Make magazine 3d printer buyers guide

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

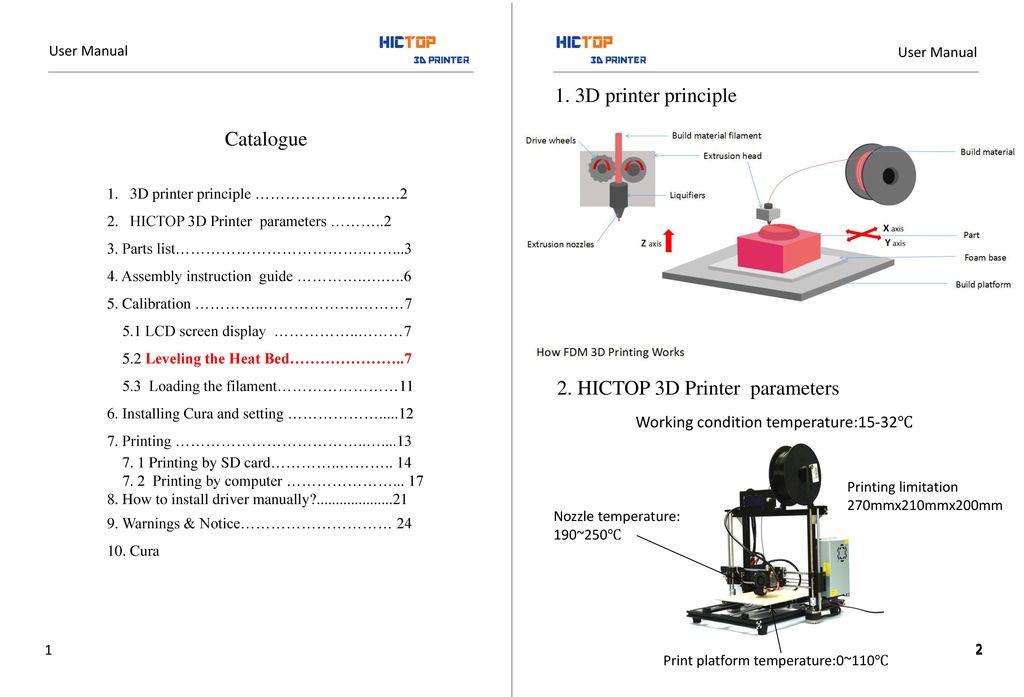

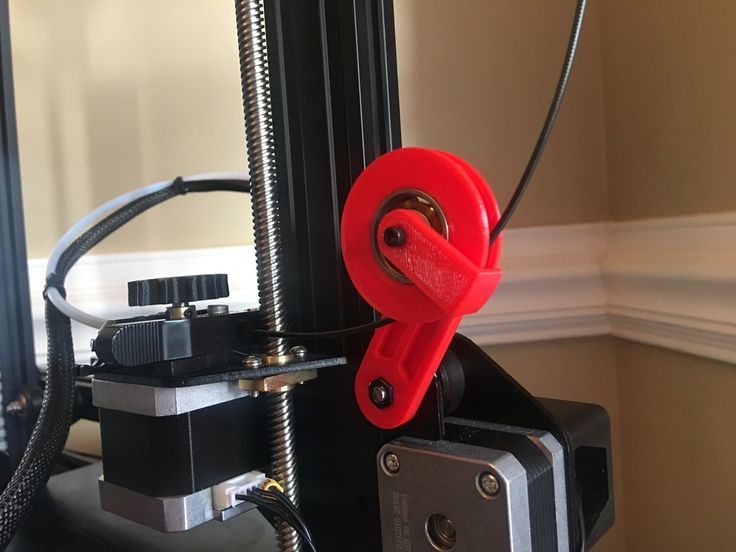

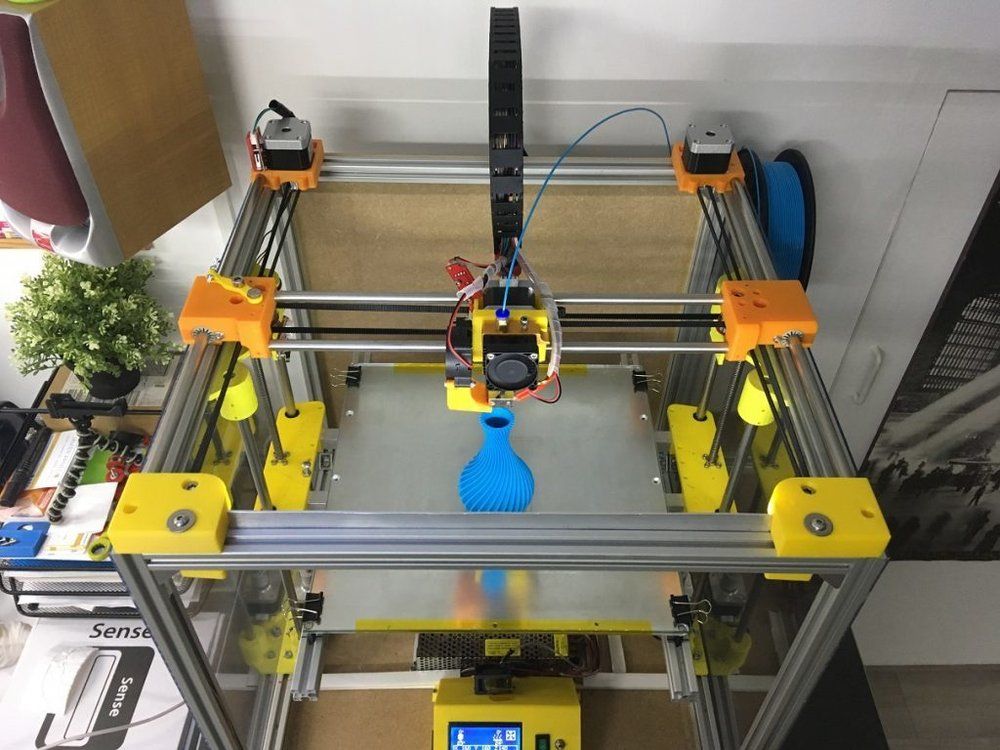

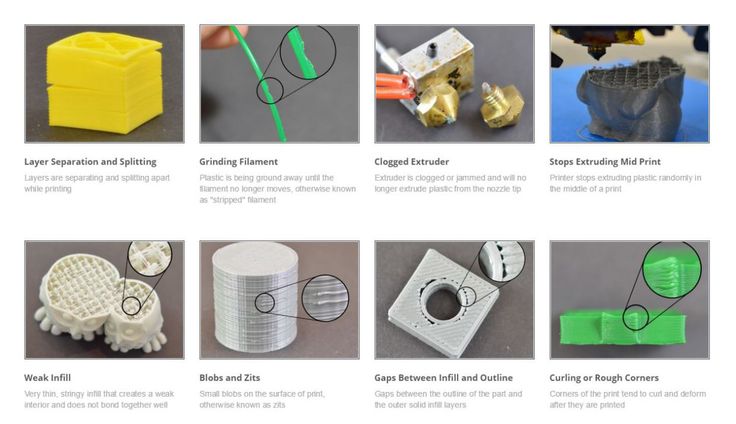

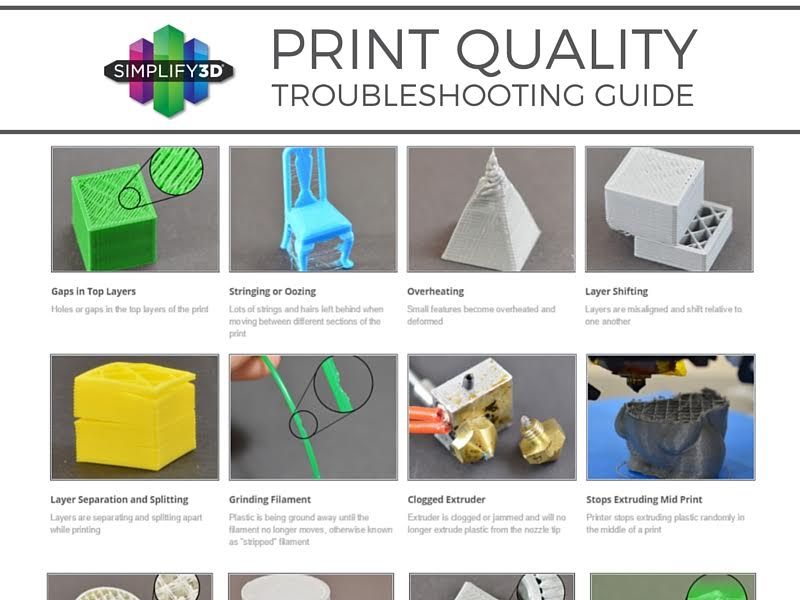

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

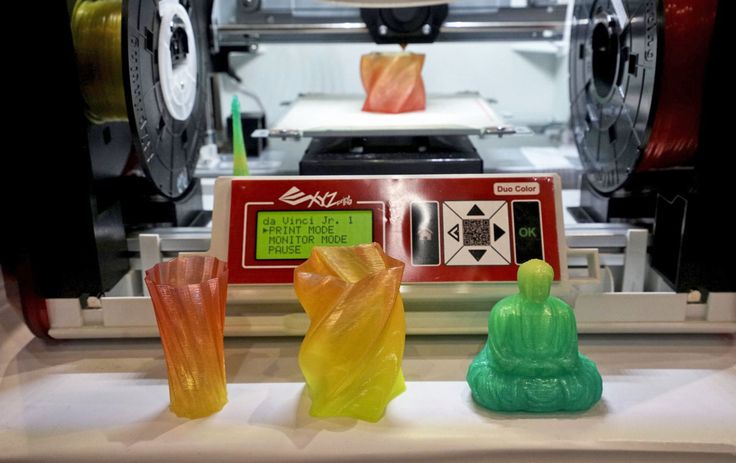

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199.95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

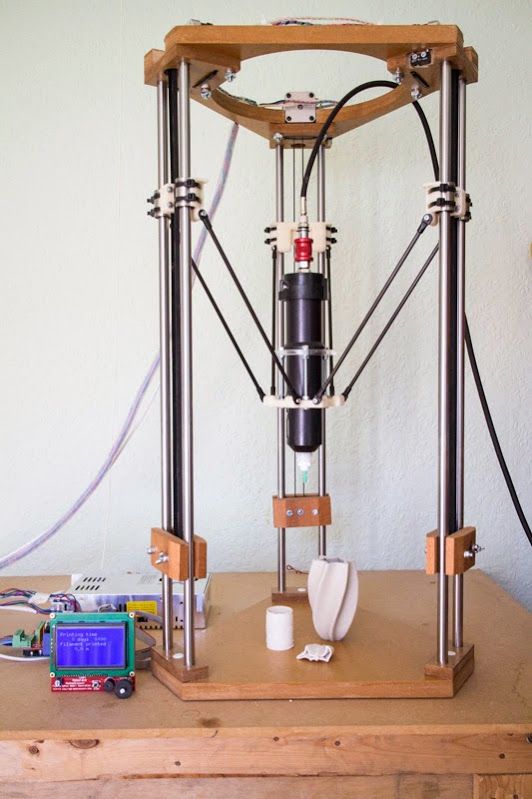

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

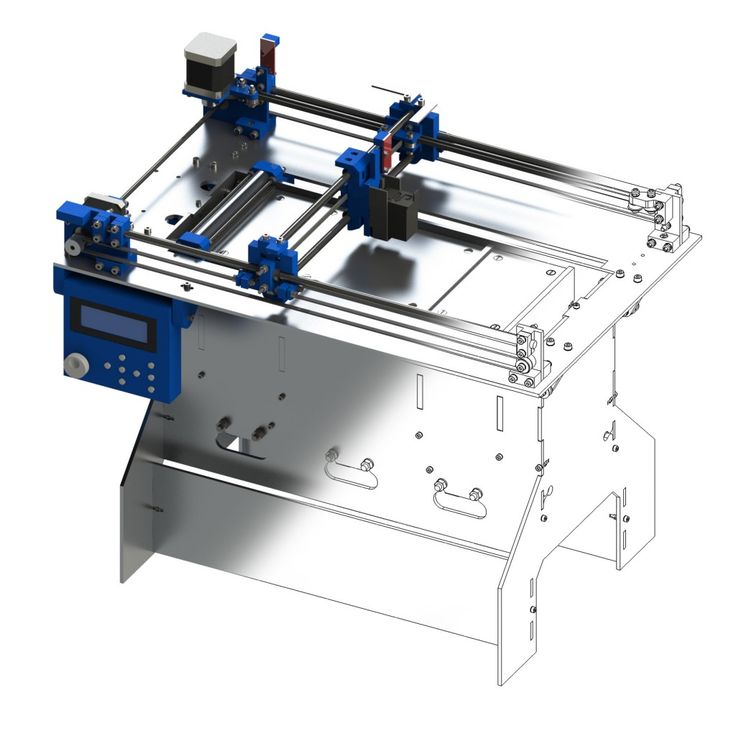

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

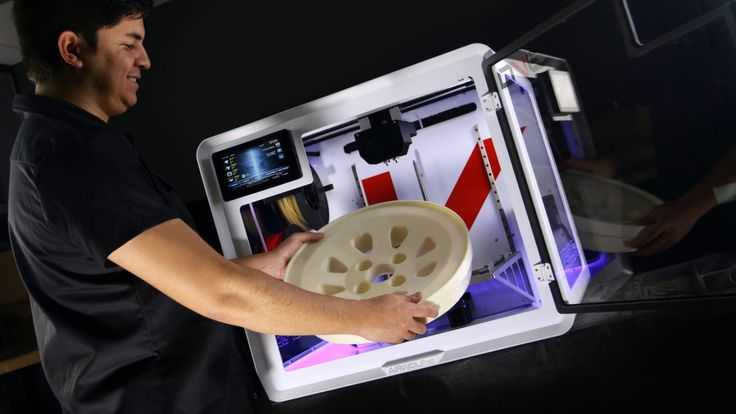

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

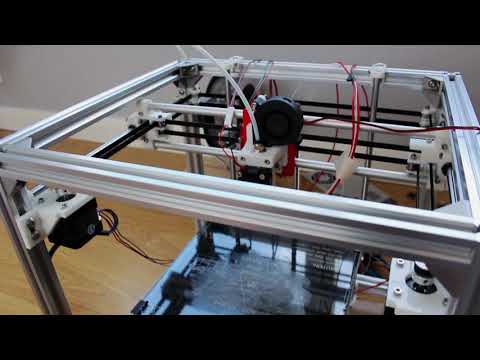

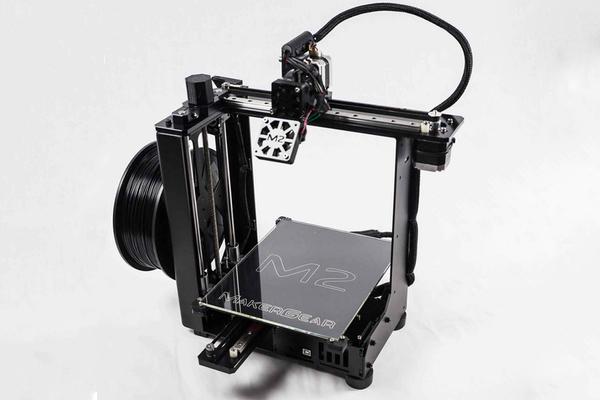

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

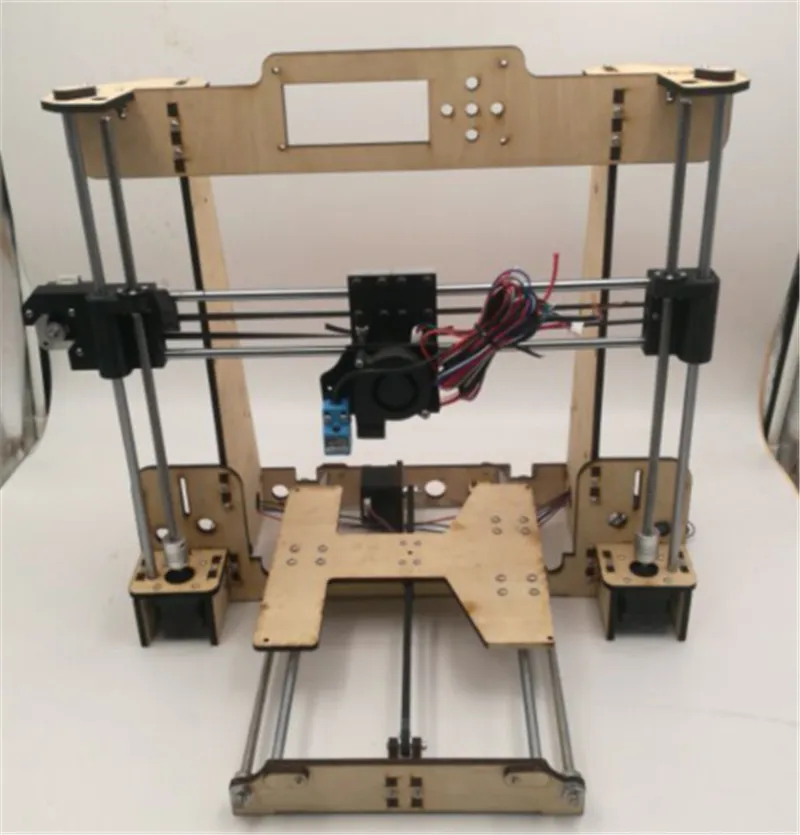

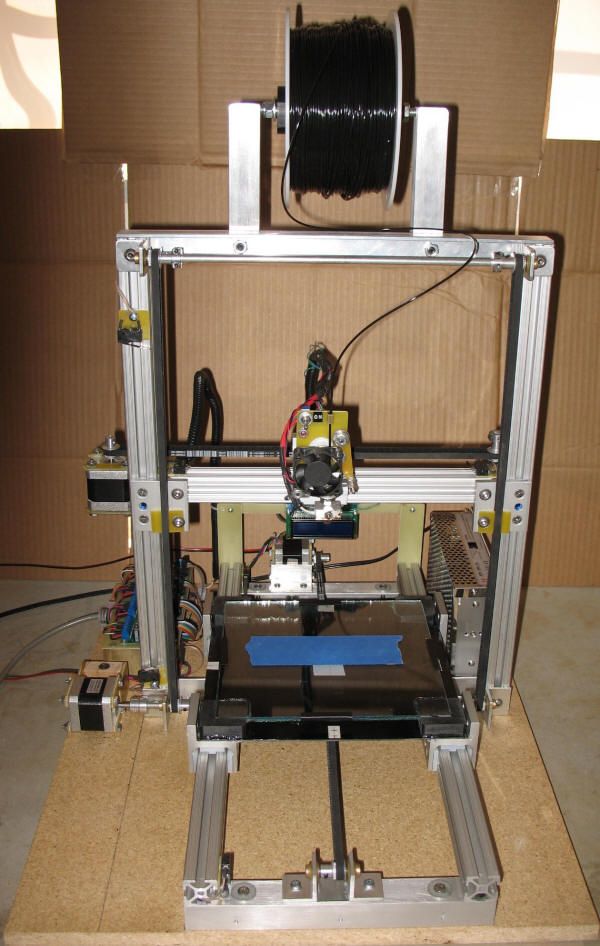

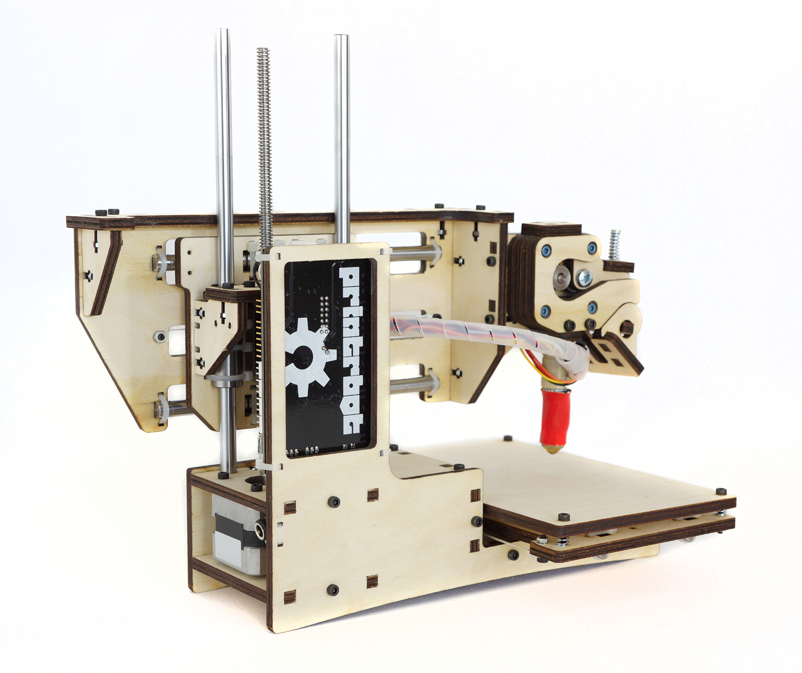

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Desktop 3D Printer Buying Guide 2022 - 3DPrint.

com

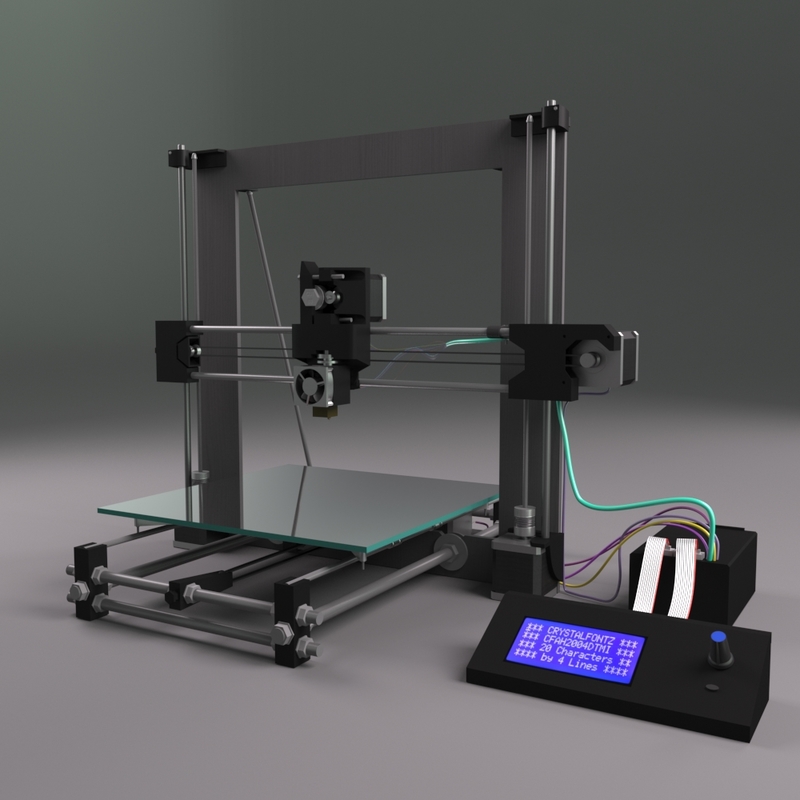

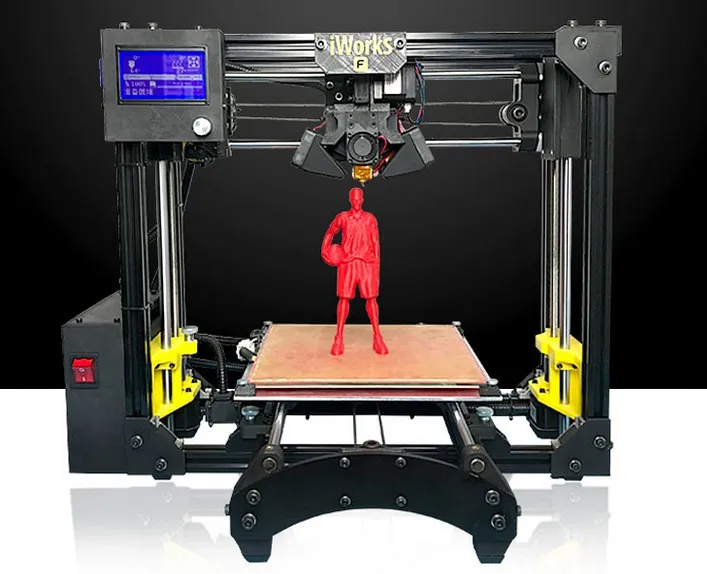

comDesktop 3D printers have evolved considerably to date—beginning as rickety hobby projects that were more often broken than working and evolving to become quite competent devices. We must point out that 3D printers to date are not as reliable or easy-to-use as your toaster or television. Some skill and determination are still required to operate today’s desktop fabbing machines. However, now for the first time, it can be a rewarding experience with comparatively little effort.

To get the most out of 3D printing, it is still desirable to master CAD and 3D modeling so that you can design and make your own objects. But simpler software and download sites have made printing models that appeal to many people much more accessible. We’ve also seen a lot of development in terms of required slicing software, which makes it easier to achieve good results with packages such as Cura.

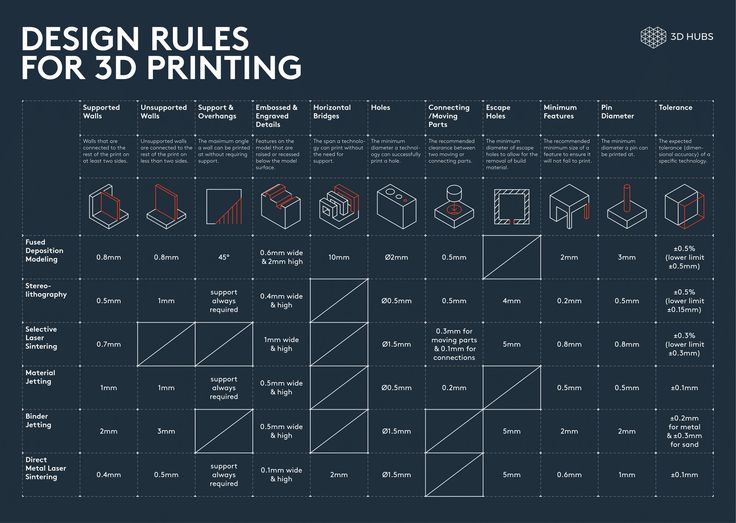

About Filament 3D Printing

To date, nearly all desktop machines are material extrusion 3D printers that extrude one of over 80 compounds of polymer filament. These printers range from around $200 to $5,000 in price. With these systems, one can now make objects in a wide range of polymers. Most of the time, your print should come out complete, as long as your printer is level, calibrated, your print bed is clean, and your filament is dry.

These printers range from around $200 to $5,000 in price. With these systems, one can now make objects in a wide range of polymers. Most of the time, your print should come out complete, as long as your printer is level, calibrated, your print bed is clean, and your filament is dry.

Usually described as fused deposition modeling (FDM) or fused filament fabrication (FFF) 3D printers, material extrusion systems are simple and produce tough thermoplastic parts that are fairly strong. Mostly using bioplastic PLA—not actually very sustainable, if we’re being honest—but also increasingly made in materials such as PETG and ASA, desktop printers have become more capable. Filament end detection, fault monitoring, multiple nozzles, more software, and greater reliability have all become more and more standard now.

With $200 printers, you’ll have to do a lot of the calibration yourselves, while printers that cost $2,000 are more reliable, have more features and bigger build volumes, and provide a finer print result. FDM printers closer to $5,000 should be more reliable and repeatable still, with better screens and more sophistication all around.

FDM printers closer to $5,000 should be more reliable and repeatable still, with better screens and more sophistication all around.

About Resin 3D Printing

FDM is not the only technology for desktop 3D printers, however. Vat polymerization—including stereolithography (SLA) and its cousin, digital light processing (DLP)—has been making advances in the desktop market. These printers work with photopolymers, materials that can be skin irritants. In their liquid form, resins can have severely negative health effects. Indeed some materials may be carcinogenic.

We would, therefore, never recommend these printers for households with small but eminently curious and mobile children. If you always wear gloves and eye protection, however, then these printers can be operated safely. The key detail here is that skin contact allergies build up over time due to exposure and can lead to diminished quality of life.

If operated safely, SLA printers can make very highly detailed models. These can be used as molds or for casting either in an impression mold or through lost wax casting. They can also be used for very sophisticated end-use parts, but are mostly not fit for use in consumer-facing parts, unless specifically certified for this. The SLA portion of the market is fast developing, but collective knowledge on these printers is limited but improving.

These can be used as molds or for casting either in an impression mold or through lost wax casting. They can also be used for very sophisticated end-use parts, but are mostly not fit for use in consumer-facing parts, unless specifically certified for this. The SLA portion of the market is fast developing, but collective knowledge on these printers is limited but improving.

We’ve divided up the market into the following:

- Low-cost desktop 3D printers (priced $150 to $800): Mostly bought by consumers and hobbyists

- Midrange 3D printers (priced $850 to $,2000): Safer and more reliable, bought by consumers and some businesses

- Professional 3D printers ($2,500 to $6,000): Aimed at businesses.

Essentially, if you’re looking to spend the least amount of money possible and willing to put in the time, get a low-cost printer. If you want to have better results with less work, buy a midrange systems. If you need the advanced features, buy a pro printer.

Voxelab Aquila: $199

I have a Voxelab Aquila at home and I really like it. The Voxelab is a pared-down Prusa clone that’s easy to assemble and works well. A friend of mine actually found it easier to assemble than a Prusa Original. The controls work well enough. With some elbow grease, it puts out nice prints. There’s an accompanying software package called VoxelMaker that is easy to use as well. Overall, the glass bed is much better than others in this price category and it is just easier to use across the board. Do expect to be involved in mastering this printer, but if you put in the time, it is very rewarding.

Creality Ender 3 V2: $262

One of the best-selling 3D printers worldwide, the Creality Ender 3 V2 is a quiet and easy to operate model. You can add features such as auto-leveling to it, a nice addition that saves time. On the whole, this printer is a lot of bang for your buck, when tweaked. A lot of people have it as well, which means that you can generally get good community support.

Artillery Sidewinder SWX2: $439

Several friends of mine have various Sidewinder models and the Artillery Sidewinder SWX2 is a workhorse. Quiet and reliable for the price point, it also packs a lot of features. It’s capable and usable. Bed heating on this model is very fast indeed, which saves you a lot of time. This printer can print coherently at much faster rates than most of its brethren.

Original Prusa Mini+: $440

I have an Original Prusa Mini+ and I completely adore it. Build volume is a bit small, so sometimes you’re left disappointed when you’re unable to make certain items. Aside from that, it’s a dream. The prints I get off of this thing are nothing short of amazing. Tight, sharp, and accurate with good detail. Do get the filament sensor option. There is some assembly required, but this tiny machine is my go-to printer at home. Comes with Prusa-flavored software, which is easy to use and has good controls.

Anycubic Photon Mono X: $240

At this price point, the Anycubic Photon Mono X is a surprisingly well-made resin printer. It works. The software is good enough, with an overall strong UX. The screen is easy-to-use, as is the accompanying software. The printer is value-engineered to make the most of its LCD projector and has a good build volume. It’s worth noting that object size will still tend to be limited with resin printers generally. Parts can come out of this printer with great precision and accuracy. For the price, it’s a great little machine.

It works. The software is good enough, with an overall strong UX. The screen is easy-to-use, as is the accompanying software. The printer is value-engineered to make the most of its LCD projector and has a good build volume. It’s worth noting that object size will still tend to be limited with resin printers generally. Parts can come out of this printer with great precision and accuracy. For the price, it’s a great little machine.

In this segment, the Creality and Artillery are good workhorse printers that are viable choices. If you want to spend the least amount of money possible and still print relatively large objects, my current favorite is the Voxelab. It’s easier to use and just a bit more well made all around. If small objects suffice and you’re able to spend a bit more, then get the Prusa Original, which packs a lot of quality components and workmanship in a small form factor. The prints off of the Prusa are a dream and it’s easy to use. In this segment, price changes and deals per region are legion. So, the prices will fluctuate often and may make a big difference depending on where you are and when you buy.

So, the prices will fluctuate often and may make a big difference depending on where you are and when you buy.

Original Prusa i3 MK3S+: $1,000

As for the Original Prusa i3 MK3S+: Prusa offers good support, a fantastic community, and a supremely well made printer. This is my go to recommendation for nearly everyone I meet. It’s just utterly fantastic and so well-made. Tweak this thing, understand it, and you’ll get utterly amazing prints off of it. It can be finicky when manhandled, so, in a shared environment, it may be less helpful than something that has fewer options and tweaks. Other than that, this could comfortably be your first and last 3D printer. You can take this thing from your first print to manufacturing. I kid you not. I love this 3D printer.

CraftBot Plus Pro: $1,400

I’m a big CraftBot fan and the CraftBot Plus Pro is a straight up fire-and-forget printer with a large build volume, a nifty touch screen, and good build volume. It’s not complicated, has remained largely unchanged for a few years now ,but it is dependable and good value. A great option for in the classroom or in a shared environment.

A great option for in the classroom or in a shared environment.

Dremel Digilab 3D45: $1,300 to $1,800

The Dremel Digilab 3D45 is another simple but easy-to-use printer. It is very easy from the get-go and generally works very well. With widely diverging prices on offer right now, something truly weird is going on with the pricing, which could indicate that the model is to be replaced. This is a good printer for a classroom or shared workspace. Prints are never amazing, but it just works. This will be a very limiting printer for those who wish to tweak and experiment at length. You’ll get better results from a Prusa Original, if you want to put in more time.

Formlabs Form 3+: $3,500

The Form 3 3D printer from Formlabs. Image courtesy of Formlabs.

The Formlabs Form 3+ offers great software, industry-leading UX, and as close as you can get to one-click 3D printing. I love using these machines and love having them around the house. They’re reliable and good systems that keep on printing. Consumable costs will become excessive if you start manufacturing with these, but from one printer to a cluster or library-full, these are fantastic machines. More functional materials and design changes that solve problems for users make this a sure-fire pick. If you’re making jewelry, lost-wax casts, or moulds, then this should be your pick.

Consumable costs will become excessive if you start manufacturing with these, but from one printer to a cluster or library-full, these are fantastic machines. More functional materials and design changes that solve problems for users make this a sure-fire pick. If you’re making jewelry, lost-wax casts, or moulds, then this should be your pick.

Ultimaker S5: $6,400

Older now, the Ultimaker S5 has optimized more materials for it over time and more settings available. Quick interchangeable nozzles are a huge win for anyone in a corporate setting. They’ll also save you lots of money. It’s a very reliable printer with a high repeatability that is very easy to use. It gets pricy when you choose the optional air manager, but it’s an unbeatable pick if you’re an enterprise customer looking for an FDM machine.

BCN3D Epsilon W50 $9000

The BCN3D Epsilon W50 is a big machine that’s made to appeal to users in a shared environment. A great choice for corporate labs, offices, and universities. The filament bays inside the machine are lovely and it’s reliable and easy to use. A high-price choice but one that could really pay off for the right client.

The filament bays inside the machine are lovely and it’s reliable and easy to use. A high-price choice but one that could really pay off for the right client.

If you would ask me for one printer to buy, then I would recommend that you get a Prusa Original MKS3 for $1,000. This is a supremely well-made machine that, with a bit of tweaking, can get you some of the best 3D prints out there. And it will last you a long time.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: Anycubic Photon Mono X • Artillery Sidewinder • Buyer Guides • CraftBot Plus Pro • Creality Ender 3 V2 • Dremel DigiLab • formlabs • Formlabs Form 3+ • prusa • Prusa i3 MK3S+ • ultimake s5 • ultimaker • Ultimaker S5 • Voxelab Aquila

Please enable JavaScript to view the comments powered by Disqus.

3D Printer Buyer's Guide

Think It Right

Start-up Costs

Consumables Costs

Operating Costs and Savings

Service and Maintenance Costs

The Toughest Economics Survive

ConclusionsChoosing the right 3D printer is important now more than ever. A wisely chosen 3D printer will greatly speed up the iterative development process.

Think things through

Hard times are the strongest argument for investing in 3D printing and its opportunities. Money spent on a 3D printer will provide strategic benefits not only in the long term: it will increase the efficiency of development, accelerate the time to market for new products, and this will immediately lead to lower costs. The mainstream trend in 3D CAD technology is to use more and more models in the early stages of development - this increases the level of collaboration on the project, and the detected errors are eliminated long before production begins. In large-scale developments that require gradual fine-tuning (the so-called iterative developments), 3D printers, at quite reasonable costs, can reduce the overall cost of the model. nine0003

nine0003

Wherever 3D printers appear, they revolutionize the world. Designers can bring their concepts to life in full color realistic models. Marketers begin to promote a product even before its production begins. In some cases, 3D modeling technology can be used for small-scale production of samples. But in order not to make a mistake in the choice, the decision maker must evaluate not only the direct costs of acquiring a 3D printer, but also all the others - often they can decide the fate of the purchase. It is even more important to find out in advance how 3D printers differ from each other and by what parameters you can compare devices from different manufacturers. nine0003

Start-up costs

Factors to consider include the cost of the device, maintenance during the first year of operation, the cost of post-treatment equipment, and possible additional equipment. Add to this the starter kit of consumables, installation and training costs, maintenance during the second year of operation and beyond. nine0003

nine0003

These costs are not always obvious. Beware of "basic" kits. What does such a kit actually include? Some manufacturers limit it to the main device, and in order to get a fully functional system (or, in some cases, implement certain functions), you will have to invest in additional equipment for pre- or post-processing. Moreover, the devices of some manufacturers have increased requirements for energy consumption and operating conditions (for example, their operation is associated with the release of toxic fumes and the formation of chemical waste). nine0003

Some kind of post-processing is required for any 3D printer product, but the methods of this processing are extremely diverse, including in complexity. It is one thing when the product is enough, for example, to blow it with compressed air or immerse it in water to wash off the dust, and quite another when it comes to special devices and special cutters for removing mechanical supports. Depending on the manufacturer of the machine and its features, you may need additional ventilation equipment or special stands just to install the 3D printer in a convenient position for work. nine0003

nine0003

Consumables costs

Another factor is the cost of consumables. It varies greatly depending on the type of processing, the specific geometry of the components and the specific application. For example, the use of a 3D printer for conceptual modeling requires that many parts be created in a short time during the development of a new product. Since some materials are objectively more expensive than others, the use of expensive materials will be too costly. In addition to the cost of materials, there may be others related to the manufacturing process and at first not manifested in any way. Some machines use simple, commercially available interchangeable printheads. Others require critical components only from the manufacturer. Moreover, in this case, additional materials are used for the structures supporting the protruding elements and the solvent containers. The starter kit is often supplied with the device, and its size and composition significantly affect the costs during the first year of operation. nine0003

nine0003

When estimating the cost of consumables, identify the various components of these costs. The objective comparison parameter is the cost per unit volume of the simulated part - this is more reliable than comparing the cost per unit weight of the manufactured product. Be realistic about future work: the consumable requirements for modeling mobile phone components may be different than when modeling an exhaust pipe or pump housing.

All types of 3D printers use more material when working than what is left in the finished part - the material is taken with a margin. Some systems provide for the reuse of some or all of the consumables, others do not allow any reuse. These differences in process organization can lead to significant differences in material costs over time.

Some used consumables are difficult to dispose of or reuse, while others can be downright dangerous. All these are additional costs. nine0003

Operating costs and savings

The time factor contributes greatly to the overall cost picture. On different devices, the execution time of the same process can vary by more than five times. The same applies to individual operations: some operations require more actions than others (including the setting of parameters, which affects the scheduling of tasks and the need to involve qualified personnel). nine0003

On different devices, the execution time of the same process can vary by more than five times. The same applies to individual operations: some operations require more actions than others (including the setting of parameters, which affects the scheduling of tasks and the need to involve qualified personnel). nine0003

Similar printers from two different manufacturers can form comparable products, but differ significantly in speed and cost of production. For example, let's take a model of a pulley with a diameter of 6 inches (see figure). The average cost of making a multi-color part on a machine from manufacturer A is $3.41 per cubic inch of production, while it is $5.56 per cubic inch for making single-color components on a printer from manufacturer B, which is almost twice as much. . Manufacturer A's printer takes (including setup time) 5.17 hours to produce one part; the material cost would be less than $47. Manufacturer B's printer takes 21.63 hours to complete the same job for $80 supplies, and the model will need to be repainted later. nine0003

nine0003

The next article of potential time and money savings is device performance. This term refers to the total amount of output that can be produced in a certain time. Using reference parts with different geometries (see graph), manufacturer A's printer is producing 120-220 cubic inches of product in 24 hours, and manufacturer B's printer is only 15-25 cubic inches in the same time, so in terms of overall productivity, The performance of the first device is almost an order of magnitude better. nine0003

Some printers can make multiple copies of a sample (or different samples) in a single pass, allowing multiple users to work. Thus, productivity can also be calculated based on the number of copies of reference samples that can be made in a given time. This factor is very important when an entire engineering department or a group of students share the same 3D printer. What kind of time savings and productive work can we talk about, for example, when an engineer is tenth in line and waits a week for a part to be manufactured according to his project . ..

..

Considering all relevant factors, including purchase, service, and shipping costs, as well as the performance that comparable 3D printers can deliver, there is a significant difference in part cost and lead time. Some of the results of comparing printers from the two leading companies are shown in the graphs.

Service and maintenance costs

Finally, you need to evaluate how much general and routine maintenance will cost, whether there is a guarantee and for how long it will be provided, what exactly is covered by the guarantee and what is not. nine0003

Conclusions

In short, just as when choosing a car, you look not only at its cost, but also at convenience, appearance, evaluate its reliability, take into account fuel consumption, so buying a 3D printer requires the same careful approach. Investing wisely in a 3D printer can help you reduce your product development costs and get your product to market faster, which is a huge advantage in a highly competitive environment.

CAD and graphics 7`2009

- 3d printer

- consistent software distribution

3D printer filament buyer's guide

- home

- 3D printing technologies

- Weld FDM, FFF and FGF material nine0114

- 3D Printer Plastic Filament Buyer's Guide - Part 3

Article start at link - part 2

15 - PC-ABS

Polycarbonate ABS alloy (PC-ABS) is a tough thermoplastic that combines the strength and heat resistance of polycarbonate with the flexibility of ABS. Widespread in the automotive, electronics and telecommunications industries, it is one of the most widely used industrial thermoplastics in the world. nine0003

USER NOTE

As a 3D printing filament, PC-ABS has all the same benefits, but there is a downside, a slightly more complex printing process. Firstly, PC-ABS is hygroscopic, so it is recommended to dry it before printing, or at least store it in proper conditions. Second, it requires a high printing temperature of at least 260°C. Thirdly, it tends to shrink, and, as a result, the deformation of the first printed layer, therefore, a high temperature of the printing table is also required (not less than 100 °C and not more than 140 °C). nine0003

Firstly, PC-ABS is hygroscopic, so it is recommended to dry it before printing, or at least store it in proper conditions. Second, it requires a high printing temperature of at least 260°C. Thirdly, it tends to shrink, and, as a result, the deformation of the first printed layer, therefore, a high temperature of the printing table is also required (not less than 100 °C and not more than 140 °C). nine0003

WHEN SHOULD PC-ABS THREADS BE USED?

Functional prototypes, tools, and small-scale end-use parts that must withstand minor shocks and impacts.

Summary

-

pluses : combines the best qualities of PC and ABS

-

minuses : this material needs high operating temperatures of the heating tip of the extruder and the printed table, and therefore intelligent to the roller. pre-drying before printing

16 — PEEK

The American company Imperial Chemical Industries (ICI) developed polyetheretherketone (PEEK) back in the 1980s. In its basic form, this material is a high purity, semi-crystalline polymer containing repeating monomers of two ester groups and a ketone group.

In its basic form, this material is a high purity, semi-crystalline polymer containing repeating monomers of two ester groups and a ketone group.

PEEK belongs to the polyketone polymer family (PAEK), along with other family members such as PEK, PEEKK, PEKK or PEKEKK. However, it outshines its relatives due to its outstanding properties and wide range of applications, making it the most widely used of this particular group of polymers. nine0003

Let's look at some of the more well-known PEEK attributes.

PEEK properties:

-

PEEK has a number of attractive features, especially when it comes to the production of functional prototypes and parts. Here is a summary of the most important properties:

-

High resistance to temperatures up to 260°C (480°F) as well as aggressive liquids, gases and high pressure no decomposition with water or high pressure steam

-

Light weight: PEEK has a low specific gravity of 1.

3 g/cm 3 which is less than half that of aluminum and one sixth that of steel.

3 g/cm 3 which is less than half that of aluminum and one sixth that of steel. -

Self -combusted material - high antifriction properties, low friction

-

High crease resistance

-

Very low abrasion

-

Citing the dosage and slight fertility and slight ignorance and slight fertility0003

-

Exceptional insulating properties

-

Excellent resistance to sterilization at a high temperature of

-

Fully used

Some of these high -stability properties can be additionally improved by combining PEEK with composite materials, such as glass -wind , molybdenum disulfide or carbon fiber.

PEEK limits

Unfortunately, as with all materials that are used in additive manufacturing, PEEK also has some limitations.

For starters, it can be handled at very high temperatures. The melting point of PEEK is 343°C (649.4°F).

When it comes to chemical resistance, PEEK struggles to resist chlorine/bromide, concentrated sulfur and nitric acid, as well as ketones and nitrobenzene. PEEK is also exposed to halogens and sodium, which limits its use in certain industries. nine0003

PEEK is also exposed to halogens and sodium, which limits its use in certain industries. nine0003

In addition, PEEK has low UV resistance. This can be circumvented by adding a layer of pigment, which consists of special soot particles. Carbon grades provide improved UV resistance and can be used in certain applications where higher UV resistance is required.

Overall, the technical advantages and possibilities far outweigh the limitations of the material, opening up a wide range of applications where PEEK-based objects and parts can be used or even replace conventional materials such as steel or aluminum. nine0003

17 - PEKK

PEKK is a high performance polymer from the PAEK family with a wide range of applications. The material is highly versatile: it combines chemical resistance, flame retardant properties and mechanical properties that are among the highest of any known thermoplastic material. The crystallization rate is slightly slower than PEEK, which makes it much easier to control and can result in better layer adhesion. Due to improved interlayer adhesion, PEKK can achieve even higher tensile strength compared to PEEK. nine0003

Due to improved interlayer adhesion, PEKK can achieve even higher tensile strength compared to PEEK. nine0003

Due to its chemical resistance, PEKK can be used as a material for components exposed to acids and hydrocarbons, such as fuels and lubricants. Many polymer materials, when placed in a vacuum, begin to decompose, releasing gaseous short polymer chains or even monomers. In PEKK, this tendency to decomposition with gas formation is very weakly expressed - practically absent - therefore, it is possible to manufacture external parts of spacecraft from it, which are in vacuum, without fear of their decomposition due to gas formation. Finally, its high operating temperature makes it suitable for the production of components located in engine compartments. It is generally understood that PEKK will be printed and left in an amorphous state. PEKK is very sensitive to moisture. nine0003

PEKK vs. PEEK

PEKK and PEEK have very similar chemical structures, with two key differences.

The chemical structures of PEEK (top) and PEKK (bottom) are marked by the different placement of the last bond on the right.

-

PEKK replaces one of the flexible ester bonds with a more rigid ketone group. This increases the glass transition temperature (Tg) - where the material first begins to soften - by about 15°C above PEEK. nine0003

-

The second ketone group is selectively ortho (straight) or para (curved) substituted. By changing the number of straight and curved sections, it is possible to control the melting temperature and crystallization rate.

For example, a PEKK polymer with 60% straight and 40% curved segments will melt at around 305°C and crystallize so slowly that it is often referred to as "pseudo-amorphous".

The same polymer with 80% straight and 20% curved segments will have a melting point of about 360°C and a crystallization rate similar to PEEK. nine0003

Tunable PEKK crystallization rate allows the FFF user to take advantage of both the extreme performance of PAEK and the easier handling of amorphous materials. Simply put, PEKK is easier to 3D print than PEEK (i.e., better adhesion to the layer), and yet it offers similar strength and resistance properties (i.e., better dimensional accuracy).

Simply put, PEKK is easier to 3D print than PEEK (i.e., better adhesion to the layer), and yet it offers similar strength and resistance properties (i.e., better dimensional accuracy).

Most PEKK filament users report successful prints on the first try, and many find it as easy to print as ABS. The material is also available in carbon fiber reinforced types. nine0003

18 - PEI / ULTEM - Alternative to PEEK

While the demand for PEEK-based parts is growing exponentially in various industries, pharmaceuticals, petrochemicals or food packaging, its high cost keeps it out of the industry. Fortunately for all consumers, there is an alternative: ULTEM is a polyetherimide (PEI) derivative.

Polyetherimide (PEI) is an amber to clear amorphous thermoplastic. Although both materials - PEEK and PEI - have the same resistance to high temperatures, they belong to different families of thermoplastics. PEEK has several different forms, PEI, on the other hand, lacks a ketone in its molecular structure. For a complete analysis of material properties, compare PEEK and PEI. nine0003

For a complete analysis of material properties, compare PEEK and PEI. nine0003

In 1982, GE's plastics division developed PEI. In 2007, SABIC acquired the rights to commercialize it under the registered trademark ULTEM. In addition to the basic ULTEM, a number of its less expensive modifications are produced, which, as a rule, differ in properties towards lower impact strength and operating temperature, which can make them less suitable for use in extreme conditions. In recent years, SABIC, the manufacturer of ULTEM, has received a number of aerospace certifications, allowing the material to be used to 3D print plastic parts for commercial aircraft. nine0113

Stretch strength: Peek has a higher tensile strength than PEI

Certificates: ULTEM ® 3D-compatible thread received aerospace certificates

Thermal resistance: Peek has a higher thermal resistance than PEI 9000 90

PEEK and ULTEM

® filament pricePEEK filament price

Polyetheretherketone (PEEK) material is one of the most expensive plastics on the market: its wholesale price can vary from manufacturer to manufacturer0132 from 400 to 700 dollars per kilogram .