What do 3d printers make

What can you make with a 3D printer?

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

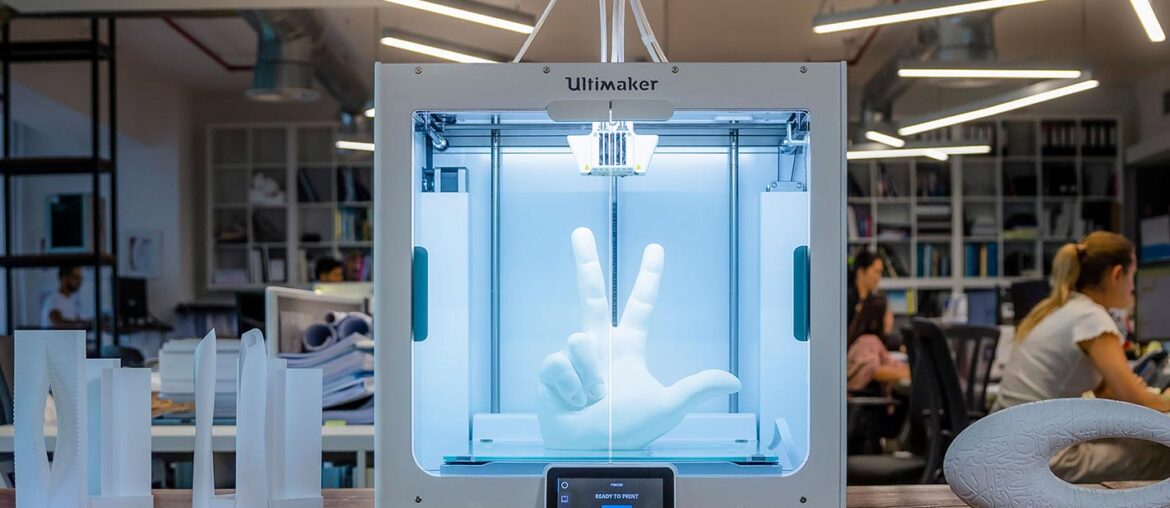

What can you make with a 3D printer and additive manufacturing technologies?

In one way or another, 3D printing is being used in almost all industries. So, when you’re wondering what can be made with additive manufacturing, the short answer is almost anything.

Applications of additive manufacturing

Many industries are harnessing the power and flexibility of 3D printing. Here are some of the most common products that are currently made with 3D printing:

- Consumer products (eyewear, footwear, design, furniture)

- Industrial products (manufacturing aids and tools, prototypes, functional end-use parts)

- Automotive and aerospace prototypes and final parts

- Medical, healthcare, and dental products

- Prosthetics and orthotics

- Architectural scale models and maquettes

- Reconstructing fossils and ancient artifacts

- Reconstructed evidence for forensic pathology

- Movie props

This list is not exhaustive, and 3D printing is used for a huge variety of purposes. And it’s not just final manufacture, it can help improve almost every phase of the manufacturing process, starting right from the beginning.

Transforming design with rapid prototyping

Aside from the ability to transform the production of final parts, one of the most useful and common applications of 3D printing and additive manufacturing is for rapid prototyping. Using 3D printing to develop new products is helping manufacturers around the world reduce time to market and increases opportunities for efficiency and innovation.

Back to menu

Why use 3D printers for rapid prototyping?

Basically, because it’s cost effective and fast, in fact, with 3D printing, it can be possible to go from an initial idea to a working prototype in a matter of days. This could cut weeks out of product development time. Depending on the application, you could even make a fully functional prototype in the final material, allowing you to better evaluate and test your designs.

If you need to make changes, you’ll find that iterations are faster and cheaper to make, allowing you and your team to work quickly to improve all aspects of your products.

And you need not stop at prototyping: 3D printing can also be used for short-run production, one-off custom products, or full-scale final part production – and also spare parts. It’s a complete end-to-end technology, so it can transform every aspect of your business.

Sectors that use 3D printing and applications of additive manufacturing

3D printing and additive manufacturing are exceptionally flexible and can be used in almost all industries. Here are a few of the most common industries and examples of how 3D printing and additive manufacturing are being used.

Industrial applications of the additive manufacturing process

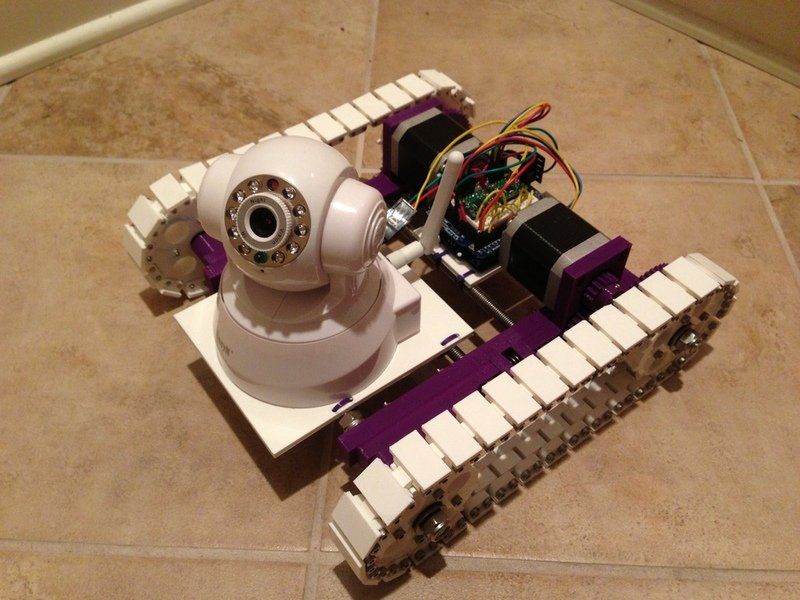

3D printing is fast becoming a key technology for efficient design and production in the industrial sector. Examples of industrial 3D printing applications where additive manufacturing can enhance performance and cut lead times and costs include manufacture of machinery and industrial equipment, production line components, robots, and end-of-arm-tooling (EOAT), molds, manufacturing aids, tooling, jigs, and fixtures.

Back to menu

Data courtesy2

3D printing in the automotive industry

Car makers around the world are using 3D printing to design and build prototype and final car parts – as well as spare parts, tools, jigs, and manufacturing aids. Overall, additive manufacturing has shortened the design and production process and has allowed for on-demand manufacturing, which reduces the need for inventory, warehousing, and storage.

But it isn’t just brand-new vehicles that benefit. Automotive enthusiasts are using 3D printed car parts to restore classic cars.

Automotive 3D printing case study

HP 3D printing helps CUPRA Racing create lightweight components for a new race car

Barcelona based SEAT is the only company that still designs, develops, and manufactures cars entirely in Spain. CUPRA is a stand-alone company within the SEAT organization that produces high-performance vehicles, including race cars.

During the conceptualization stages of their new racing car the CUPRA Leon Competición, CUPRA was faced with the challenge of quickly creating prototypes for some of the car’s lightweight components, including side mirrors, air vents, and a central control module for the steering wheel.

CUPRA turned to 3D printing - specifically the HP Jet Fusion 5200 Series 3D Printing Solution. Together, they were able to rapidly iterate designs, test those designs, and progress to the final product in a reduced time frame.

HP Metal Jet reduces car part production time at Volkswagen

Volkswagen, one of the world’s largest and most innovative vehicle makers, has adopted HP Metal Jet technology to produce high-performance functional car parts with specific structural requirements, such as gearshift knobs and mirror mounts.

Data courtesy3

“Our vision to industrialize additive manufacturing is quickly becoming a reality with HP Metal Jet. It is a game changer for the automotive industry,” says Dr. Martin Göede, Head of Technology Planning and Development for Volkswagen.

It is a game changer for the automotive industry,” says Dr. Martin Göede, Head of Technology Planning and Development for Volkswagen.

Back to menu

3D printing in the aviation and aerospace industry

Aviation and aerospace companies were early adopters of printing and additive manufacturing. As you might expect, some of the most rigid performance standards apply to this industry, and that creates the need for parts that are reliable in demanding conditions. Engineers who are designing and manufacturing for commercial and military aviation and aerospace need components made from the highest performance materials, and 3D printing is being used at all stages of design and production.

Back to menu

3D printing in the construction, architecture, and interior design industries

While 3D printed houses are already commercially available, most construction companies use the technology to produce pre-fabricated parts, often onsite.

These are usually large-scale concrete printing systems with wide nozzles that allow for large flow rate. This can be used to lay down concrete layers quickly, but also repeatably. However, 3D printing can also be used for more delicate and refined parts and intricate models as well.

Prior to construction, 3D printing can be beneficial to architects during the design phase. Take, for example, the Korean 3D printing service HS HI-TECH which used HP Multi Jet Fusion 3D printing technology to create uniquely designed architectural elements and build modular structures.

3D printing can also bring great benefits in terms of innovation and design freedom for interior design, home decoration, and furniture – such as custom-designed furniture and lighting.

Back to menu

3D printing for the medical and healthcare industry

The medical and dental industry is one of the fastest-growing adopters of additive manufacturing. From medical devices to prosthetics and even bioprinting, the applications of additive manufacturing for the medical industry are wide-ranging and often revolutionary.

The benefits of 3D printing for medical and dental

The freedom afforded by 3D printing and the ability to provide personalized solutions for patients in an efficient manner is driving huge growth in the medical and dental sectors. When coupled with detailed scanning, 3D printing can be used to provide highly customized patient-specific solutions like orthotics, prosthetics, or dental appliances.

Thanks to rapid prototyping, medical device manufacturers have freedom to design new products and help bring new medical devices to the market faster than ever.

Medical 3D printing case studies

Everex manufactures medical devices faster and at a lower cost

Everex is an Italian engineering company that creates unique and technologically advanced products that specialize in instruments for in-vitro diagnostic (IVD) analysis, the concept, and design of which are proposed by the customer.

Everex has recognized 3D printing as a crucial technology for new products, specifically in the field of diagnostic instruments.

One of Everex’s devices is called Hemo One, which is used to analyze samples of blood through clinical chemistry. All parts that comprise Hemo One were previously produced using traditional methods, but now are made with 3D printing or additive manufacturing.

Data courtesy4

Biotec Italia s.r.l. produces electromedical parts faster with HP 3D Printing

Biotec Italia s.r.l. produces machinery for electromedical and aesthetic applications. Biotec wanted to manufacture parts for its CoaxMed machine, a revolutionary combination of monopolar, bipolar, fractional radiofrequency (RF), low-frequency ultrasound, vacuum massage, and cryliposculting technologies, and turned to HP Multi Jet Fusion (MJF) technology to help accelerate production.

3D printing for orthotics and prosthetics

With its core focus on enhancing patient comfort, the medical industry is leveraging the capabilities of 3D printing to create patient-specific devices, like prosthetics and orthotics. The benefits of design freedom and rapid production of customized devices make 3D printing an appealing alternative versus traditional manufacturing methods.

The benefits of design freedom and rapid production of customized devices make 3D printing an appealing alternative versus traditional manufacturing methods.

Data courtesy5

Additive manufacturing for bioprinting

One of the most revolutionary applications of 3D printing is its potential use in the nascent field of bioprinting. Around the world, biotech firms, researchers, and academics are exploring the possible use for 3D printing in tissue engineering applications to create cells and organs, including inkjet bioprinting techniques, where layers of bio-ink, that is mostly comprised of cells, are deposited onto a hydrogel substrate, and are then slowly built up to form fully 3D structures.

Back to menu

The role of 3D printing technology during the COVID-19 pandemic

In spring 2020, hospitals were confronted with a new challenge when the COVID-19 virus began to take hold around the world. It wasn’t long before the global supply of personal protective equipment (PPE) and medical devices were dwindling, and the medical community turned to technology to solve the shortage. Throughout the pandemic, 3D printing was used to supply healthcare staff with much-needed PPE, as well as spare parts to fix overworked ventilators.

It wasn’t long before the global supply of personal protective equipment (PPE) and medical devices were dwindling, and the medical community turned to technology to solve the shortage. Throughout the pandemic, 3D printing was used to supply healthcare staff with much-needed PPE, as well as spare parts to fix overworked ventilators.

Global corporations, start-ups, and even high-school students with 3D printers answered the call. Thanks to 3D printing, millions of items of PPE and ventilator parts have now been shipped to hospitals around the world.

HP 3D Printing helped enable the design and manufacture of millions of critical medical parts to help mitigate the medical supplies shortage.

3D printing in the dental industry

The dental industry may contain the single most 3D printed object in the world: the mold for clear aligners. These molds can be 3D printed with powder- and resin-based 3D printing processes, and with material jetting. But this is not the only dental product to be 3D printed: in fact, crowns, dentures, and surgical guides can all be made too.

But this is not the only dental product to be 3D printed: in fact, crowns, dentures, and surgical guides can all be made too.

Dental 3D printing case study

SmileDirectClub scales dental aligner 3D print production to deliver straighter smiles to millions

SmileDirectClub is the first direct-to-consumer med-tech platform for teeth straightening and transforming smiles. SmileDirectClub had a dental aligner production method in place since its inception in 2014, but due to its growing customer base, the company needed a manufacturing technology that would allow them to meet the increasing demand for at-home clear aligner therapy. Their previous technology produced delicate, fragile parts at slow speeds and high costs.

Data courtesy6

“The volume output over a 24-hour time frame was low and we needed to find a way to increase volume output,” said John Dargis, Vice President of Manufacturing for SmileDirectClub.

This led Dargis and his team to research technologies that would enable them to mass-produce molds to create dental aligners, and thus deliver orthodontic solutions to customers more quickly. Today, they use HP 3D Printing, and the impact has been transformative.

Back to menu

3D Printing in the consumer goods industry

3D printing in the footwear sector

Before shoes were made in a range of uniform sizes, they were all custom made to fit individual feet. However, the requirement to produce in large quantities made custom production prohibitively expensive.

With 3D printing, custom-made footwear can be produced, even at scale.

“One hundred years from now, we might look back and see that the moment of industrialization where we had to fit into pre-existing sizes and styles was a blip in the history of shoemaking,” says Elizabeth Semmelhack, senior curator at the BATA Shoe Museum in Toronto. “Today, we’re moving back to bespoke footwear.”

“Today, we’re moving back to bespoke footwear.”

Data courtesy7

This revolution is led by new technologies that scan your foot and create a digital 3D model of your foot. That model is sent to a 3D printer, which creates a unique insole that you can wear inside any shoe, allowing everyone to experience a new era of truly personalized shoe shopping.

3D printing in ophthalmology and eyewear

3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

Eyewear 3D printing case study

HORIZONS OPTICAL manufactures parts for custom eyewear with HP Multi Jet Fusion.

HORIZONS OPTICAL develops technologies and services to ophthalmic laboratories, optical chains with production capacity, and other industries in the optical sector. HORIZONS OPTICAL’s “Made4U” concept allows customers to personalize their eyewear based on their unique physical characteristics, visual needs, and personal taste.

Data courtesy8

With HP Multi Jet Fusion technology, HORIZONS OPTICAL created an end-to-end solution for customized eyewear. This includes using specialized software to take a 3D scan of the face, collect biometric data, allow customers to virtually try on glasses, and choose from a range of color options for the frames. Once the customization and fitting processes are completed, the glasses are sent to be 3D printed.

Back to menu

3D printing in the jewelry and wearables industry

3D printing can produce jewelry with direct or indirect production processes. Direct includes the creation of an item straight from a 3D design, while indirect manufacturing is 3D printing a mold that will be used to later create an item of jewelry. Working in either of these ways is helping to revolutionize the jewelry industry around the world.

3D printing in the sports equipment sector

Unlike other clothing and fashion sectors, the sports equipment industry places its primary focus on performance. This means that offering a customized fit can enhance the performance of an athlete and give them a competitive edge over their opponents. 3D printing is helping to provide custom-made equipment and footwear to sports professionals and athletes around the world.

This means that offering a customized fit can enhance the performance of an athlete and give them a competitive edge over their opponents. 3D printing is helping to provide custom-made equipment and footwear to sports professionals and athletes around the world.

Sports equipment 3D printing case study

Cobra Golf and Parmatech 3D print custom made golf putters

Cobra Golf and Parmatech used HP Metal Jet to launch Cobra Golf’s 3D printed golf putter: the KING Supersport-35. This limited edition, fully 3D printed putter with SIK face technology delivers the next level in personalization and putter performance.

Data courtesy9

Other 3D printing applications for the sports industry can range from protective sports equipment, including helmets and padding, or even innovative table tennis accessories.

Back to menu

3D printing in the education sector

3D printers have a variety of applications in the classroom and can enable teachers and students to create new models and prototypes quickly and cheaply.

There are still only a few degree courses that entirely specialize in additive manufacturing, but they are growing all the time, and many engineering, design, or product development departments will now have access to an onsite 3D printer. This is in addition to courses that allow students to specialize in CAD and 3D design, all of which can encompass experience with 3D printing.

No matter what the subject is, if the production of rapid models or prototypes is required, 3D printing is the optimum solution. Whether architectural, industrial, or even artistic models are required, 3D printing offers the fastest way to work, the best results, and a chance to future-proof the education of students around the world.

Back to menu

Want to continue learning?

Footnotes and disclaimers

- Data courtesy of Cupra

- Data courtesy of Fast Radius

- Data courtesy of Volkswagen

- Data courtesy of Everex Srl.

- Data courtesy of Twikit. Printed by ZiggZagg (HP DMN partner)

- Data courtesy of SmileDirectClub

- Data courtesy of Superfeet

- Data courtesy of Horizons Optical SLU

- Data courtesy of Cobra Golf

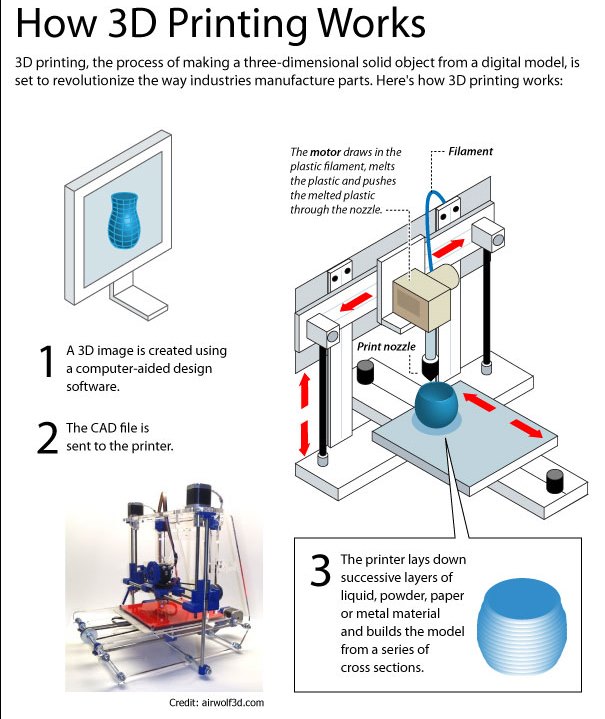

3D Printing: What It Is, How It Works and Examples

3D printers might seem like they're right out of a science fiction movie, but they're proving to be useful in a variety of industries. | Image: ShutterstockHow Do 3D Printers Work?

3D printing is part of the additive manufacturing family and uses similar methods to a traditional inkjet printer — albeit in 3D. Additive manufacturing describes the process of creating something in layers, adding material continuously until the final design is complete. This term most often refers to molding and 3D printing.

It takes a combination of top-of-the-line software, powder-like materials and precision tools to create a three-dimensional object from scratch. Below are a few of the main steps 3D printers take to bring ideas to life.

Below are a few of the main steps 3D printers take to bring ideas to life.

How Does a 3D Printer Work?

3D printers are related to additive manufacturing. 3D printers use computer-aided design to understand a design. When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

3D Modeling Software

The first step of any 3D printing process is 3D modeling. To maximize precision — and because 3D printers can’t magically guess what you want to print — all objects have to be designed in a 3D modeling software. Some designs are too intricate and detailed for traditional manufacturing methods. That’s where CAD software comes in.

Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is being hailed as a true game changer in many industries. This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

3D PRINTERS USE MODELING AND SLICING SOFTWARE TO GUIDE THE PRINTER IN CREATING EACH OBJECT. Video: Digital Trends

Slicing the Model

Once a model is created, it’s time to “slice” it. Since 3D printers cannot conceptualize the concept of three dimensions, like humans, engineers need to slice the model into layers in order for the printer to create the final product.

Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

The 3D Printing Process

When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to finally take over. The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

3D Printing Materials

There are a variety of different materials that a printer uses in order to recreate an object to the best of its abilities. Here are some examples:

Acrylonitrile Butadiene Styrene (ABS)

Plastic material that is easy to shape and tough to break. The same material that LEGOs are made out of.

The same material that LEGOs are made out of.

Carbon Fiber Filaments

Carbon fiber is used to create objects that need to be strong, but also extremely lightweight.

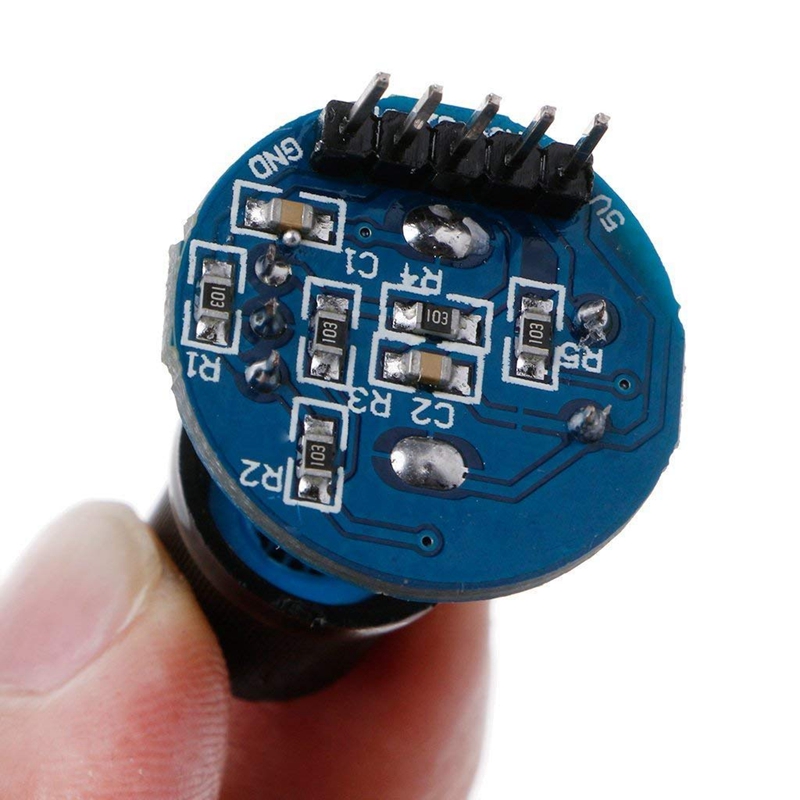

Conductive Filaments

These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology.

Flexible Filaments

Flexible filaments produce prints that are bendable, yet tough. These materials can be used to print anything from wristwatches to phone covers.

Metal Filament

Metal filaments are made of finely ground metals and polymer glue. They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

Wood Filament

These filaments contain finely ground wood powder mixed with polymer glue. These are obviously used to print wooden-looking objects and can look like a lighter or darker wood depending on the temperature of the printer.

The 3D printing process takes anywhere from a few hours for really simple prints, like a box or a ball, to days or weeks for much larger detailed projects, like a full-sized home.

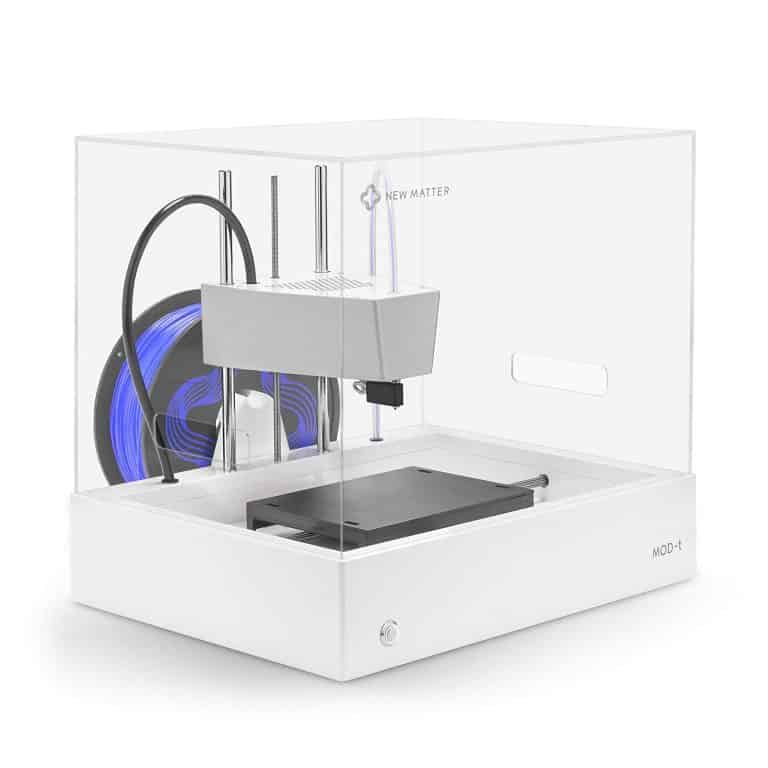

How Much Do 3D Printers Cost?

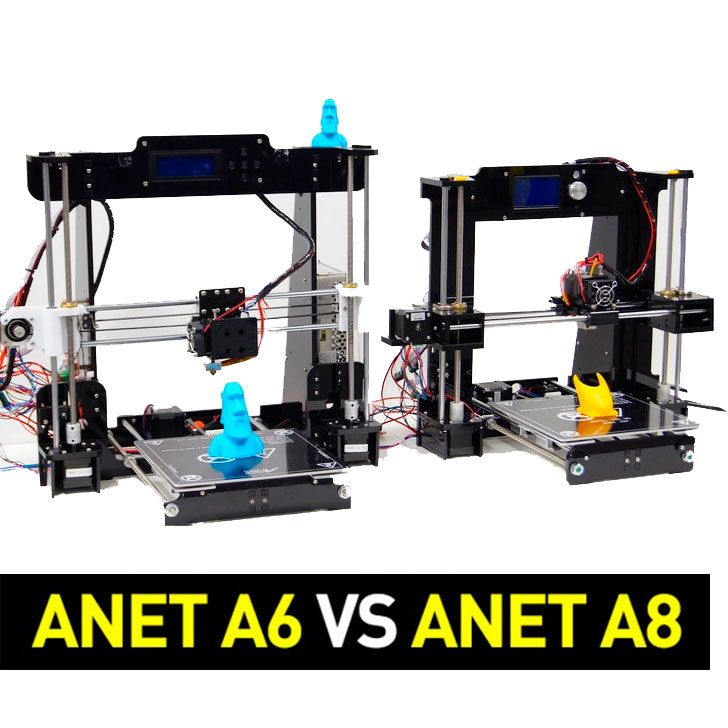

The cost of 3D printers vary based on the size, specialty and use. The cheapest 3D printers, for entry level hobbyists, typically range from $100 to $500. More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

3D Printing Processes and Techniques

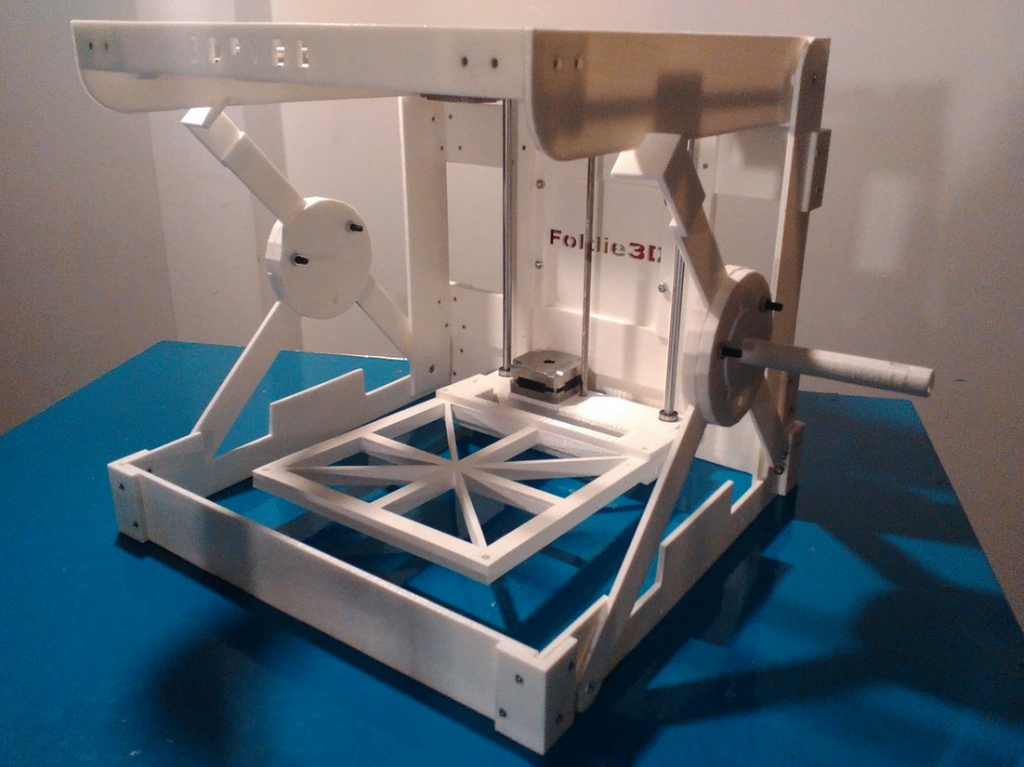

here are also different types of 3D printers depending on the size, detail and scope of a project. Each different type of printer will vary slightly on how an object gets printed.

Fused Deposition Modeling (FDM)

FDM is probably the most widely used form of 3D printing. It’s incredibly useful for manufacturing prototypes and models with plastic.

Stereolithography (SLA) Technology

SLA is a fast prototyping printing type that is best suited for printing in intricate detail. The printer uses an ultraviolet laser to craft the objects within hours.

The printer uses an ultraviolet laser to craft the objects within hours.

Digital Light Processing (DLP)

DLP is one of the oldest forms of 3D printing. DLP uses lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Continuous Liquid Interface Production (CLIP)

CLIP is amongst the faster processes that use Vat Photopolymerisation. The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

Material Jetting

Material Jetting applies droplets of material through a small diameter nozzle layer-by-layer to build a platform, which becomes hardened by UV light.

Binder Jetting

Binder Jetting utilizes a powder base material layered evenly along with a liquid binder, which is applied through jet nozzles to act as an adhesive for the powder particles.

Fused Deposition Modeling (FDM)

FDM, also known as Fused Filament Fabrication (FFF), works by unwinding a plastic filament from a spool and flowing through a heated nozzle in horizontal and vertical directions, forming the object immediately as the melted material hardens.

Selective Laser Sintering (SLS)

A form of Powder Bed Fusion, SLS fuses small particles of powder together by use of a high-power laser to create a three-dimensional shape. The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

Multi-Jet Fusion (MJF)

Another form of Powder Bed Fusion, MJF uses a sweeping arm to deposit powder and an inkjet-equipped arm to apply binder selectively on top. Next, a detailing agent is applied around the detailing agent for precision. Finally, thermal energy is applied to cause a chemical reaction. Direct Metal Laser Sintering (DMLS) also utilizes this same process but with metal powder specifically.

Sheet Lamination

Sheet Lamination binds material in sheets through external force and welds them together through layered ultrasonic welding. The sheets are then milled in a CNC machine to form the object’s shape.

Directed Energy Deposition

Directed Energy Deposition is common in the metal industry and operates by a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder. The powder is applied to a surface and energy source, which then melts the material to form a solid object.

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing? nine0012

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer—that is, it builds or grows. nine0005

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that converts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0005

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

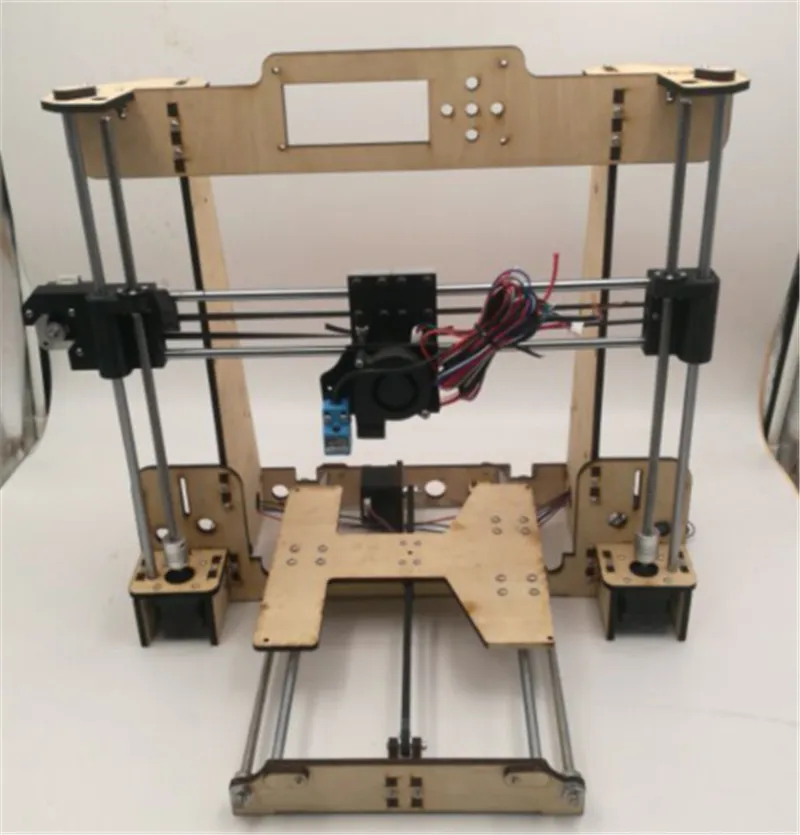

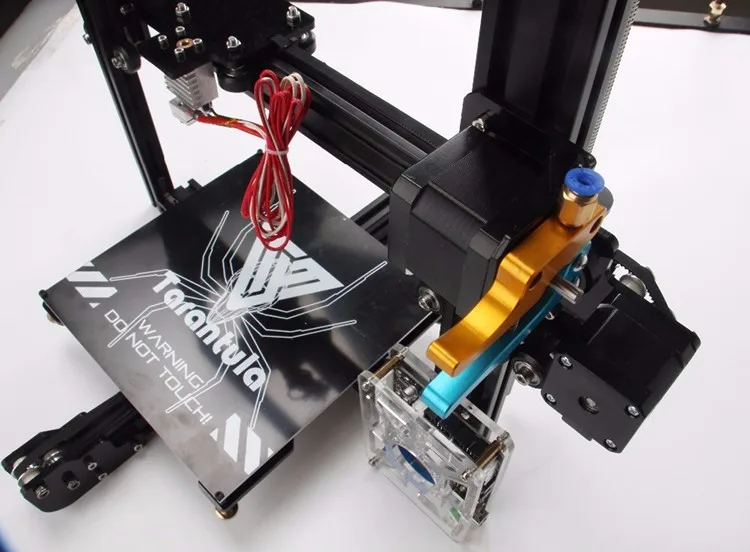

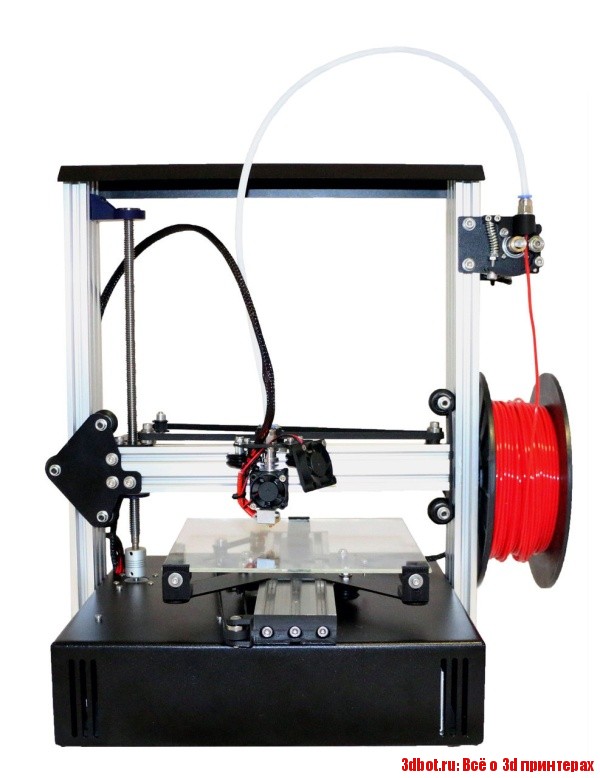

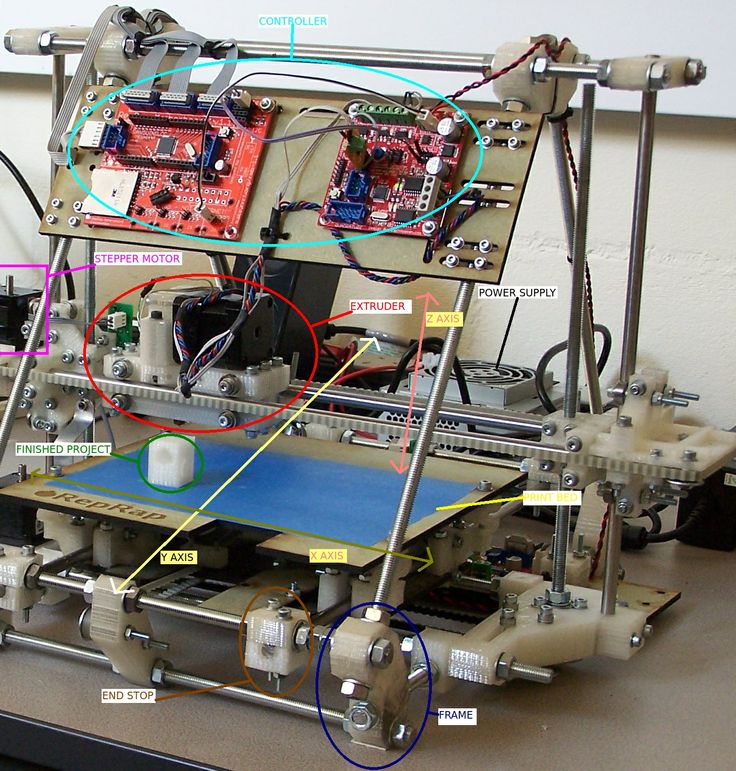

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed? nine0021

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical usage examples:

Here are some typical usage examples:

Custom Models

Create custom products that perfectly match your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.

Cost reduction

The cost of 3D printing end-use parts and prototypes is low due to the materials and technology used. Reduced production time and material consumption as you can print models multiple times using only the material you need. nine0005

How to choose and buy a 3D printer? →

what a 3D printer can do

3D printing possibilities

Unfortunately, the current level of awareness in 3D technologies leaves much to be desired. It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

3D printing application

When talking about the use of 3D printing, it is worth considering not only the existing possibilities, but also the prospects. Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers. nine0005

1. Prototyping

The best use of 3D printing is for its intended purpose. Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval. nine0005

Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval. nine0005

2. Small-scale production

For small-scale production, 3D printing is a godsend. The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts. nine0005

This application of 3D printing is extremely relevant for frequent orders for small batches of parts. nine0005

3. Repair and restoration

Another application of 3D printing is the repair and restoration of damaged parts. For these purposes, 3D printing is ideal. You can carry out such a procedure both independently, with the appropriate skills and equipment, and in specialized 3D printing services, such as 3DDevice. First, a correct 3D model is built on the basis of the damaged product. 3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time. nine0005

4. Production of functional models and finished components

One of the industrial applications of 3D printing is the production of functional models and finished components. Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components. nine0005

Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components. nine0005

Other questions and answers about 3D printers and 3D printing:

- Opportunities What is the future of 3D printing?

- Finance How to choose the right 3D printer?

5. Household items

Need an office organizer? Or a knife holder? Any household items can be printed on a 3D printer. The advantage of this application of 3D printing is that there are no restrictions when developing 3D models. That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively. nine0005

Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively. nine0005

6. Toys and souvenirs

Having a 3D printer makes it very easy to make a child happy – just make cute 3D toys. There are already some pretty interesting projects of collective 3D printed games, and in the future this list will only expand. This application of 3D printing will please not only children, but also enthusiastic collectors, because on a 3D printer you can print figures of any characters and attributes of computer games and films. And color 3D printing will make it possible to produce exclusive full-color souvenirs - miniature figurines of real people. To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual. nine0005

7. Design products

For creative people, there is another use for 3D printing. 3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production. nine0005

3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production. nine0005

8. Capabilities of a 3D printer

We have listed the main capabilities of a 3D printer, but they do not end there. 3D printing finds application in a wide variety of industries. With its help, electronics, various components, food and even living tissues are printed. Of course, this list will be replenished in the future, but already now it impresses with its scale. We hope that we were able to provide information about the existing application of 3D printing in an accessible way.