3D clay printer price

3D Potter - Real Clay 3D Ceramic Printers

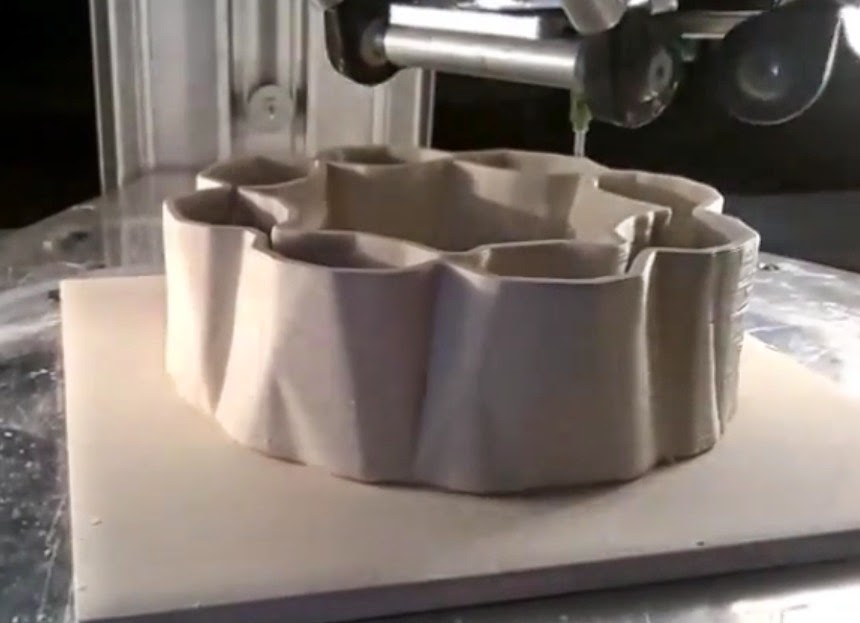

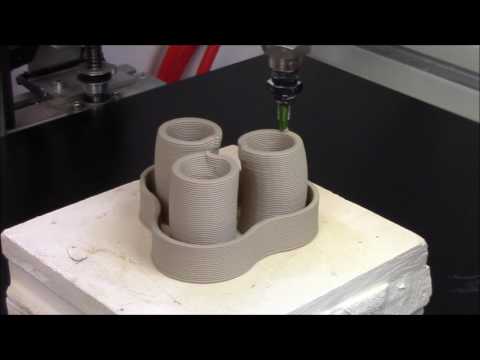

Our line of 3D Clay printers have some unique features when compared to other 3D printers. We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.

3D Printing Cement is here! We have combined our Scara Elite and Small 50 pump with Sikacrete® 3D printer cement developed by Sika USA. This is a versatile and convenient way of printing large-scale architecture and structures.

The Scara Elite is the first viable large-scale ceramic 3D printer using 3D printing material. It is capable of printing multiple objects non-stop. The Elite with the Small 50 can pump up to 3.5 gallons of material per minute through 85 feet of 1″ hose.

They work together so well, we decided to make them a package.

The possibilities are endless!

PR Articles/Videos

Great entry-level printer

More info

10 Proreliable and accurate

More info

Full size, Full control

More info

View this post on Instagram

A post shared by rrreefs (@rrreefs)

View this post on Instagram

A post shared by RAEL (@rrael)

View this post on Instagram

A post shared by BARCELONA3DCERAMICS (@bcn3dceramics)

See More

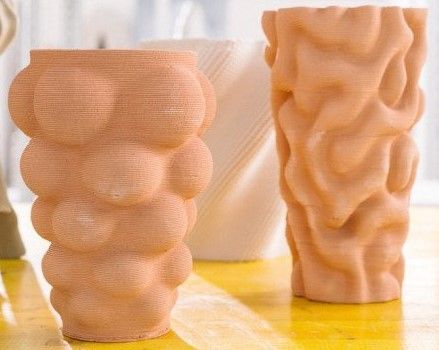

3D Potter is proud to offer assembly tutorials and troubleshooting videos for our printers. Our printers can be used with Potterware, a beginner-friendly program to design pots and vases of all shapes, sizes, and patterns.Check out our Youtube channels to see our videos!

Our printers can be used with Potterware, a beginner-friendly program to design pots and vases of all shapes, sizes, and patterns.Check out our Youtube channels to see our videos!Assembly Videos

Main Channel

3D Potter accepts payment of Bitcoin (BTC) for our products. If you wish to pay by BTC, please contact us.bitcoincash:qr5wmqhnylzr0hcewfrla852xxy9zhp94uugrxy9ay

Here at 3D Potter, we like forward-thinking and preserving the environment. Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles.https://www.tesla.com/referral/dan47410

3D Potterbot Scara V4 Ceramic 3D Clay Printer — Real Clay 3D Ceramic Printer

The Scara V4 is the first viable large-scale ceramic 3D printer using real clay. The advanced design and substantial construction can take on board loads like the 3D Potter 4000ml clay extruder.

The advanced design and substantial construction can take on board loads like the 3D Potter 4000ml clay extruder.

1. Scara v4

2. Closed loop stepper on X, Y, Z, extruder

3. Extruder size of your choice.

4. 5 anodized aluminum nozzles (standard sizes: 3, 4, 5, 6, and 8mm when extruder is purchased)

5. Parts Box: Alan key set, grease, Acme driver tool, tie wraps, extra screws

6. Power Supply

SpecificationsPrinting Envelope:

X/Y- 72" Diameter Circle (1829mm)

Z- 45” (1143mm)

Minimum Printing Envelope:

X/Y- 22" Diameter Circle (558mm)

Printer size:

W-34” L-18” H-44”

Normal operational space needed: W-40” L-36” H-~70”

Maximum operational space needed: W-88” L-88” H-~84”

Height to the top of the extruder fully extended is H~84” (2134mm)

Weight with extruder: 90 lbs. (41kg)

(41kg)

Average speed: 1.2’’ to 3.9’’/s (30 to 100 mm/s)

Power Supply: Output - 24V ~15 amps, Input - 110-220V, 50-60 Hertz.

Power consumption: 24V ~8 amps, ~192 Watt

Main controller board running Duet3D with Atmel SAM4E8E: 120MHz ARM Cortex-M4

Full control through web interface, no apps or software installation. Non-WiFi versions are available, please contact us if you would like this type of connection (Ethernet connection).

* http://www.igus.com

Some components may be re-manufactured

** https://en.wikipedia.org/wiki/Harmonic_drive

Duet Web Control is a fully developed UI for the Scara. Opened in a web browser, it can be used on your laptop, tablet, phone, or other WiFi capable device.

Print StatusOnce a print is started, it shows information about the model being printed. Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

The G-Code Files page allows g-code files for printing to be uploaded, edited, or downloaded. A summary of the file is given such as size, layer height, and what the file was generated by.

Software requirementsNone! The only requirements is a web browser interface.

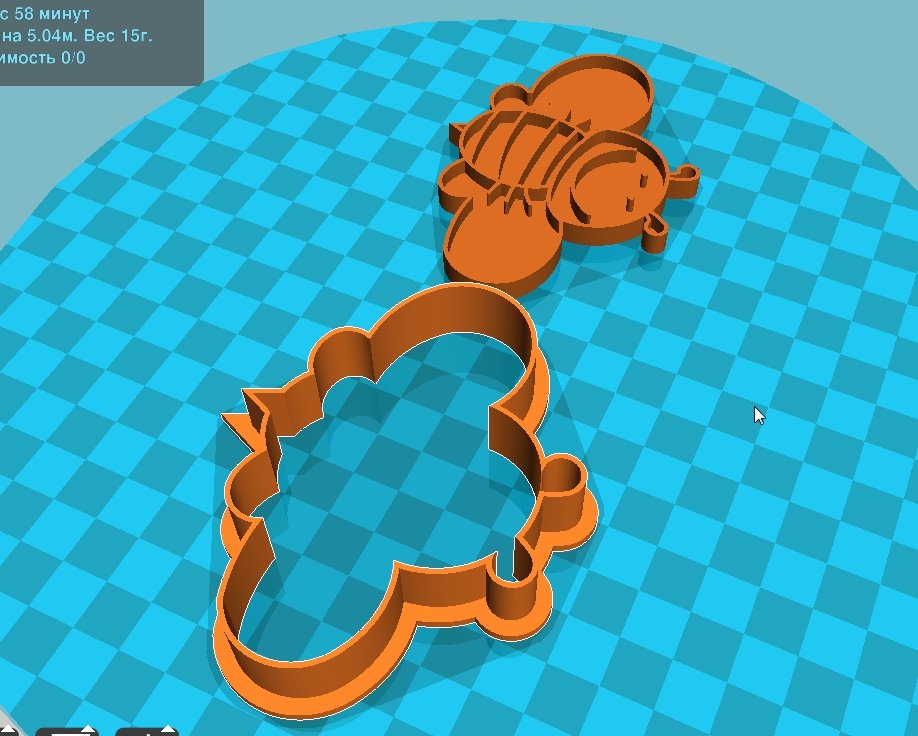

For object generation, the Scara V4 is similar to the rest of the 3D Potter line ceramic printers. It's is just like any other 3D printer which requires an STL file to be sliced by a third-party program. We recommend Simplify3D or Cura, and then loading the file to the SD card in the printer, which can be done over WiFi.

Build envelope

The build envelope diagrams represent the 45 in Z height. We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

The Scara V4 build envelope is quite unique because it's capable of printing 360 degrees with continuous rotation. This means you can create a huge vessel with the printer initially residing inside the vessel or structure. This opens up a whole another opportunity to print small habitat structures (houses). Larger printers are available for this potential habitat project.

Another unique ability is printing multiple objects within the specified envelope in a sequential mode. For instance you could print a particular vessel starting on the far left side and continue to print these vessels until there is no more space left.

Speed and noiseThe Scara V4 is capable of extreme speeds however speed is relative when it comes to ceramic 3D printing. Realistically you probably don't want to exceed 130 mm/s. There are many factors which determine the speed like nozzle size, layer height, and achieving a good adhesion on interlayer of the clay.

The Scara V4 is very quiet, so it can be operated in any area without disturbing the surrounding environment.

Construction and designWe were able to achieve high precision and accuracy with this large Scara arm robot only through diligent design and robust construction techniques. The majority of this structure is out of heavy aircraft grade 6061 aluminum utilizing CNC and welded components for maximum strength and rigidity. The main rail components are from IGUS* which is one of the leading German manufacturers of precision guide rails. The drive motors consist of very sophisticated hybrid closed-loop stepper motors. These have on-board computers with telemetry that continually update their position for zero error positioning.

Drive mechanismsThis is no souped-up 3D printer, this is a dedicated heavy duty purpose-built robot. The main drives are sophisticated harmonic drive units**. These are the same drives used on large industrial robots similar to the ones that are now in most of the large manufacturing facilities. These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

The real advantage is this machine can be positioned on a substantial table top and you can start printing right away within a limited envelope area. Or you can give it its own dedicated space for partial or full envelope.

The space needed is really determined by the end-user and how much of the print envelope they choose to use. Whether on the table top or on the floor, the Scara V4 will require direct mounting for maximum stability. This is achieved with multiple screws to secure the printer to the surface it is on. If you choose to use a tabletop it must be of substantial construction, the minimum is 1.5" thick heavy plywood or wood construction. If a inadequate table is used, the results from the printer will be diminished depending on the build envelope and speed at which the prints are created with.

From flophouses to palaces: ten 3D-printed buildings

iPhone-priced garbage houses and palaces printed in a few days. We tell how 3D printing has transformed the construction industry and what modern printers are capable of

Refuge from the elements in Amsterdam - 8 sq. m

In 2015, the Dutch bureau Dus Architects built a tiny house of 8 square meters. m. It is located in the industrial area of Amsterdam, and anyone can rent it. Despite the small area, the shelter has a veranda and a sofa that converts into a double bed. The bathroom, also created on a 3D printer, is taken outside. The shelter was built from bioplastic based on linseed oil. To make a stable house without heavy frames, the engineers designed the walls in the form of a honeycomb.

Photo: DUS Architects

Urban Retreat is part of a temporary functional housing project. The Dutch authorities hope that 3D printing will help provide housing for victims of natural disasters in the future.

Garbage and clay houses - 30 and 60 sqm m, the cost of which was only about $ 1,000. The building received the symbolic name Gaia - in honor of Gaia, the ancient Greek goddess of the Earth, since only natural materials were used in the construction.

Engineers believe the cost-effective technology can be used to build temporary shelters for victims of natural disasters or refugees. The house became part of the Shambhala Village project, the first settlement in the world where all buildings will be printed.

Photo: WASP

Another WASP project is the futuristic Tecla house created in 2021 with Mario Cucinella Architects. Residential building with an area of 60 sq. m printed in 200 hours.

Photo: dezeen

The company's printer can use both concrete and a biodegradable mixture of clay, straw, rice husks and hydraulic lime as "ink". Construction takes place in two stages: first, the concrete frame of the wall is printed, and then the printer fills its inner layer with clay. The main advantage of the technology that WASP uses is the absence of construction debris.

The main advantage of the technology that WASP uses is the absence of construction debris.

Printed house in the suburbs - 37 sq. m

An unusual house in Stupino near Moscow is one of the first projects of Apis Cor, a Boston startup with Russian roots. The construction of the building was completed in the winter of 2017. House of 37 sq. m was built in 20 hours, and its cost was ₽590 thousand. The material sets only at temperatures above 5°C, so the construction site was covered with a tent. At the same time, the finished building can withstand temperatures down to minus 35°C. For construction, an industrial printer weighing 2.5 tons was used, which allows you to design up to 100 square meters. m of housing per day.

Unlike most competitors, Apis Cor prints its buildings on site rather than assembling them from prefabricated blocks. The house in Stupino became an advertisement for startup technology: Apis Cor founder Nikita Chen-yun-tai intended to sell printers, not houses. The idea of the Russian startup was successful - even Time wrote about an innovative house in the Moscow region.

The idea of the Russian startup was successful - even Time wrote about an innovative house in the Moscow region.

Homes for the homeless - 38 and 45 sq. m

Icon is an American robotics startup focused on 3D printing of large-scale objects. For example, together with NASA, they designed a prototype rocket landing pad, and are now planning a project for a printed lunar space station, Olympus. But the company is also engaged in more mundane buildings.

Together with design firm Logan Architecture, Icon printed six houses for the poor in 2020. Each area is 38 sq. m. For construction, a Vulcan II 3D printer and special concrete were used. All buildings have an equipped kitchen, living room, bedroom and bathroom. The 3D quarter was built on the territory of an already existing community for the former homeless, where more than two hundred people now live.

Photo: Shane Reiner-Roth / The Architect's Newspaper

In Mexico, Icon is partnering with New Story, a foundation that raises donations to build safe, affordable housing for the poor. In 2019th project organizers said they plan to print 50 houses, each of which will have two bedrooms, a bathroom, a kitchen and a living room. The area of Mexican houses is 45 square meters. m.

In 2019th project organizers said they plan to print 50 houses, each of which will have two bedrooms, a bathroom, a kitchen and a living room. The area of Mexican houses is 45 square meters. m.

Photo: Icon

Because 3D-printed houses are built many times faster and cheaper than usual, they can be a lifesaver for the homeless.

"Lotus House" - 60 sq.m. m. It was designed by students of the University of Washington as part of the Solar Decathlon China 2018 competition. The task of the participants was to create an environmentally friendly building that would run on alternative energy sources. The student team went further and decided that even the construction process itself should be waste-free and carbon-neutral.

The building itself is only partly 3D printed. On it, engineers made molds for casting concrete walls. The advantage of this approach is that the printed designs can be used at least a hundred times. In conventional construction, wooden molds are used, which wear out after only two castings.

The building itself was made in the shape of a lotus - the designers said that they wanted to emphasize the beauty and delicacy of Chinese culture in the design.

Photo: Liam Otten / Archinect

Germany's first two-storey printed house - 80 sq. m

A two-story villa printed in North Rhine-Westphalia is an example of the use of 3D printing in the construction of luxury housing with custom design. The living area of the building was 80 sq. The 3D villa is a joint project of MENSE-KORTE ingenieure+architekten and developer PERI GmbH.

Photo: Mense-Korte

The villa was built using a unique BOD2 3D printer that can print pipes. This feature gives designers a free hand: complex engineering solutions on BOD2 can be completed faster and cheaper than with standard construction. ArchDaily writes that an innovative printer used in the construction of a German villa can print 1 sq. m wall in just five minutes.

Curve Appeal Ecosystem House - 240 sq.

m

m Another example of conceptual 3D printing is the Curve Appeal 240 sq. The building belongs to WATG Urban Architecture Studio. The printing of the building was completed in 2020.

Construction lasted three years. The building project was created back in 2016, and then won first place in The Freeform Home Design Challenge. Designers received $8,000 from the organizers to implement the concept.

Photo: WATG

Curve Appeal is made from 28 printed panels. The unusual design maintains the microclimate of the house: according to the designers, the temperature inside the building does not depend on the weather outside.

The world's largest printed building in Dubai - 641 sq. m

The world's largest 3D printed building is located in the UAE. Building with an area of 641 sq. m for the municipality of Dubai in 2019 was built by Apis Cor - the same startup with Russian roots that printed a house in the Moscow region. According to the plan of the Dubai authorities, by 2030, 25% of new buildings will be built using 3D printing, as the technology allows to reduce the cost of construction by six times.

Photo: Thomas Page / CNN

The structure and appearance of the building is similar to a conventional building, made of concrete and rebar. It took 500 hours to print, but preparations for construction took three whole years. The creator of Apis Cor, Russian Nikita Chen-yun-tai, said that this project brought him $ 1 million in revenue and attracted new customers. Among them is the Orwo film studio from Louisiana, for which the startup will print scenery for films.

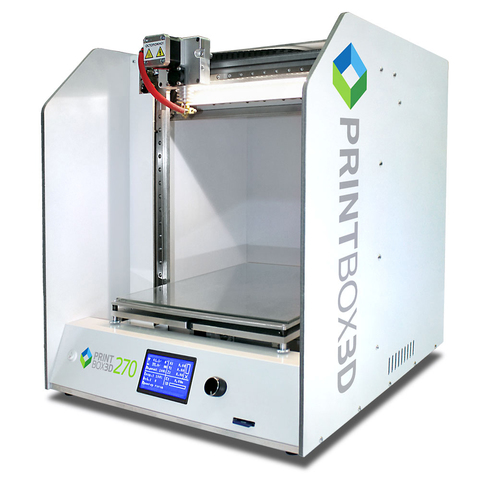

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

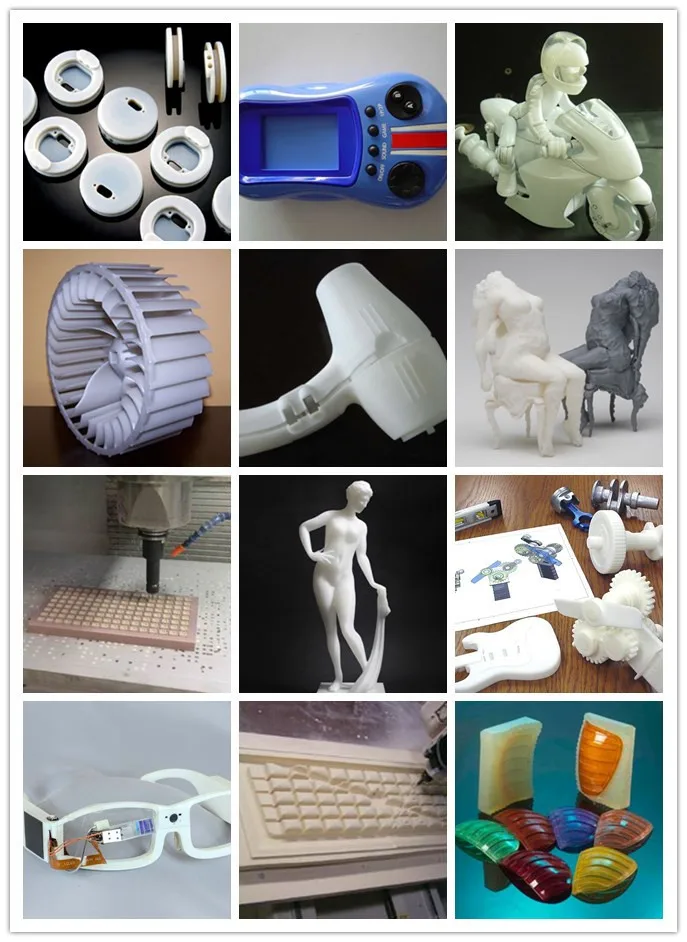

A construction 3D printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

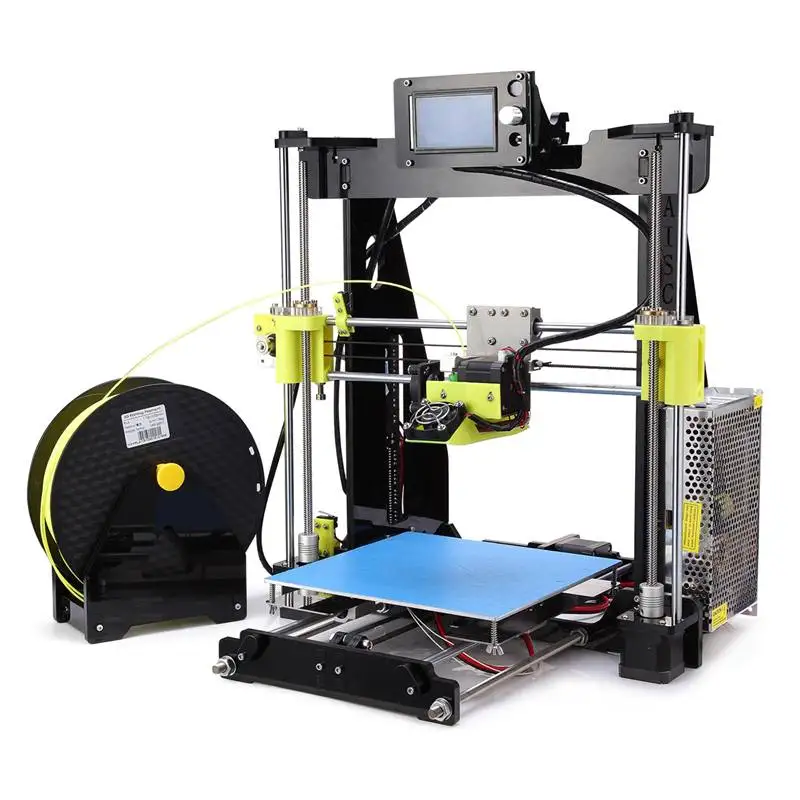

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalable: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27.

• Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars.

• Partially built houses : Only the shells of the houses are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.).

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This design 3D printer is fast at up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3.8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another.

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mud3D-Bots087 concrete printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only).

WASP Crane WASP “Infinity 3D Printer”

• Assembly size: Ø 6.3 x 3 m

• Material: Concrete / Earth materials

• Country: Italy 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers job projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Q3D scale project "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

Construction printing services

Contour Crafting 3D Printing System

• Build size Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology.