Solidscape 3d printer for sale

S300 Series by Solidscape 3D Printers In-Depth Review

ADVERTISEMENT

Table of Contents

3D printing market is showing a remarkable surge in the growth of 3D printer applications. And, the jewelry niche, being one of the most dominating markets, too, has started to realize the nuances of benefits of including 3D printers in their production process.

Hence, the companies are also making room for newer technologies to provide better 3D printers for precise outputs. S300 series by Solidscape is a pair of 3D printers that are specially designed for the jewelry industry.

These printers use wax modeling for making castable waxes. One can design jewelry using various metals such as gold, platinum, silver, etc.

The ability to convert complex and rarest designs into reality makes these S300 series 3D printers the real gem. Although the niche often suffers from ups and downs in the demand, companies offering customized designs always stay on top of their games. And, 3D printers help make that possible in the easiest way possible.

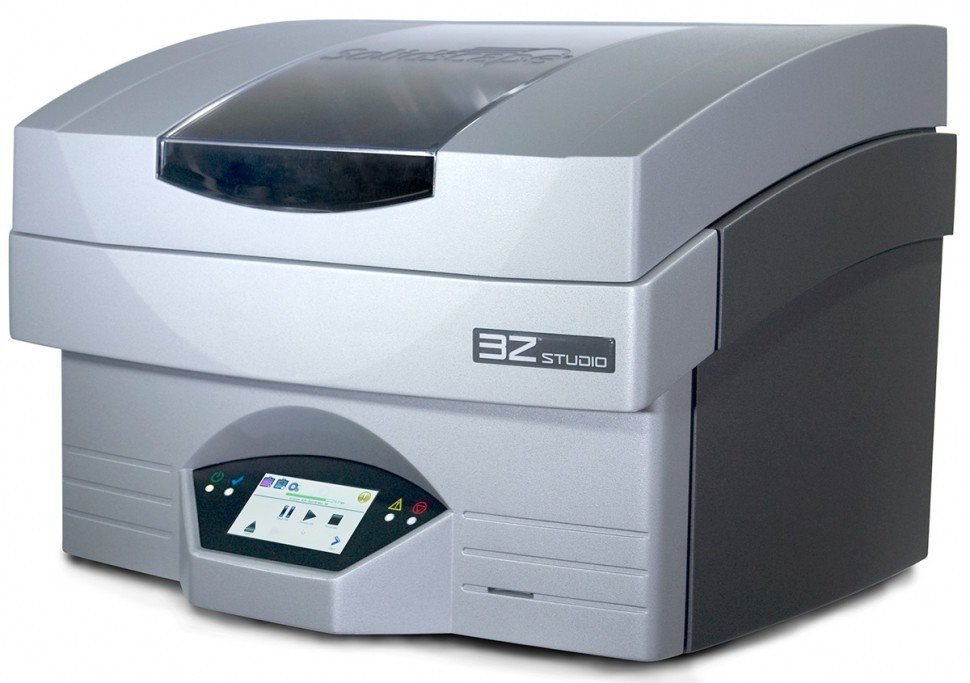

Solidscape has come up with four variants of S300 series: Studio, S350, S370, and S390. While the technology remains the same, each of these variants differs in terms of resolution, speed, and production volume.

ADVERTISEMENT

Introduction to Solidscape S300 Series

Solidscape S300 series are based on multi-jet modeling which is very similar to the ink-jetting process in 3D printing. The S300 series 3D printers are released to serve different needs of individuals as per their job requirements.

Studio: This is the S300 series first 3D printer designed for those working alone or with a small setup. Such as those owning small design studios or those who are custom retailers. One can build few designs in a day. Mass production isn’t possible using this 3D printer.

Such as those owning small design studios or those who are custom retailers. One can build few designs in a day. Mass production isn’t possible using this 3D printer.

S350: This is the next S300 series 3D printer. If you are a manufacturer of jewelry that requires high-end design, you can choose S350 without a doubt. The 3D printer can print a considerable volume of designs in a day.

S370: This 3D printer was brought in to provide better throughput. And, also to increase the speed of production to the next level by providing printing of a greater number of designs than S350 at once.

S390: The S300 series has more to add to the list. The S390 was introduced recently, by far, the most accurate 3D printer for jewelry designing. The 3D printer offers speed and accuracy at the same time. One can produce a large volume of designs per day with the highest resolution.

All these four 3D printers can help make great advancements in the field of jewelry making. The company released four versions to reach out to the different levels of community involvement in jewelry making.

The company released four versions to reach out to the different levels of community involvement in jewelry making.

So, let us unveil how these 3D Printers are making a huge difference.

ADVERTISEMENT

S300 Series Review

S300 series, as stated above, is for custom jewelry designers. One who wants to create complex jewelry that are not possible otherwise can surely be benefited by the use of these 3D printers.

Features

All the variants of the S300 series flaunt extremely amazing features. The S300 series is backed with a number of unmatched properties, difficult to find with other choices.

- Mess-Free Casting: The 3D wax patterns can be cast directly with the help of S300 series 3D printers. A direct route that takes the design to the investment casting makes the entire process easy and streamlined.

- Cast in All Metals: The 3D printers prepare molds that can be cast in almost any metal of your choice suitable for casting.

You can cast in gold, silver, platinum and many other castable materials.

You can cast in gold, silver, platinum and many other castable materials. - Best Resolution: Even the resolution provided by the Studio 3D printer from the S300 series is amazing. You can very well imagine the results in terms of accuracy that S390 provides. Going up on the list would get you an even better resolution. You can expect the 3D printers to get you spectacular symmetry, perfection to details, wall thickness, and repeated excellence.

- Hands-Free Post Processing: This is one of the best features of the S300 series. Because the support can be separated by melting it away in a non-toxic liquid, there is no need to make any extra effort during the post-processing methods. You would be left with the great finished mold with smoothest surfaces.

ADVERTISEMENT

Specifications

The size of the variants of the S300 series has almost a similar specification. The 3D printers are designed to occupy 21.4 x 18 x 16 inches (558 x 495 x 419 mm) volume. The build space of 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) is available.

The build space of 6 x 6 x 4 inches (152.4 x 152.4 x 101.6 mm) is available.

The studio 3D printer comes with 6 x 6 x 2 inches (152.4 x 152.4 x 50.8 mm). These printers weigh 36 kgs which are decent enough to handle.

Working within the operating temperature of 60 to 75 degrees Fahrenheit, it is safe to use. Moreover, power consumption is also decent.

Price

There is a huge price difference in the various variants of the S300 series. While S350 costs around $39,650, S390, the latest release by the company is priced at $55,650. The studio series is cheaper of all and S370 lies somewhere in between S350 and S390.

Although these printers seem too costly in the beginning, the way these helps in streamlining the entire jewelry manufacturing process makes these prices very well justified.

First Impressions

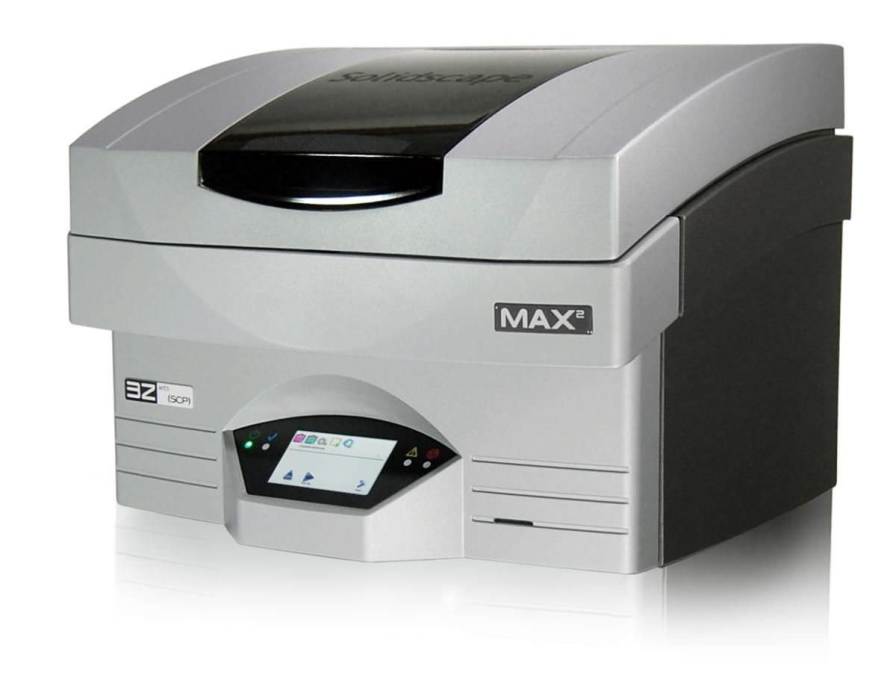

You are going to love the design of this 3D printer. Compact and comes in black color with a screen in the front for setting the desired design for printing. This one-touch operating 3D printer gets you the easiest possible way for creating designs and making room for complex designs.

This one-touch operating 3D printer gets you the easiest possible way for creating designs and making room for complex designs.

You can place it in at your workstation inside your house or in your office. It won’t take much space. Moreover, you can different variants to suit your needs. So, you can choose as per your budget and working goals.

ADVERTISEMENT

Setup

There is not much one needs to do to set up the 3D printer. The company offers a handbook and there are many documents available on their website as well to help you proceed with the setup.

Just a few steps and you can start printing your test design right away. The 3D printers are well sorted in terms of functionality and the redesigned delivery system gets users improved performance as well as enhanced assembly process. Not just that the printer is easy to use, the service requirements of the hardware is simple to meet.

Printing Type/Cost

As mentioned above, the printer runs on multi-jet modeling. This technology is similar to the inkjet printing and offers great Z-axis resolution with the lowest possible layer thickness for high resolution. The technology is used for depositing casting wax material which is done each layer at a time.

This technology is similar to the inkjet printing and offers great Z-axis resolution with the lowest possible layer thickness for high resolution. The technology is used for depositing casting wax material which is done each layer at a time.

Once the layer sets up, another layer is deposited over the prior one. The best part is dissolvable support material.

This helps in making the entire post-processing method as simple as a piece of cake. You just need to dissolve the support in the non-toxic liquid to get the mold ready instantly.

Print Quality

S300 series 3D printers provide amazing print quality. You can create designs that look difficult enough to be considered impossible. However, with the S300 series, these designs can be given shape with the help of S300 series 3D printers.

The S300 series offers layer thickness between 0.00025 inch (0.00635 mm) to 0.001 inch (.0254 mm) at 0.00025 (0.00635mm) increments.

Users can select between the range and 3D print as desired. Even the resolution is something one must give a glance. With the stunning resolution of 5000 dots/inch (197 X 197 dots/mm) in both X, Y axis, one can expect the design to be highly precise.

Even the resolution is something one must give a glance. With the stunning resolution of 5000 dots/inch (197 X 197 dots/mm) in both X, Y axis, one can expect the design to be highly precise.

The parts produced by the S300 series have a great surface finish. This also depends on the layer thickness selected and can range up to 32 micro-inches.

To start printing, the one-touch process makes the job easier. The system covers fully automated fault detection features. Also, the printers are smart enough to start printing from the point of interruption to get the best print quality possible.

ADVERTISEMENT

Software

The company has tried its best to get users the easiest possible way to work with the S300 series 3D printers. Hence, there is no room for extra effort in any phase of the design. The one-click software makes that goal of the company possible. The software included with the S300 series 3D printers is capable of scaling CAD files directly without the need to make any manual intervention.

Any .STL or .SLC files can be made available for printing with the use of one-click software. To connect the printer with the PC, one can use the high-speed USB 2.0 port or the ethernet port. Windows is the only operating system compatible with S300 series printers.

Customer Service

Users are well served in terms of assistance from the company. You can connect with the support through email and phone numbers. The technician is also available just in case. So, you can keep printing your designs without any worry.

Pros/Cons

The S300 series 3D printers have some pros and cons important to underline.

PROS:

- Great print resolution

- One-touch operation

- Easy to handle

- Accurate designs

- Hands-free support elimination

- Fast and precise design

- Different variants for different purposes

CONS:

- The products are pricey, especially the high-end ones

- Not Support for MAC users

ADVERTISEMENT

Factors Influencing Purchase Decision

Before putting a hand full of money into a 3D printer, it is necessary to check all the aspects beforehand.

3D Printer cost: As stated before, the S300 series is packed with four different printers falling in different price ranges. Those who are operating a small studio may find Studio 3D printer economical. However, the price is still a concern. These are not cheap but are worth it. So, it completely depends on how much one can invest in a 3D printer.

3D Print quality: There is no doubt that the 3D printers falling in the S300 series are designed for easy and best quality prints. So, you can trust the printer for getting you high-resolution prints with minimum intervention possible.

3D Print speed: The studio S300 series 3D printer isn’t a very speedy option. This is suitable for those printing a few designs every day. However, if you are looking for a full-fledged operation and owns a piece of huge jewelry designing company, you may think of investing in the S390 series which comes with the highest speed and volume of production.

3D Printer capability: It is noticeable. Every 3D printer falling under the S300 series has been able to design complex geometries with ease.

3D Printer Practicality: In practical use, the S300 series could be employed for various usage. The application would differ depending on the scale of production. One can definitely choose the S300 series for all professional applications related to jewelry designing.

3D Printer User expectations: The expectations in terms of quality have been addressed perfectly by the company. However, the price is still a challenge that restricts its accessibility to the majority of the masses.

Verdict

Jewelry designing has been an undeniably important part of our trend. The demand is surging, and people are getting inclined towards custom jewelry, specially designed for keeping their uniqueness intact. Because of which the industry is falling prey to a competition that seems impossible to carry on for most of the designers.

Either it’s a small town or a big city, jewelers find it difficult to cope with the existing demands of the customers. The brink of success can only be crossed if jewelry designers start getting their hands dirty with custom designing. And, the S300 series can help make that possible.

The 3D printers series, made for those who love getting creative with jewelry designing, instead of manufacturing the old designs with few changes. An industry that seeks newness and uniqueness in every design presented, can only be served by a 3D printer capable of providing speed, accuracy, and simplicity.

S300 series has got all that. The price isn’t that economical for many but is capable of paying a huge time when considered as a long-term investment.

5 Best 3D Printers For Jewelry 2022 (All Price Ranges!)

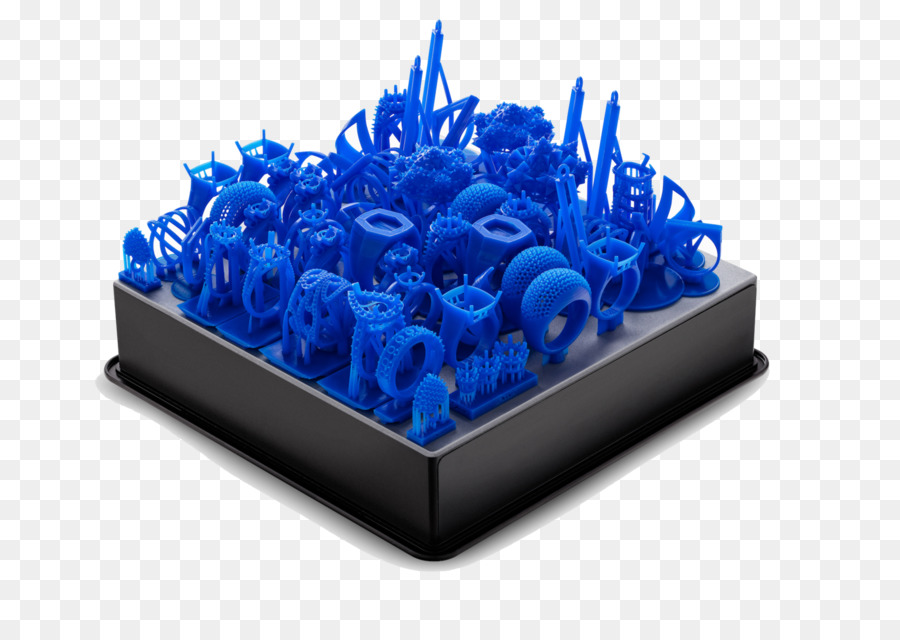

3D printing jewelry rarely means 3D printing actual wearable pieces made from filament or resin, but instead using a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design, used to create a mold that is burned out and cast via investment casting or lost wax casting.

- We also have an article ranking some of the most beautiful 3D printed jewelry.

In fact, much jewelry is now created this way. There are entire factories of resin 3D printers set up to create castable wax resin models to be molded and then melted to create high-end jewelry.

However, owning your own jewelry 3D printer gives you more control over your production, and saves you money compared with paying someone to print your own molds. Castable resin molds can be produced for rings and other jewelry pieces for just the cost of the resin used, perhaps a dollar or two, whereas you could end up paying $25+ for someone to print it for you.

To insert the table into a page, post, or text widget, copy the Shortcode and paste it into the editor.

| Name | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Elegoo Mars 2 Pro | 129 x 80 x 160 | $250 | Elegoo here |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here |

| Formlabs Form 3 | 145 x 145 x 185 | $3,499 | Dynamism Store here |

| Solidscape S325 | 6″ x 6″ x 4″ | Quote | Get a Quote here |

| EnvisionTEC D4K Jewelry | 148 x 83 x 110 | Quote | Get a Quote here |

- CAD File: Either design your own jewelry piece on CAD software, pay someone to design your desired piece, or pay for an existing jewelry STL file online and download it.

- Slice & Prepare: If not already an STL or other compatible file, export it as one. Then import it into your 3D slicer and slice it for printing.

- Print the model: Use a castable wax resin designed for jewelry model 3D printing.

- Molding: Pour your molding material over your wax jewelry model, and leave it to harden.

- Melt the wax: Heat your new mold so that the original wax model melts and evaporates, leaving a hollow empty space inside with the exact dimensions of your planned jewelry piece.

- Casting: Pour melted liquid metal e.g. gold, silver or platinum into the mold to cast it.

Resin 3D printers are considered the best 3D printers for jewelry. They are used with specialized castable wax resins, which rather than going from solid to liquid when heated, transition directly into a gas from their solid state.

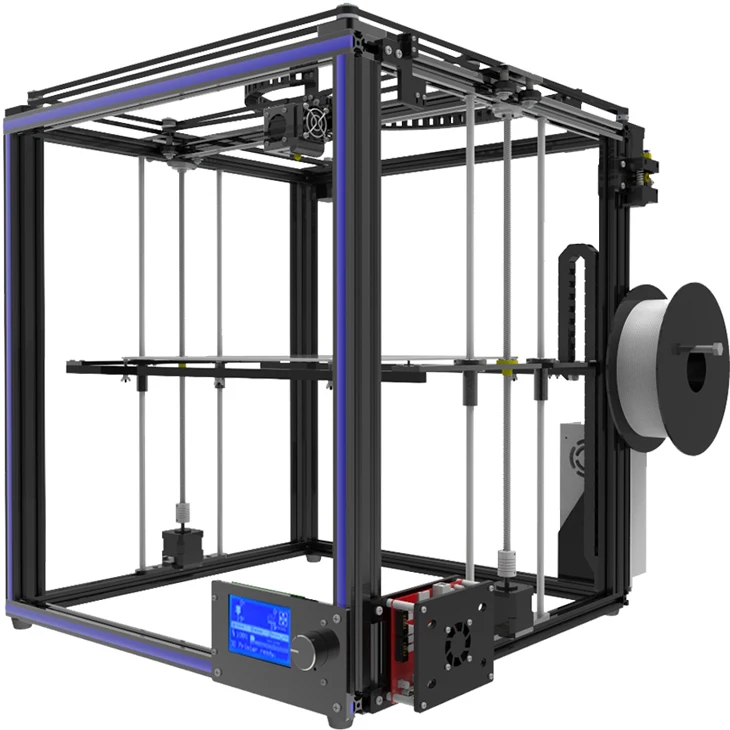

Though prevalent, FDM 3D printers are very rarely used as 3D printers for jewelry. They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Additionally, the better the jewelry 3D printer quality, the less finishing the resulting jewelry piece will need to perfect it.

What do jewelry 3D printers make?Usually they 3D print wax jewelry molds, for example of ring designs before any stones are set, or individual chain links.

However, they can also be used to create like-for-like “fitting pieces” for testing the fit of an as-yet unmade ring for a client’s finger. Though making the final ring would be expensive and take time, an exact replica can be made on a jewelry 3D printer in just minutes to test the sizing.

This saves the trouble of creating a piece just to find it doesn’t fit properly. Whereas for jewelry molds specialized castable resins are required, for these fitting pieces standard resins can be used.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

The best 3D printers for jewelry

1 — Elegoo Mars 2 Pro

- Jewelry 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 129 x 80 x 160 mm

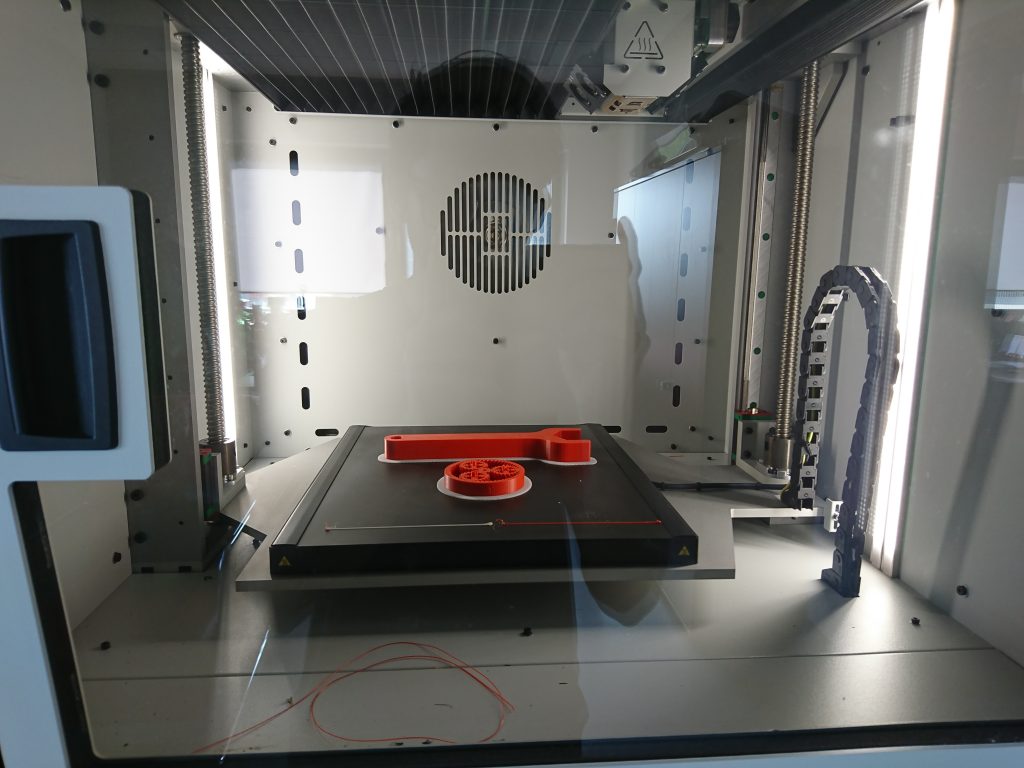

Featuring a 6-inch monochrome LCD screen offering HD 2K resolution, the Elegoo Mars 2 Pro offers precise jewelry printing for the price. Rather than DLP or SLA, the Mars 2 Pro uses LCD printing to cure entire resin layers at once, quickening print speeds and able to print at 30-50mm/h.This is the detail we achieved when using the Elegoo Mars 2 pro – enough for fine jewelry pieces.

Other 3D printers for jewelry on this list offer better quality, but for the price the Mars 2 Pro is a great option. It is sturdily built with its CNC-machined aluminum structure for better stability, and the mono LCD is upgraded for improved lifespan to save you money over the long term. It’s one of the best 3D printers for jewelry under $500.

It’s one of the best 3D printers for jewelry under $500.

The Elegoo Mars has Z-axis resolutions of up to 0.00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

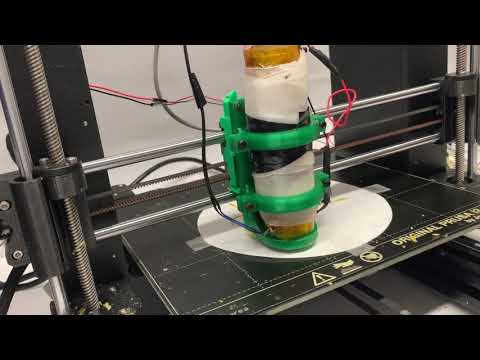

The video below even shows, from start to finish, how accurately you can make wax models for gold jewelry using a standard Elegoo Mars. Even this standard version produces good quality wax models, and the Elegoo Mars 2 Pro comes with several upgrades on the original.Printing on our Elegoo Mars 2 Pro – read our full review here.

2 — Peopoly Phenom

- Jewelry 3D printer price: $1,999 — Available on Matterhackers here

- Build volume: 276 x 155 x 400 mm

The Peopoly Phenom offers truly enormous printing volumes, almost unheard of for a jewelry 3D printer. For jewelers looking to produce many rings or other pieces simultaneously, this larger volume provides space for dozens of wax jewelry models. If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

With its 4K high resolution projection quality using MSLA technologies, the Phenom produces crisp, accurate and consistent jewelry molds. MSLA takes elements from both LED and LCD technologies, the result being fast, accurate and repeatable jewelry 3D printing.

- The even larger version, the Peopoly Phenom L, is available here.

- For faster print speeds, the premium Peopoly Noir is available here.

The Phenom uses Chitubox resin 3D slicer, useful if you’ve previously used it previously on another printer. Overall, it’s one of the best 3D printers for jewelry, and a great choice for people looking to make large numbers of castable wax jewelry models.

3 — Formlabs Form 3

- 3D for jewelry price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

Seen as the gold-standard in professional resin printing, the Form 3 is capable of fantastic precision, with its new custom Light Processing Unit (LPU) using lenses and mirrors to accurately print jewelry models.

For the price, the Form 3 offers 25-micron resolutions and very consistent and repeatable printing. For those looking for a 3D printer for jewelry able to produce the same design flawlessly again and again, or for producing custom intricate designs, the Form 3 can handle both without issue.

Formlabs make their own castable wax resins designed for jewelry with “crisp settings, sharp prongs and smooth shanks.” Within the Formlabs workflow therefore is a complete jewelry production process for wax models, though the Form 3 also excels as a dental 3D printer and in other industries, too.The Form 4, and several jewelry wax models it 3D printed.

4 — Solidscape S325

- Price: Requires a quote

- Build volume: 6” x 6” x 4”

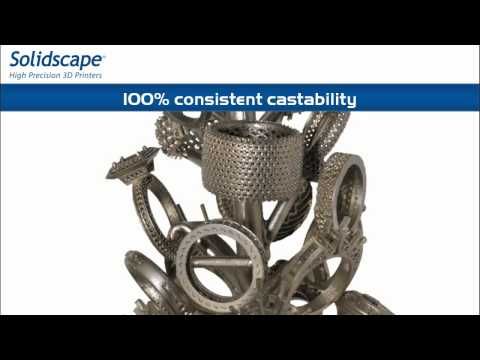

Soliscape make specially designed jewelry 3D printers, so any Solidscape printer you buy is optimized for jewelry printing. Whereas other printers like the Form 3 are designed to excel in a number of industries, the Solidscape S325 is designed with jewelry wholly in mind.

The S325 is the cheapest of Solidscape’s jewelry 3D printer range. It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

The S325 is capable of 0.001-inch layer thicknesses, with accuracies of 0.005 inches. Overall, as a specialized 3D printer for jewelry, Solidscape have a rich history in jewelry 3D printing and can be trusted to deliver high-quality and precise ring wax models, time and time again.

Get a quote*

*One of our trusted partners will be in touch following a quote request.Compressed by jpeg-recompress

5 — EnvisionTEC D4K Pro Jewelry 3D printer

- Jewelry 3D printer price: Requires a quote

- Build volume: 148 x 83 x 110 mm

Described by EnvisionTEC are the highest resolution professional-grade desktop 3D printer, as well as claiming to have the fastest speed, the D4K is well suited to jewelry 3D printing. Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

EnvisionTEC are the originators of DLP 3D printing, having pioneered the process more than a decade ago. Now, their advanced D4K Pro can produce accuracies of up to 25 microns in the XY resolution, and 1 micron on the Z axis.

The jewelry 3D printer works well with EnvisionTEC’s WIC100 Series wax material, used to then burn out and investment cast precious jewelry. Though it’s an industrial 3D printer costing over $10,000, larger jewelers will find the D4K one of the best 3D jewelry mold printers.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Advantages of owning a jewelry 3D printer

- Saves money long term: rather than paying a 3D printing service $20+ to print your mold for you, you can print your own wax jewelry molds for just a dollar each.

- Control your own jewelry production: with the ability to print jewelry in-house, you control your own workflow and apart from resin shortages, cannot be slowed down by supplier failures. Your order will always be top priority.

- Fast: going from CAD model to a piece ready to be investment cast is quick, especially when you can print and cast everything in one place.

- Very accurate: precise, smooth and intricate jewelry is not an issue for jewelry 3D printers, some able to print with below 10-micron accuracy to capture your ring’s most delicate and beautiful features.

- Repeatable and scalable: 3D printers for jewelry can create potentially dozens of identical or customized ring molds at once, perfect for scalable jewelry production.

3D printers Solidscape, Inc.

Designation

Designation

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC. nine0003

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd. nine0003

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc. nine0003

nine0003

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

Maker Farm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc. nine0003

nine0003

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3D Monster

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co. nine0003

nine0003

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc. nine0003

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd. nine0003

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS + ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd. nine0003

nine0003

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd. nine0003

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co. , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

Alphabet 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd. nine0003

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co. , Ltd.

, Ltd.

8

INDIGO 3D

1

Aconity3d

6

OR Laser

3

Farsoon Technologies

5

QIDI Technology

11

Shenzhen Twotrees Technology Co., Ltd.

7

Mingda

18

Elegoo

14

Longer

9

Sunhockey

2

DUPAS3D

1

Kelant

5

Voxelab

3

DIYMARIA

1

VSHAPER

CREASEE

CNC Barcenas

5

Vistar

11

Kingroon

1

IdeaFormer

3

F2 Innovations

3

Sindoh

8

Eplus3D

8

Print Technology

Print Technology

Plastic Jet Printing (PJP)

8

MultiJet Modeling (MJM) Technology

1

SLA printing technology

Sterolithography (SLA) technology

2

Film Transfer Imaging (FTI)

MultiJet Printing (MJP)

20

Multi-Jet Modeling (MJM) Technology

2

Stereolithography (SLA)

115

Selective Laser Sintering (SLS)

65

Direct Metal Sintering (DMS)

6

Granular

5

Fused deposition modeling (FDM/FFF)

962

DoD/SCP Technology

6

PolyJet 3D printing Technology

19

The EnvisionTEC 3D-Bioplotter 3D printing technique

2

Direct Light Projection (DLP)

31

Photopolymerization

Digital Light Projection (DLP)

5

Digital Light Processing (DLP)

64

Additive Layer Manufacturing (ALM)

2

Laser Stereolithography (LSLA)

1

Direct Light Processing (DLP)

1

Electron Beam Melting (EBM)

6

Laser welding CLAD

6

Laser sintering (LS)

4

Layer by layer manufacturing (LOM)

5

Selective laser melting (SLM)

31

Laser Engineered Net Shaping (LENS)

1

Direct Metal Laser Sintering (DMLS)

11

Laser metal melting (LC)

10

Direct Metal Tooling (DMT)

7

Solid Creation System (SCS)

3

Ultrasonic Additive Manufacturing (UAM)

3

Composite Filament Fabrication (CFF)

1

Drop on Demand (DOD)

1

Lithography Ceramic Manufacturing

1

Melted and Extruded Modeling (MEM)

7

Drop-On-Demand (DOD)

Sliding Separation Process (SSP)

9

Smooth Curvature Printing (SCP)

2

Plastic Sheet Lamination (PSL)

1

Selective Heat Sintering (SHS)

1

ColorJet Printing (CJP)

7

Micro-SLA

1

DLP-SLA

3

WDM (Layer Waxing)

2

SLA-sla

Direct Metal Printing (DMP)

7

HP Multi Jet Fusion technology

2

3D Daylight Polymer Printing (DPP)

2

Smart-Positioning-System Technology (SPS)

2

LCD Stereolithography

62

UV LED DLP

4

Single Pass Jetting (SPJ)

1

Atomic Diffusion Additive Manufacturing (ADAM)

1

bioprinting

3

Powder Binder Jetting (PBJ)

10

Reset filters

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Known for its daVinci line of desktop 3D printers, XYZprinting is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.