Hp jet fusion 3d 4200 printer price

HP Jet Fusion 3D Series vs. Formlabs Fuse 1+ 30W

Printer

Price

Starting at $27,999. Complete setup starting from $39,243.

Build your quote in our online store and buy directly from Formlabs via sales or locally from a worldwide partner network.

Price range is $270,000-$430,000 for the 4200 series and $350,000-$500,000+ for the 5200 Series.

Complicated and opaque pricing, requires multiple quote requests and negotiation.

Technology

Selective Laser Sintering (SLS)

The Fuse 1+ 30W is the first benchtop industrial SLS 3D printer that offers high quality, compact footprint, and a complete, simplified workflow at a fraction of the cost of traditional industrial SLS systems.

Multi Jet Fusion (MJF)

HP MJF 3D printers use an inkjet array that first deposits fusing, detailing, and coloring agents, and during another pass, exposes the powder bed to infrared energy which fuses the part’s layers together. While the process is different, the end result is similar to SLS.

Build Volume (W × D × H)

Fuse 1+ 30W:

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Jet Fusion 5210/5200/4200:

38 x 28.4 x 38 cm

15 x 11.2 x 15 in

Materials

Four popular materials, more coming soon

The Fuse 1+ 30W currently prints with Nylon 12, Nylon 12 GF, Nylon 11, and Nylon 11 CF. Nylon 12 is a general purpose, versatile material with high detail and great dimensional accuracy. Nylon 11 is a ductile, strong, flexible material for when durability and performance are key. Nylon 12 GF is a glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Nylon 11 CF is a carbon-filled composite for end-use applications that require both high stiffness and superior strength. More materials are coming soon.

Five materials, depending on the printer

HP 5210/5200/4200 MJF printers can print with Nylon 12, Nylon 11, glass-filled Nylon 12, and TPU. The 5210/5200 series can also print with PP, while the 4200 series can print with TPA.

The 5210/5200 series can also print with PP, while the 4200 series can print with TPA.

Requirements

Compact format and no special requirements

The Fuse 1+ 30W has a compact form and a low footprint. Inert gas environment is optional. The lower energy consumption means that it can run on standard AC power without requiring specialized infrastructure.

Large space and specialized infrastructure

HP MJF 3D printers are substantially larger and their ecosystem comes with a larger operating footprint. They require specialized power infrastructure and a dedicated computer for print setup. These represent additional costs and time to the customer that are not captured in the quote.

Ease of Use

Plug and print

From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process. Easy workflow empowers anyone at your company to use the system independently after a quick online or in-person training.

Highly complex

Multi-day setup and training with on-site installation required. The complex workflow and the steep learning curve mean that the system requires a skilled technician in-house to operate and maintain.

Efficiency

Minimal waste

Parts in the Fuse 1+ 30W’s build chamber can be packed tightly together to maximize density. Thanks to the 30% powder refresh rate for all materials, you can print with up to 70% recycled powder for unlimited cycles. This means that you can print with minimal waste for tightly packed production builds.

Wasteful

The MJF process requires you to space parts widely apart to reduce the potential for thermal buildup. Recommended pack density is limited to roughly 8-10%, which means that you’ll need to throw away as much material as the amount that goes into the printed parts.

Throughput

High

The Fuse 1+ 30W is designed for nonstop throughput. It comes with a removable build chamber, allowing you to start new prints within 1-2 hours after the previous print has finished to minimize downtime. Cooldown time takes only about half the print time for large builds, an industry-leading value that allows you to get to finished parts quickly.

It comes with a removable build chamber, allowing you to start new prints within 1-2 hours after the previous print has finished to minimize downtime. Cooldown time takes only about half the print time for large builds, an industry-leading value that allows you to get to finished parts quickly.

High

The 5210/5200/4200 models are optimized for high throughput, but the recommended cooldown time for MJF is 2x the print time, which means that the total time until parts are ready for post-processing is comparable to the Fuse 1.

Post-processing

All in one

The Fuse Sift is a safe, efficient powder recovery system for the Fuse 1+ 30W. This all-in-one station combines part extraction, powder recovery, storage, and mixing in a single free-standing device. Highly convenient and compact, this is the most functionality you'll get in a single device on the SLS market.

Expensive

HP’s post-processing station offers similar functionality, but at an 8x higher price.

Maintenance

Efficient

The Fuse 1+ 30W is designed for minimal upkeep. The system offers proactive maintenance alerts and a full-color touchscreen interface guides you through every step of printing and maintenance.

Labor-intensive

A less user-friendly workflow means that the operator has to carry out a long list of manual maintenance steps between each print.

Software

Free and easy to use

Formlabs' free print preparation software, PreForm, makes it easy to set up a print in minutes and offers advanced tools to manually refine as needed. Try it now. You can also use the online Dashboard to manage printers, materials, and teams. Available for Windows and Mac.

Paid and complicated

HP software solutions offer similar features, but using 3rd party software is also recommended, for an additional $12,000. Print setup requires intensive fine tuning, which results in a steep learning curve and the need for a skilled operator to prepare prints.

Service

Standard and Premium Service

Up to three years of standard or premier support service with direct phone and email support, customized on-site training, on-site visits and repairs from local certified SLS experts, annual preventative checkups, and worry-free warranty—all for an affordable price.

Expensive

HP offers multiple service tiers that offer similar benefits, but cost $35,000-$53,000 annually—enough to buy up to two complete Fuse 1 setup each year.

Do you have more questions about the differences between these solutions?

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

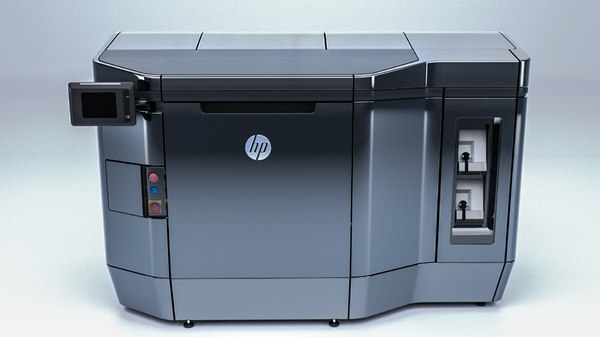

HP HP Jet Fusion 3D 4200 3D Printer

Properties

| Build Volume | 380 x 284 x 380 mm (15 x 11.2 x 15 in) |

| Layer Resolution Low | 0. 07 mm (0.0027 in) 07 mm (0.0027 in) |

| Layer Resolution High | 0.08 mm (0.0031 in) |

Documents

- 4AA6-4894EEP.pdf

Reviews

HP

4.3 1 reviewsPrint Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Dec 29, 2021

It is a very good service

| Brand | HP |

| Machine type | 3D Printer |

| Technology | MJF (MultiJet Fusion Technology) |

| Materials | PA11 Nylon, HP PA-12, PA-12 with Glass Beads |

| Website | http://www8. hp.com/us/en/printers/3d-printers.html hp.com/us/en/printers/3d-printers.html |

| Average Price | $200,000.00 |

The HP Jet Fusion 3D Printing Solution reinvents how you prototype and produce functional parts, delivering quality output, up to 10 times faster at half the cost

Reviews 4.3

1 reviewsPrint Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Dec 29, 2021

It is a very good service

or

Forgot password?

Remember Me

By using this Service, you agree to our Terms and that you have read our Privacy Policy, including our Cookie use.

HP Starts Shipping Jet Fusion 3D 4200 Printer 3D Printers The first to receive the devices are the company's partners who supported the development of the novelty - Jabil, Materialise and Shapeways.

Jet Fusion 4200 operates on the basis of “HP Multi Jet Fusion technology”, which is a modified SLS (Selective Laser Sintering): layers of special powder are poured layer by layer, the desired areas of the layer are selectively sintered under special lighting. Powder from unused areas can sometimes be reused. HP claims that its devices are more reliable, print faster (advantage up to x10) and better, and the infrastructure being created in the form of professional software and the market for materials will make their use as convenient as possible.

The printing process is as follows: the model file and powder are loaded into the Processing Station, which prepares the printing process in the ”Build Unit”. Next, the Build Unit is removed from the station and installed in the printer itself, and printing starts.

Main specifications of the Jet Fusion 3D 4200 Printer (without Processing Station):

- Maximum part size: 406 x 305x 406 mm

- Layer height: 0.07 to 0.12 mm

- Unit size: 2178 x 1238 x 1448 mm @ 730 kg (unpackaged)

- Features: 380 volt power supply, 2 terabyte HDD, Ethernet interface

Processing Station weighs from 450 kg and measures from 1926 x 1245 x 2400 mm to 3121 x 1571 x 2400 mm (with fast cooling installed).

Read more about HP Jet Fusion 3D printers here.

The Jet Fusion 4200 is currently printing with HP's proprietary 3D High Reusability PA12 resin (with the ability to reuse “excess” powder). The device will also support materials from alternative manufacturers (the concept of Open Platform). For example, Evonik recently announced the release of its plastic. Printing materials will also be supplied by BASF, Arkema and Lehmann and Voss.

Ramon Pastor, Vice President of HP, commented: “6 months ago we released information about our Jet Fusion 3D and a list of forward-thinking companies looking to join HP on the industrial revolution. We hope that this cooperation will lead to a joint development, as a result of which we will achieve unparalleled quality and print economy.”

We hope that this cooperation will lead to a joint development, as a result of which we will achieve unparalleled quality and print economy.”

Also soon, HP plans to release a more budget solution with speed and layer height limitation HP Jet Fusion 3D 3200 with a price of 130 thousand dollars. With Processing Station - $155,000. The price of Jet Fusion 4200 is not reported.

Recall that Megan Whitman (Meg Whitman - Director of HP) announced her intention to release a 3D printer back in 2013. Then it was planned to show the finished model in 2014. In reality, HP announced the readiness of the technology and the serial prototype only in May 2016.

Overview of HP 3D printers at IMTS 2018 industrial plant operating on SHS technology - Jet Fusion 4200.

Video

HP Metal Jet

Features

- Printable area - 430x320x200 mm

- Layer thickness - from 50 microns

- Material - AISI 316 steel

- Price - on request

According to the company's representatives, HP Metal Jet provides a productivity increase of up to 50 times and has a lower cost of the resulting products, compared with counterparts working on other technologies.

The HP Metal Jet features twice the number of print lines and four times the number of nozzles compared to competing solutions.

Volkswagen will be an early adopter of the HP Metal Jet as the automaker plans to make stainless steel parts.

The high precision and low cost of prints make the HP Metal Jet a top competitor for a range of technologies from SLM to injection molding.

Metal Jet sales start in 2019. The cost will not exceed 400 thousand dollars. The price tag for competing solutions starts at $1 million.

HP Jet Fusion 4200

Features

- Print area up to 380x284x380 mm.

- Layer thickness - from 80 microns.

- Material - polyamide 11 and 12

- Price - on request

In addition to the Metal Jet, Hewlett-Packard's pavilion featured machines from the Jet Fusion line - the Jet Fusion 4200 industrial SHS machine and the 500/300 series color SLS printer.

SHS (selective heat sintering) technology is similar to SLS. The main difference is that a thermal print head is used instead of a laser. According to Hewlett-Packard, the Jet Fusion 4200 print speed is 10 times faster than competitors' SLS solutions.

The speed, ease of use, and relatively low cost of $200,000 or more make the Jet Fusion 4200 a replacement for plastic injection machines. Material for printing - polyamides "nylon 11" and "nylon 12".

HP Jet Fusion 500/300

Specifications

- Printable area up to 332 x 190 x 248 mm

- Layer thickness - from 80 microns

- Material - polyamide 11 and 12

- Price - on request

The HP Jet Fusion 500/300 Series SLS printers are designed for plain and full color polyamide printing. The price of devices - from 50 thousand dollars - this makes them affordable for small and medium-sized businesses.

The Jet Fusion 500 and Jet Fusion 300 models feature "the world's first integrated and automated material feed system," as the manufacturer calls it, which simplifies the 3D printing process, reduces user intervention, and improves overall efficiency. The devices support major file formats such as OBJ, VRML, and 3MF.

All post-processing and preparation of the powder for reuse does not require additional modules - these processes take place inside the plant.

Sales of HP Jet Fusion 500/300 series 3D printers in Russia will begin in 2019. By pre-ordering from the Top 3D Shop, you can get the actual prices and purchase offer for these models at the time of sale.

Total

HP continues to develop the market for professional 3D printing equipment, applying its own new developments in its products. The presented models - HP Metal Jet, Jet Fusion 500/300 and Jet Fusion 4200 - promise the user not only the traditional quality for this manufacturer, but also the lower cost of prints, which is no less important.