Reprap 3d printer review

RepRap 3D Printer Review 2022

4.8

See Price

In many ways, the RepRap project was the catalyst for bringing 3D printing to the masses, extracting a traditionally expensive technique from the bowels of design studios with deep pockets to hobbyist workshops.

The ramifications brought on by the RepRap are still felt to this day. The simple tenets of self-replication and low prices through the competitive refinement of the basic RepRap design mean 3D printing has never been so affordable and accessible.

With so many RepRap inspired models on the market to choose from, we’ve focused on what is widely considered the most popular and revered RepRap printer, the Original Prusa i3 MK3S. Not only does this model equate to years of fine-tuning, but upholds the ethos of the original 2005 RepRap with self-assembly and low running cost.

Nearly fifteen years on from the original, let’s dive in and explore what the modern iteration of the RepRap has to offer.

| Printing Area | 250 mm x 210 mm x 210 mm |

| Layer Resolution | 50 – 350 microns |

| Supported Filament | ABS, PLA, PET, HIPS, FLEX, ASA, Bronzefill, Polypropylene, Carbon-enhanced, Laywood, Laybrick, Nylon, T-Glase, Bamboofill, etc. |

| Filament Diameter | 1.75 mm |

| Extruders | 1 |

| Extruder Diameter | 0.4 mm |

Table of ContentsShow

Design & Features

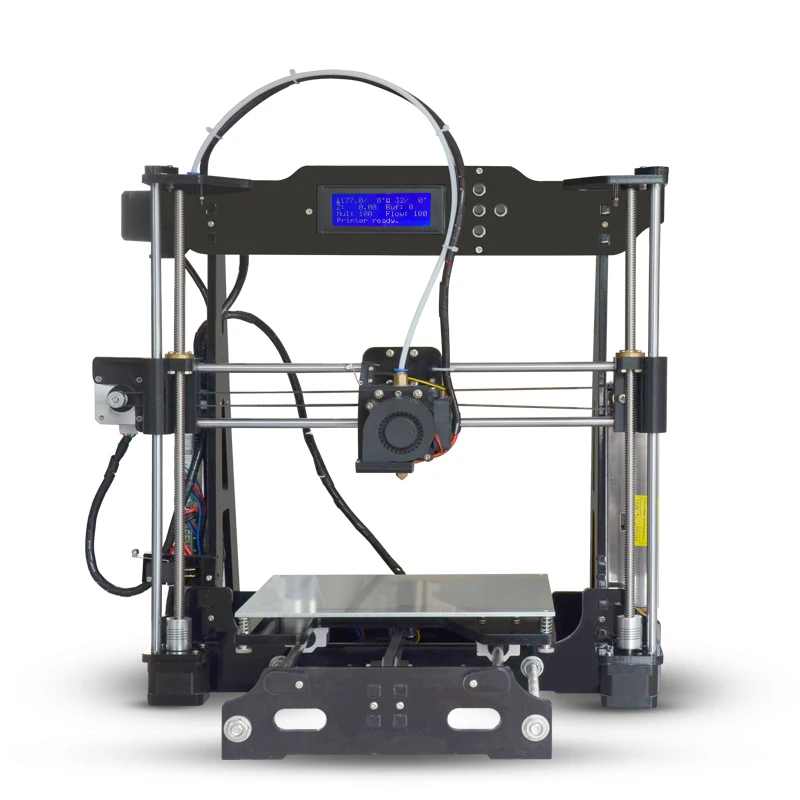

Visually, it is a refined take on the DIY aesthetic bolstered by a rather alluring black and bright orange color scheme. The Original Prusa i3 MK3S looks like a hobbyist kit form 3D printer but without the rough edges or its innards unceremoniously exposed in a chaotic mess. The Dural milled frame, aluminum extrusions, and overall attention to design makes this one of the more attractive assembly kits out there, not to speak of its rigidity.

Side by side, you’d be hard pressed to find any surface similarities between the original RepRap and the i3 MK3S, but rest assured that many of these remain. Chiefly, retaining the core Cartesian configuration using Fused Deposition Modelling.

The build area measures 250 mm x 210 mm x 210 mm, which isn’t far off the dimensions of the original RepRap. Layer resolution ranges from 50 to 350 microns alongside a max print speed of 200 mm per second.

Layer resolution ranges from 50 to 350 microns alongside a max print speed of 200 mm per second.

A single direct drive extruder with a Bondtech drive gear designed to grip onto filament on two sides (and an optical filament sensor) powers the printing process with a 0.4 mm E3D V6 nozzle that can easily be swapped for a bigger diameter if required. The alloy spring steel sheet bed with a PEI surface (meaning no glue, tape, etc.) is heated and removable, held in place by magnetic holds and fitted low corner temperature compensation tech to avoid undue warping.

As for filament support, the i3 MK3S is one versatile printer: ABS, PLA, PET, HIPS, FLEX, ASA, Bronzefill, Polypropylene, Carbon-enhanced, Laywood, Laybrick, Nylon, T-Glase, Bamboofill, and more, all in standard 1.75 mm diameter.

Onboard controls come in the form of an integrated LCD with SD card reader with the option of Wi-Fi connectivity through an Octoprint interface. Software-wise, the i3 is designed to work with Prusa’s own Slic3r Prusa Edition or Prusa Control. The first being for advanced users who want tinkering options, while the second is for casual makers who favor ease of use.

The first being for advanced users who want tinkering options, while the second is for casual makers who favor ease of use.

The i3 also includes a whole host of small, but acutely smart features such as a power loss recovery mode that allows prints to resume even if the power cuts out, automatic mesh bed leveling, and 9 point calibration with skew axes compensation.

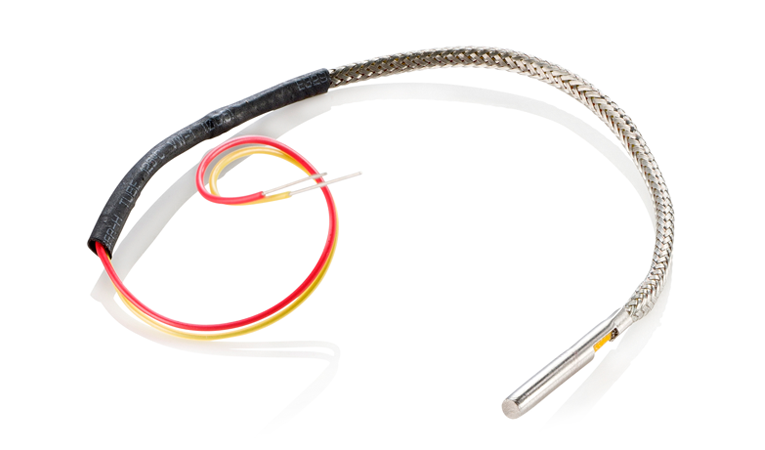

But, that’s not all; EINSY RAMBo motherboard that detects and recovers from skipped steps and layer shifts, sensorless X-Y axes homing, an array of temperature sensors and thermistors, and a fan RPM detector that shuts off the printer if it goes below a certain threshold to avoid damaging the extruder.

Assembly & Packaging

The Original Prusa i3 MK3S ships as a kit and as such requires full assembly. Don’t let this worry you though as we found the instruction manual (which ships as a hard copy with the printer) to be hands down the best we’ve come across with detailed color infographics, non-patronizing instructions injected with a welcome dose of humor.

The packaging is unsurprisingly excellent with a well ordered Tetris like arrangement of boxes and components. The protective material is ample and of high quality. We also particularly like that each of the boxes/bags/components is clearly labeled and linked to the instruction manual so finding what part to use next is wonderfully simple. Rest assured, the package includes Prusa’s now signature packet of Haribo candy.

It is also worth mentioning that the software setup was a doddle. We used Prusa’s Slic3r software, and it was up and running in no time. Interestingly, Prusa also provides settings for a bunch of third-party slicers like Cura and Simplify3D. The manufacturer could have only supplied settings for its software but decided to extend a helping hand to users even if they opt for other software. A nice touch in our book and illustrative of the whole ethos behind Prusa as a company.

Printing

What can we say? The printing process is not only hassle-free and enjoyable; the prints come out amazing. We pushed the i3 during our time with it and never did it fail to print superbly from small detail oriented pieces to larger more ambitious ornamental models.

We pushed the i3 during our time with it and never did it fail to print superbly from small detail oriented pieces to larger more ambitious ornamental models.

Another aspect of the printing process that stood out was how quiet the Prusa i3 MK3S is thanks in part to Trinamic2130 drivers and the ultra silent Noctua fan on the extruder. To nail it home, Prusa has also included a Stealth mode that makes the device even quieter.

Support

Prusa support needs no introduction, and the i3 MK3S continues in that illustrious tradition with 24/7 support through either email or live-chat in a selection of various languages as well as a thorough user guide and even how-to videos made by Jo Prusa himself.

Alongside, Prusa has a knowledge base and forum teeming with versed users eager to help everyone and anyone with any problems they may encounter. Furthermore, the universal praise for the i3 means the internet is peppered with user groups, YouTube channels, and forums designed for owners to congregate and aid each other.

The printer itself ships with a 2-year warranty for the kit version for consumers based in the EU, while the fully-assembled model and for those located anywhere else in the world, the warranty is a 1-year deal.

For those that want to forgo the assembly experience and get printing straight out of the box, Prusa conveniently sells a fully assembled and tested i3 MK3. You do pay upwards of a third more for the pleasure though.

Verdict

Statistics don’t lie: the Prusa i3 is the most used printer across the globe and with solid reason. We inescapably fell under its charm from the moment the package arrived, and our appreciation for this marvelous printer just grew the more we experimented.

As is the case with all open-source designs, there are numerous RepRap vendors, and the quality of their products wavers considerably from one to the next. With the Original Prusa i3 MK3S, you are guaranteed a quality product that props itself up upon the pillars of the original RepRap while improving upon it with a selection of modern features. In other words, the i3 MK3S is a safe bet and one that gets our backing.

In other words, the i3 MK3S is a safe bet and one that gets our backing.

Furthermore, the printer is future proof and fully upgradable to the next MK iteration when Prusa launches it thanks to handy upgrade kits.

The 6 Best RepRap 3D Printers in 2022

Back in the early 2000s, 3D printers were elephant-sized behemoths that cost tens of thousands of dollars. Now, FDM 3D printer giants like Ultimaker and Makerbot, and low cost 3D printer manufacturers like Creality and Prusa exist — because of one sector-defining innovation. That was the RepRap 3D printer movement.

What is a RepRap 3D Printer? And What Does RepRap Mean?

RepRap is short for “replicating rapid prototyper” — aka a self-replicating 3D printer.

A RepRap 3D printer is one designed in line with the RepRap ethos: 3D printers that can self-replicate and print parts to make more RepRap 3D printers. These new RepRap printers can then print more RepRap printers, and so on.

The RepRap movement has done more to democratize 3D printing than anything else. RepRap 3D printers preempted the first DIY 3D printer kits, with these open source 3D printers encouraging tinkering and innovation, advancing the technology.

RepRap 3D printers preempted the first DIY 3D printer kits, with these open source 3D printers encouraging tinkering and innovation, advancing the technology.

| Name | Max Build Volume (mm) | Price | Where to buy for the best price? | Alternative Purchase Option |

|---|---|---|---|---|

| Prusa i3 MK3S | 250 x 210 x 200 | $749 / $999 | Kit available on Prusa store here | Fully assembled on Prusa store here |

| Creality Ender 3 Pro | 220 x 220 x 250 | $190 | Creality Store here | Amazon here |

| Prusa Mini | 180 x 180 x 180 | $399 | Prusa Store here | |

| Anet A8 | 220 x 220 x 240 | $159 | Amazon here | |

| Creality CR-10 / V3 | 300 x 300 x 400 | $369-499 | Amazon here | 3DJake UK & Europe |

| FLSUN QQ-S Pro | 255 x 255 x 360 | $369 | Amazon here |

Source: reprap.org

Source: reprap.org3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

History of the RepRap movement and RepRap 3D Printing

The RepRap movement was founded by Dr Adrian Bowyer, then a Senior Lecturer at the University of Bath, during 2004 and 2005. He was awarded an MBE by Queen Elizabeth II in 2019 for his services to 3D printing.

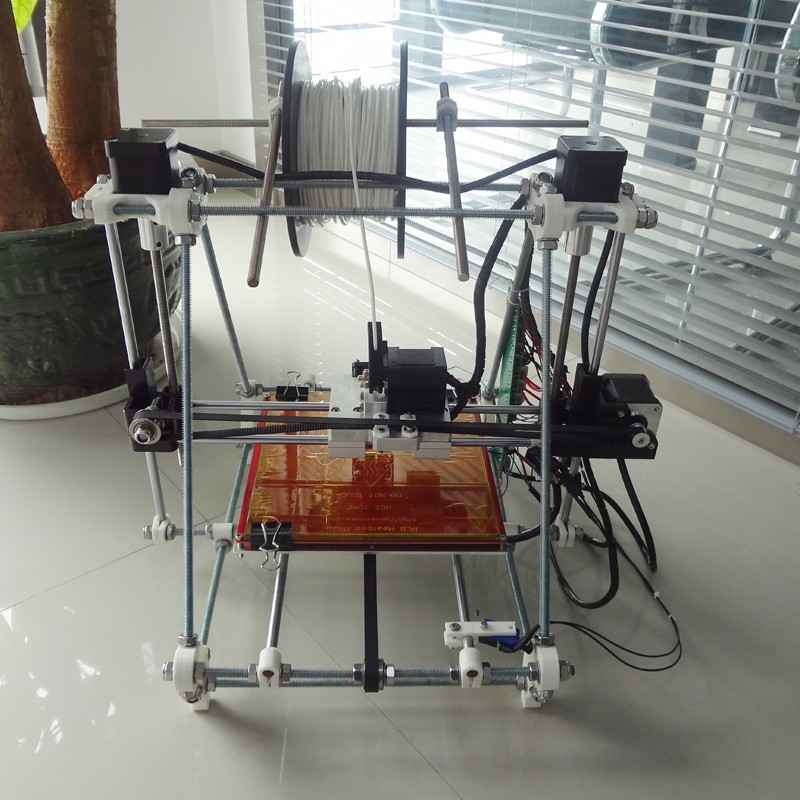

The first RepRap 3D printer invented by Dr Bowyer was the RepRap Dawin, named after Charles Darwin who first theorized evolution. You could build one for a few hundred dollars if you got the plastic parts printed and then bought the electronics.

These were the first ever low cost 3D printers; DIY 3D printers you could build yourself. What was previously inaccessible became possible for anyone to have at home if you had enough tech know-how.

And if you were given the plastic parts 3D printed by a friend or someone else, you were morally obliged to print more plastic parts for anyone else who wanted a RepRap. That way, the RepRap movement could spread exponentially, with more printers in service to help others make their own 3D printers.

That way, the RepRap movement could spread exponentially, with more printers in service to help others make their own 3D printers.

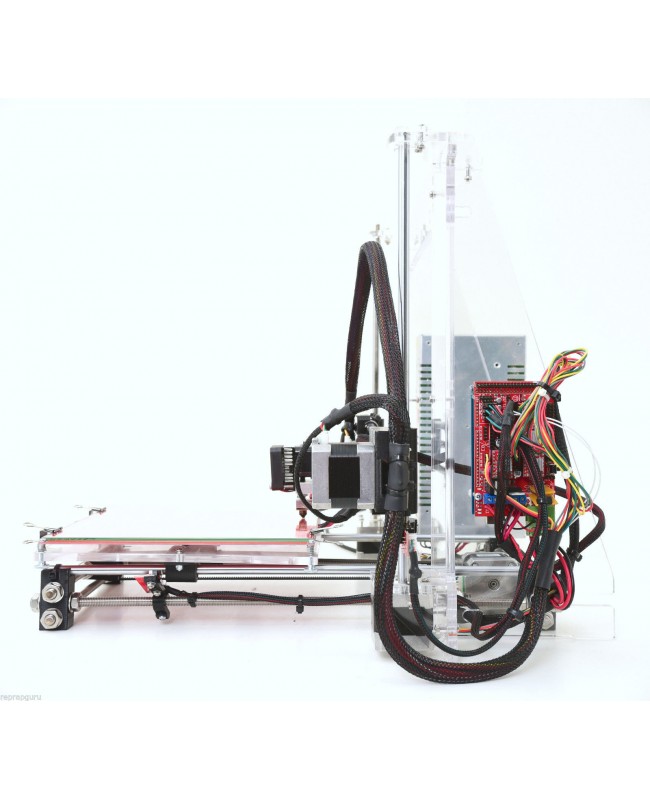

The first RepRap 3D printer — RepRap Darwin

It was basic, it looked like it was from the 80s, but it worked. It worked for $200 while other 3D printers costed $10,000+. This spurred on the open source 3D printing revolution that has led us to the cutting-edge FDM 3D printers we have today.

Named after Charles Darwin, this is the 3D printer that really kickstarted the RepRap movement.The Darwin plays an important part in the history of 3D printing, and allowed people to now 3D print from home provided they had the technological know-how. It wasn’t pretty and it doesn’t hold up against the far superior RepRap 3D printers that are about today, but in 2008 the Darwin was a big deal, and is looked back upon fondly today.Dr Bowyer’s RepRap printer with its “child”, another RepRap 3D printer it printed the plastic parts for.

If you’re interested in finding out more about the history of 3D printing, click here.

Best RepRap 3D Printer: The Criteria

Judging these printers was different to how we usually rank our printers. This is because many printers that were revolutionary in their time have since been outclassed by newer and more powerful machines. We therefore graded these RepRap printers on:

- Price-performance ratio: does it perform well for the price?

- Versatility: can it print many materials?

- Reliability

- Must be a RepRap printer or inspired by the RepRap movement.

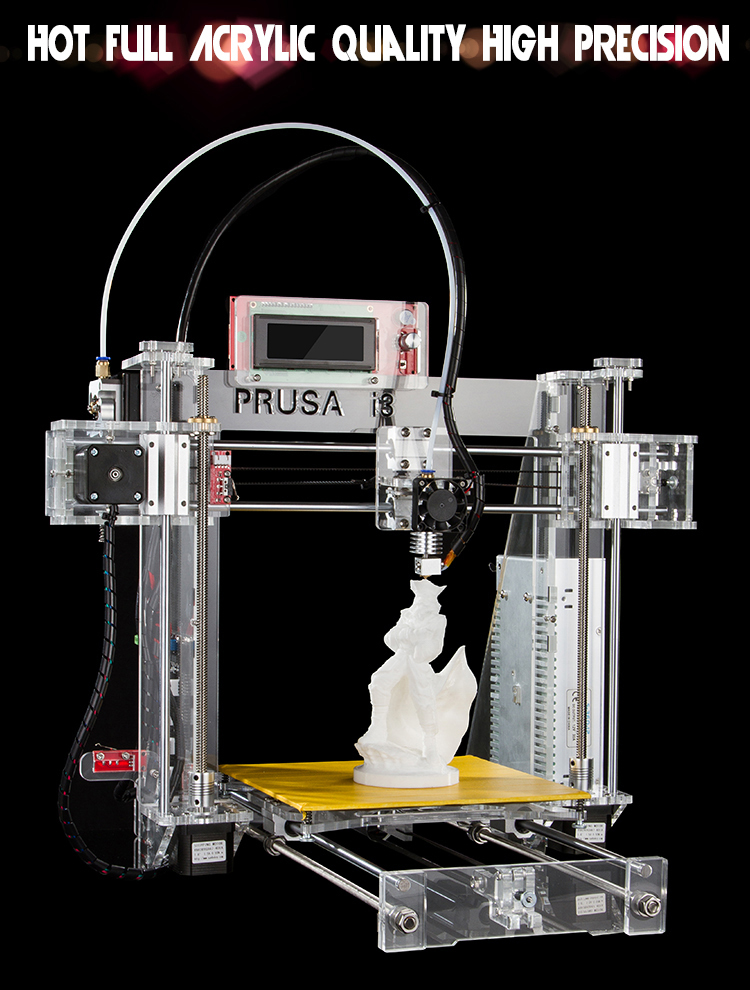

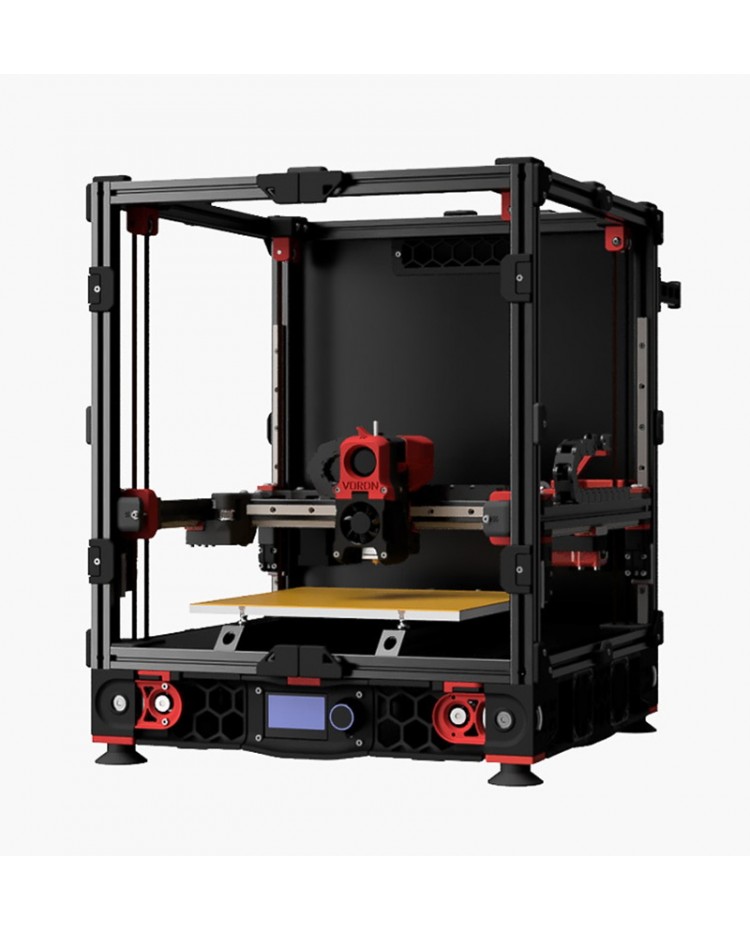

1. Prusa i3 MK3S

- Company based: Czechia

- Price: $749 as a kit — Available on Prusa store here / $999 fully assembled — Available on Prusa store here

- Build volume: 250 x 210 x 200 mm

The myth. The printer. The legend. The Prusa RepRap kit is the unmistakable king of RepRap 3D printers. There’s a reason why Josef Prusa’s invention shot him into the 3D printing stratosphere and landed him a place on Forbes’ 30 under 30 list — the printer is incredible.

Sporting a 250 x 210 x 200 mm print volume as well as up to 50-micron layer resolution, the Prusa i3 is accurate and reliable. It’s designed to be simple to use, and true to the RepRap philosophy can print all its plastic components. As a result of its success, Josef Prusa has had to print over 200 more Prusa 3D printers, so this Prusa farm can print enough Prusa 3D printers to keep up with demand! Prusaception.

If you’re looking for a consistent and high-quality RepRap 3D printer or 3D printer kit, look no further. You can buy your Prusa 3D printer pre-assembled, or build your own to save a few hundred dollars. It prints with layers up to 0.05mm for great precision and surface finish, features a spring metal build plate for changeable PEI sheets, and is also a fast 3D printer, able to travel at over 200mm/s.

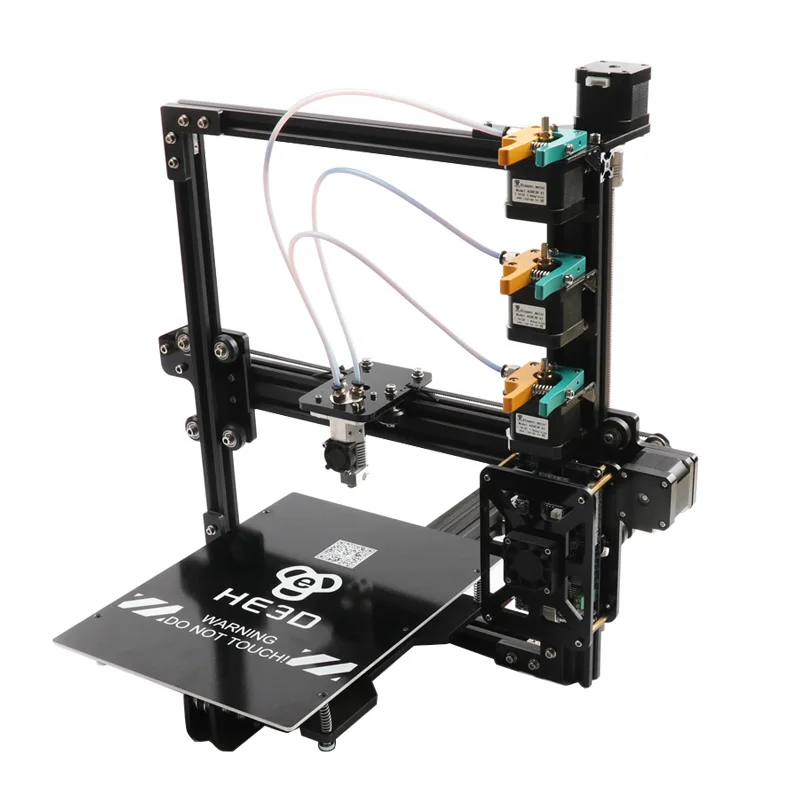

For business who want to print tougher filaments like Polycarbonate or Nylon, the Prusa i3 MK3S can handle that, too. The extruder heats up to 300C, and the high quality E3D V6 nozzle can handle even abrasive filaments. You can even upgrade the Prusa to print 5 different color filaments simultaneously with the $300 Multi Material Upgrade kit.

You can even upgrade the Prusa to print 5 different color filaments simultaneously with the $300 Multi Material Upgrade kit.

- You can purchase Prusa’s Multi Material Upgrade Kit here.

Overall, we cannot recommend it enough, and it will go down in the 3D printer hall of fame in years to come.

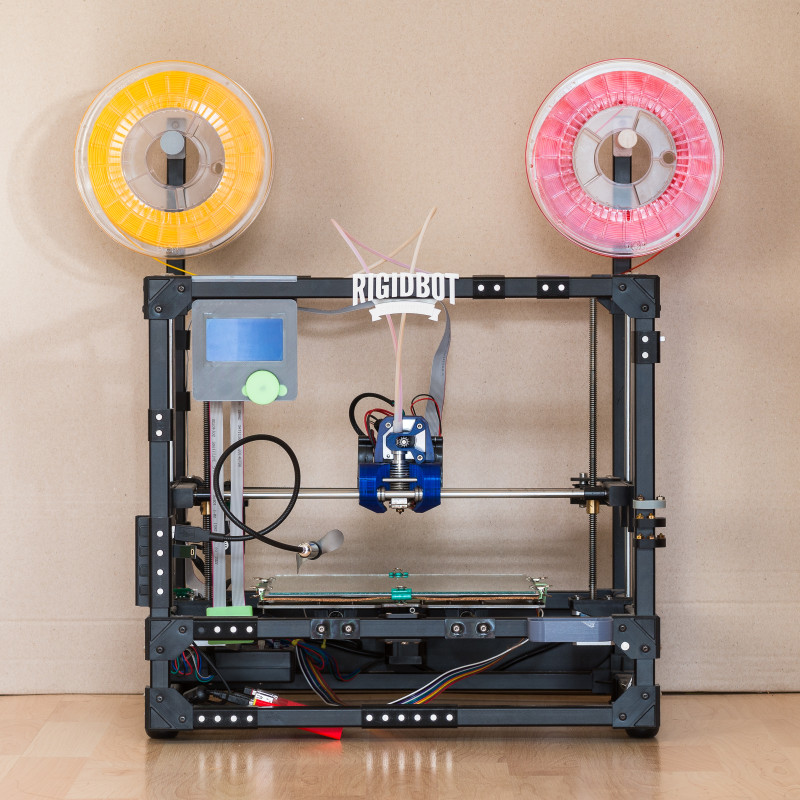

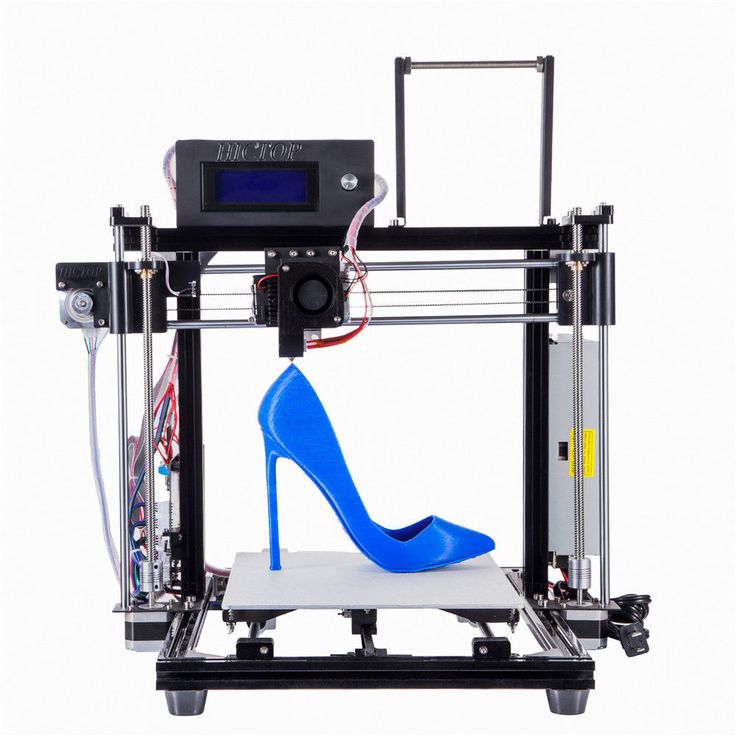

The Prusa i3, encompassing printers such as the MKS3 shown above, is the undisputed king of RepRap 3D printers.2. Creality Ender 3 Pro

- RepRap 3D printer price: $190 — Available on Creality Official Store here / Available on Amazon here / 3DJake UK & Europe here

- Print volume: 220 x 220 x 250 mm

Creality 3D printers are known for their simplicity to assemble, and the Ender 3 Pro is a great example of that. Creality say that you can completely assemble it from package to print-ready in 10 mins using 20 screws, though for new makers this is likely to be quite optimistic.

- View the full specs in our Ender 3 review.

The high quality extruder reduces the chances of the Ender 3 clogging during printing, and Creality have upgraded a number of key areas in the Pro version of the Ender 3. These include an upgraded power supply, improvements to print bed leveling, and a new print bed system to prevent warping and make finished prints easier to remove.

These include an upgraded power supply, improvements to print bed leveling, and a new print bed system to prevent warping and make finished prints easier to remove.

Experienced makers know that the Ender 3 Pro is absolutely up there with the best low cost RepRap kits. It’s very accurate for the price, with precision of up to 100 microns, and it combines this with workhorse-like reliability. You get a good size print volume, fairly fast print speed (up to 180 mm/s), and it’s also fairly quiet. You get very good quality prints and reliability for a 3D printer under $300, and we highly recommend it to anyone willing to invest the time to master it.

3. Prusa Mini

- Company based: Czech Republic

- Price: $399 — Available on Prusa Store here

- Build volume: 180 x 180 x 180 mm

For those who want most of the Prusa MK3S’s main benefits, but in a more compact package and for cheaper, the Prusa Mini could be perfect for you. With a smaller 180 x 180 x 180 mm build area, it’s a smaller printer that can fit on most desktops, but it can still calibrate itself, and offers the same 0. 05mm precision for great quality prints.

05mm precision for great quality prints.

Whereas the MK3S comes with a filament sensor, for the Mini this is an optional upgrade. Moreover, with slightly lower extruder temperatures, you can’t print tougher filaments like Polycarbonate on the Mini, but you can still print filaments like PETG, PLA, ABS, ASA and flexible filaments.

The Mini comes with Prusa’s own PrusaSlicer 3D slicer, and if you run into any problems, you can speak with Prusa’s support team 24/7. Overall, it’s a great lower cost RepRap 3D printer for great quality, reliable prints at a lower price.

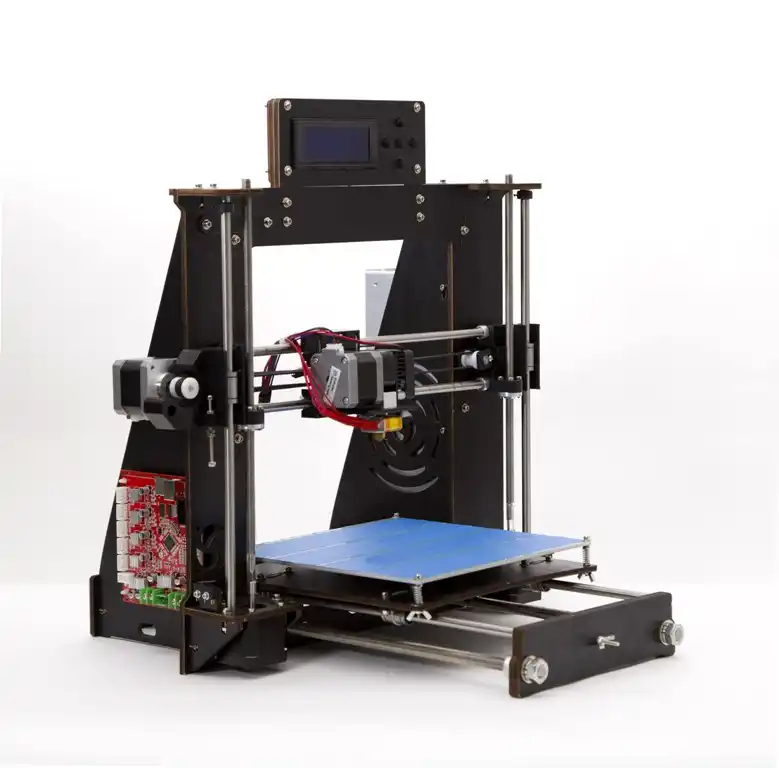

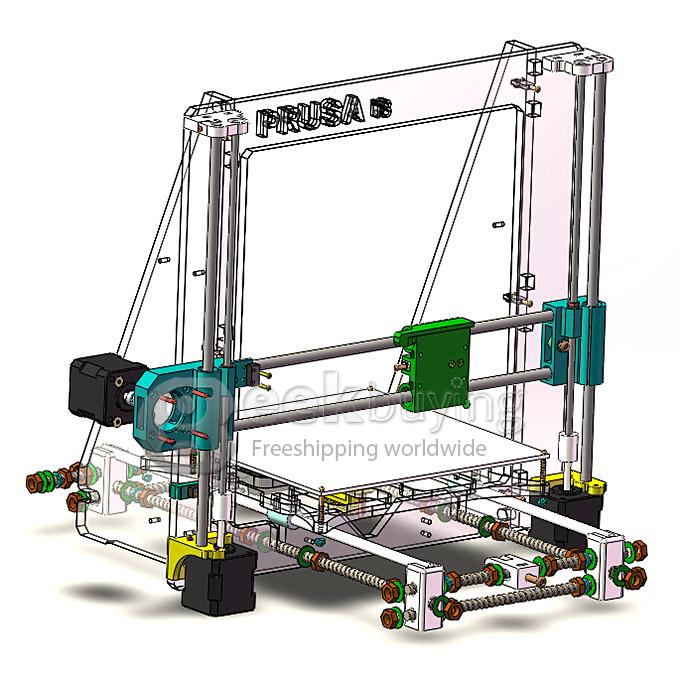

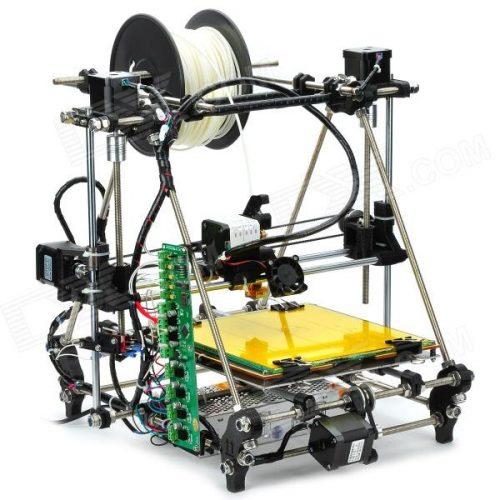

4. Anet A8

- Company based: China

- 3D printer price: $160 — Available on Amazon here

- Print volume: 220 x 220 x 240 mm

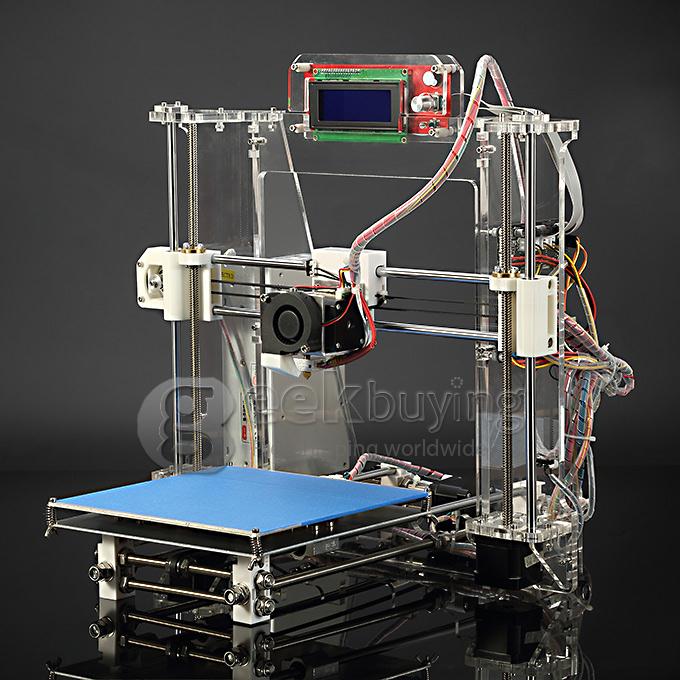

We feel the Anet A8 counts as a RepRap 3D printer since it is Anet’s spin on the Prusa, one of the most famous RepRap kits. It’s cheap and cheerful — you get what you pay for with this DIY 3D printer kit, with extra marks for its consistency and versatility. It’s versatile as it can print so many 3D printer filaments: PLA, ABS, PVA, Nylon, PP, wood and more.

It’s versatile as it can print so many 3D printer filaments: PLA, ABS, PVA, Nylon, PP, wood and more.

For under $200 you can’t expect peak performance, though the minimum layer height of 0.1mm is fine for most printing. Despite not having a weighed down aluminium frame or a dual extruder, the Anet A8 is fairly precise. The stainless steel rail rods, gears and bearings make the printing process more steady, though stability will be slightly worse than if the structure was made of metal.The different parts of the Anet A8 to assemble this DIY kit.

The Anet A8 does not come assembled; you’ll need to build it yourself following Anet’s step-by-step instructions. Most find this more rewarding than buying a plug & play 3D printer, and it’s a great way to learn more about how they function. You can print with your Anet A8 using 3D slicers including Cura and Repetier-Host, and transfer your 3D printer models over via SD card.

Despite the cheap price, the Anet A8 comes with a few neat features. It comes with a heated bed, meaning it can print ABS and PETG, rather than just PLA. It’s also got quite a large printing volume: 220 x 220 x 240 mm. Overall, if you’re looking for a RepRap 3D printer which doesn’t break the bank and gets you started in 3D printing, the Anet A8 is a great option at just $200.

It comes with a heated bed, meaning it can print ABS and PETG, rather than just PLA. It’s also got quite a large printing volume: 220 x 220 x 240 mm. Overall, if you’re looking for a RepRap 3D printer which doesn’t break the bank and gets you started in 3D printing, the Anet A8 is a great option at just $200.

5. Creality CR-10 / CR-10 V3

- Price: $369 / $499 — Available on Amazon here / 3DJake UK & Europe here

- Build volume: 300 x 300 x 400 mm

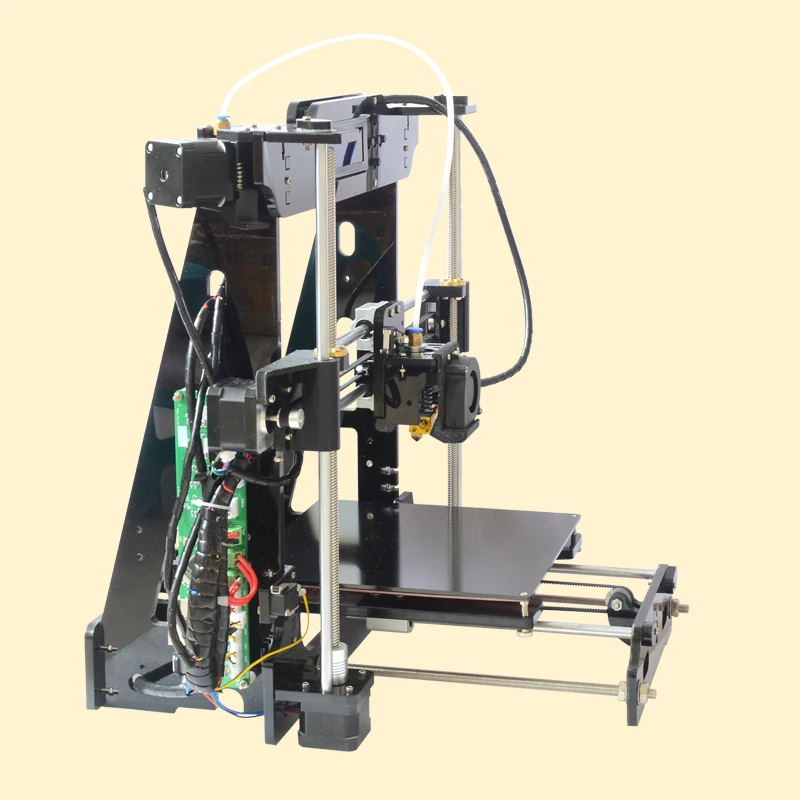

Creality are known for releasing some of the most highly rated and reliable low cost RepRap 3D printer kits in recent years, with multiple iterations of the popular CR-10 available. We’ve picked both the original CR-10 and the V3, so you can choose between the upgraded but more expensive version, or the lower cost and classic original.

Though a RepRap kit at heart, the CR-10 can be assembled in under an hour without much DIY skill, making it a good 3D printer for beginners.

Not only is it reliable, but for the price it can print huge models, at up to 300 x 300 x 400 mm. It truly is a large 3D printer. In addition, the ability to print with a minimum layer thickness of just 0.05mm is very precise for a RepRap 3D printer kit for $500.

It truly is a large 3D printer. In addition, the ability to print with a minimum layer thickness of just 0.05mm is very precise for a RepRap 3D printer kit for $500.

Complementing this printing precision is the stronger and heavier frame supported by triangular z-axis beams that feature on the CR-10 V3 — but not on the standard CR-10. The frame shape has changed to a more triangular shape — more similar looking to the original RepRap Mendel! — in order improve print stability and reduce the Z axis wobble, key to improving print quality.

The CR-10 also has a filament breakage detector that pauses if it detects any issues without ruining your print, and can automatically resume printing in the event of a power outage. These are key features that you really don’t appreciate until disaster strikes 49 hours into a 50 hour print and they save you — but are an absolute life-saver. Overall, we highly recommend the Creality CR-10 V2.

All the Creality CR-10 source files are available here.

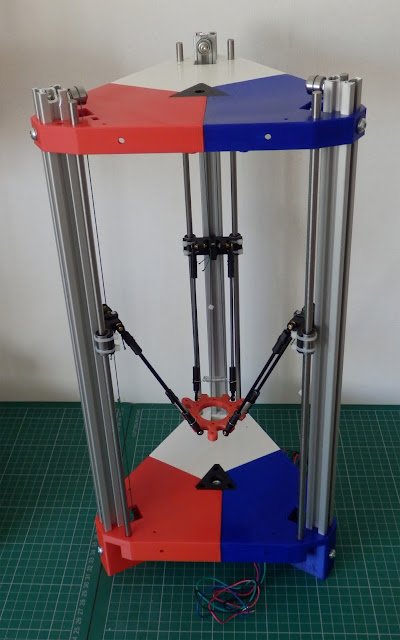

6. FLSUN QQ-S Delta — Upgrade on the RepRap Kossel

- Price: $369 — Available on Amazon here

- Build volume: 255 x 255 x 360 mm

- We have also tested and reviewed the FLSUN QQ-S, which you can view if you click our FLSUN QQ-S review.

There are a number of great RepRap Kossel 3D printers, including the FLSUN QQ-S that we were very impressed with in our 3D printer review. The FLSUN QQ-S is a delta 3D printer that you can buy almost fully pre-assembled for $369. Delta 3D printers are typically tall and thin, with the FLSUN QQ-S able to print up to 360 mm tall prints, with an XY axis of 255 mm.

Kossel RepRap machines were thought of as tougher to master 3D printers for more experienced makers. Now with the FLSUN QQ-S the learning curve is far reduced, especially since the RepRap upgrade ships to you almost completely assembled. The 3.2-inch touchscreen is very easy to use, and the printer comes with an SD card with the 3D slicer software on it, though you can also connect to the printer via WiFi.

Another main selling point is that it’s noticeably (or perhaps unnoticeably!) quiet — FLSUN claim it prints at under 50 dB. This, coupled with the fans and cooling system to avoid overheating and reduce any bad smells, makes the FLSUN QQ-S a great RepRap printer for your home. It retains the quick printing, around 30% faster than the average printer, so if time is of the essence, you could do worse than go with the FLSUN QQ-S.

It’s accurate, quiet, fast and doesn’t take up too much space on a desktop. We recommend it highly. The only drawback is that it may not seem as truly RepRap as it comes more or less pre-assembled, but it evolved from the original RepRap Kossel design so we feel it is worthy of inclusion.

BONUS — RepRap Mendel — Legendary RepRap 3D Printer

The first RepRap 3D printer on this list chosen because of its legacy rather than present performance, the RepRap Mendel is a true veteran of the game. The second iteration of the RepRap machines, the Mendel was the successor to the Darwin machine. It was designed and created by Ed Sells, a student of Dr Adrian Bowyer.

It was designed and created by Ed Sells, a student of Dr Adrian Bowyer.

Named after Gregor Mendel, the ‘father of genetics’, this RepRap 3D printer weighs around 7kg and can print a fairly large 200 x 200 x 140 mm. Though it has a number of improvements over the Darwin, the sheer nostalgia and impact the Darwin has had since its introduction over a decade ago puts it above the Mendel for us.

The RepRap Mendel, the second iteration of the original Darwin 3D printer.For more RepRap-related information and further reading:

Our interview with Dr Adrian Bowyer, discussing founding the RepRap movement

Our long-form feature story on the entire history of 3D printing

Our ranking of the best DIY 3D printer kits

Ways to get a free 3D printer

Category "RepRap" - a community of 3D printer owners 3DToday

A section for real do-it-yourselfers: all sorts of information on building and improving handicraft printers.

M448

Loading

11/16/2022

1522

RepRap

eight

Subscribe to the author

Subscribe

Don't want

Good day, dear colleagues.

FB902 was purchased a long time ago and various models were printed on it, including PLA (recently), ABS (initially), but the print quality was not satisfactory, and the table dimensions 220x220 left no room for creativity.

I decided to make a printer with a print area larger than 310x310 mm.

Dashing trouble, the beginning.

Yes, what's so complicated, now we'll do everything.

It seems that the most difficult p...

Read more

Reprap

28

Subscribe to the author

Subscribe

Don't want to

I started to miss Mitya's print area, and the features of delta kinematics involve scaling with reference to the diameter, but here the places in my workshop turned out to be only 480 * 380 - the delta is not suitable in any way climbs. I don't need two printers either, so the delta is either for sale or for spare parts. I did not want to sell my favorite machine for nothing, so it was decided to put it on the organs. Of the organs, the 12th Khiva rails and the brain of Duet2 Wifi seemed the most valuable. Plus...

I did not want to sell my favorite machine for nothing, so it was decided to put it on the organs. Of the organs, the 12th Khiva rails and the brain of Duet2 Wifi seemed the most valuable. Plus...

Read more

petez

Loading

07.11.2022

3051

RepRap

13

Subscribe author

Subscribe

Don't want

The Voron V0 is a great printer. However, there are a few things I didn't like about it. And there are a couple of tasks that I would like to implement in an FDM 3D printer, and, in particular, high-precision printing from thermoplastics.

The main thing that annoyed me on my V0 was the need to turn the bolts in order to level the table. To print with a 0.1 mm nozzle, this must always be done, and I had to print near the console mount. At the same time, in the older series of printers, there is a printer under...

At the same time, in the older series of printers, there is a printer under...

Read more

RepRap

56

Subscribe to the author

Subscribe

Don't want

Foreword: Do not judge strictly, this article was written for almost a year, corrected several times and partially rewritten. The beginning was published on another forum (there it turned out to be of no interest to anyone).

Good afternoon, morning, evening, night... well, to each his own! In general, let's go!

Immersion in the world of 3D printing started with banal boredom for me... (after retirement, there was nothing to do at home, and hunchback "on Uncle for 28 kopecks - religion does not allow!!!") Cargo about...

Read more

xolodny

Loading

02. 11.2022

11.2022

1216

RepRap

25

Subscribe to the author

Subscribe

Don’t want to

I recently wrote a POST here, in which I used an m35sp-9t type motor to drive the extruder

The motor is remarkable in its performance characteristics:

560 ° = / 7.8. steps per 1 complete revolution

breakaway force - 35.3 mN*m at approx. mounting holes - 42 mm

In short - more than enough...

Read more

xolodny

Loading

29.10.2022

2826

RepRap

eighteen

Subscribe to the author

Subscribe

Don't want to

I use this steel "turbo-burner" as a lifesaver

The device has undergone a number of upgrades, among the latest of which is the transition from long (bowden) to short bar feed. The task was solved by the crutch method - an extruder was mounted on top of the print head - a BMG clone with an m35sp-9 motort

The task was solved by the crutch method - an extruder was mounted on top of the print head - a BMG clone with an m35sp-9 motort

With this:

The motor is inexpensive and high-torque, present in a large number of decommissioned office equipment (printers, scanners, MFPs). From the complexity...

Read more

RepRap

ten

Subscribe to the author

Subscribe

Don't want

It's curious that Flying Bear Reborn has been delayed for me, more than a year already. Not because he is beautiful, but simply does not pass through the balcony door. And very lazy to parse. If so, I wanted to finish it a little to the state of a printer, but suddenly a small “Hercules” appeared and all the few free time slices were given to it.

Read more

RepRap

eleven

Subscribe to the author

Subscribe

Don't want to

Good mood to all!

While a long article is being prepared, I decided to share some useful stuff with the community.

During the operation of the BIQU h3O extruder,

, I encountered a small, but not very pleasant problem with, namely, to fill the rod into the extruder, there is also that quest. A careful examination of the device made it possible to find out that since the extruder was designed not only for a filament of 1.75 mm, but also for 2.85 mm, we have an inlet guide channel of about ...

Read more

RepRap

27

Subscribe to the author

Subscribe

Don't want

In the previous episodes, it was about what I bought for the price of a conditional flying bear of a second-hand small "Hercules". This was done to close the old gestalt, to look at engineering solutions and production culture. Well, I did, yes. Curiously, the product even printed. But in a boxed form, it was of no further interest, so attempts were made to make an interesting porridge out of an ax.

Read more

RepRap

5

Subscribe to the author

Subscribe

Don't want

Good day to all!

I'll probably start writing about building a new printer in order to establish some kind of starting point and give myself a light kick)

My first printer, which served me faithfully for about 5 years, needs to be improved for a long time. Rather, not in refinement, but in a complete rebuild. In fact, he will only be a donor of parts for the new printer. I will not disassemble it until the last part necessary to build a new application is printed ...

Read more

- 1

- 2

- .

..

.. - 80

What is a 3D printer?

What is RepRap technology and what are its advantages

RepRap project

When getting acquainted with 3D technologies, users often come across the term "ReRap". In this section, we will explain what RepRap technology is and what its benefits are.

In this section, we will explain what RepRap technology is and what its benefits are.

The RepRap project started in 2005, when 3D printing was just starting to take off. Its founder is Dr. Adrian Bower, a lecturer in mechanical engineering at the British University of Bath. The purpose of the RepRap project is to enable people to set up their own production system at minimal cost.

Initially, the RepRap project was open source and all source materials were available for download on the Internet. The activity was carried out through the founder's blog, and anyone could download drawings and diagrams of interest. Actually, accessibility is one of the main advantages of the project.

RepRap 3D printer

RepRap stands for Replicating Rapid Prototyper. Literally translated, it is “a (self) replicating rapid prototyping mechanism”. It is the ability to independently reproduce their own parts that the RepRap 3D printer is interesting in the first place. With the purchase of such a printer, users get the opportunity not only to complete 3D printing with a variety of materials, but also, if necessary, to manufacture a similar, “daughter” device.

This useful ability of this 3D printer significantly reduces its cost. Thanks to this, the user gets the opportunity to produce quite complex products without organizing an expensive production infrastructure. Thus, this technology allows anyone to create the necessary objects without much cost and effort. You will only have to spend money on plastic for 3D printing.

Other questions and answers about 3D printers and 3D printing:

RepRap 9 technology0244

Since its inception, RepRap technology has received a lot of positive feedback. RepRap 3D printers have earned the name of the simplest and most affordable 3D printing devices on the planet. An even greater public outcry was caused by the news that 3D printers of this class were able to reproduce electrical circuits. This is a new step in the development of non-self-replicating devices.

This was a brief description of the RepRap technology. We hope the information was helpful. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.