3D printer bridge test

Bridging Test | Best Objects & How to Optimize the Settings

- Author

- Recent Posts

Martin

Martin has a M.Sc. in physics and has gained many years of experience in industry as a lab manager and quality assurance manager. He has now tested dozens of 3D printers and is happy to share the collected experience with each new article.

Latest posts by Martin (see all)

- BQ-Hurakan vs. Ender-3 V2 Neo | Comparison, Pros & Cons - November 10, 2022

- Mouse Ears (Brim Ears) vs. Warping in 3D Printing – Guide - November 10, 2022

- Ender-5 S1 vs. Ender-5 Pro | Comparison, Specs, Pros & Cons - November 9, 2022

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Poor bridging behavior often leads to frustration in 3D printing. However, the behavior can be easily optimized and even more easily tested.

A bridging test tests how well the 3D printer can print 90° overhangs. Good bridging test objects use as little filament as possible and offer multiple bridge lengths. Bridging tests are available either in slicer plugins or on platforms like Thingiverse.

These are the best bridging test objects:

- Bridging Test in the Calibration Shapes Plugin in Cura

- “Bridging Test (Customizable)” by walter (link to object)

- “Double Helix bridging torture test” by WildRoseBuilds (link to object)

- “Bridge Calibration Test” by 3D-ME (link to object)

After an introduction of these bridging test objects, you will learn how to easily optimize the bridging behavior.

- Calibration Shapes Plugin in Cura

- “Bridging Test (Customizable)” by walter (link to object)

- “Double Helix bridging torture test” by WildRoseBuilds (link to object)

- “Bridge Calibration Test” by 3D-ME (link to object)

Table of Contents:

- 1 Temperature Tower Before Bridging Test

- 1.

1 Temperature tower from the Cura Calibration Shapes

1 Temperature tower from the Cura Calibration Shapes - 1.2 Heat Tower from Akiland

- 1.

- 2 The Best Bridging Test Objects

- 2.1 Bridging Test from the Cura Calibration Shapes

- 2.2 Bridging Test by walter on Thingiverse

- 2.3 Double Helix Bridging Torture Test by WildRoseBuilds on Thingiverse

- 2.4 Bridge Calibration Test from 3D-ME on Thingiverse

- 3 Bridging Optimization in 3D Printing

- 3.1 Increase the Cooling

- 3.2 Decrease the Print Speed

- 3.3 Decrease the Printing Temperature

- 3.4 Avoid Bridging Through Other Orientation

- 3.5 Supports for Bridges

Temperature Tower Before Bridging Test

Before you optimize the bridging behavior and perform a bridging test, you should first find out the perfect temperature for your filament. Only then can you print error-free bridges.

Just as for the bridging test, there are pre-built models for temperature towers in Cura in the Calibration Shapes plugin. In addition, there are various temperature towers on Thingiverse as a free download.

In addition, there are various temperature towers on Thingiverse as a free download.

Temperature tower from the Cura Calibration Shapes

Via the Marketplace in Cura, you can install the free plugin Calibration Shapes. Besides the standard calibration cube, retraction/stringing test and much more, there are temperature towers.

The temperature towers are available for different filament types, for example PLA or ABS. The different towers all have the same shape and go from 180 to 220 °C for PLA and 210 to 250 °C for ABS.

In principle, the shape of the temperature towers is always the same. One bridge of the same length is printed per temperature level to test the extrusion of the filament at that temperature. If the right temperature is there, you will get perfect bridges.

The handy thing about the Calibration Shapes plugin are the included scripts for the respective test models. To adjust the printing temperature at each new level, it requires a script to change the G-code accordingly. You can find the script menu in Cura at the top of the menu bar: Extensions > Post Processing > Modify G-Code

You can find the script menu in Cura at the top of the menu bar: Extensions > Post Processing > Modify G-Code

Heat Tower from Akiland

If you prefer to use something from the 3D printing community, there are also very good models for temperature towers on Thingiverse, such as the “Heat tower (190-240) 5mm steps” by Akiland (link to object).

As the name suggests, this temperature tower goes from 180 °C to 240 °C in 5 mm steps and is therefore suitable for PLA. Here, too, a bridge is printed at each temperature. In addition, a 45° overhang is printed on the other side.

The Best Bridging Test Objects

A good bridging test object is characterized by the fact that it is either customizable or directly offers different bridge lengths. It should also use as little filament as possible to test bridging behavior.

If you use Cura as a slicer, you have the choice to use an object from the Calibration Shapes plugin. But there are also excellent tests on Thingiverse that all work without a script or other G-code changes.

Bridging Test from the Cura Calibration Shapes

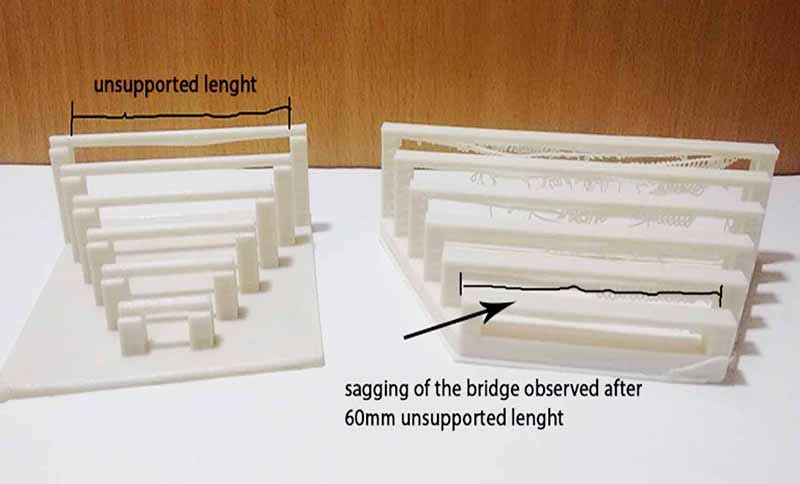

The bridging test from the Calibration Shapes plugin in Cura offers ten different bridge lengths from 10 to 50 mm. If you want to print even longer bridges, you could simply scale the model larger (but then remember that the labeling will no longer be correct).

The bridging test is constructed in such a way that the individual bridges are not in the same layer on the Z-axis, but are always offset a little further up. This means that they are printed one after the other and an ever-increasing spiral staircase is created on which the bridging behavior is tested.

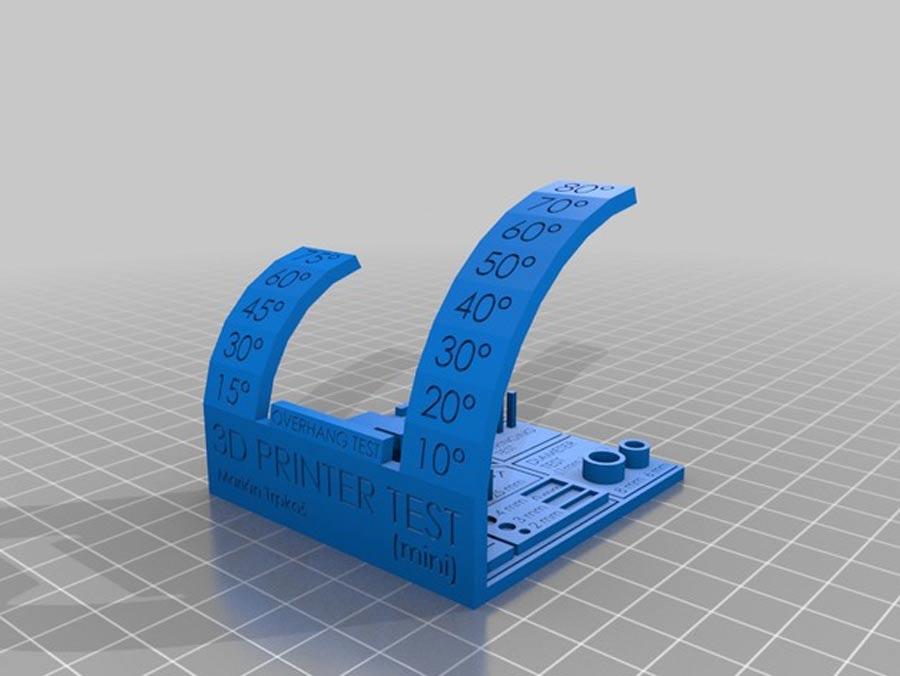

In the plugin, there is also an overhang test object with which you can test overhang angles from 40° to 80°. If your bridging test was ok, this test object will surely work as well.

Bridging Test by walter on Thingiverse

The very popular “Bridging Test (Customizable)” by walter is available on Thingiverse (link to the object).

Using the built-in customizer in Thingiverse, you can still customize the object to your liking. You can set the minimum and maximum bridge length, the number of bridges, the width of the bridges and their Z-distance. You can then download your customized object at the click of a button.

You can set the minimum and maximum bridge length, the number of bridges, the width of the bridges and their Z-distance. You can then download your customized object at the click of a button.

Except for the missing labels on each bridge, this bridging test is very similar to the test from the Calibration Shapes plugin in Cura but is also perfect for testing bridging behavior.

Double Helix Bridging Torture Test by WildRoseBuilds on Thingiverse

The “Double Helix bridging torture test” from WildRoseBuilds on Thingiverse gives you the possibility to print a pretty bridging test (link to the object). I like the idea – I don’t know about you, but my shelf is overflowing with useless calibration objects…

The disadvantage of this object is that the bridge length is always the same. To get different bridge lengths, you would have to print the object with different scales more often. And then we are back to the topic of waste.

Therefore, this object is more suitable for a quick test in between with which you want to check a previously calibrated 3D printer again (e. g. if you use a new filament).

g. if you use a new filament).

Bridge Calibration Test from 3D-ME on Thingiverse

During the development of the “Bridge Calibration Test” by 3D-ME on Thingiverse, efficiency was the main focus (link to the object). This test uses as little filament as possible to test the bridging behavior.

You test the different bridge lengths by printing single bridges with different lengths. To make the test more difficult for the printer, there is a small weight of printed filament on top of the bridge.

Bridging Optimization in 3D Printing

Poor bridging behavior is a common problem in 3D printing. Now that you know how to best test it, it’s time to learn how to optimize it.

There are a total of 3 important settings with which you can improve the bridging behavior:

- Increase the cooling (or fan speed)

- Reduce the printing speed

- Reduce the printing temperature

There are also two emergency solutions: Avoid bridging completely by changing the orientation of the object or print supports for the bridges.

Increase the Cooling

The most important setting to be able to print better bridges is cooling. If the filament is too liquid, it will flow down due to gravity. If the temperature is too high or the cooling too low, the filament remains too liquid and the bridge bends down.

If you increase the cooling rate, the filament will solidify faster and stay exactly where the print head extruded it. In most slicers, you change the cooling rate with the fan speed.

If your fan speed or cooling rate was already set to 100% by default, the following settings will help you.

Decrease the Print Speed

During bridging, the liquid filament is held on one side by the already printed bridge and on the other side by the nozzle. If the speed is too high, the length of the area where the filament is still liquid is too long, resulting in sagging bridges.

In order for the filament to harden quickly enough, a low print speed is important in addition to good cooling. In some slicers, you can set the print speed for bridges individually. Either way, you should try to reduce the speed in steps of 5 to 10 mm/s and check the result afterward.

In some slicers, you can set the print speed for bridges individually. Either way, you should try to reduce the speed in steps of 5 to 10 mm/s and check the result afterward.

Decrease the Printing Temperature

You should have already covered this point with the temperature tower. With the correct printing temperature, you prevent the sagging of bridges.

If the temperature is too high, the filament is still too soft and will sag. However, the printing temperature must not be too low to avoid other printing errors or poor print bed adhesion.

Avoid Bridging Through Other Orientation

With some objects, it often makes more sense to simply turn it 90° in another direction to avoid bridges completely. Although this is only an emergency solution and does not solve the basic problem, it is a quick and frustration-free solution for some models.

Supports for Bridges

Another emergency solution is to insert supports for the overhangs or for the bridges. Inserting supports sometimes feels like giving up, but especially with long bridges, it is often the only way to print them without errors.

Inserting supports sometimes feels like giving up, but especially with long bridges, it is often the only way to print them without errors.

Most of the time, the bridge is also oriented in such a way that the supports do not leave any visible remains after you have removed them from the object.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

7 Tricks You Should Know

If you’ve ever been frustrated with filthy 3D Printing Bridges, stay reading for some simple suggestions on keeping your 3D printing bridging clean!

What is 3D Printing Bridging?

Bridging issues are very prevalent, and thankfully, they’re pretty simple to solve. In 3D printing, bridging is an extrusion of material that connects two raised points horizontally. However, if you’re reading this, your prints’ bridges are probably not too horizontal. Don’t be too hard on yourself.

In 3D printing, bridging is an extrusion of material that connects two raised points horizontally. However, if you’re reading this, your prints’ bridges are probably not too horizontal. Don’t be too hard on yourself.

So, let’s take a look at some quick pointers for getting the best bridging 3D printing results!

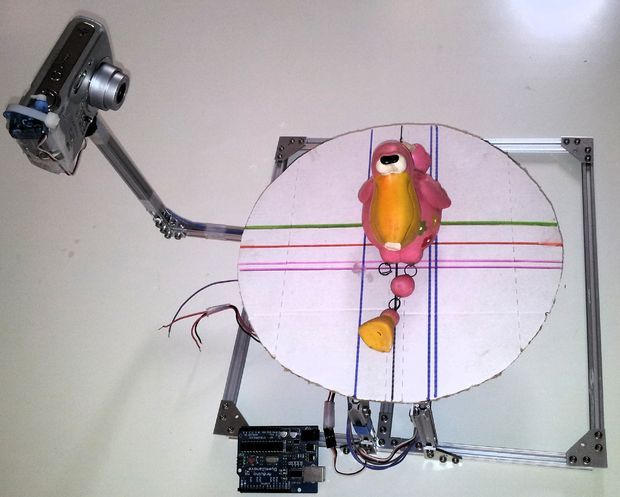

Examine Your Printer

Before fiddling with the settings, check to see how well your printer can (or can’t) bridge. This bridging test can be printed. You’ll see which bridge lengths are difficult for your printer in just one print. Bridges with a span of 50 to 100 mm are decent, whereas bridges with 150 mm or more are exceptional. Don’t be concerned if this test fails; the goal is to determine the scope of the problem.

Increase cooling

Increase your print cooling first to improve your printer’s bridging capabilities (print fan speed). When manufacturing bridges with a low print cooling setting, the filament will simply sink into a molten mass. As a result, start at 100 percent fan speed and monitor for bridge improvements.

As a result, start at 100 percent fan speed and monitor for bridge improvements.

Your fan setting is too high if you’re experiencing blockage or poor layer adhesion. Reduce it by 5% at a time, and then the following simple remedy.

Reduce the Flow Rate

The material must set rapidly to cleanly bridge a gap. If there’s too much-molten filament coming out of the nozzle, it won’t have time to solidify. This will likely result in your print looking like the London Bridge is collapsing.

Your printer will be able to extrude a constant flow of filament that can cool into a lovely bridge by lowering the Flow Rate (or Extrusion Multiplier) in your slicer.

Reduce the temperature

The following suggestion is relatively similar to the one before it. The printing material will not have enough time to cool and set if the nozzle temperature is too high and too much filament is allowed to flow. This will likely cause the filament to stick to your nozzle or build a messy bridge.

A temperature tower is an excellent tool to see how your printer reacts to various temperatures. You’ll need to tweak the G-code such that the temperature changes with each level to print one. Select Extensions > Post-processing > Modify G-code and add the “Vary Temp With Height” plug-in to get to this option in Cura.

You can set the height increment (how often you want to modify the temperature) and the temperature increment from here (for how much you want to change it). In the Thing details, the designer of the temperature tower model provides the necessary code for Slic3r and Cura.

Reduce the print speed

High print speeds might also impact the quality of the bridge. The filament will not have enough time to attach to the preceding layer or set in time to bridge a gap if your nozzle moves too quickly. In other words, high print speeds can lead to massive messes.

Reduce your print speed in 10-mm/s increments until you notice a difference. But don’t go too slowly. If your nozzle goes too slowly, the filament will droop after being suspended in the air for too long. So, experiment with different speeds until you discover the one that suits you best.

If your nozzle goes too slowly, the filament will droop after being suspended in the air for too long. So, experiment with different speeds until you discover the one that suits you best.

Change the model’s orientation

If you’re sick of fiddling with settings to acquire longer bridges or simply don’t have the time, try orienting your model to completely (or mostly) eliminate bridges. Remember the 45° rule: If an overhang exceeds 45 degrees, you’ll need to consider supports.

Check out our post on how to master printing overhangs more significant than 45 degrees if you’re feeling very bold.

Supports should be added

Why not use them while we’re on the subject of support? Bridge supports will alleviate your concerns about sloppy bridges. They can be a headache to remove, but we have a guide to help you succeed with support.

Remember that after printing, you’ll need to remove the supports! Sanding and other types of post-processing are your allies! Some models make removing the print nearly impossible, or it’s challenging to do it without ruining the print’s surface.

Adjust your Slicer’s 3D Printing Bridging Setting

Change your Slicer’s setting according to your needs. On PrusaSlicer gives better results with long 3D printing bridging. However, on Cura, you need to enable the 3D Printing bridging setting under Experimental Tab or search for 3D printing bridging.

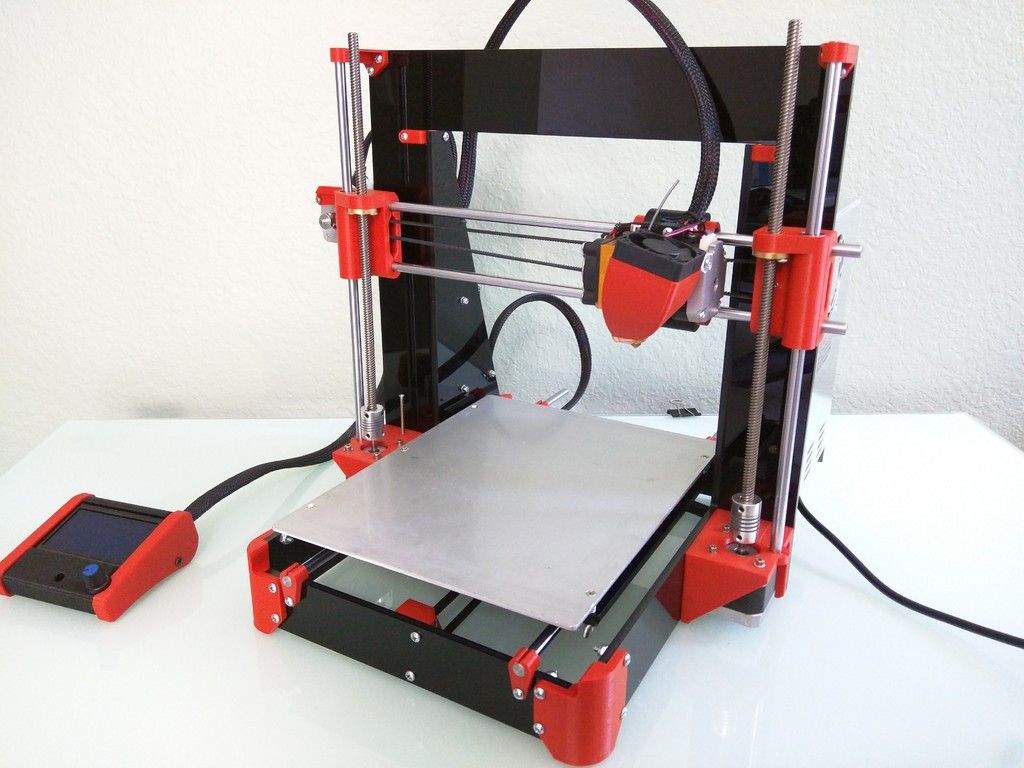

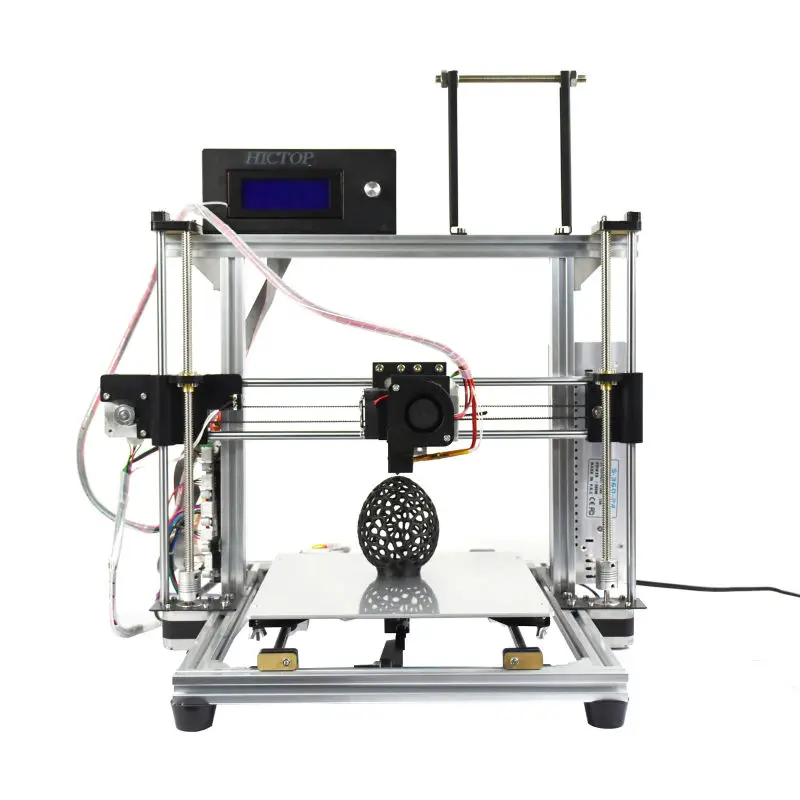

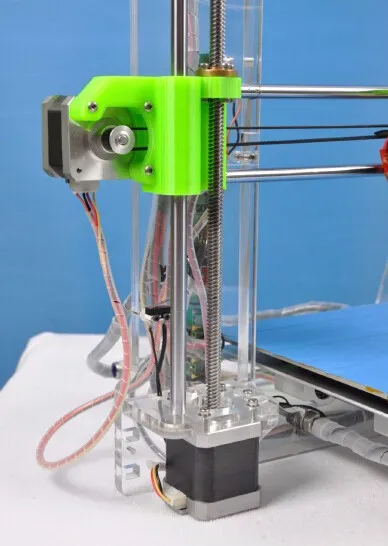

10 models for 3D printer calibration. Set up your printer

Before you start printing on a 3D printer, you need to test it. For this, special models are most often used to diagnose and calibrate the device. Next, we will list the top 10 models for calibration, in our opinion.

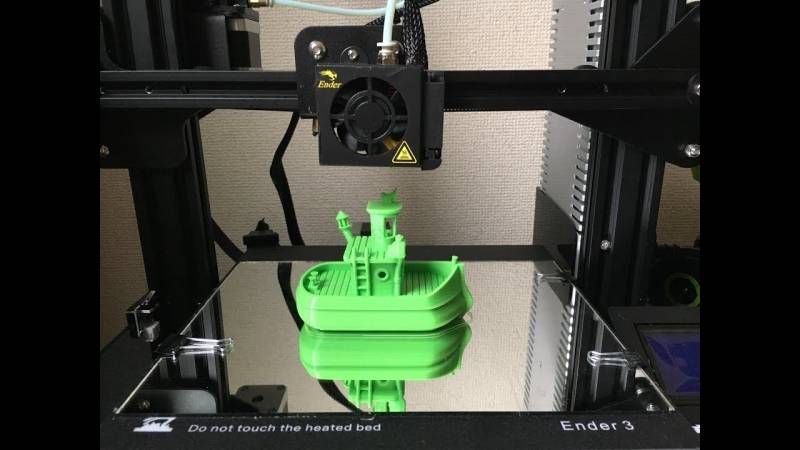

3D Benchy

Among all 3D printing tests, the flagship is 3D Benchy. This model is a boat that can test everything from protrusions to extrusion. If you want to test your 3D printer, then the benches will help you determine the optimal settings for the ideal result. On Thingiverse, more than three thousand users posted photos with their samples, and the boat itself was printed by more than a hundred machines and no fewer materials.

Model reference

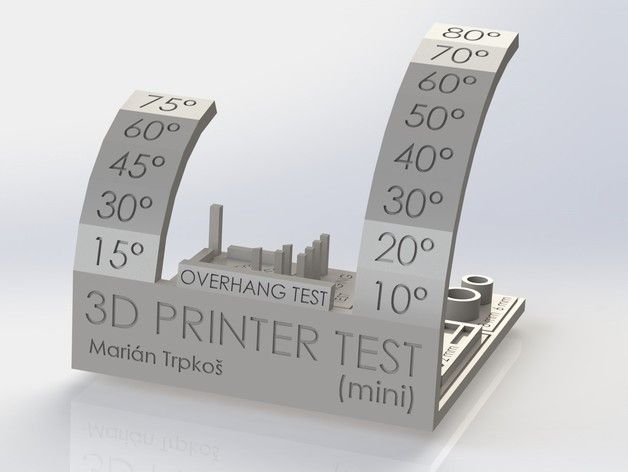

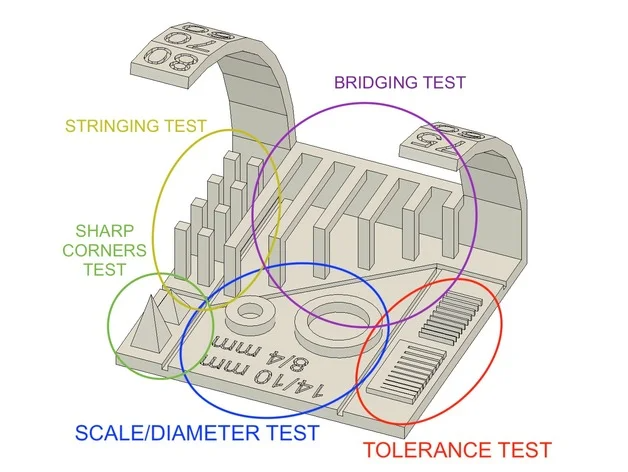

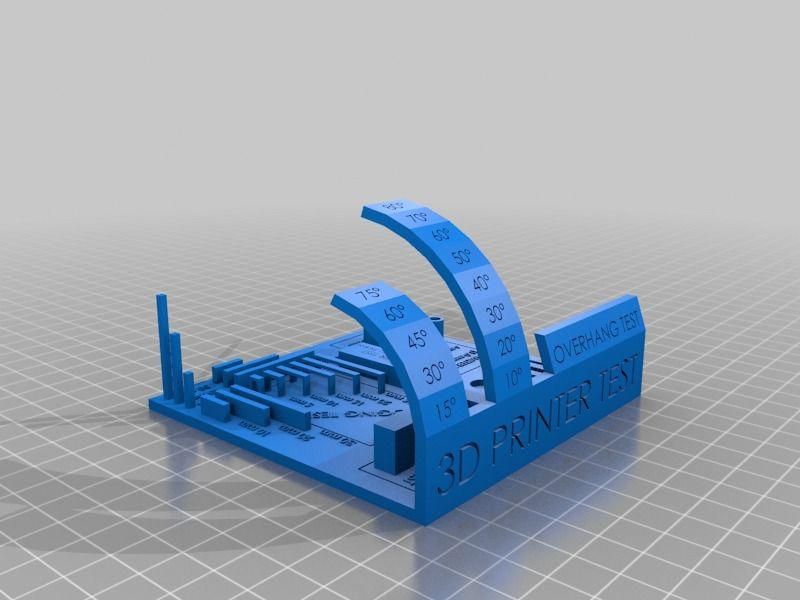

All-In-One

A very interesting model, which is called “all-in-one”. Everything is presented in the model: canopy, bridge, string, temperature and belt tension test, extrusion. This is an ideal model for testing the device at several levels at once. A manual is included with the model to help you troubleshoot any issues you find. On Thingiverse, more than 75 users have posted test results on different 3D printers and different materials.

Model Reference

XYZ Calibration Cube

Very simple and fast model for testing. This is a cube with a side of 20mm. It helps to gain dimension by adjusting the steps in millimeters. Also, the model allows you to test extrusion, vibration, temperature. This cube was printed simply by countless 3D printers and a variety of materials.

Model Link

Cali Cat

Nice little calibration cat or just Cali Cat is a simple model that allows you to test the accuracy of the device, as well as detailing, lugs, bridges, vibration and extrusion. And all this in just one hour. More than 2.5 hundred users have submitted their test results on the service.

And all this in just one hour. More than 2.5 hundred users have submitted their test results on the service.

Model Reference

Phil A. Ment

The MatterHackers Mascot is a Phil A. Ment test model. It was originally intended for manufacturers. The description mentions the fact that Phil has several functions. And they were originally designed specifically for 3D printers. The model has small inserts, relief details, cylinders of vertical and horizontal orientation, ledges. In addition, the model contains chamfers, bridges and fillets. And this miracle is performed by a domed helmet. The record size on the service is 5,1397mm. A total of 84 models were published.

Model Link

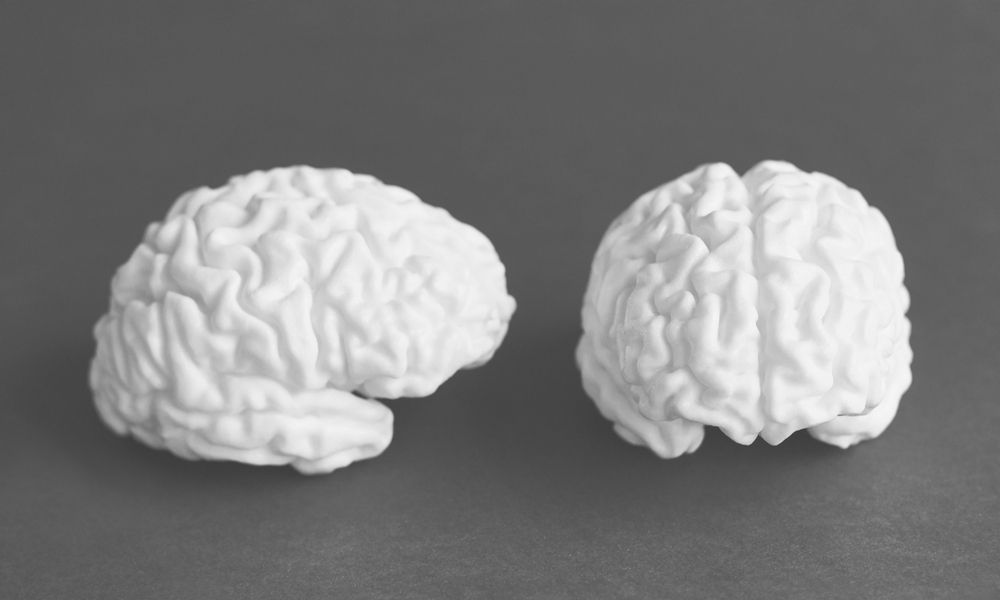

Calibration Temperature Tower

You can use this model to adjust the heat of your 3D printer. You can also test for different materials at what temperature the print comes out better.

NEW model Autodesk

This is a new model, or rather not even a model, but a whole procedure that will allow 3D printer manufacturers to show all the capabilities of devices to Kickstarter supporters. And of course, calibrate. The test was developed by Andreas Bastian and is a consolidated STL file that is able to test the system for the following indicators:

And of course, calibrate. The test was developed by Andreas Bastian and is a consolidated STL file that is able to test the system for the following indicators:

- authorization;

- alignment;

- accuracy;

- bridge, etc.

The model has it all. For example, if the 3D printer is set up well, then the horizontal function will be performed with a minimum of problems.

Model Link

PolyPearl Tower

If you want to test curves, cuts, bridges, cuts, then this model can be a great solution. In the description for this test model, the name "torture tower with a twist" appears. It is worth trying to use it for calibration.

Model Link

Rapid Screening

This model is a very quick test to check temperature, cooling, and retract function. Among the advantages of the model is its cost-effectiveness. The model will weigh only 0.23g. With its help, you can immediately remove the "strings".

Model Reference

Parametric Calibration Object

A particular difficulty in calibrating a 3D printer is lowering the stage level. With this model, you can draw the right conclusions to improve the first layer of printing, and as a result, get better prints.

Model Reference

Top 10 Models for 3D Test Printing

3DPrintStory 3D printing process 10 best models for test 3D printing

3D Benchy

What is this 3D model? 3D Benchy is the flagship of all 3D printer tests. This model tests everything from overhangs to extrusion quality. If you want to test your 3D printer, then Benchy will help you clarify the settings that need to be fine-tuned for high-quality 3D printing in the future.

Who created? CreativeTools

Who typed? Nearly 3,000 Thingiverse users have posted print information for this model. Benchy has been printed using hundreds of 3D printer models and materials.

Where to find? Thingiverse

All-In-One 3D Printer Test

What is this 3D model? All-In-One 3D Printer Test - this is exactly what is reflected in the name of this 3D model! Overhangs, bridges, filamentous plastic residue, extrusion, temperature, belt tension - this model tests it all. If you want to test your 3D printer, be sure to check out this 3D model! After 3D printing, you will find the necessary troubleshooting tips by reading the manual that came with the model.

Who created? majda107

Who printed? About 75 Thingiverse users have posted their finished 3D prints of this model. On different printers and from different materials.

Where to find? Thingiverse

XYZ 20-mm Calibration Cube

What is this 3D model? This XYZ 20-mm Calibration Cube is a simple, fast and lightweight model to test your 3D printer. Its main purpose is to help you fine-tune the accuracy of your 3D printer by adjusting the steps per mm. But you can also check temperature, extrusion and vibration.

Its main purpose is to help you fine-tune the accuracy of your 3D printer by adjusting the steps per mm. But you can also check temperature, extrusion and vibration.

Who created? iDig 3D-printing

Who printed? This model is presented on Thingiverse in 700 variants from users. It was printed on a huge number of different 3D printers using different materials.

Where to find? Thingiverse

Cali Cat – The Calibration Cat

What is this 3D model? The Cali Cat is a simple and adorable model that tests your 3D printer's accuracy, overhang, detail, overlap, extrusion and vibration in less than an hour! Designed for initial calibration, this cat will help you calibrate your printer in no time.

Who created? Design

Who printed? More than 250 Thingiverse users have posted information about printing this 3D model. It is printed on different models from different materials.

Where to find? Thingiverse

MatterHackers' Mascot Phil A. Ment

What is this 3D model? Phil A. Ment is an adorable mascot from MatterHackers designed to help manufacturers calibrate their 3D printers as described by the developers themselves: “Phil has several features specifically designed to test your 3D printer. These features include small inlays, fine embossed details, overhangs, vertical and horizontal cylinders, fillets, chamfers, lintels, and even his perfectly domed helmet.”

Who created? MatterHackers

Who typed? Thingiverse hosts 84 user-generated print options. Phil A. Ment has been 3D printed using various materials. Its minimum and maximum dimensions are respectively: 5 and 1397 mm in height!

Where to find? Thingiverse

Smart Compact Temperature Calibration Tower

What is this 3D model? As the name suggests, this model is an intelligent compact temperature calibration tower. The test model tests overhangs, lintels, plastic residue, and even your 3D printer's ability to print curved shapes. This tower is a great way to quickly calibrate your 3D printer's temperature.

The test model tests overhangs, lintels, plastic residue, and even your 3D printer's ability to print curved shapes. This tower is a great way to quickly calibrate your 3D printer's temperature.

Who created? gaaZolee

Who printed? 33 Thingiverse users posted their finished 3D prints of this model, which they used to calibrate their printers. Various materials have been used.

Where to find? Thingiverse

Open-Source Printer Evaluation

What is this 3D model? This is an open source 3D model from Kickstarter and Autodesk, designed to provide manufacturers with a standard benchmark for evaluating the performance and quality of a 3D printer. Many manufacturers like to showcase their printer models by printing a 3D model on them. But when one person is printing a 3D Benchy and another is printing a vase, it's hard to know how to compare the two 3D printers. This STL file contains various features such as bridges, overhangs and fine detailing. All these elements help to check the accuracy and resolution of 3D printing.

All these elements help to check the accuracy and resolution of 3D printing.

Who created? Kickstart in partnership with Autodesk

Where to find? Github

PolyPearl Tower

What is this 3D model? The PolyPearl Tower is a great way to test bridges, bends, lugs, tension and more. This is a 3D model, which is presented in the description as a torture tower with a twist. It will definitely help you to calibrate your 3D printer settings in conjunction with the material you are using for 3D printing.

Who created? Polymaker_3D

Where to find? Thingiverse

Ultrafast and Economical Stringing Test

What is this 3D model? This model is a super-fast way to check the temperature, cooling and retraction of your 3D printer. This model weighs about 0.23g and will reveal excess material between the voids in your model in no time!

Who created? s3sebastian

Where can I find it? Thingiverse

Bed Leveling Calibration Test Object (Parametric)

What is this 3D model? Leveling the table is often the most difficult part of calibrating a 3D printer.