3D printer army men

3DShook– 3D Print your Toy Soldier Army at Home – 3DShook

With 5 exclusive toy soldier collections consisting of 79 soldiers in total, create the best war and battle scenarios ever by 3D printing toy soldiers. Our toy soldiers are carefully sculpted from scratch by our designers.

Of course you can mix-and-match all of our soldiers and create an epic battle! If you’re up for a little DIY project, you can paint each figurine. We’ve seen nail polish work great on PLA but other paints will do the job just as well.

By using your 3D printer to print toys at home – it’s a fun and cost-effective way that complete re-defines play-time…PLUS you don’t need to be worried about something breaking…just print it again!

Please remember it takes approximately 2 hours to print each soldier. So let’s explore our 5 collections of toy soldiers.

1. KNIGHTS Army

Build your Medieval kingdom army with our 15 3D printable knight soldiers set. Each soldier is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & armor.

Knights Army by 3DShook

Knights Army by 3DShook

2. SAMURAI Warriors

Print a fierce Japanese Samurai army with our 16 3D printable Samurai warriors currently offered in the 3DShook catalog. Japan’s military nobility fighters, ready-to-print & always ready for battle! Each soldier is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & armor.

Samurai Warriors by 3DShook

Samurai Warriors by 3DShook

3. ARMY Guyz

Print our classic Army Guyz with 16 3D printable soldiers to choose from. Dressed in military uniform and armed with weapons. These soldiers may remind you of your childhood or Pixar’s animated film Toy Story. Each army man is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & attire.

Army Guyz by 3DShook

Army Guyz by 3DShook

4. ARMY Girlz

Print our Army Girlz with our 16 3D printable soldiers to pick from. Dressed in military uniform and armed with weapons. These girls don’t take orders from nobody!! Each army woman is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & attire. Girl Power!

Dressed in military uniform and armed with weapons. These girls don’t take orders from nobody!! Each army woman is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & attire. Girl Power!

Army Girlz by 3DShook

Army Girlz by 3DShook

5. REBEL Girlz

These girls aren’t what you think they are, their professional at kicking butt and stand up against authority and control. In non-Western societies, these types of rebels exist and we created an amazing collection consisting of 16 3D printable rebel girls! Each woman is carefully sculpted by our designers in different poses & equipped with historically accurate weapons & attire. Girl Power!

Rebel Girlz by 3DShook

Rebel Girlz by 3DShook

We are always creating new and interesting toy designs to 3D print – stay tuned for more toy soldiers & accessories We welcome all of our users to share your prints with us in our user gallery

Happy Printing!!!

The 3DShook team

3d Army Men - Etsy.

de

deEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(355 relevant results)

Overview: 3D printers in military service

The military industry has always been at the forefront of progress: many inventions either began their life path as military or dual-use products, or, in the very first years after their appearance, were involved in this area. In this age of digital technology, this fate has not escaped 3D printing.

In this age of digital technology, this fate has not escaped 3D printing.

3D printers are actively used by military contractors and direct employees of all branches of the military.

In this article, we will talk about the use of 3D printing in the military-industrial complex around the world: from providing military equipment with spare parts, to operational printing of drones and buildings anywhere in the world. nine0003

Tables

- In Russia

- in the world

- - Aviation

- - Fleet

- - Military Weapons

- - Construction

- - Construction

- - Self -Probrition - Self -Probrition - Self -Production - Self -Production

- Conclusion

In Russia

JSC "Federal Research and Production Center "Titan-Barrikada", which develops missile systems and military vehicles, bought and uses in prototyping a kit based on the 3D printer XJRP SPS450B. The kit consists of two devices: directly a 3D printer with a large print area, working on SLA technology, and a polymer curing chamber. nine0003

The kit consists of two devices: directly a 3D printer with a large print area, working on SLA technology, and a polymer curing chamber. nine0003

XJRP SPS450B 3D Prototyping Kit.

Source: pechat3d.ru

The 3D printer is planned to be used to create miniatures of future parts, cases or mechanism assemblies. The first product made on this 3D printer was a prototype wheel with a tread.

Ilyushin specialists plan to produce some simple parts for the Il-112V military transport aircraft using 3D printing.

Il-112V transport aircraft model. nine0044

Source: © ITAR-TASS

Together with specialists from the Voronezh Aircraft Plant (VASO), PJSC 'Il' specialists use 3D-printed parts as test samples, which will be replaced with originals made by the classical method before departure . But in the future, it is planned to master the printing of simple components that will be installed on mass-produced aircraft.

Pavel Chernikov, First Deputy Director General of PJSC Il, said: “The IL-112V is being created from scratch, and many parts and components need to be improved during installation on the aircraft. We started using a 3D printer to see how right or wrong our calculations were. Such technologies make it possible not to interrupt the finalization of finished products, which, in turn, significantly reduces the installation time of equipment and reduces the cost of the production process.” nine0003

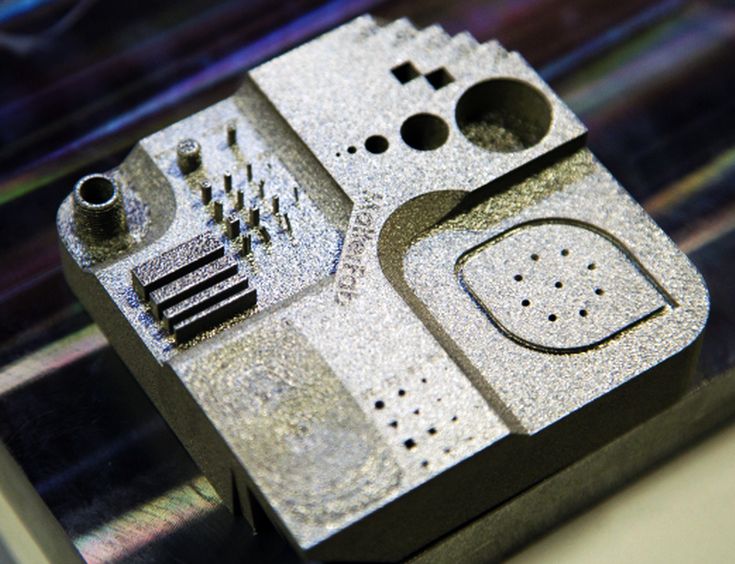

Research and Production Corporation 'Uralvagonzavod' named after F.E. Dzerzhinsky JSC has purchased an S-Max 3D printer manufactured by ExOne.

Source: 3dtoday.ru

This printer is designed for making sand molds. Molds are used for casting metal blanks. As the deputy chief metallurgist of NPK Uralvagonzavod said: 'We will no longer have to manufacture expensive foundry equipment for experimental, new products and complex castings of small series. It will be enough for the designer to develop a 3D model of the required casting, according to which, also in 3D, the mold will be designed and manufactured. Finished rods will go to the foundry. In addition, to solve the problems of the corporation, they can be transported to any distance.' nine0003

It will be enough for the designer to develop a 3D model of the required casting, according to which, also in 3D, the mold will be designed and manufactured. Finished rods will go to the foundry. In addition, to solve the problems of the corporation, they can be transported to any distance.' nine0003

Source: 3dtoday.ru

This is not the first professional 3D printing system used by Uralvagonzavod. In 2015, the company purchased a Fortus 400mc 3D printer manufactured by Stratasys Corporation. This printer is used in the production of parts for the T-14 "Armata" tank and other vehicles manufactured by Uralvagonzavod.

T-14 tank ('Object 148') on the 'Armata' platform.

Source: OAO 'NPK 'Uralvagonzavod'

Representatives of the enterprise note that the introduction of 3D printing saves time and production resources. It is not required to spend forces on turning metal samples. If a part doesn't fit, it's easier to reprint it than remake it.

If a part doesn't fit, it's easier to reprint it than remake it.

Russian Helicopters Holding, according to its CEO Andrey Boginsky, plans to 3D print about a hundred parts for rotorcraft by 2020.

Andrey Boginsky.

Source: © Yuri Smityuk/TASS

In 2018-2019, it is planned to carry out a series of bench tests in order to obtain all the necessary certificates for printed parts by mid-2020. In total, it is planned to test about a hundred parts and assemblies.

Compared to traditional parts, 3D-printed parts are lighter and their production will be deployed at the Kazan Helicopter Plant. As a result of the use of parts obtained by 3D printing, the holding plans to reduce the cost of products. nine0003

Worldwide

The road to military 3D printing is not paved with roses. When we hear about cool 3D printed military projects, we have to consider some of the challenges that come with doing them.

Soldiers get to know FORTUS.

Source: all3dp.com

Quality certification problem. Many things that the army is supposed to produce using 3D printing are designed for harsh operating conditions, they are subject to high requirements for compliance with dimensions, geometry and quality, and an unsuccessfully printed part can lead not only to monetary losses, but also to the death of soldiers . This issue will most likely be resolved by certification of the 3D printers themselves. nine0003

Insufficient printing speed for the army. Even the most expensive 3D printer is not fast enough. There are also issues of privacy/security, copyright, and many other little things that are not obvious at first glance.

While these issues are being addressed, the US Department of the Navy decided to host a 3D printing hackathon. 12 organizations were invited to participate, which showed their developments in the field of 3D printing for the Navy. According to the participants, fully or partially printed inventions: “Allow to improve the ability to maintain combat readiness.” nine0003

According to the participants, fully or partially printed inventions: “Allow to improve the ability to maintain combat readiness.” nine0003

One of the new and memorable developments was the four-legged transporter robot (MeRlin). It turned out to be quite compact and can run, jump and walk up and down stairs. Three-dimensional printing made it possible to create, right in the supporting frame of the robot, a hydraulic manifold that serves to transfer energy to the robot drives. Those interested in robotics will find Merlin similar to the transport robots of Boston Dynamics.

Robot device “Merlin”.

Source: all3dp.com

Aviation

A 3D-printed drone was launched from one of the British Royal Navy ships at sea, HMS Mersey. The device was created in collaboration with the University of Southampton.

EOS 3D printed drone launch.

Source: all3dp. com

com

The case is made of nylon, using laser sintering technology. With a wingspan of one and a half meters, the drone weighs only three kilograms. The main task of this project was to create a small drone for exploring the surroundings, which can be quickly printed on board the ship. nine0003

The drone, named SULSA, was equipped with a small video camera. Management was carried out by researchers from Southampton using video cameras. The flight, with a range of 500 meters, lasted only a few minutes, but proved that 3D printed drones could be launched from the sea.

SULSA drone route during test flight.

Source: www.southampton.ac.uk

3D printing will solve the problem of limited ship capacity by allowing equipment to be printed at sea as needed. The only thing you need to have on board to print a drone is a 3D printer and a supply of nylon, which is disproportionately cheaper than a case made using traditional technologies, and takes up much less space. nine0003

The only thing you need to have on board to print a drone is a 3D printer and a supply of nylon, which is disproportionately cheaper than a case made using traditional technologies, and takes up much less space. nine0003

The only drawback is the print speed, but it is expected to improve in the near future. Engineers from the American Army Research Laboratory (ARL) are trying to fight this shortcoming. They are developing drones that can be made within a day. Engineers are building drones that can be used to assist soldiers in communication, delivery, and aerial surveillance.

Eric Sopero demonstrates his drone to US troops.

Source: all3dp.com

Drones are made using off-the-shelf motors and propellers, but their body is almost entirely 3D printed. The maximum speed of the drone is 55 miles per hour. Drones can either be controlled by the operator from the remote control or operate in a completely autonomous mode. Work continues to reduce noise and increase flight range, maneuverability and payload.

Work continues to reduce noise and increase flight range, maneuverability and payload.

The US Army is partnering with the Marine Corps to develop an unmanned vehicle parts catalog that can be downloaded to an employee's tablet. The software of this catalog allows you to order or 3D print a product directly from it. nine0003

American soldier with a drone.

Source: all3dp.com

In addition to experiments with drones, 3D printing is also used in “big” aviation.

For example, the US Air Force has announced that it will 3D print the toilet seats of military transport aircraft. The announcement comes after a scandal erupted when it was reported that each toilet seat cost the Air Force $10,000 to replace.

Airplane seat for $10,000. nine0044

Source: all3dp.com

The public, which already believed that the government did not always save on military spending, was extremely outraged. After an investigation initiated by one of the senators, the military department announced that it would print toilet seats on 3D printers.

After an investigation initiated by one of the senators, the military department announced that it would print toilet seats on 3D printers.

Why is the toilet lid so expensive? These covers were mass-produced by Lockheed Martin, and in 2001 this giant of the military industry stopped their production. In addition, the military department explained that the C-5 toilet seat is not only a cover, but also part of the lavatory wall, which is designed to protect the body of the aircraft from corrosion that can be caused by urine. nine0003

According to the manufacturer, its high cost is due to the need to suspend the production of other goods. In the case of independent production of the Air Force, the spare part will cost only $300.

The manufacturer now claims that the US Air Force does not own the copyright to this cap. It is not known how this lawsuit will end, but the Air Force says that they will no longer buy this spare part, because they can make it themselves much cheaper.

As stated in the department: “The use of 3D printing allows us to create parts that are no longer produced, which leads to a significant reduction in costs.”

C-5 transport aircraft.

Source: all3dp.com

Another example of 3D printing was demonstrated by the Maryland Marines. Using 3D modeling and 3D printing, they made a $70,000 F-35 fighter jet part for just 9 cents. The Marines were assisted by Sam Pratt, a mechanical engineer in the design office of the Carderock Additive Technology Factory. nine0003

Sam revealed that he was with a support platoon in South Korea teaching CLB-31 Marines how to design 3D models and how to use 3D printing. His main task was to test the performance of 3D printers on marine vessels. He also taught employees how to use Solidworks CAD.

Sam Pratt teaches Marines about 3D printing.

Source: all3dp.com

When there was a problem with printing a part needed to repair the F-35, a Marine officer offered to team up to cooperate. It turned out that the employees had already developed this part, but could not find the right dimensions. The fact is that they used a hobby-grade 3D printer and the free 3D editor Blender - Blender is ideal for implementing art projects, but it is difficult to create engineering products in it. nine0003

It turned out that the employees had already developed this part, but could not find the right dimensions. The fact is that they used a hobby-grade 3D printer and the free 3D editor Blender - Blender is ideal for implementing art projects, but it is difficult to create engineering products in it. nine0003

US Marine at the 3D printer.

Source: all3dp.com

Pratt helped solve modeling and printing problems, the part was printed in PET-G.

Currently there are about 90 parts for ground vehicles that are approved for 3D printing in the military, you can download one of these parts and print it.

Large manufacturers are also moving forward and mastering 3D printing technologies. Thus, the giant of the aviation and military industry Lockheed Martin is actively investing in 3D printing. nine0003

Lockheed Martin uses 3D printing in its manufacturing processes, with more than a hundred 3D printers in its arsenal for prototyping, tooling and printing finished products.

There are several reasons why Lockheed Martin uses 3D printing: up to 80% reduction in production time, up to 40% reduction in part weight, proven reliability of parts in difficult environments, and most importantly, the ability to further increase production in the near future.

For example, it takes 18 to 20 months to manufacture fuel tanks for spacecraft using traditional technologies. The production of such a tank by 3D printing takes two weeks. In this case, a better uniformity of the structure of the tank elements is achieved. The tanks are manufactured using a Sciaky printer using EBAM (Electron Beam Direct Manufacturing) technology, in which a bar of metal material is heated by an electron beam.

Source: all3dp.com

Lockheed Martin's 3D printed products have already passed the lab testing stage and are in active use. Some of them travel around our solar system: the Jupiter-exploring Juno satellite has eight 3D-printed brackets, and the Orion spacecraft uses printed high-pressure valves.

Fleet In South Korea, loudspeaker grilles for aircraft carriers are being 3D printed. Shipping these gratings from Europe took up to seven months and cost $612 each. The printed part is made in 4-5 hours and costs about $35. Printing parts reduces their cost and production time, and localization of production reduces dependence on foreign supplies, which may be delayed or become unavailable for various reasons. nine0003

General Electric has contracted with the US Navy to develop software for rapid 3D printing of spare parts for ships, aircraft and other critical military installations. The contract, worth nine billion dollars, is designed for four years and provides for the creation of technology "digital duplicates" - a complex of software, base models and hardware. This technology will be used both for those spare parts that are no longer manufactured, and for new parts of ships and aircraft. nine0003

Designed with a ConceptLaser 3D printer. Source: all3dp.com

Source: all3dp.com

The project is being implemented in two stages: at the first stage, software and hardware parts will be developed, at the second they will be combined into a complex capable of quickly creating the necessary products using laser metal melting technology (DMLM).

Ammunition and small arms

The US Army has designed and 3D printed a fully functional grenade launcher called “R.A.M.B.O”. The development of the grenade launcher took about six months. He shoots grenades also made using 3D printing. nine0003

R.A.M.B.O.

Source: all3dp.com

The grenade launcher consists of 50 parts, all of which, with the exception of springs and hardware, are printed on a 3D printer.

3D printed grenade launcher parts.

Source: all3dp.com

R.A.M.B.O. demonstrated characteristics similar to the M203 underbarrel grenade launcher made in the traditional way. nine0003

nine0003

A US Marine team is 3D printing and testing small explosive containers that can be used on the battlefield.

3D printed container for explosives.

Source: all3dp.com

The development of small arms began with the private sector - with the most primitive samples of pistols. On the Internet, you can find drawings of products such as the sensational Liberator. The first 3D printed pistol was printed on a professional Stratasys Dimension SST printer. The gun is chambered for 9 caliber rounds.mm and is charged during assembly.

A pistol whose main components are made of plastic and printed using a 3D printer. Frame: YouTube

Source: YouTube

The very possibility of obtaining weapons using 3D printing so excited the public that the drawings of the “Liberator” were withdrawn from public access, and the United States introduced a ban on 3D-printed weapons.

Solid Concepts created a replica of a .45 Browning M19 pistol using selective metal laser sintering11 - Solid Concepts 1911 DMLS. The first sample withstood 50 shots, later ones are capable of firing 600 shots without visible damage.

Solid Concepts 1911 DMLS.

Source: Solid Concepts Inc.

Recently, the ban on the distribution of 3D printed weapons was lifted by a court decision. So, it is now possible to print weapons in the USA, with some restrictions: they can be no more than 50 mm in caliber and models cannot be freely available. This ban was easily circumvented by Defense Distributed, which posted models of their rifle for sale on one of the online services. nine0003

Source: depositphotos.com

“Our models are not in free distribution, as buyers pay money for them,” a company representative said.

Uniforms and protection

The Vatican decided to use 3D printing technology to produce traditional Swiss Guard headdresses.

Swiss Guard.

Source: all3dp.com

The Swiss Guard is the personal guard of the Pope. From time immemorial, their form was made of metal, but now they have decided to keep up with the times. A 3D printed helmet will be significantly cheaper and, more importantly, lighter. nine0003

3D printed helmet prototype.

Source: all3dp.com

Helmets are made of PVC, they bear the coat of arms of Pope Julius II, who founded the Swiss Guard in 1506.

The US military turned to the creators of the Iron Man suit, a movie character, for help in creating uniforms for the soldier of the future. The military commissioned Legacy Effects to develop and print the prototype components for the TALOS Special Outfit Kit. nine0003

TALOS will contain a cooling system to maintain a comfortable temperature in the suit, a tactical display and an integrated exoskeleton.

Uniform concept of the future.

Source: 3dprintingindustry.com

The studio team will join the large team already working on the project, which includes bioengineers, combat veterans and technologists.

Construction

The US Army Research Engineering Team printed a large building in just 21 hours. The area of the building is 47.5 square meters. The barrack-style building is the result of a three-year US Army Construction Engineering Research (ACES) program with a laboratory in Champagne, Illinois. nine0003

3D printed barracks.

Source: all3dp.com

Such a short time spent on the construction of the building means that such temporary structures will become more affordable with the development of 3D printing. These buildings can be used as housing for refugees or temporary housing in case of natural disasters.

Construction 3D printer in progress.

Source: all3dp.com

The building looks like an ordinary house, but in the future such buildings can be given any look. Such buildings are also more energy efficient than traditional ones - they require less energy for heating and cooling. nine0003

ACES cuts building materials in half and allows printing with local materials. Reducing the need for labor is 62%, compared with the construction of plywood structures.

Concrete placement with a 3D construction printer.

Source: all3dp.com

Self-Sustaining

Collaboration between the US Army Research Laboratory and the Marine Corps has led to the development of PET filament technology, for 3D printing, from plastic waste such as bottles from under water. nine0003

According to the military, water bottles and plastic packaging are the most common litter on the battlefield. Both US and allied forces produce large amounts of this waste, and the ability to recycle it will reduce the cost of transporting raw materials. The filament obtained from recycled materials, provided that it is properly cleaned and dried, is completely equivalent in tensile strength to its analogue from primary raw materials.

The filament obtained from recycled materials, provided that it is properly cleaned and dried, is completely equivalent in tensile strength to its analogue from primary raw materials.

Source: all3dp.com

A plant is being developed, housed in a standard shipping container, that will allow the production of filament from waste. nine0003

The US Army is also developing food printers. Their advantages are obvious: the possibility of reducing the cost of food, compared with the traditional delivery of rations from abroad; the possibility of compiling an individual menu, in accordance with the preferences of each soldier; the possibility of individual balancing of the diet, depending on the dietary needs of each soldier.

The printer, like classic 3D printers, stacks components in layers.

3D printed food. nine0044

Source: all3dp.com

The printer uses the ultrasonic agglomeration method to 3D print small snacks.

Electronics

University of Massachusetts Lowell researchers have developed a new way to 3D print conductive components for radar systems. They have created a new type of ink that allows radars to be made using 3D printing.

3D printed electronic components. nine0044

Source: all3dp.com

The development was sponsored by Raytheon, one of the defense industry companies.

According to the developers: “The use of this technology makes it possible to obtain cheaper and more versatile systems than those obtained by classical methods. This technology has obvious advantages in the military sphere, but it can also be used in civilian industry, for example, in the production of weather stations or unmanned vehicles. The main problem was obtaining ink with desired properties, capable of working with high-frequency radiation.” nine0003

Applying ink to a plastic plate.

Source: all3dp.com

Two heads with different operating principles are installed on the 3D printer. One applies the ink by spraying, the second fixes them by microvibration. Radar system components such as a voltage controlled capacitor (varicap), phase shifter (for electronic control of phase array radar systems) and frequency filters can be manufactured using this technology. nine0003

The ink material is based on nanoparticles that can be injected into molten plastic and then solidify with it, creating conductive structures.

The US Air Force Research Laboratory teamed up with American Semiconductor to create a silicon-polymer memory chip.

Using 3D printing technology, they have developed a new ultra-flexible chip with built-in sensors.

Dan Berrigan holding the new flexible chip.

Source: all3dp.com

According to American Semiconductor, the silicon wafer is 2000 angstroms thick. This tiny chip can measure humidity levels, temperature, muscle fatigue, and so on. This makes it ideal for use in new technologies for monitoring the well-being of wounded soldiers or the elderly.

This tiny chip can measure humidity levels, temperature, muscle fatigue, and so on. This makes it ideal for use in new technologies for monitoring the well-being of wounded soldiers or the elderly.

Flexible electronics technology is being developed not only by research laboratories, but also by industry giants.

Apple, Boeing and the Massachusetts Institute of Technology formed an alliance to collaborate with the US Department of Defense in the field of flexible electronics. The goal of the alliance is to have high quality flexible electronics by 2020.

The Department of Defense plans to provide a consortium called the FlexTech Alliance with $75 million over 5 years and raise $96 million in additional funding.

Smart clothes.

Source: all3dp.com

The consortium includes 96 companies, 11 specialized laboratories, 42 universities and 14 state and regional organizations. The key partners of the consortium are Apple, Boeing, General Electric, General Motors, Lockheed Martin, Motorola Mobility, Qualcomm and many others. Partner universities include Cornell, Harvard, Stanford, New York University and the Massachusetts Institute of Technology.

Partner universities include Cornell, Harvard, Stanford, New York University and the Massachusetts Institute of Technology.

The practical application will be primarily focused on military targets such as uniforms with vital sign monitors. Pressure sensors can also be installed on vehicles to monitor deformation in key areas. nine0003

The civilian application of such microcircuits will help athletes control body function and improve performance, and people suffering from cardiovascular disease, control and prevent seizures. This technology will allow hospitals to monitor their patients en masse.

Prospects

British scientists and engineers are working on growing military drones using chemical technology.

Hydroponic Chemputer. nine0044

Source: all3dp.com

Military developers explore all possible and impossible technologies. In this case, they are working on a "chemcomputer". “Chemputer” is a registered trademark of BAE Systems. The technology is being developed by Professor Lee Cronin of the University of Glasgow and is a 3D printing of biomaterial drones and aircraft.

The technology is being developed by Professor Lee Cronin of the University of Glasgow and is a 3D printing of biomaterial drones and aircraft.

Unlike classic 3D printers, a chemputer carries out chemical reactions at the molecular level, creating everything from electronics to wings. nine0003

Drone prototypes.

Source: all3dp.com

While British scientists are inventing new printing technologies for the military, simple makers are creating weapons of the future using conventional 3D printers.

So, David Wirth created a hand railgun in his workshop.

David Wirth with his railgun.

Source: all3dp.com

Possibly inspired by the computer game Quake, he created this weapon using CAD, a 3D printer and an Arduino platform. The railgun can use aluminum or graphite bullets as ammunition, firing them at a speed of 250 m/s. The design is based on six huge capacitors, which, with a total weight of about nine kilograms, store more than 1800 joules of energy for each shot. The railgun also consists of batteries, two parallel contact rails and a pneumatic ammunition supply system. nine0003

The railgun also consists of batteries, two parallel contact rails and a pneumatic ammunition supply system. nine0003

Schematic diagram of a railgun.

Source: all3dp.com

Tests have shown that the railgun is inferior to a conventional pistol in terms of shot energy, but can penetrate a centimeter sheet of plywood. For comparison: stationary military railguns accelerate the projectile to a speed of 13,000 miles per hour in 0.2 seconds, the speed of a projectile from the Wirth apparatus is 560 miles per hour.

Conclusion

3D printing technology is increasingly used in the military. The main role in its promotion is played by the need to reduce costs. On-site 3D printing of parts helps to solve the problems of logistics and supply, allowing you to save time and money on delivery, which is important for the army and aviation, and even more so for the navy - it is impossible to foresee ashore and take with you everything that you might need, and delivery boarding at sea is expensive. nine0003

nine0003

We have cited as examples only a small part of cases on the stated topic - it is impossible to describe in one article all the prospects for the use of 3D printing in the military industry. And most of the solutions used by the military in production are also relevant for the civilian sector.

You can buy a 3D printer for production in Top 3D Shop — our experts will help you choose the best equipment for solving any tasks.

Want more exciting news from the world of 3D technology? nine0003

Follow us on social media networks:

VK

YouTube

TOP 3D Shop-your expert in the 3D-technical market

STL File ・ 3D-printing design for loading ・ CULTS

RUSSIAN SOLDIER COMES WITH A RIFLE AK

5 €

SEATED SOLDIER

5 €

nine0577 AMERICAN OFFICER VIETNAM5 €

AMERICAN SOLDIER ON GUARD

5 €

AMERICAN PARATROOPER AIMING A RIFLE AT A SOLDIER

5 €

PARATROOPER WITH EQUIPMENT

5 €

DRIVER OF A MODERN RUSSIAN SOLDIER

5 €

nine0577 RUSSIAN SOLDIER SIT WITH GUNS5 €

Best 3D printer files in Game category

Deactivated

Flea bot.

(Mechanical flea)

(Mechanical flea) Free

Auto Marble Machine

Free

nine0577 BookFree

HOMERO FUNKO POP COLLECTION LOS SIMPSON / HOMERO FUNKO POP COLLECTION LOS SIMPSON

7.74 €

Flexible Octopus

Free

Kid's toy lock

Free

The mandalorian-Yoda baby

11.29 €

nine0004Bestsellers in the Game category

Chopper motorcycle print-in-place

1 €

Abandoned damaged spaceship compatible killteam in the dark or boarding action game

13.83 €

Nice flexi dragon

1. 77 €

77 €

8.47 €

USS EnterSurprise - printable game container for tiny F14 jet fighters

3.76 €

Articulated dragon

3.76 €

FLEXIBLE CHRISTMAS SNOWMAN

2,60 €

Voidwalker Exosuits Truescale

€14.83

WARFORGED VOIDWALKER EXOSUIT UPGRADE KIT

9.41 €

Nintendo Switch Crystal Dock - classic and OLED version

3.11 €

Octopus 2.0

3.76 €

chaos terminators

€16.75 nine0697 -fifty% 8.

Learn more