Iiip 3d printer review

Monoprice Select Mini Review 2022

4

See Price

Let’s say you’re in the market for a budget 3D printer. It’s tough: there are models that are vastly overpriced, models that have to be manually assembled from parts, and some that simply aren’t good enough to justify even a very low price. What if you saw a printer far less expensive than the rest? Would you trust it?

Maybe you should. We’re talking, of course, about the Monoprice Select Mini. It’s an absolutely tiny printer designed for people looking to explore the world of 3D printing, without breaking the bank. So how does it hold up? Let’s find out!

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Supported Materials | PLA, ABS, HIPS, PVA, TPU |

| Connectivity | USB, SD Card |

| Printing Speed | 55mm/s |

| Build Volume | 4. |

Table of ContentsShow

Design

This printer’s design is about as simple as they come. It has a single extruder, and prints onto a heated bed. The build area is, as you’d expect, fairly small – roughly the size of a can of Coke. Still, this is about average for a printer in this price range, so there are no complaints on this front.

Since this printer is designed for beginners, we were pleased to see that it ships fully assembled and pre-calibrated. In fact, thanks to the four-post leveling system, you shouldn’t have to calibrate it too often. Instead, you can focus on the fun part: actually printing things.

You can control this printer either with a PC or directly, using the built-in screen to select models for printing. There’s also a USB port and SD card slot, and the printer actually includes a USB stick with models so you can get printing right away.

Printing

The first thing you should know is that the Select Mini is slow. Its top speed is about half as fast as its rivals, and worse, it tends to fail when running even at that. You’ll be far better served with a slow and steady approach. This seems to create the most consistent, high-quality models.

Its top speed is about half as fast as its rivals, and worse, it tends to fail when running even at that. You’ll be far better served with a slow and steady approach. This seems to create the most consistent, high-quality models.

Now, bear in mind that this is a budget 3D printer. Despite this, we found its prints come out looking pretty good! Sure, you can still see the layers, and intricate details aren’t replicated all that well, but with a little patience (and post-processing), you’ll find you can actually do quite a lot with the Select Mini.

Budget 3D printers tend to have one characteristic in common: lack of versatility. You can expect to print with PLA, maybe ABS too, at best. Incredibly, the Monoprice Select Mini supports both of these materials, as well as HIPS, PVA, and TPU. It’s not even limited to using a proprietary filament, so you can really go wild.

Features

Part of this printer’s appeal is its simplicity. As such, it doesn’t have many advanced features to speak of. Rather, it tries to make things as easy for new users as possible. Take software, for instance: it works with Cura, Repetier, Simplify3D, and most other popular modeling or slicing programs.

Rather, it tries to make things as easy for new users as possible. Take software, for instance: it works with Cura, Repetier, Simplify3D, and most other popular modeling or slicing programs.

As you grow more comfortable using a 3D printer, you might want to add some upgrades. The Select Mini is perfect for this, since its inner workings are easily accessible, and its firmware easily flashed. In fact, we’ve found guides for everything from changing the hot end to adding wireless functionality.

If you’ve used a 3D printer before, it’s unlikely that this model will blow you away. It’s aimed at beginners and has a price point to match, after all. However, if you’re completely new to printing and just want something to tinker with as you learn, there are a few models better than this one.

Cost

So how much do you think this printer costs? Brace yourself – it actually retails for around $190, making it among the cheapest 3D printers we’ve seen. Now, it’s not available directly from Monoprice anymore since they’ve released the Mini v2 for the same price. However, it can still be picked up by third-party retailers.

However, it can still be picked up by third-party retailers.

The freedom to use third-party filament means you can keep your material costs down. Evidently, if you want to print often, this will increase to some degree, but since there’s no support for exotic filaments, things shouldn’t get too out of hand.

This printer is perfectly priced and has enough versatility to corner the low-end market. Frankly, we’re amazed that this isn’t the go-to recommendation for people looking to get into 3D printing for the first time.

Support

Despite its low prices, Monoprice offers a 30-day money back guarantee on all its printers. Once you’ve committed to keeping the unit, a year-long limited warranty takes effect. This is pretty good coverage, especially since there’s no risk of breaking anything during assembly.

On the other hand, Monoprice only offers basic troubleshooting tips and 3D printing tutorials in its support section. You can use the ticket system, email, phone, or live chat to get more detailed help. Our only issue is that the returns link only works on some pages, throwing an error on others.

Our only issue is that the returns link only works on some pages, throwing an error on others.

Honestly, this level of support was unexpected. Too often, low-end 3D printers try to sell their product and then wash their hands of it. That’s clearly not the case with Monoprice, and for that, we applaud them.

Monoprice Maker Select Mini V2 Review

Monoprice’s $200 3D printer shouldn’t be great, but it is

By Forrest Daniels

DT Recommended Product

“It's more evolutionary than revolutionary, but Monoprice’s Maker Select V2 still offers a ton of bang for your buck.”

Pros

- Affordable

- Sturdy construction

- Reliable printing

- Decent print quality

Cons

- Small build envelope

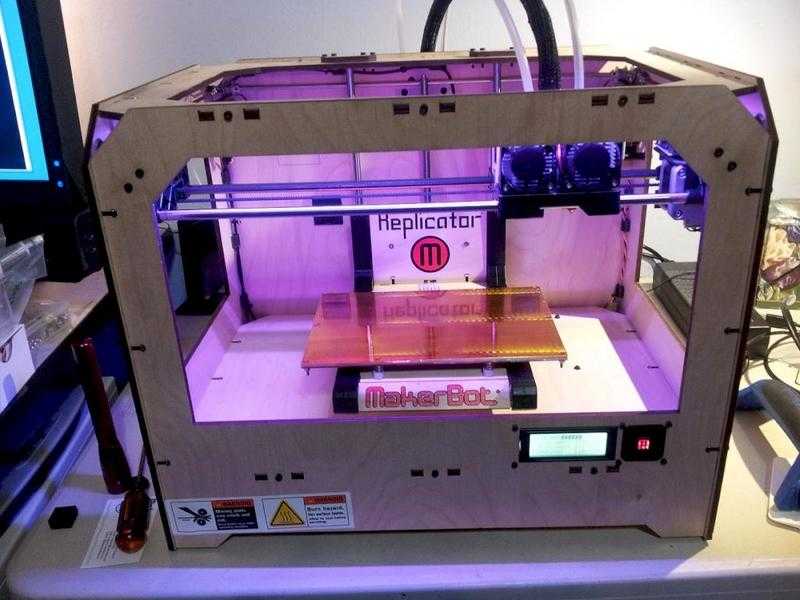

A couple years ago, Monoprice took the 3D printing world by storm with a the original Maker Select Mini: a 3D printer that only cost 200 bucks, and had all the bells and whistles we could ever ask for. Now, it’s back with version two of that revolutionary printer — so naturally we took it for a spin to see how it stacks up to the original.

Now, it’s back with version two of that revolutionary printer — so naturally we took it for a spin to see how it stacks up to the original.

Contents

- Standout Features and Specs

- Setup and Configuration

- Design and Build Quality

- User Interface and Software

- Print Performance

- Our Take

Standout Features and Specs

Monoprice’s V2 builds upon the first generation’s solid set of specs and features by adding a few minor (but important!) upgrades.

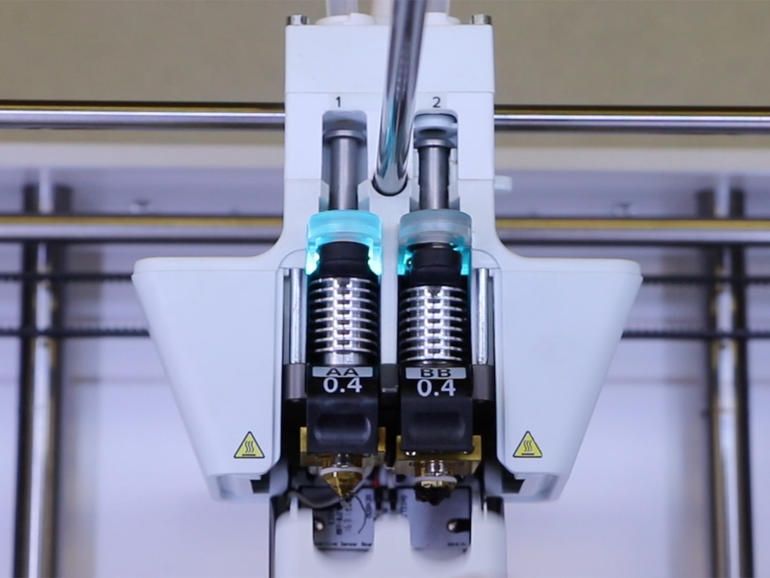

Among these improvements is an all metal hot end, which improves heating and helps prevent clogging, as well as a heated/insulated printing bed, which boosts print adhesion and prevents warping.

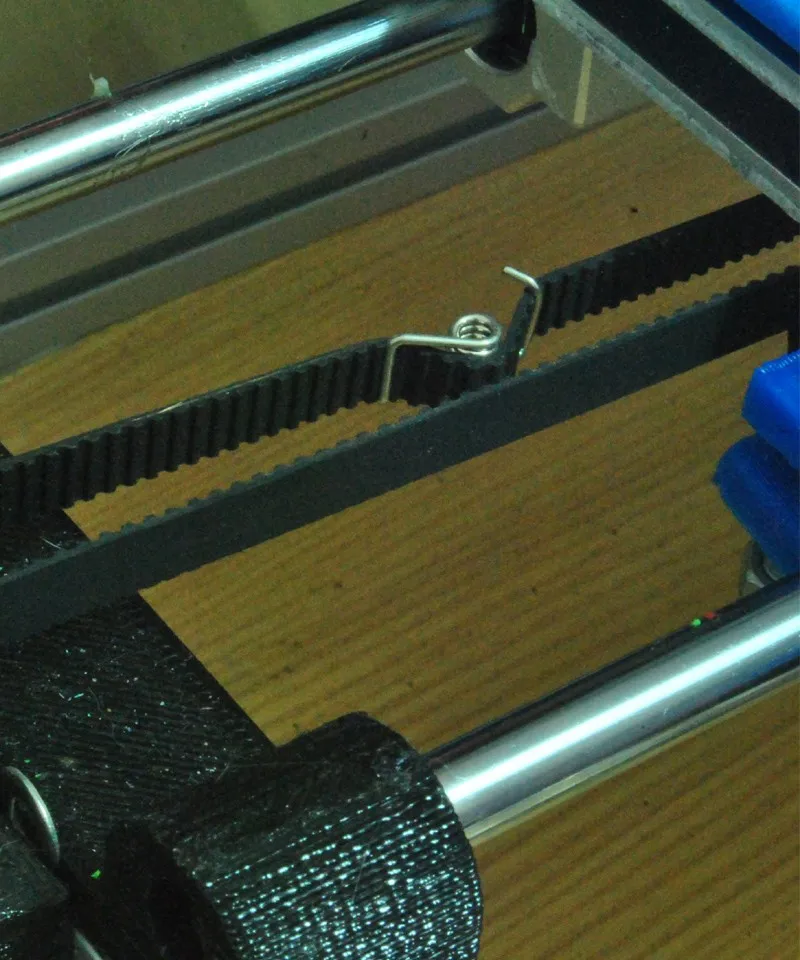

Riley Young/Digital TrendsAlong with this improved heated bed, the V2’s build surface also features a special pad material (similar to BuildTak) that promotes adhesion during printing, and also makes parts easy to remove after they’ve finished. Finally, MP also equipped the V2 with an internal cooling fan that helps prevent everything from overheating.

There are also a few things that haven’t changed. Just like the first generation, the V2’s max resolution sits at 100 microns (0.1 millimeters), which is fairly average, but acceptable for the price. Its build envelope is also a perfect 4.7-inch cube, just like it was on the first generation. Again, this spec is somewhat average, but still not bad.

This V2’s setup is quite possibly the easiest we’ve ever encountered.

The all-metal hot end retains the same maximum temperature of 230, which allows you to print with a fairly wide range of filament types, but does limit you from some of the more exotic higher temperature materials. As for inputs and outputs, you can load your models onto the Mini V2 using a Micro SD card, a direct USB connection, or even do it via WiFi through Monoprice’s new mobile app.

All in all, the V2 is certainly more of an evolution than a revolution, but Monoprice’s improvements are smart ones that do big things for the printer’s reliability and overall performance — and it only costs you an extra $20.

Setup and Configuration

The V2’s setup is quite possibly the easiest we’ve ever encountered. It comes completely assembled and factory calibrated, so all you have to do is unbox it and supply some electricity. There’s not even an on switch — just plug it in, and you’re off to the races.

Riley Young/Digital TrendsFrom there, Monoprice’s super straightforward interface makes the remaining setup steps nearly foolproof. Things like loading filament and fine-tuning the print bed are all extremely simple to execute.

To offer a comparison, we’d say setting up the V2 is about as complicated as setting up a brand new toaster. It’s simple as hell, but it might take a bit of fiddling around before you find the ideal settings that result in that perfect, golden-brown slice of toast.

Design and Build Quality

Lifting this printer out of the box surprised us — it’s astonishingly heavy for its size. This is largely due to the Mini V2’s all-metal construction, which makes it an incredibly sturdy machine that doesn’t wiggle around too much during printing.

Monoprice gave everything a makeover in terms of aesthetics.

It’s also pretty easy on the eyes. Most of the V2’s mechanisms are tucked behind its metal exterior and hidden from view, so the machine doesn’t look as rudimentary and utilitarian as some of its competitors. Better yet, despite the printer’s sleek design and tucked-away components, its inner workings are still easily accessible.

To be fair, we never needed to tinker with the V2 at all during our testing process, but accessible design and easily-replaceable parts are something we love to see on a printer. Ten points to Gryffindor Monoprice.

User Interface and Software

Monoprice scores high marks in this category. Both the onboard software and desktop-based slicer programs are wonderfully simple to use — though the latter isn’t necessarily thanks to Monoprice.

Riley Young/Digital TrendsAs with all its printers, Monoprice’s Select Mini V2 is designed to work with whatever slicer program (the software that translates your 3D design into instructions a printer can follow) you desire. We used Cura: one of the most powerful and customizable slicers on the planet, which now includes pre-configured profiles for many of MP’s most popular printers. This makes the whole process extremely convenient, as you no longer have to manually configure your machine.

We used Cura: one of the most powerful and customizable slicers on the planet, which now includes pre-configured profiles for many of MP’s most popular printers. This makes the whole process extremely convenient, as you no longer have to manually configure your machine.

The onboard user interface similarly straightforward, and hasn’t changed too much since the first generation. The V2 boasts the same knob-based navigation scheme and the same intuitive menu trees — but Monoprice gave everything a makeover in terms of aesthetics.

Suffice it to say you won’t have any trouble using this machine.

Print Performance

Don’t let the price tag fool you — the Select Mini V2 prints like a dream.

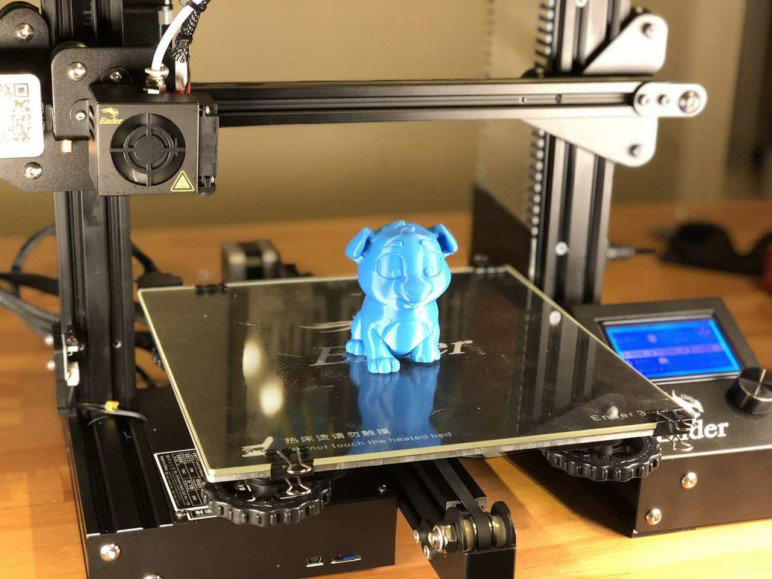

Our first print using the Mini was the infamous ‘lucky cat’ model, which Monoprice pre-loaded onto the printer’s SD card. Unsurprisingly, it turned out great, since most models like this are fine-tuned by the manufacturer. So in order to get a better idea of how the V2 performs, we ran it through our standard suite of benchmarks.

The first of these, as always, was the 3DBenchy: a tugboat-shaped torture test designed to highlight a printer’s strengths, weaknesses, and quirks. Much to our delight, the Mini V2 did a fantastic job. No matter what parameters we set, the tugboat always came out clean, accurate, and very consistent from layer to layer. Some of the superfine details of the boat didn’t come through as clearly as we’d like, but it’s worth noting that nearly all FDM printers struggle in this area, and the Select Mini V2 performed just as well (if not better than) as most printers that cost 10 times as much. Other tricky elements, like steep overhangs and unsupported spans, were also reproduced without any significant errors.

After a couple weeks of printing random (usually Star Wars-related) objects we found on Thingiverse, we found that the Mini V2 is also quite reliable. Whereas some 3D printers leave you feeling worried and unsure if they’ll complete the job, we felt highly confident with this machine.

The only real drawback here is the V2’s relatively small build envelope.

Thanks to the printer’s heated bed and solid construction, it doesn’t often fail mid-print — unless of course you make a slicing error and prepare the model improperly. This printer is still bound by the laws of physics, so we definitely recommend printing with supports unless you’re certain you don’t need them.

All in all, Monoprice’s new-and-improved Select Mini earns high marks for performance. We did experience a few flubs, failures, and funky-looking prints, but these were the exception, not the norm. The V2 prints just as well (and in some respects, even better) than printers with far larger price tags. The only real drawback here is the V2’s relatively small build envelope, which limits the range of objects you can create with it.

Our Take

The Maker Select V2 is definitely more of an evolution than a revolution — but in this case that’s a good thing. Monoprice didn’t need to reinvent the wheel with this machine, and thankfully, it didn’t try to. Instead, it threw on some new tread and made a rock-solid product that’s better than the original — and the original was already pretty great. The V2 might not be the best 3D printer on the planet, but you’ll be hard pressed to find a better blend of price and performance.

Instead, it threw on some new tread and made a rock-solid product that’s better than the original — and the original was already pretty great. The V2 might not be the best 3D printer on the planet, but you’ll be hard pressed to find a better blend of price and performance.

Is there a better alternative?

If your main concern is getting the most bang for your buck, then look no further. You won’t find this many features packed into such an affordable package anywhere but Monoprice.

If $220 is too steep for you, we also highly recommend the MP Mini Delta, which is about $60 to $70 cheaper, but does have a slightly smaller build envelope.

If build area is your main concern, then we’d recommend checking out the Monoprice Maker Select Plus — arguably one of the best printers we’ve ever reviewed. In terms of print performance, it’s nearly identical to the Maker Select Mini V2, but it does have a far larger build area that allows you to print much bigger objects. It also has a touchscreen, which is nice.

How long will it last?

If you treat this little guy well, it’ll likely give you a long life in return. Due to its all metal construction, durable components, ample replacement parts, and Monoprice’s continued software support, the Select Mini V2 seems well suited for a long life on your desktop.

Should you buy it?

Yes, yes, a thousand times yes! This printer offers a near perfect blend of price and performance, so if you’ve been waiting patiently for an affordable printer that doesn’t suck, then your time has come.

Editors' Recommendations

- AMD quietly slashes the prices of some of its best CPUs

- Meta Quest 3 is coming, but is Quest 2 still worth buying?

- Creative’s Katana V2X PC soundbar promises the same sound in a smaller footprint

- What is AMD 3D V-Cache? Here’s how it could change PC gaming

- Lenovo ThinkPad X1 Fold Gen 2 hands-on review: a sleek redo

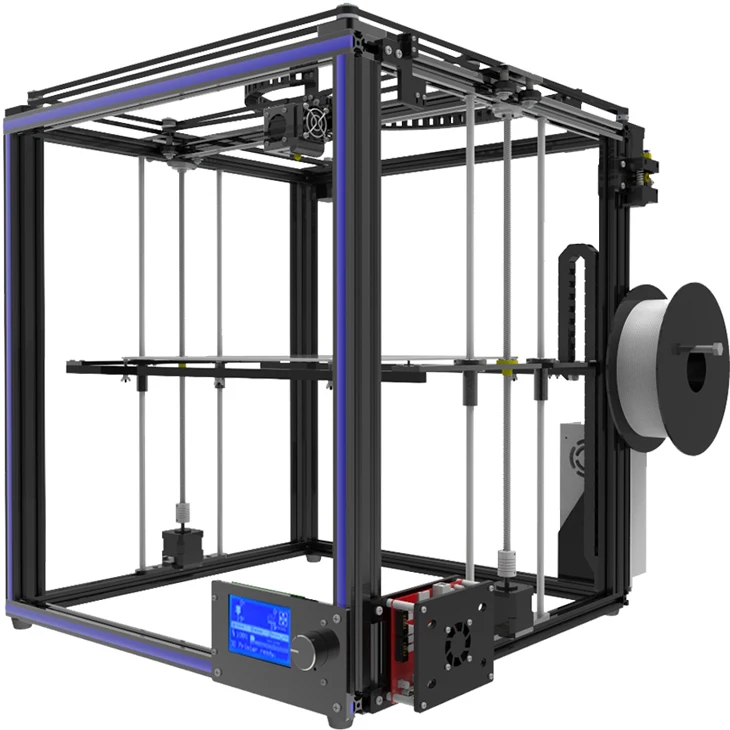

Overview of industrial 3D printers of popular brands

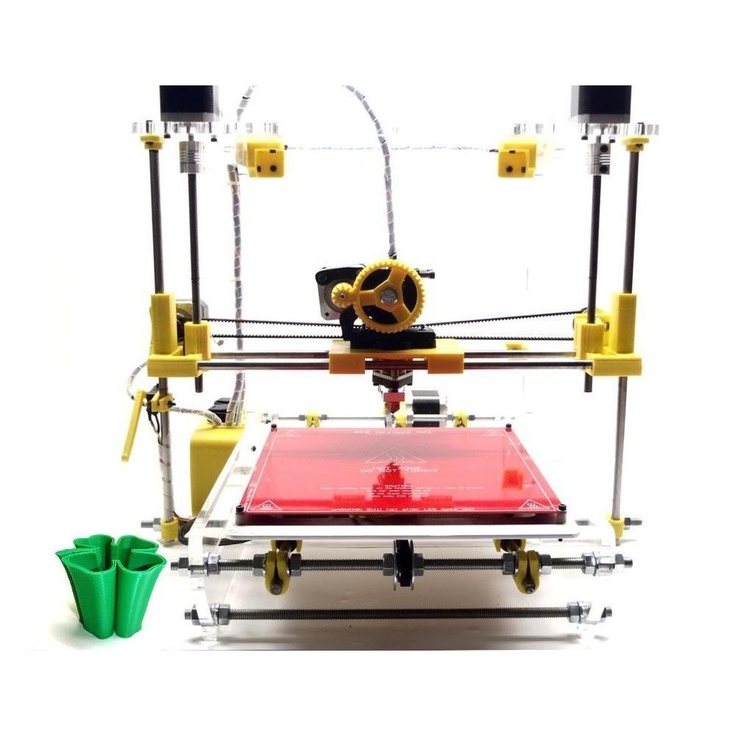

Industrial 3D printers have become popular because of the possibilities they offer. The equipment allows to produce customized products at the stage of product modeling. Users can improve existing CAD models or design entirely new shapes. All this leads to a reduction in the cost of products and prototypes. The market offers a diverse range of devices. The most iconic models are described below. nine0003

The equipment allows to produce customized products at the stage of product modeling. Users can improve existing CAD models or design entirely new shapes. All this leads to a reduction in the cost of products and prototypes. The market offers a diverse range of devices. The most iconic models are described below. nine0003

Overview of industrial 3D printers

3D Systems

The American company 3D Systems is at the forefront in all areas of 3D printing. Brand technology helps to significantly reduce the time for design, prototyping, mass production. Most frequently purchased models:

• The DMP Flex 350 3D Printer can print a variety of alloys with high precision. The next generation of equipment is characterized by high performance and accurate reproduction of the digital model. The machine works on DMLS technology and is able to operate around the clock. The technique is equipped with the option of rational use of raw materials, the work is automated at each stage of printing. Unused powder is reused, reducing the cost of the final project. Embedded software controls the entire production cycle, from parameter setting to material quantification and waste disposal. Finished products are characterized by low weight, strength, it is possible to print specimens with a dense structure, identical in properties to cast ones. nine0003

Unused powder is reused, reducing the cost of the final project. Embedded software controls the entire production cycle, from parameter setting to material quantification and waste disposal. Finished products are characterized by low weight, strength, it is possible to print specimens with a dense structure, identical in properties to cast ones. nine0003

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, automotive industry, medicine, jewelry industry, automotive industry, medicine, jewelry industry |

| Housing color | gray |

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Platform | metal |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Minimum wall thickness | 150 µm |

• The DMP Factory 350 3D printer has incorporated the advantages of the previous model, supplementing the list of advantages with an automatic powder circulation module. The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use. nine0003

The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use. nine0003

Photo: 3DSystems

Features:

| Country | US |

| Applications | aviation and space, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry |

| Housing color | gray | nine0031

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm | nine0031

| Minimum wall thickness | 150 µm |

• The DMP Factory 500 3D printer is a machine optimized for industrial scale. The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements. nine0003

The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements. nine0003

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, jewelry industry, mechanical engineering, medicine, metal industry, mechanical engineering, medicine |

| Housing color | white-grey |

| Dimensions | 3010x2290x2820 mm | nine0031

| Construction area | 500x500x500 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm; 90 µm |

| Layer thickness | metal |

| Platform | metal |

| Print Technology | DMP |

| Operating system | Windows 10 Pro, 64 bit |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Number of lasers | 3 |

| Laser Power | 500 W |

| Laser wavelength | 1070 µm |

• The ProX 800 3D Printer sets the standard for performance and fine detail. The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste. nine0003

The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste. nine0003

Photo: 3DSystems

Features:

| Country | US |

| Application area | architecture, foundry industry, interior design, foundry industry, education, dentistry, foundry industry, interior design, foundry industry, education, dentistry |

| Housing color | gray | nine0031

| Communication interface | LANs, IEEE 802.3 using TCP/IP and NFS, USB |

| Dimensions | 1370x1600x2260 mm |

| Construction area | 650x750x550 mm (including build platform) |

| Layer thickness | 125 µm |

| Platform | mesh |

| Print media | photopolymer |

| Print Technology | SLA |

| Operating system | Windows 10 |

| Warranty | 12 months |

| Minimum element size | 125 µm |

| Maximum weight of model | 75 kg |

| Maximum resolution | 4000 DPI |

3DCeram

The French brand 3DCeram offers services and equipment for 3D printing of original ceramic products. For development work, serial production of samples of complex geometry, the following machines are used:

For development work, serial production of samples of complex geometry, the following machines are used:

• 3D printer CERAMAKER 100 is a brand development aimed at additive manufacturing of ceramic products. This modification is actively used in the chemical and aviation industries, the medical field, jewelry, watchmaking. The equipment operates on the principle of layer-by-layer curing by a laser installation of a special composition of ceramic powder and photopolymer. The latter is a binder and is burned out after the alignment of the object is completed. nine0003

Photo: 3DCeram

Features:

| Country | France |

| Applications | aviation and space, automotive, nuclear industry, interior design, railway, mechanical engineering, medicine, dentistry, shipbuilding |

| Dimensions | 1000x1500x1900 mm |

| Construction area | nine0027 100x100x100 mm|

| Layer thickness | 50 µm |

| Material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER 900 3D printer reproduces objects with a surface roughness of less than 2 µm. Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable. nine0003

Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable. nine0003

Photo: 3DCeram

Features:

| Country | France |

| Applications | foundry industry, jewelry industry, medicine, mechanical engineering, dentistry |

| Dimensions | 1060x2250x2040 mm |

| Construction area | 300x300x100 mm |

| Layer thickness | 35 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER C3600 ULTIMATE 3D printer is a large scale production equipment. The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology. nine0003

The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology. nine0003

Photo: 3DCeram

Features:

| Country | France |

| Industries of application | foundry industry, jewelry industry, medicine, mechanical engineering |

| Dimensions | 2100x1800x2500 mm |

| Construction area | 600x600x300 mm |

| Layer thickness | 25 to 125 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

| Number of lasers | 4 UV lasers |

| Laser wavelength | 405 nm |

VoxeiJet

The German company VoxeiJet produces 3D machines for the production of sand molds and cores. The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

• The VoxelJet VX 200 HSS 3D printer is a compact system based on polymer powder sintering technology. The equipment is used for research purposes and to create new resources for the HSS process. An open system makes it possible to control the settings of print modes and parameters of temperature, layer thickness.

Photo: VoxelJet

Features:

| Country | Germany |

| Application area | interior design, aviation and space, automotive, prototyping |

| Construction area | 290x140x180 mm |

| Layer thickness | > 80 micron |

| Print material | polyamide |

| Print Technology | BJ |

• The VoxelJet VX 1000 HSS 3D printer works with polymers. The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products. nine0003

The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products. nine0003

Photo: VoxelJet

Features:

| Country | Germany |

| Applications | prototyping, mechanical engineering, interior design |

| Construction area | 1000x540 mm |

| Print material | polyamide, nylon |

| Print technology | BJ |

• The VoxelJet VX 4000 3D printer is a 3D sand mold printing system. The printer is capable of producing large items or a series of small items in a single cycle. The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting. nine0003

The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting. nine0003

Photo: VoxelJet

Features:

| Country | Germany |

| Dimensions | 20000x7800x4000 mm |

| Construction area | 4000x2000x1000 mm |

| Layer thickness | 300 micron |

| Print material | sand |

| Print Technology | BJ |

| Maximum resolution | 600 dpi |

Inss Tek

The Korean company Inss Tek has focused on working with alloys. DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

• The MX-Lab 3D printer is designed for the manufacture of functional devices, remodeling, reconstruction and restoration work, special coatings. The device uses DMT technology, which provides the necessary mechanical characteristics of the finished product, a unique density, the finest microstructure. Entry-level DMT machine with 3-axis laser system is suitable for material properties study, prototyping, alloy development. nineFeature:

| Country | South Korea |

| Applications | aviation and space, metallurgical industry, mechanical engineering, foundry industry |

| Dimensions | 700x700x860mm; 200 kg |

| Construction area | 150x150x150 mm |

| Layer thickness | 150 micron |

| Print material | metal |

| Print Technology | DMP |

| Operating system | Windows 7 |

• InssTek MX-600 3D Printer - The machine is configured to produce small objects with specified mechanical characteristics. Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed. nine0003

Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed. nine0003

Photo: InssTek

Features:

| Country | South Korea |

| Applications | foundry industry, metallurgical industry |

| Dimensions | 2000x2900x2550mm; 6.5 t |

| Construction area | 450x600x380 mm |

| Layer thickness | 250 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

• The InssTek MX-Grande 3D Printer is an industrial system designed for producing large objects. The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding. nine0003

The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding. nine0003

Photo: InssTek

Features:

| Country | South Korea |

| Applications | automotive industry, nuclear industry, foundry industry, mechanical engineering, metallurgical industry, oil and gas industry, shipbuilding |

| Construction area | 4000x1000x1000 mm |

| Layer thickness | 750 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

Conclusion

Large-scale manufacturing giants actively use additive technologies, while developed countries open large research centers and develop state programs. Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable. nine0003

Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable. nine0003

Source

Tags:

Industrial 3D printers, 3D Systems company, DMP Flex 350 3D printer, DMP Factory 350 3D printer, DMLS technology, 3DCeram brand, CERAMAKER 100 3D printer, CERAMATE3AKER3AKER60 3D printer VoxeiJet, 3D printer VoxelJet VX 200 HSS, Inss Tek

Other materials:

- Zortrax 3D Printed Sports Helmet for Cats

- QIDI TECH S-Box 3D Printer - Reliable Heavyweight! nine0960

- 3D Scanner Review: RangeVision PRO5M, Shining 3D PRO HD, Calibry, KSCAN20, Shining 3D HX

- Go!SCAN SPARK vs HandySCAN SILVER/BLACK: which scanner is right for you?

- Printing with nylon (Nylon) on a 3D printer technology features

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

nine0000 Overview of the best photopolymer 3D printers from leading manufacturers

You are here

Home

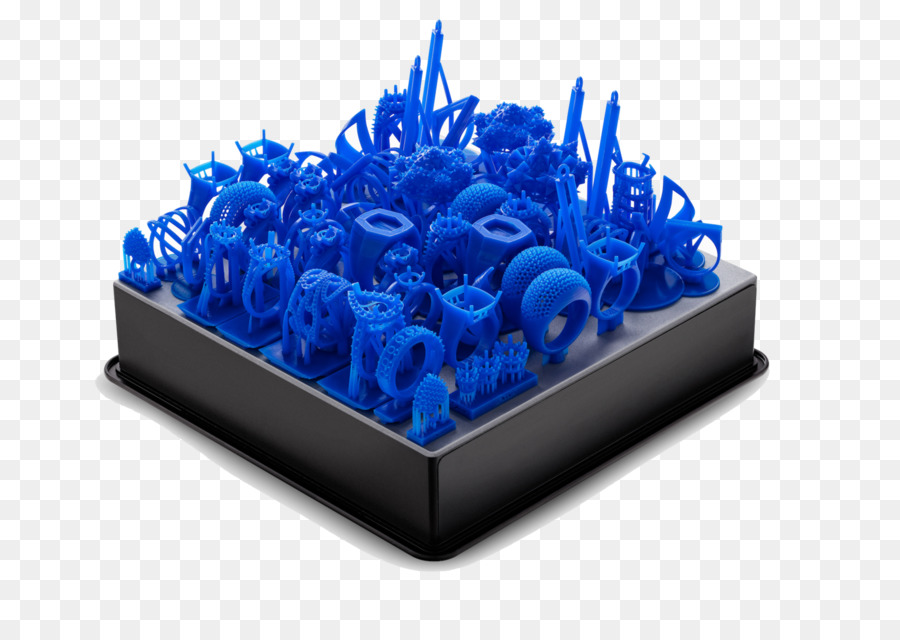

Photopolymer 3D printers produce ultra-precise samples, use a wide range of materials, and work at high speed. The equipment helps reduce the time spent on the project. Additive technologies make it possible to quickly create layouts or prototypes, quickly test them, correct them, and produce improved models. Photopolymer printers with a large print area allow you to line up large objects without additional assembly or set up small-scale production. nine0003

Overview of photopolymer printers of various brands

Industrial equipment

When choosing the best photopolymer 3D printer for industrial use, preference is given to copies with high speed and quality of produced objects. Compatibility with a variety of resins and their rational use are also important.

Compatibility with a variety of resins and their rational use are also important.

3D Systems provides innovative solutions and advanced 3D services. The brand develops devices, polymers, programs, services in accordance with market demands. Photopolymer printers of this brand are always included in the ratings of advanced innovations. For each industry, the manufacturer produces adapted technologies and reliable equipment. nine0003

Popular models:

- The ProX 800 3D printer is an upgraded version of the iPro 8000 using SLA technology. Industrial machinery is designed for the production of large-sized objects or the production of large batches of small products. High resolution makes it possible to print models with the required accuracy, excellent detail, and a smooth surface. The printer produces parts in quality comparable to samples obtained by milling. The model is distinguished by an intuitive process of work, economical consumption of raw materials, a quick procedure for changing the components used.

nine0960

nine0960

Photo: 3DSystems

Specifications:

| Country | US |

| Applications | Architecture, foundry, interior design, education, dentistry |

| Housing color | Gray |

| Communication interface | LANs, IEEE 802.3 using TCP/IP and NFS, USB |

| Dimensions | 1370x1600x2260 mm |

| Construction area | 650x750x550 mm (including build platform) |

| Layer thickness | 125 µm |

| Platform | Mesh |

| Print material | Photopolymer |

| Print Technology | SLA |

| Operating system | Windows 10 |

| Warranty | 12 months |

| Minimum element size | 125 µm | nine0031

| Maximum weight of model | 75 kg |

| Maximum resolution | 4000 DPI |

• The ProX 950 3D Printer is an upgraded version of the iPro 9000 that uses stereolithography principles. The device produces objects with high resolution, the finest detail. The model is focused on industrial scale, suitable for the manufacture of large items or serial production of small or medium samples. The device uses a wide range of materials, and embedded software allows you to manage the additive manufacturing process and offers tools for making better parts. nine0003

The device produces objects with high resolution, the finest detail. The model is focused on industrial scale, suitable for the manufacture of large items or serial production of small or medium samples. The device uses a wide range of materials, and embedded software allows you to manage the additive manufacturing process and offers tools for making better parts. nine0003

Photo: 3DSystems

Specifications:

| Country | US |

| Applications | Architecture, foundry, advertising and souvenirs, interior design, dentistry |

| Housing color | Gray |

| Communication interface | LAN, IEEE 802. |

| Dimensions | 2200x1600x2260 mm |

| Construction area | 1500x750x550 mm (including build platform) |

| Layer thickness | 125 µm |

| Platform | Grid |

| Print material | Photopolymer |

| Print Technology | SLA |

| Operating system | Windows 10 |

| Warranty | 12 months |

| Minimum element size | 125 µm |

| Maximum model weight | 150 kg |

| Maximum resolution | 4000 DPI |

Equipment for professional use

Specialized 3D printers are machines designed to create precise 3D models. The hardware has been tested on a variety of objects with different levels of detail and build platform sizes. The technique creates layouts, prototypes with the highest accuracy and surface quality, and is also able to replicate products in small batches. Some modifications of professional printers are focused on a specific industry, but there are also universal machines. nine0003

The technique creates layouts, prototypes with the highest accuracy and surface quality, and is also able to replicate products in small batches. Some modifications of professional printers are focused on a specific industry, but there are also universal machines. nine0003

Nexa3D is the creator of the fastest technology available to professionals and startups. The equipment operates according to the patented LSPc technology using a structured light matrix.

The Nexa3D NXE400 3D printer is an ultra-fast stereo lithography machine for professional use. The model is available to organizations of all sizes. The impressive volume of the working chamber makes it possible to build a large object or many small ones in one go. The modular design helps to quickly change components, update the system. The strength of finished products meets industry standards. Optimized software is responsible for maximum printing speed and accuracy. The Senor feature makes it possible to track elements through a digital twin. nine0003

nine0003

Photo: Nexa3D

Specifications:

| Applications | Prototyping, interior design, engineering, education, advertising and souvenir manufacturing |

| Housing color | Black |

| Communication interface | LAN, USB, Wi-Fi |

| Construction area | 280x165x400 mm |

| Layer thickness | 50 µm; 100 µm; 200 µm |

| Platform | Mesh |

| Print material | Photopolymer |

| Print technology | LSPc |

| Operating system | Windows 7, Windows 8, Windows 10 |

| Warranty | 12 months |

The 3DSystems brand supplies equipment that ensures print accuracy, high production speed. Printed copies are strong, with a significant margin of safety, smooth surface. nine0003

Printed copies are strong, with a significant margin of safety, smooth surface. nine0003

Top brand 3D printers in 2020:

- The Figure 4 Standalone 3D printer is an ultra-fast machine for small batch production or rapid prototyping. The unit provides wear resistance and accuracy of parts. The technique helps to reduce production costs without losing the quality of printed objects. Switching of materials is carried out simply and quickly, which makes it possible to expand the range of manufactured items.

Photo: 3DSystems

Specifications:

| Country | US |

| Applications | Foundry, medicine, education, advertising and souvenirs, dentistry, jewelry, prototyping |

| Housing color | nine0027 White|

| Communication interface | LAN, USB, Wi-Fi |

| Dimensions | 681х704х1356 mm |

| Construction area | 124. |

| Layer thickness | from 10 µm |

| Platform | Grid |

| Print material | Photopolymer |

| Print Technology | DLP |

| Operating system | Windows 7, Windows 8, Windows 10 |

| Warranty | 12 months |

• Figure 4 Jewelry 3D printer is a machine for jewelry design. The device helps to create jewelry of impeccable quality. Suitable for prototyping jewelry designs, checking their compliance with customer criteria. High performance, perfect surface finish, flexibility of application make the model the best in its class. nine0003

Photo: 3DSystems

Specifications:

| Country | US |

| Applications | Jewelry industry |

| Dimensions | 426x489x971 mm; 34.5 kg |

| Construction area | 124.8x70.2x196 mm (including build platform) |

| Print media | Photopolymer |

| Print Technology | DLP |

• The ProJet 3600 MAX 3D Printer is designed with multiple layout modes to expand your prototyping potential. The device quickly pays for itself due to its high throughput, and it can also be used to "grow" voluminous objects much faster than on other devices. nine0003

Photo: 3DSystems

Specifications:

| Country | US |

| Applications | Foundry, education, advertising and souvenir production |

| Print material | Photopolymer |

| Print technology | MJP |

Conclusion

Today, the choice of photopolymer printers is huge. The equipment is used not only in dentistry and jewelry, but also in the architectural field, the automotive industry, and the household appliance repair segment.

Decent quality prints and a rich range of materials allow the introduction of equipment in various sectors of production and prototyping. Before purchasing the device, it is important to correctly determine the goals that will be set for the machine. This will help to calculate the budget and choose the right 3D printing technology.

3 using TCP/IP and NFS, USB

3 using TCP/IP and NFS, USB  8 x 70.2 x 196 mm (including build platform)

8 x 70.2 x 196 mm (including build platform)