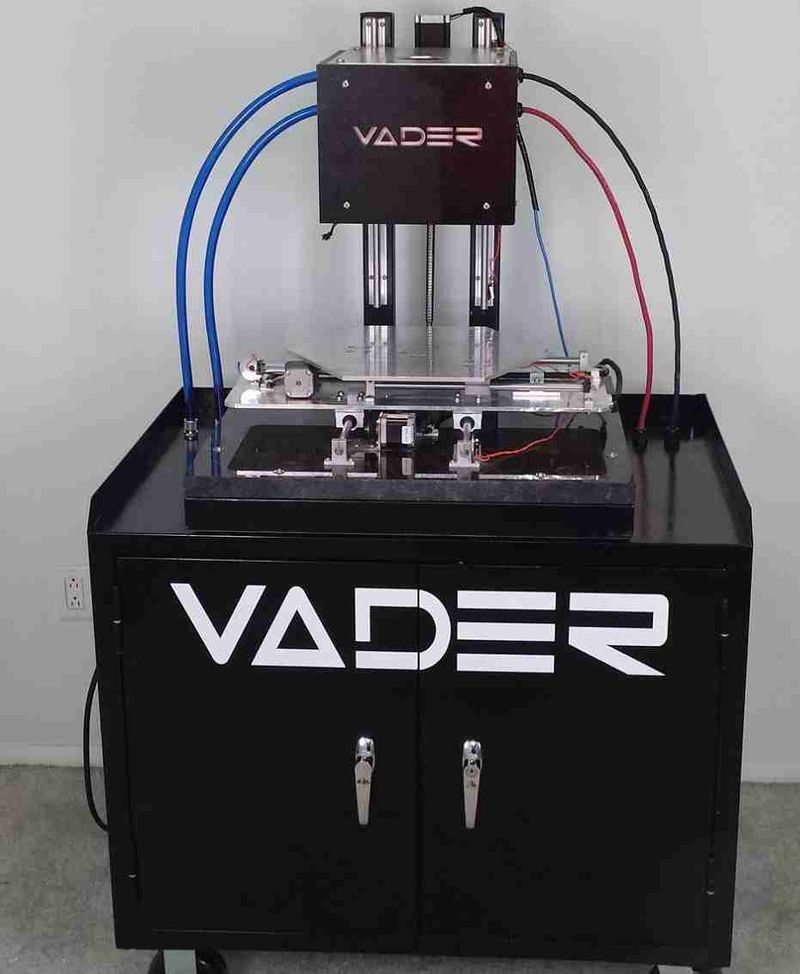

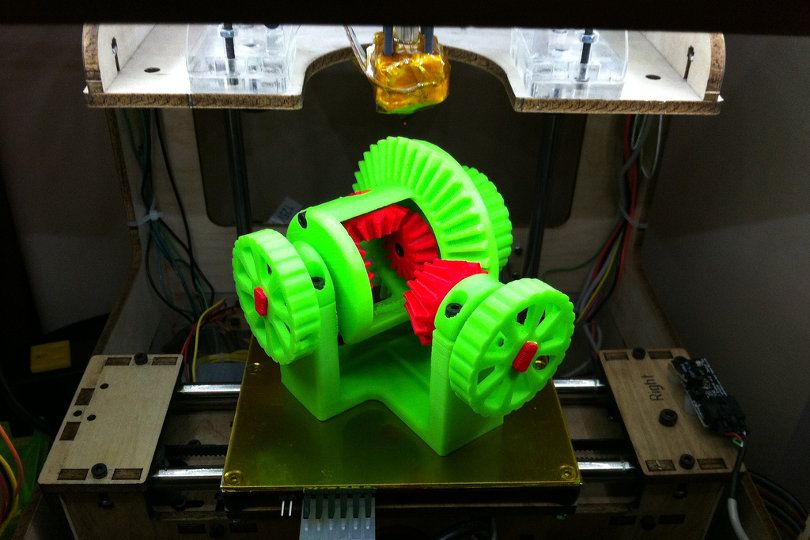

Mechanical parts

Another beneficial use for 3D printers is the creation of mechanical parts – either for sale in large industries or for personal repairs. Many products of 3D printing aren’t sold directly to consumers, but are created by companies – or third-party contractors – as components of a larger project. One example is GE Aviation’s 3D-printed fuel nozzle, which rolled out in 2015.

Small machine shops or individuals looking to make home repairs can also employ the same techniques for their projects. 3D printing has made it far easier to reproduce parts for machines that might no longer be in production or would take too long to arrive.

Biomedical devices

One particularly exciting aspect of 3D printing is the ability to print biomedical devices customized to individuals. For example, some companies are developing 3D-printed, custom prosthetics for amputees; these prosthetics are designed to be far more comfortable for the user.

“[Biomedical engineers are] 3D printing components for people that better match their characteristics than the off-the-shelf components,” Cola said. “I think where you see this tech going is more toward the performance and athletic side of the business, where you have athletes fully regain their performance levels after injuries, or maybe even enhance their performance levels with 3D components tailored to their needs.”

Other notable uses of 3D printing in the healthcare space are in ongoing efforts to develop printable organs for patients in need of transplants, and the printing of chemicals and proteins to develop new medicines.

Design

When engineers design a product, they must keep in mind the limitations of the production process. 3D printers can create parts previously considered unachievable with traditional manufacturing techniques. This opens an entirely new world in the design phase, which can lead to better, more efficient products and components. Many of these 3D-printed creations add value to important products, while others are downright unusual.

Many of these 3D-printed creations add value to important products, while others are downright unusual.

“It opens your mind up to everything you can do with it,” Paulsen said. “I’d really like to take this technology off the pedestal and say, ‘This is a normal manufacturing process,’ just like anything else.”

Copyrights and 3D printing

As 3D printers proliferate, so do the means of easily reproducing protected intellectual property. Roy Kaufman, managing director of business development and government relations at Copyright Clearance Center, warns that the manufacturing industry could be approaching its “Napster moment.” By that, he means the experience of the entertainment industry when music and movies could be quickly reproduced and pirated online.

“I think we’re going to see, as we see with almost every technology, two things happen: Things get cheaper, and they get better,” Kaufman said. “As the quality of the printers gets better, the available materials to print get better, and as costs come down, you get to that moment – the Napster moment. [That’s] when the means of reproduction are now so diffuse, the ability to reproduce at a low cost had been so spread out, that you can no longer really enforce your rights entirely effectively with existing IP [intellectual property] laws.”

[That’s] when the means of reproduction are now so diffuse, the ability to reproduce at a low cost had been so spread out, that you can no longer really enforce your rights entirely effectively with existing IP [intellectual property] laws.”

That moment could be coming quickly, Kaufman said, or it might not come at all. However, the mere fact that 3D printers are becoming more widespread makes it a plausible scenario that requires appropriate strategic planning. Kaufman suggested insulating your company by guaranteeing your supply chain and the quality of your products.

Tip: Protect your products from unlicensed 3D printing by guaranteeing your supply chain and your product quality. Also take measures to make sure your own business doesn’t accidentally steal intellectual property.

“[The consumer] might pay a premium for the assurances of the supply chain,” Kaufman added, “but they want to know that it’s not just a matter of what [the product] looks like but that it’s right. Testing and certification will become more important.”

Testing and certification will become more important.”

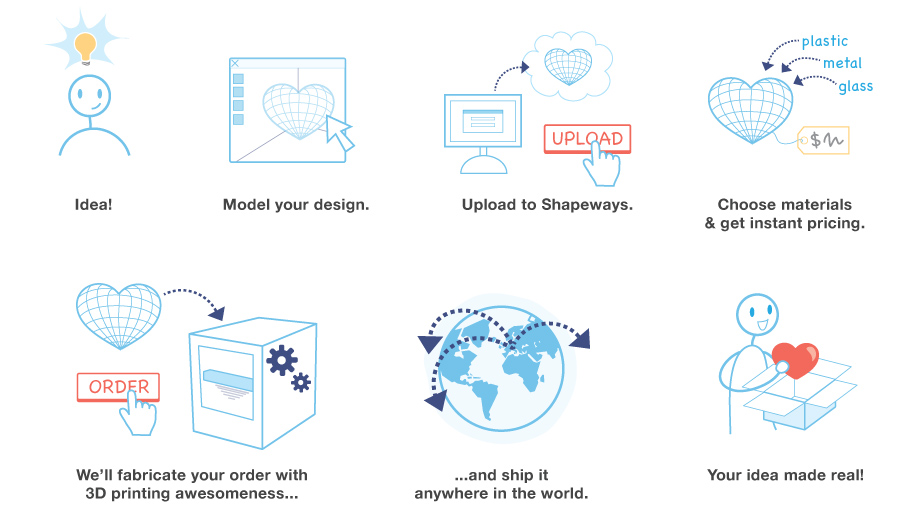

Within these major developments, there also lies opportunity. 3D printing will allow manufacturers to license the rights to their designs, which could be made downloadable to the licensee to 3D print. The technology could also bring production levels more in line with demand, thereby saving on production, shipment and storage costs.

“If you look at a typical pharmacy, for example, they have all these medicines with a sell-by date and are hoping someone will come in and need a prescription for it before they have to throw it out,” Kaufman said. “They pay to store it, pay to save it, and maybe even have to keep it in a central warehouse. But imagine your local CVS can print everything under license, get the chemicals from the pharmaceutical company, and maybe even [the] machine. The company doesn’t have to make things that might never get taken, never has to ship them, and never has to store them. Everything can be manufactured as needed. ”

”

The future of the industry

According to Sarah Boisvert, founder of Fab Lab Hub, “we’ve gotten past the hype stage” of 3D printing. The rumors about being able to 3D print everything under the sun have died down, and people are beginning to understand the practical aspects of 3D printing. This doesn’t mean the industry doesn’t face challenges moving forward, though.

Boisvert mentioned the need for skilled manufacturing workers. She isn’t alone in her concern, as the National Association of Manufacturers (NAM) continues to harp on the difficulties manufacturing companies face when seeking qualified employees. In a recent NAM study, 46.3% of small and midsize manufacturers surveyed consider finding quality employees a serious problem.

With 3D printing becoming an increasingly feasible integration into the supply chain for manufacturers, it’s critical that manufacturers have the employees with the skill set to properly work the printers in an efficient and timely manner. Additionally, the current price and speed of 3D printing can pose an issue for supply chain integration, Boisvert explained. At the end of the day, the decision to use 3D printing boils down to whether it truly makes sense for your business and if the cost is worth the benefit.

Additionally, the current price and speed of 3D printing can pose an issue for supply chain integration, Boisvert explained. At the end of the day, the decision to use 3D printing boils down to whether it truly makes sense for your business and if the cost is worth the benefit.

“We use everything,” Boisvert said of her manufacturing process for Potomac Photonics, another company she helped found. “We use 3D printing, laser cutting … I think it’s integrating 3D printing into the production flow and into the supply chain. No matter what tool you have, it’s about choosing the right tool for the job.” [Related: 3D Printing Jobs]

Top 3D printer picks for at-home small businesses

3D printing technology has come far enough that it’s now available at home. In fact, the 3D printers below are great choices for at-home small businesses.

1. Original Prusa MINI

The Original Prusa MINI is the best overall choice for at-home small businesses. It takes up less than 2 square feet of precious desktop space, and its build area occupies about 355 square inches. Its layer resolution spans 50 to 200 microns, and you can easily use it with many types of filaments. Calibration can be challenging, but for the $350 price, this issue might be worth bearing.

It takes up less than 2 square feet of precious desktop space, and its build area occupies about 355 square inches. Its layer resolution spans 50 to 200 microns, and you can easily use it with many types of filaments. Calibration can be challenging, but for the $350 price, this issue might be worth bearing.

2. Ultimaker S3

The Ultimaker S3 is your best bet for printing larger objects. You can use it with many materials and achieve a layer resolution of 20 to 600 microns. It’s also relatively compact for a large object printer, with a build area of about 530 square inches. However, it’s known to be slow to print, and its $4,080 price tag is quite high.

3. Anycubic Vyper

If you need to print large objects but can’t afford Ultimaker’s models, the Anycubic Vyper might better suit your needs – and budget. You’ll get at least 100 microns of layer resolution for $680. You also get about 950 square inches of build area and a built-in accessories drawer. Some reviewers, though, have noted that the Vyper results in excessive initial stringing and uneven build quality.

Some reviewers, though, have noted that the Vyper results in excessive initial stringing and uneven build quality.

3D printing continuously evolves. Years ago, rumors spread about the possibility of 3D printers being in every home by now. While that notion proved too ambitious, there are practical implications of 3D printing that can benefit your small business.

3D printing consistently shows its worth, based on its prototyping, design considerations and mass customization. Keep tabs on changes as the industry evolves, and use 3D printing when it’s cost- and time-effective for your company.

Max Freedman and Adam Uzialko contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

6 Ways 3D Printing Will Give Your Company a Competitive Edge

Many managed IT service providers are finding it necessary to start offering 3D printing solutions. Though the technology isn’t brand new anymore, many businesses have yet to embrace this technology and without knowing are losing their competitive edge. It’s high past time to update your business technology! According to statistics, 71.1% of manufacturers have embraced 3D printing and 52% of manufacturers foresee the technology growing tremendously over the next 3 to 5 years. These statistics should have any company that has yet to invest in 3D printing worried. The following are some ways 3D printing will give you a competitive edge against your business rivals:

It’s high past time to update your business technology! According to statistics, 71.1% of manufacturers have embraced 3D printing and 52% of manufacturers foresee the technology growing tremendously over the next 3 to 5 years. These statistics should have any company that has yet to invest in 3D printing worried. The following are some ways 3D printing will give you a competitive edge against your business rivals:

1. Timely Development of Prototypes

Developing prototypes and blue-chips is a vital aspect of any manufacturing process. However, this step is known to take lots of time, effort, and resources as everything must be perfect. To achieve this, the piece(s) will undergo many modifications and alterations before it is finally accepted. Not only does this take time, but it also incurs high costs. Due to being computer-controlled and the fact that it gives you a preview of the final product before processing, 3D printing allow you to produce prototypes in a much shorter time frame while saving you money.

2. High Quality Products

The modern customer is all about quality. He or she would rather pay more for a top-notch product than pay less for a substandard product. 3D printing solutions help you offer your market high quality products at a lower cost. The computer-controlled 3D printer provides an exact replica of the original product or prototype ensuring the quality is second-to-none. This explains why important products such as dental braces, jet engine fuel nozzles, and aircraft and satellite parts are being produced using 3D printers.

3. Less Equipment

In comparison to a manufacturing plant, 3D printers occupy a smaller space and yet produce similar (if not better!) products. The equipment can easily be adjusted to produce different parts unlike the traditional plant operation that produces a specific piece. Less equipment means you save on space, lower the cost of operation and maintenance, and also speed up the manufacturing process. There is also less concern over an interruption that could halt the operation as 3D printers are more versatile.

4. Reduces Overhead Costs

One of the biggest concerns a company has is overhead costs which include rent, administrative costs, power, and much more. A large plant will occupy a larger space (higher rent), will require more operators (higher cost of labor), and will incur more cost in terms of maintenance and service. The costs associated with 3D printing are much lower because the printer occupies lesser space, requires minimal human intervention, and is cheaper to maintain and service due to fewer moving parts. As a company you will be better positioned to offer lower prices to your customer due to lower overhead costs when using 3D printing.

5. Minimal Manpower

Operating 3D printing equipment isn’t as labor intensive as the traditional manufacturing plant. In fact, most advanced 3D solutions are 100% computer-controlled and come with Smart technology. Considering that it is much smaller than the usual processing plant, the number of people required to maintain or service a 3D printer is also fewer. Today’s printers use a range of raw materials, can be integrated with different software, and can even operate remotely.

Today’s printers use a range of raw materials, can be integrated with different software, and can even operate remotely.

6. Boost Efficiency

Unless your systems are efficient and reliable, you will spend lots of time, effort and money correcting errors. For instance, a faulty production line may cease production causing delays (and, of course, angry customers). Getting a replacement part may take days, if not weeks. As the price of printers drops and technology continues to improve, 3D printing is becoming more efficient and reliable. Not only is the printer less likely to break down, it is also easy to replace a faulty component. This allows you to focus on other important areas of the company.

There you have it—six ways 3D printing offers your company a much-needed competitive advantage. It allows you to produce prototypes faster, reduces the cost of production, requires less input (human resources and equipment), and reduces overhead. Additionally, efficiency and productivity is vastly improved. To enjoy high-quality and reliable 3D solutions, it pays to engage with a reputable and experienced managed IT services provider. Not only will the firm offer the latest and best solutions, but also they will be available to provide technical support.

To enjoy high-quality and reliable 3D solutions, it pays to engage with a reputable and experienced managed IT services provider. Not only will the firm offer the latest and best solutions, but also they will be available to provide technical support.

Which 3D printing business will be successful? / Habr

What kind of successful business can be opened using 3D printers? I will make a reservation right away that so far there are few such examples. I'll tell you about some of them.

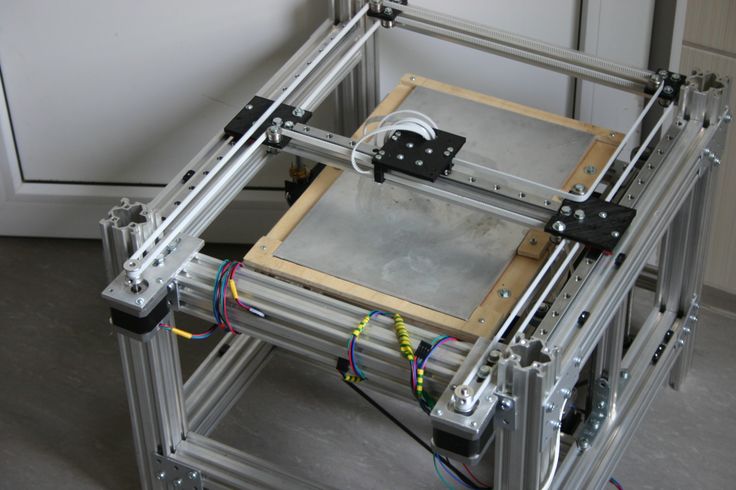

3D Printing Studio

The first thing that comes to mind is setting up a 3D printing studio. Its business model is based on modeling and printing models for the client. The main success factor is to ensure a consistently high level of equipment utilization. For such a project, it is more important to focus on mass replication than on printing single copies, even in large volumes. The cost of printing a small model should be low, and the labor costs should be high. The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it. nine0003

The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it. nine0003

You can build such a studio with almost any level of investment: start with one or two printers, gradually increase the equipment fleet or immediately invest in a 3D printer fleet. You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

Small-scale production

The second most popular business idea is a small-scale production studio. In this case, the main task is not to find a client, but to understand what product will be in demand. There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region. nine0003

They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region. nine0003

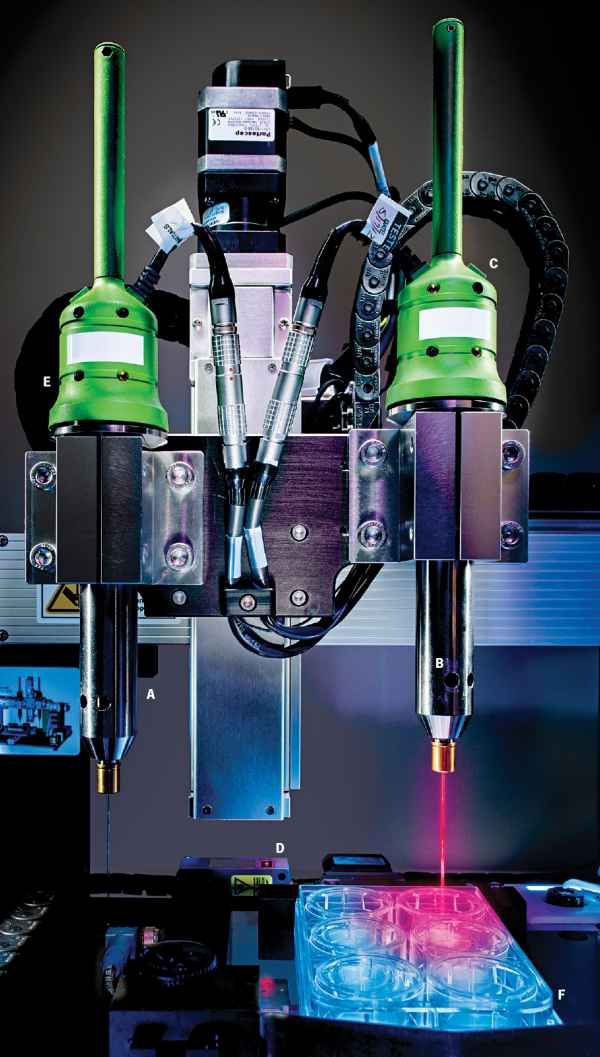

3D printing of medical products

The third version of the 3D printing studio is medical. Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general. nine0003

The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general. nine0003

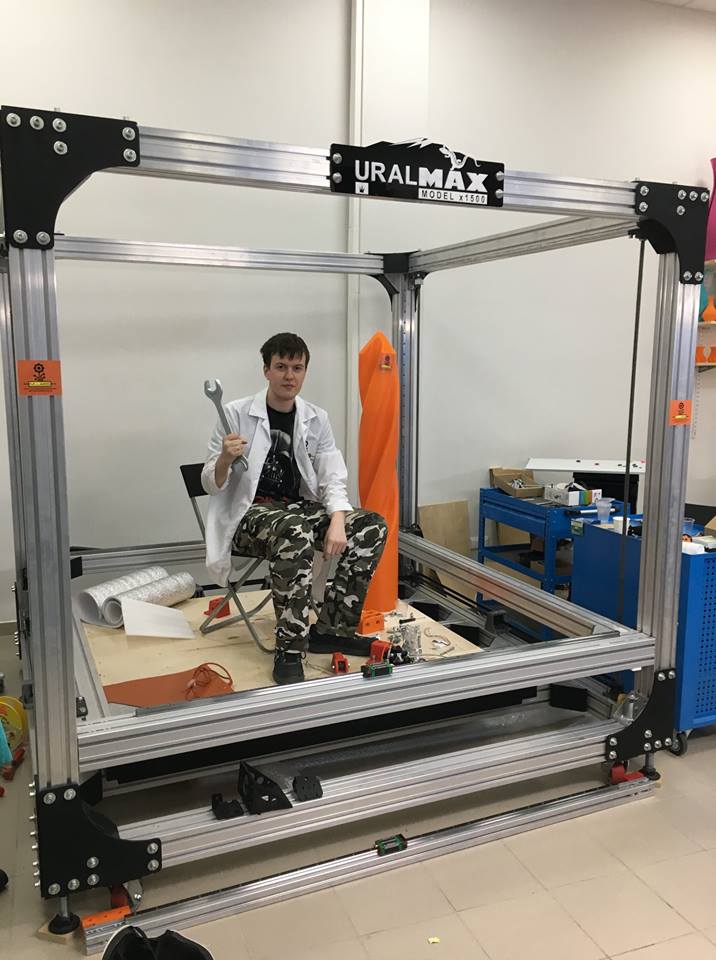

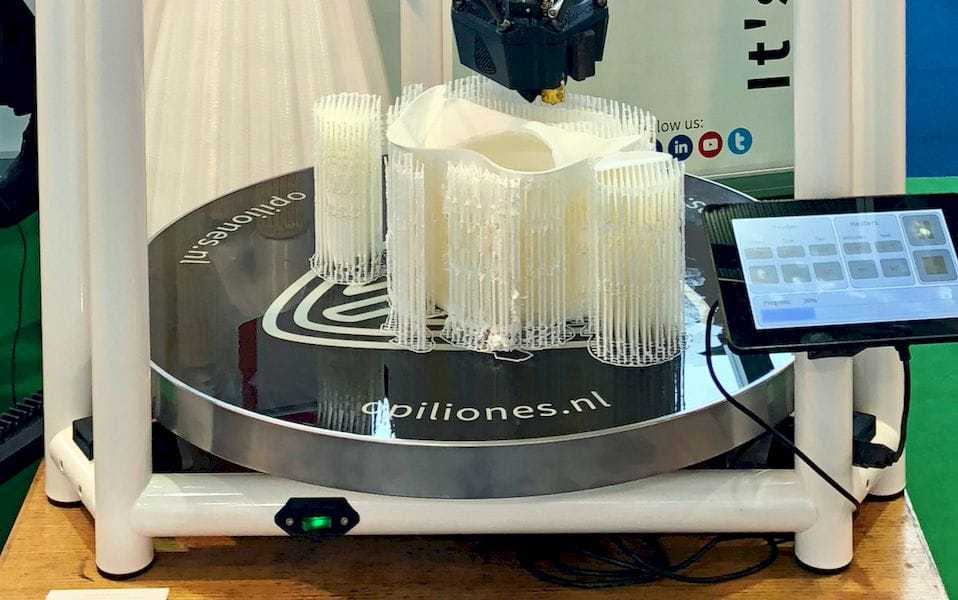

3D printing of art objects

Fourth place will be given to art. 3D printing of sculptures is another way to capitalize on this technology. Creating a large art object is not an easy task, and certainly not a cheap one. However, many interiors or public spaces are in need of an aesthetic upgrade. Modern sculptors began to use the new technology in their work precisely to create final products, and not prototypes or layouts, as one might think. To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials. nine0003

This makes the sculpture almost indistinguishable from those made from natural materials. nine0003

Another option is to show the model in full size, without post-processing, which allows viewers to see the 3D printed model at different stages of its creation.

It is difficult to fit into a short article all the variety of opportunities that 3D printing offers to enthusiasts of this technology, but we see that every day there are more and more new interesting stories of its application. It gives impetus to the development of new technologies and brings innovation to seemingly established areas such as the creation of sculptures or gingerbread. As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward". nine0003

Alexander Kornveits

Founder and CEO of Tsvetnoy Mir

3D printing business ideas

Blog navigation

Search articles

Categories

Latest articles

Popular articles

-

How to draw with a 3D pen?

12/16/2015

16742 views

Connect the 3D pen and let it warm up for a few seconds.

Insert ABS or PLA filament into the feed hole...

Insert ABS or PLA filament into the feed hole... Read more

-

10 improvements for your Ender-3

Posted in: Basics of 3D printing, 3D Printing Tips and Tricks

09/22/2021

11899 views

10 inexpensive upgrades to improve the stability, performance and security of the most popular Ender 3...

Read more

-

Top 20 interesting toys for children on a 3D printer.

Posted in: 3D printing

02/15/2022

11696 views

What kind of toys can be created on a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more

-

3D Print Delamination - 5 Tips and Tricks to Avoid Delamination

Posted in: 3D printing tips and tricks, 3D printing

05/14/2019

11358 views

If you have owned a 3D printer for a while, then you are probably used to solving many problems.

Delamination is...

Delamination is... Read more

-

History of 3D pen

Posted in: Basics of 3D printing, Draw 3D

03/21/2019

9753 views

The advent of the 3D pen has led to some areas of art that were previously impossible. In this article we...

Read more

Read all articles

Recommended articles

Article archive

Startup ideas and success stories of 3D printing around the world. nine0003

-

Why it's easier to succeed with a 3D printer than you think.

Posted in: 3D Printing Business Ideas

The case for a 3D printer business. Why the first steps in such a business are much easier to take than in any other.

-

3D printing of the buildings of the future. Killa Design.

Posted in: We print 3D, 3D Printing Business Ideas

Killa Design uses 3D printing to create iconic designs that are quickly becoming landmarks, including one of the most complex structures ever built.

nine0003

nine0003 -

You won't believe these dolls are 3D printed.

Posted in: We print 3D, 3D printing business ideas

Articulated dolls are a fairly common hobby not only for children, but also for adults. A success story about turning a hobby into a business idea with a 3D printer.

-

Yves Behar made household items from recycled wood using 3D printing.

Posted in: We print 3D, 3D Printing Business Ideas

Sawdust is mixed with natural tree sap, which acts as a binder, and 3D printed into a complex swirling geometry of exclusive and natural home furnishings.

-

How are 3D printers used in light industry?

Posted in: We print 3D, 3D printing business ideas

There is such a thing as functional testing. Before putting any new product into mass production, it is necessary to find out possible flaws in operation. For this purpose, an exact copy of the product is created on a 3D printer, after which it is used for its intended purpose under various conditions.

nine0003

nine0003 -

How to make money on 3D printing?

Posted in: 3D printing tips and tricks, 3D printing business ideas

Prospects for using 3D printing in dentistry, limb prosthetics, souvenirs, building construction, etc.

-

The world's first 3D printed settlement in Latin America

Published in: 3D printing news, 3D Printing Business Ideas

Designer Yves Béhart unveiled plans to build 3D printed homes for an impoverished farming community in Latin America. nine0003

-

How are 3D printers used in the automotive industry?

Posted in: We print 3D, 3D printing business ideas

Application of 3D printers in the automotive industry, use of 3D printing technology for prototyping and small-scale production

-

Young Entrepreneur Aims to Send 3D Printed Rockets into Space

Los Angeles-based Relativity Space has already printed nine rocket motors and three second stages for its model rocket, called the Terran 1, with a first test flight scheduled for late 2020 of the year.

Learn more