3D printer boxes

3d Printed Box - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

CREATEK 3D Printable Storage Boxes

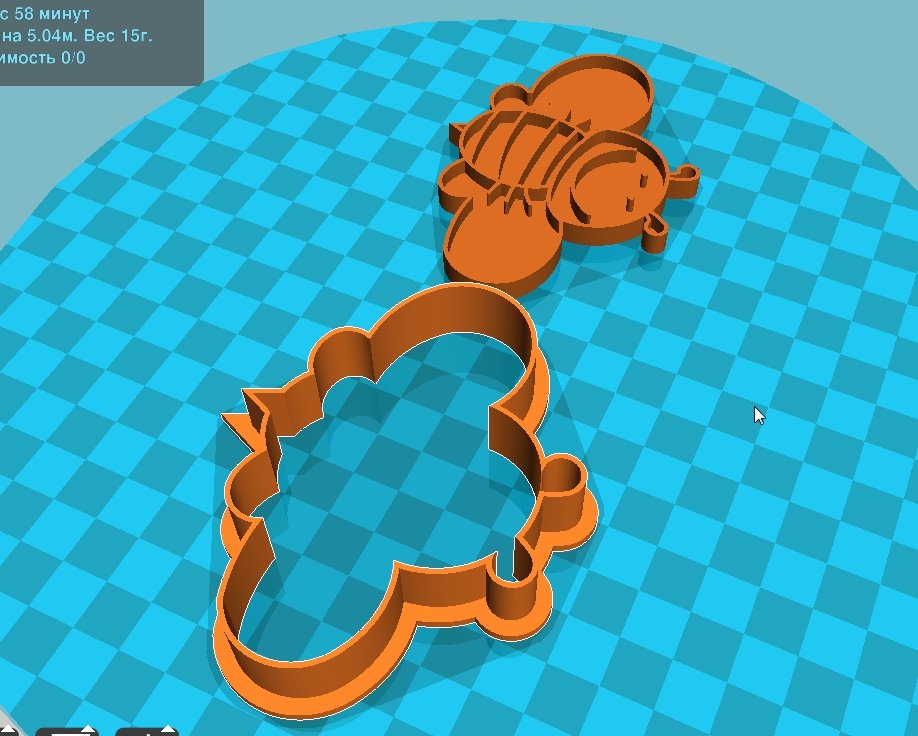

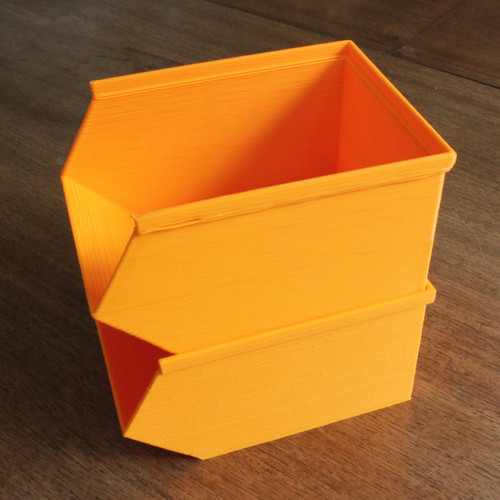

We set out to make a 3D printable product line. Something consumers can download and print at home. We’re starting with a small series of universal storage boxes. Simple, stackable, and designed for FFF 3D printing.

Today, we invite you to test our MLP (minimum lovable product). Consider this version one. We understand this version is not the most innovative, but we believe in starting small and iterating fast.

We’ll improve the product and expand the offerings as we collect feedback. You can help us out by downloading and 3D printing our files below, followed by sharing your thoughts via our feedback survey.

Happy Printing!

-Kevin from PDO & Noah from NMD

Table of Conents

- Storage Box Features

- Naming Convention

- Free STL Downloads

- Change Log: What’s New

- Printing Recommendations

- Get Notified – Product Updates

- Feedback Survey

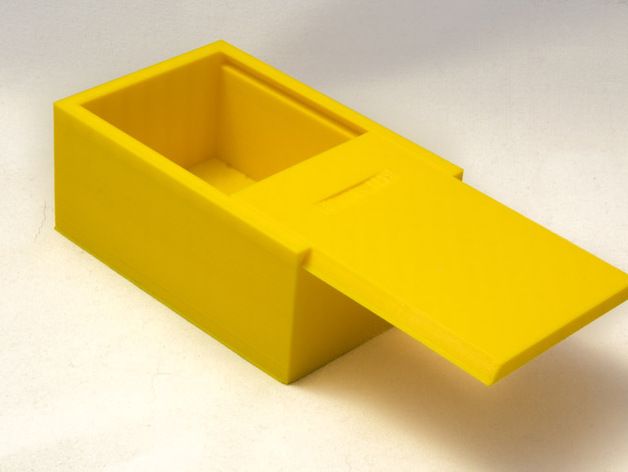

CREATEK Storage Box Features

All of our storage boxes stack, including a combination of smaller sizes that nest on a larger one.

Our unique design includes reinforced corners, providing extra-durable 3D prints – less warping.

All of our designs consider FFF 3D printing, including orientation, durability, and printing speed.

All of our designs are optimized to print without supports or rafts. Yes, we despise them too!

Each design includes a part number, making it easier to keep track of your prints and print more.

Our sizes scale with a 50mm grid, making it easy to utilize a combination that suits your needs.

Change Log: What’s New

| What’s New | Date Published | Link |

|---|---|---|

| G (grid) models released: G-100, G-200, G-300, G-400 | March 24, 2022 | Grid Series |

| S-400 models released | March 13, 2022 | 400 Series |

| Createk Product Launch: S-100, S-200, S-300 models released | February 22, 2022 | 100 Series |

CREATEK Naming Convention

Each model includes a letter and a series of three numbers. The letter represents the model type outlined below (more to be added in the future). The numbers represent the X, Y, and Z dimensions (in order) in increments of 50mm. For example, S-331 is our Standard box with a 150mm length (3x50mm), 150mm width (3x50mm), and 50mm height (1x50mm).

The letter represents the model type outlined below (more to be added in the future). The numbers represent the X, Y, and Z dimensions (in order) in increments of 50mm. For example, S-331 is our Standard box with a 150mm length (3x50mm), 150mm width (3x50mm), and 50mm height (1x50mm).

S = Standard

G = Grid

Free STL Downloads

Select your desired model number below.

Standard Files

- S-111 (v1.0)

- S-211 (v1.0)

- S-221 (v1.0)

- S-311 (v1.0)

- S-321 (v1.0)

- S-331 (v1.0)

- S-411 (v1.0)

- S-421 (v1.0)

- S-431 (v1.0)

- S-441 (v1.0)

Grid Files

- G-111 (v1.0)

- G-211 (v1.0)

- G-221 (v1.0)

- G-311 (v1.0)

- G-321 (v1.0)

- G-331 (v1.0)

- G-411 (v1.0)

- G-421 (v1.0)

- G-431 (v1.

0)

0) - G-441 (v1.0)

S-111 (v1.0) – Download STL (Thangs)

Our standard 50mm reinforced storage cube stacks with all other models. Perfect for those small parts or miscellaneous goods.

200 SeriesS-211 (v1.0) – Download STL (Thangs)

Our standard elongated 100mm x 50mm reinforced storage cube stacks with all other models. Perfect for tall skinny parts and miscellaneous goods.

S-221 (v1.0) – Download STL (Thangs)

Our standard large 100mm x 100mm reinforced storage cube stacks with all other models. Perfect for pencils, pens, and longer goods.

300 SeriesS-311 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 50mm reinforced storage cube stacks with all other models. Perfect for computer parts, larger objects, and miscellaneous goods.

S-321 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 100mm reinforced storage cube stacks with all other models. Perfect for cell phones, glasses, or other large parts.

Perfect for cell phones, glasses, or other large parts.

S-331 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 150mm reinforced storage cube stacks with all other models. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

400 SeriesS-411 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 50mm reinforced storage cube. Perfect for elongated objects, such as pencils.

S-421 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 100mm reinforced storage cube. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

S-431 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 150mm reinforced storage cube. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

S-441 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 200mm reinforced storage cube is our largest model.

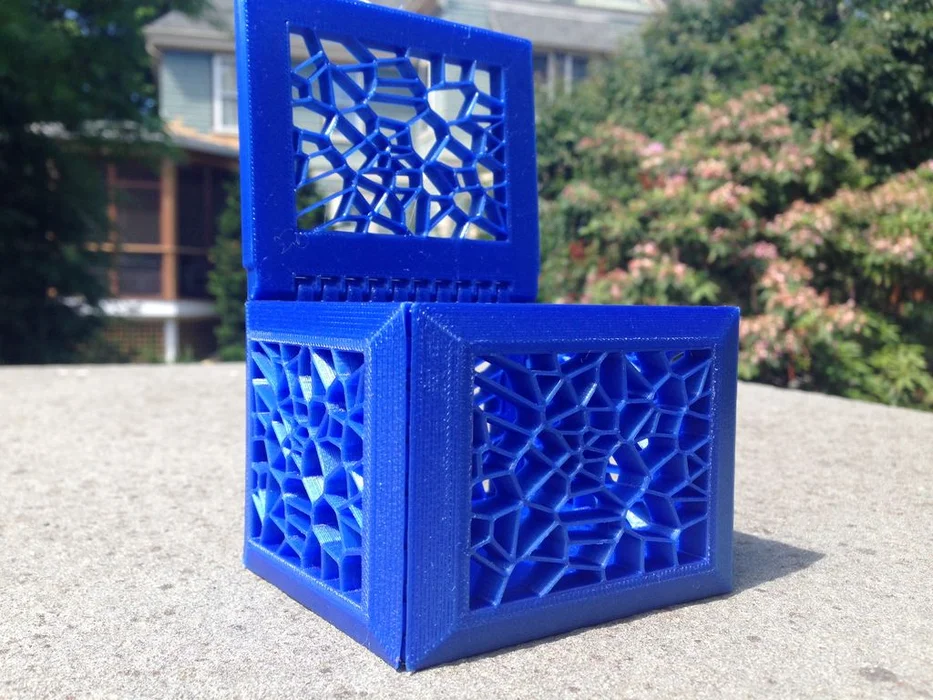

GRID –

100 SeriesG-111 (v1.0) – Download STL (Thangs)

GRID –

200 SeriesG-211 (v1.0) – Download STL (Thangs)

G-221 (v1.0) – Download STL (Thangs)

GRID –

300 SeriesG-311 (v1.0) – Download STL (Thangs)

G-321 (v1.0) – Download STL (Thangs)

G-331 (v1.0) – Download STL (Thangs)

GRID –

400 SeriesG-411 (v1.0) – Download STL (Thangs)

G-421 (v1.0) – Download STL (Thangs)

G-431 (v1.0) – Download STL (Thangs)

G-441 (v1.0) – Download STL (Thangs)

Printing Recommendations

| Layer Height: | 0.2mm |

| Nozzle Size: | 0.4mm |

| Support: | No |

| Raft / Brim: | No |

The CREATEK line will print well in most PLA and ABS filaments. We do not currently test other filament types at this time. For best printing results, follow our recommended print settings outlined above.

For best printing results, follow our recommended print settings outlined above.

For all test prints and pictures, we’ve used the following eSun PLA Pro* filament:

- Purple – eSUN PLA PRO (PLA+) 3D Printer Filament

- Green – eSUN PLA PRO (PLA+) 3D Printer Filament

*Disclosure: This post contains affiliate link(s). An affiliate link means I may earn advertising or referral fees if you make a purchase through my link, without any extra cost to you. It keeps my site free, fast, and available to everyone. Thanks for your support!

All CREATEK 3D Printable Storage Boxes are tested with eSUN PRO (PLA+) 3D Printer Filament.Get Notified – Product Updates

CREATEK Feedback Survey (3 minutes)

Here are some future improvements we have planned:

- special version that has magnets in all four corners (in the works)

- universal lids

- version that has spot for labeles

- storage grid to help organize the boxes in drawers

If you’re having printing issues, please share images and details in the PDO Community.

We value your feedback and appreciate everything you share. Your feedback will help us continue to improve the CREATEK 3D printable storage boxes. Please be descriptive, constructive, and include as much detail as possible.

Small boxes.

We print

Subscribe to the author

Subscribe

Don't want

21

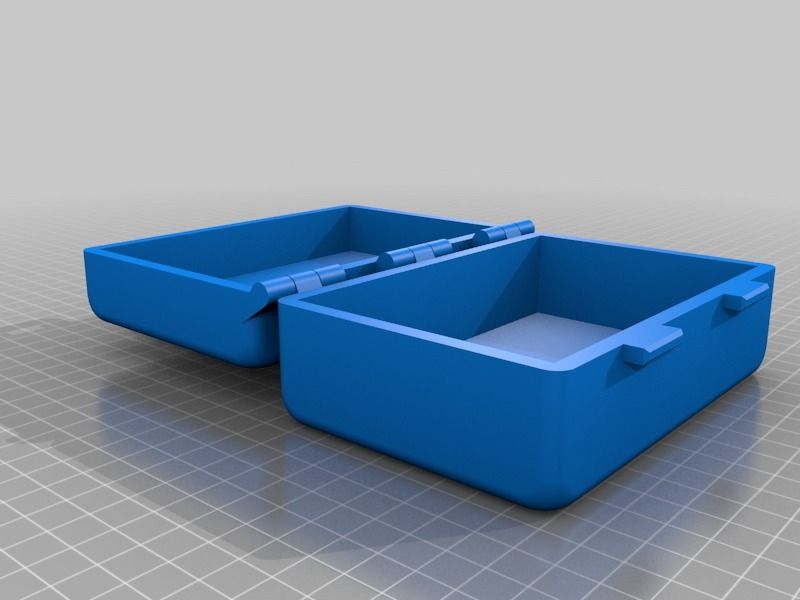

Hello colleagues!

Somehow I came across the SMD box model on the portal (many thanks to the author!)

I really liked the idea. Just mom asked me to do something similar for working with beads.

Having printed a couple of models from the author, I realized that I was not satisfied with this sample.

1. Sizes

Beads need slightly larger sizes.

2. Connecting boxes into blocks with each other.

I only need one row.

3. Place for opening.

This model has a small notch. I need to redo the opening.

4. Snap mechanism.

In this model, snapping occurs due to the dense laying of the walls and the rim on the lid. The durability of such a closure is a little confusing.

Using the sample, I modeled the box, made my own changes and corrections. Slightly changed the 'docking' node. I made it so that this node had a stopper from the bottom.

Of course now you need to print with a little support. but I don't think it will make it any more difficult.

First sighting batch.

After checking, I started printing boxes in different colors and different plastics.

This work is very useful in selecting print settings. There are a lot of identical parts and they show the behavior of the plastic very clearly when changing the printing options!

And now the entire workspace is littered with colorful details.

Work has begun on the processing and assembly of boxes.

No special treatment required. The support was sometimes removed along with the 'skirt', sometimes just with a scalpel. The main revision, drilling holes for the filament rod, cutting off the rod of the required length and gluing it in two places.

In general, quite quickly, a lot of parts were transformed into finished products!

Printed boxes and ABS and PLA. Nozzle 0.4, layer 0.2

Both plastics showed good results. Assembled without any adjustment.

Naturally, the ABS cover will not fit the PLA base. And the same type of plastic fit perfectly.

In rare cases, file a little with a needle file along the protruding part of the lock on the box lid.

I think my mother will appreciate these boxes))))) I just have time to give them for my birthday.

FDM technology, as always, pleases with its capabilities!

Happy printing everyone!

Follow author

Follow

Don't want

21

Best prints

eighteen

Subscribe to the author

Subscribe

Don't want

Maz 200

Scale 1:64

Modeling in KOMPAS-3D Home V18. 1...

1...

Read more

amforma

Loading

03.10.2022

375

eleven

Subscribe to the author

Subscribe

Don't want

Scale 1:43.

3D print master model from photopolymer Harzlabs, INDUSTRIAL ABS....

Read more

jeka_tm

Loading

03/10/2018

29680

149

Follow the author

Subscribe

Don't want

Hello.

For a long time I wanted to assemble something on hydraulics, and I grab it on YouTube . ..

..

Read more

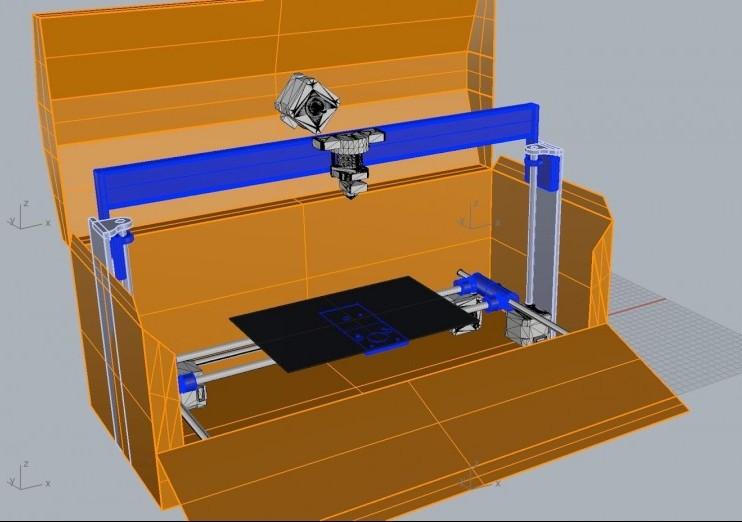

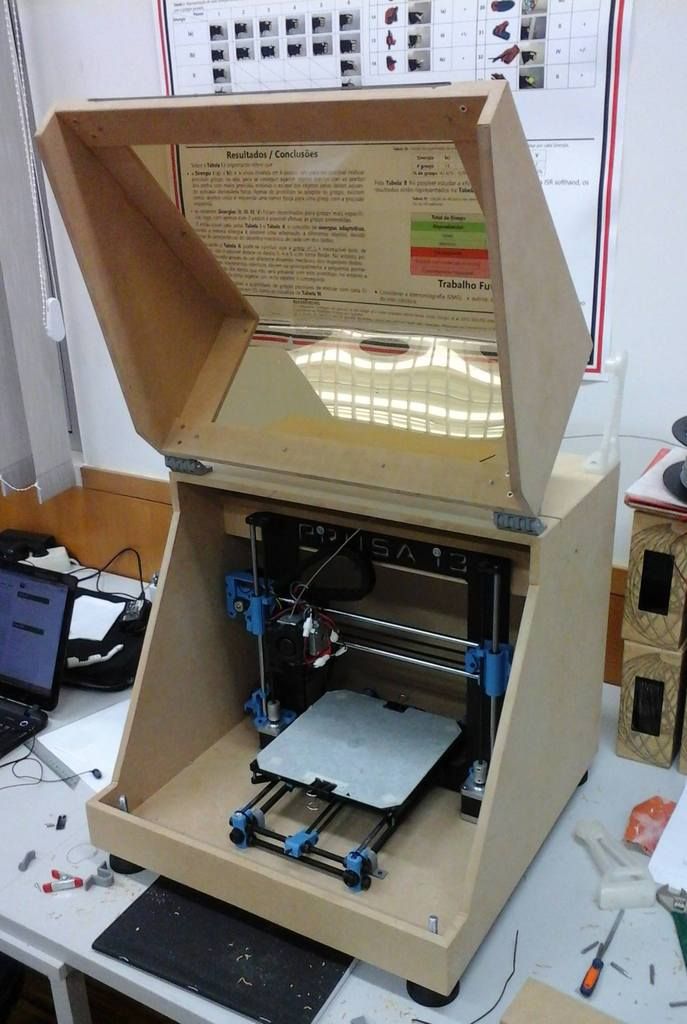

Stackable boxes for storing radio components and more

It just so happened that one of the reasons for buying a 3D printer for me was the need to print a large number of boxes for various kinds of radio electronic modules, radio components and other things. Unfortunately, it is very difficult to find high-quality boxes here, and those that are available are also not cheap. And besides the boxes, a lot of tasks have accumulated that could be quickly solved only with the help of a 3D printer. As a result, a 3D printer was purchased to solve all these problems. And the printing began. As it turned out, the models I have chosen are not without flaws. As a result, they had to be improved. Actually about it and all post.

Printed with ABS, PLA, PET-G and SBS (Wattson). Such work helped to choose the optimal print parameters for these plastics and achieve maximum quality. In order not to waste a lot of plastic for nothing, I developed a couple of test models. I wrote about this in the article “A selection of test models for calibrating and setting up 3D printer printing”, it has a separate section “Test models of stackable boxes”, and since I already wrote about this, it makes no sense to dwell on this issue. Read on the given links.

I wrote about this in the article “A selection of test models for calibrating and setting up 3D printer printing”, it has a separate section “Test models of stackable boxes”, and since I already wrote about this, it makes no sense to dwell on this issue. Read on the given links.

And so. The plan is as follows: We print the chassis ourselves from hard ABS, PLA, PET-G plastics, we print drawers with SBS, PET-G plastic. Most of all I liked to print drawers with SBS plastic. But here I was in for a pleasant surprise. the models are too thin-walled and the drawers just cracked in the corners. There was no durability. As a result, I spat and began to refine everything for myself. That is why this article is being written. I’ll clarify right away, I just finalized the models for myself.

Model source from Thingiverse 9 website0003

The author of the models Piotr Karkovski

In the post, the models modified by me, their images and their source codes are laid out. So everyone who needs to make a revision for themselves can do it without any extra effort.

In addition to the improvements, I developed several of my own models. These are accessories. Namely: a stand at the bottom to improve the stability of the boxes, side and top plugs to keep the surface straight, a couple of brackets if you want to stack the boxes like in the photo above.

Now about the print options. Since most of the elements are thin-walled, a couple of the following parameters are required for printing in the CURA slicer:

Fencing - Number of wall lines “ 2″

Fencing - Filling the gaps between the walls “ Everywhere” 79

For printing with SBS plastic, in order to avoid artifacts on the part, I strongly recommend turning off the combing

For printing, a layer height of 0.3 was used

You will have to select the rest of the parameters yourself, according to your printer, plastic, etc.

Now let's go through the models.

They are the same stackable rectangular pieces into which drawers are inserted. The set contains the following sizes:

The set contains the following sizes:

Chassis 1x1

Chassis 1x2

Chassis 2x1

Chassis 2x2

Minimal modifications were made to the models and roundings were added in the bottom area.

Drawers.

Things are a little more interesting with drawers. All the above models have been modified for printing with SBS plastics, the walls and transitions have been strengthened. also added several models with an internal, which I finalized for myself. Just because drawers are designed for SBS printing doesn't mean you can't print them with other plastics. after finishing, they are perfectly printed on all types of plastics Below are the models that are in the set:

Shuflyada 1x1

Shuflya 1x1 2 slots along

Shuflya 1x1 2 slots across

Shuflya 1x1 3 slots across

Shuflyada 1x1 4 slots across

shuffle 1x -segrade 1x 2x Drawer 1X2 2 slots along

Drawer 1X2 4 slots

Drawer 2X1 4 slots along

Drawer 2X1 8 slots

Drawer 2X2

were not finalized and the rest of the model was not finalized in my collection. I see no reason to duplicate. With regards to the 2X2 drawer, I didn’t see much reason to divide it into slots in principle.

I see no reason to duplicate. With regards to the 2X2 drawer, I didn’t see much reason to divide it into slots in principle.

Accessories.

Well, these are my personal developments. After the set of boxes gained a significant height, it turned out that it was not stable enough on the table. Somehow I didn’t really want this thing to flash one day, through my fault or through the fault of the cat, and all the contents scattered throughout the office. As a result, I designed the legs for this structure:

Stand

This thing allows the structure to stand confidently on the table. I recommend printing from the same materials as the chassis.

To reinforce the floating chassis, the following structure was developed:

Spacer 1x2 Left

Spacer 1x2 Right

To help you understand what I mean by “hanging chassis”, here is an example picture:

Great item to reinforce the structure. Left and right have been fixed in the repository. So you can put it on both sides.

So you can put it on both sides.

And now for some decor. Not everyone will like the fact that the boxes have spike connections on all sides. Sometimes you want a smooth surface. To do this, I developed stubs. Which will allow you to cover the spikes and grooves, and in case you need to print and dock a couple of boxes, you can remove them, dock the boxes and reinstall the decorative caps. It is not necessary to put them in the trailer, but for those who really want to, I added them to the repository:

plug 1x1 top

plug 1x1 bottom

plug 1x1 left

plug 1x1 right

plug 2x2 top

plug 2x2 bottom

pile of 2x2 left 9000 With the description of models and accessories is finished. And since you have read up to here, you are wondering where to download these models?

You can download them in my repository on Github

And finally, a couple of photos:

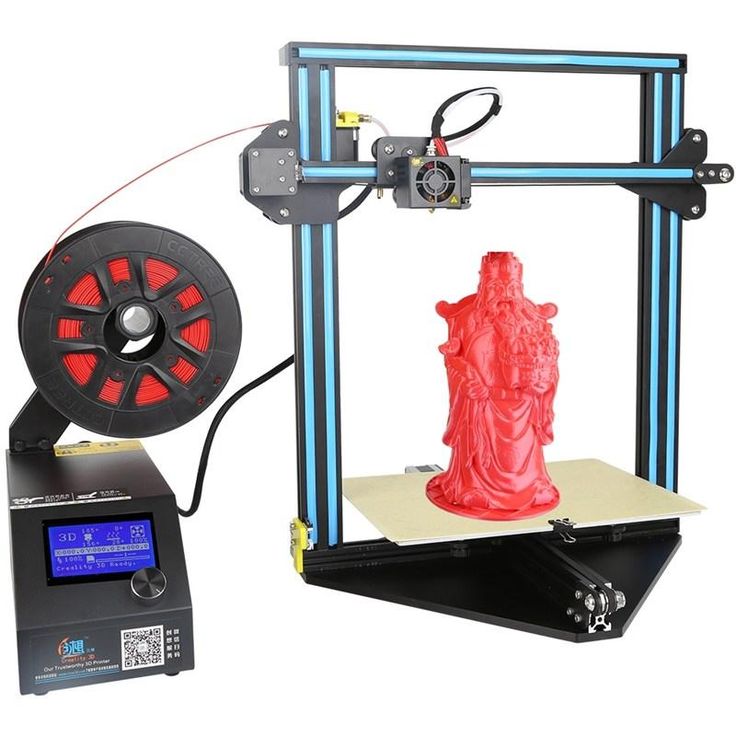

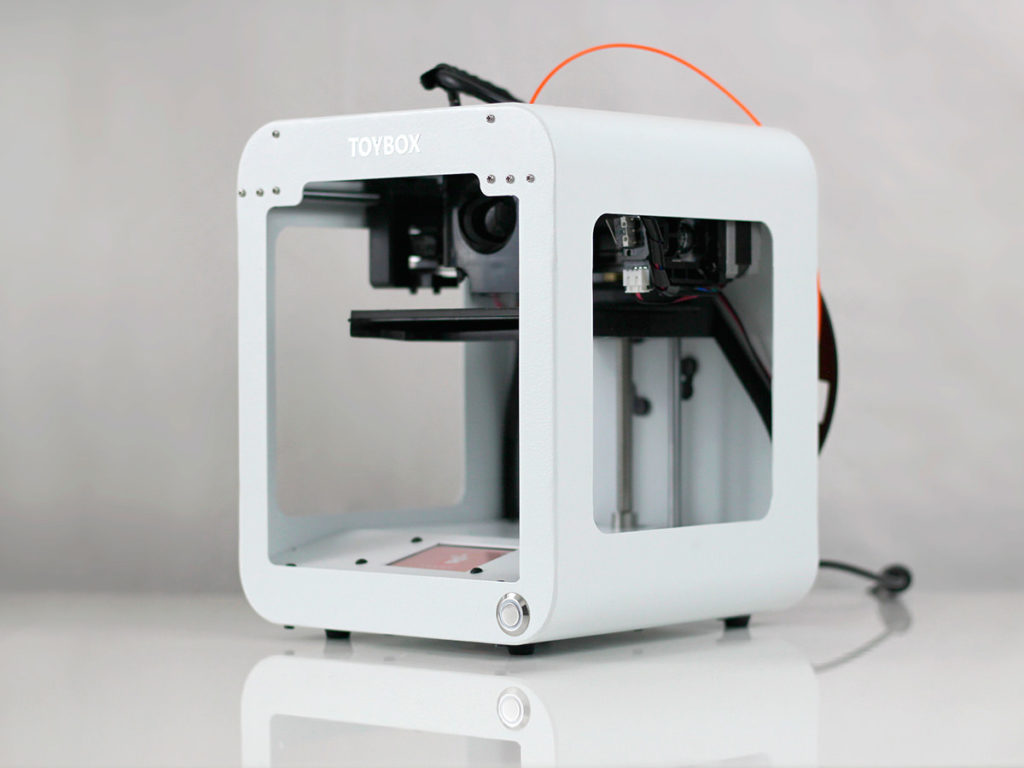

If you have not got a 3D printer yet and are thinking about which model to choose, I can recommend the following models: These links are to trusted sellers who sell original printers.