3D scanner cube

Creaform Cube-R - 3dscanningservices.net

R-Series Automated Inspection SolutionThe CUBE-R™ extends the capabilities of the MetraSCAN 3D-R™ for the dimensional measurement of parts ranging from 1 m to 3 m with metrology-grade volumetric accuracy under real-life shop-floor conditions. Unlike conventional systems, the CUBE-R™ delivers both speed and volumetric accuracy, consequently insuring a significant increase in productivity.

CUBE-R is a fast, reliable, and efficient complete turnkey solution for automated quality control applications. It features the MetraSCAN-R™, a powerful robot-mounted optical 3D scanner that can be integrated into factory automation systems without compromising on accuracy. It is the perfect alternative to solve any productivity issues caused by bottlenecks at the traditional coordinate measuring machine (CMM). Our 3D scanning CMM enables manufacturing companies to harness the power of optical 3D measurement and industrial automation. It optimizes the production cycle and throughput resulting in better product quality.

- High productivity: inspect countless parts everyday – regardless of surface

- Scans any type of material, even black, multicolored and shiny surfaces

- Complete Solution: Shop-floor ready, fully-enclosed & no integration needed

- Metrology-grade Measurements: Up to .030 mm (.0012 in.) accuracy & up to .050 mm (.0020 in.) resolution

- Volumetric Accuracy: Up to .064 mm (.0025 in.)

- Part Size Range: Measure parts up to 3 meters

- Minimal Footprint: 4.1 m x 4.1 m x 3.1 m

- 3 m parts can rotate (360o) freely at any time during measurement

- Versatile: Optimizes the production cycle and throughput by offering a simultaneous operation of data acquisition and analysis to generate a continuous and uninterrupted measurement flow

- Automatic field calibration procedure: No accuracy drift over time and continuous operation

- Minimum operator training: Easy-to-use and short learning curve to keep up with fast production pace

- At-line inspections in mass production, up to a few hundred parts/day

- At-line inspections of parts ranging up to 3 m

- Stamping parts (car body panel, car door, front end, etc.

)

) - Large parts inspection

- Body in white (BIW)

- Quality control inspections of supplier parts

- Conformity assessments of 3D models against original parts or production tooling

- Conformity assessments of manufactured parts against originals

- VXelements: Creaform’s 3D platform/application suite.

- Real-time visualization gives users a simple & efficient 3D scanning experience

- Contains all the necessary tools for highly accurate data acquisition

- R-Series Productivity Station: Addresses applications with high productivity requirements

- R-Series Industrial Computers: Rackmount computer without a screen and keyboard.

- R-Series Mounting Plate: Removable tray designed for long-term fixture installations. Essential for customers with a variety of part sizes and/or type.

Integrating Metrologic Group’s Silma X4 i-Robot and Metrolog X4 i-Robot, the CUBE-R delivers an array of benefits: The software calculates the most efficient positioning of the sensor and the best collision-free trajectories for the robot. The same software manages the optical 3D measurements, simultaneously provides advanced analysis of the results –even when computing huge point clouds–, and edits personalized, easy-to-understand reports. In short, Metrolog and Silma X4 i-Robot turn the CUBE-R™into a simple automated measurement solution, easily operated by a non-specialist operator.

“Metrologic Group is dedicated to developing the automated 3D metrology market through its X4 i-Robot platform, says Stéphane Auclair, Division Vice-President, Marketing & Product Management at Creaform-AMETEK. In addition to being recognized as world leader of dimensional metrology software, Metrologic Group is the only independent software partner to integrate robot path planning and simulation with other automation-type functionalities.

Partnering with them for the commercialization of the CUBE-R was an obvious choice for us.”

“The CUBE-R™ is yet another illustration of the ability of the Metrolog and Silma X4 i-Robot software suite to control singly the most advanced 3D measuring solutions,” says Bertrand Gili, President of Metrologic Group. “Combined with the CUBE-R™, our software suite brings advanced 3D inspection technology to the shop-floor and offers easy to program, easy to operate quality control routines for complex robotized inspection scenarios. It definitely sets a new standard in all-in-one laser line scanning robotized 3D inspection.”

3D scanning CMM: CUBE-R - Creaform - PDF Catalogs | Technical Documentation

Add to favorites

{{requestButtons}}

Catalog excerpts

METROLOGY SOLUTIONS 3D SCANNING COORDINATE MEASURING MACHINE (CMM)

R-Series AUTOMATED INSPECTION SOLUTION CUBE-R is a fast, reliable, and efficient complete turnkey solution for automated quality control applications. It features the MetraSCAN-R™, a powerful robot-mounted optical 3D scanner that can be integrated into factory automation systems without compromising on accuracy. It is the perfect alternative to solve any productivity issues caused by bottlenecks at the traditional coordinate measuring machine (CMM). Our 3D scanning CMM enables manufacturing companies to harness the power of optical 3D measurement and industrial automation. It optimizes the...

It features the MetraSCAN-R™, a powerful robot-mounted optical 3D scanner that can be integrated into factory automation systems without compromising on accuracy. It is the perfect alternative to solve any productivity issues caused by bottlenecks at the traditional coordinate measuring machine (CMM). Our 3D scanning CMM enables manufacturing companies to harness the power of optical 3D measurement and industrial automation. It optimizes the...

R-Series AUTOCALIBRATION KIT Allows the complete and automatic calibration of the C-Track and the MetraSCAN 3D-R. All the tools needed for applications requiring no human involvement. Automatic field calibration procedure No accuracy drift over time and continuous operation R-Series PRODUCTIVITY STATION This productivity station addresses applications with high productivity requirements, such as when cycle times need to be reduced and productivity increased. Multitasking Allows to carry out data acquisition while simultaneously analyzing previously acquired data enabling continuous. ..

..

CUBE-R, ISOMETRIC VIEW, CLOSED DOOR CUBE-R, INSIDE VIEW METRH SCAM3D-R CUBE-R, TOP VIEW (1) Typical value for diameter measurement on a calibrated sphere artefact. (2) Based on the ASME B89.4.22 standard. Performance is assessed with traceable length artefacts by measuring these at different locations and orientations within the working volume of the C-Track (value = maximum deviation). CREAFORM Creaform Inc. (Head Office) 4700 rue de la Pascaline Levis QC G6W 0L9 Canada Tel.: 1 418 833 4446 | Fax: 1 418 833 9588 [email protected] | creaform3d.com

All Creaform catalogs and technical brochures

-

Creaform Automated Quality Control: R-Series

5 Pages

-

ACADEMIA -3D Measurement Solutions designed for the academic world

3 Pages

-

NDT Solutions for surface inspections

5 Pages

-

HandySCAN 3D SILVER series

3 Pages

-

VXELEMENTS -FULLY INTEGRATED 3D MEASUREMENT SOFTWARE PLATFORM

7 Pages

-

The complete quality control portfolio

5 Pages

-

Shopfloor Workstation

2 Pages

-

MaxSHOT 3D: Your shot at photogrammetry

3 Pages

-

HandyPROBE - THE PORTABLE CMM FOR THE SHOP FLOOR

2 Pages

-

METRASCAN3D - 3D SCANNER AND PORTABLE CMM FOR THE SHOP FLOOR

3 Pages

-

HandySCAN AEROPACK

3 Pages

-

Go!SCAN 3D: The fastest and easiest scanning experience

4 Pages

-

High resolution scanner: HandySCAN 3D

4 Pages

Archived catalogs

-

Pipecheck: RELIABLE AND EFFICIENT 3D SCANNING SOLUTION FOR PIPELINE INTEGRITY ASSESSMENT

5 Pages

-

SmartDENT 3D-NDT Surface Inspection for the Aerospace MRO Industry

5 Pages

-

Dynamic tracking module VXtrack for inspection and dynamic measurment capabilities

2 Pages

-

Cube-R

3 Pages

-

MetraSCAN-R: THE ROBOT-MOUNTED OPTICAL CMM 3D SCANNERS FOR AUTOMATED INSPECTION

5 Pages

-

Arm-free handheld MetraSCAN 3D scanning system

3 Pages

-

VXinspect - Dimensional Inspection Software Module

2 Pages

-

VXmodel: Scan-to-CAD software module

2 Pages

Compare

Remove all

Compare up to 10 products

Creaform Cube-R automated 3D scanning system at manufacturer's price with delivery – TopStanok

- Description

- Equipment

Description

Creaform Cube R is a robotic test and measurement system that automates the quality control process.

The solution is presented in the form of an automatic robotic cell, the MetraSCAN 3D-R 3D scanner is mounted on a robot, which allows you to automatically control the accuracy of products on an industrial scale. nine0009

The scanner on which the cell is built is the only solution in the world that achieves results of this accuracy when used with a robotic arm. As a result, a huge amount of enterprise resources engaged in product quality acceptance is released. Unlike existing solutions, this 3D scanner allows manufacturing companies to harness the power of optical 3D measurement and industrial automation. This measuring machine optimizes the production cycle and productivity, which improves product quality. nine0009

Video

Standard equipment

-

Scanner

-

Box with protection system

nine0004 -

Operator Station

-

Robotic arm

- nine0008 Turntable

-

Optical tracker C-Track Elite

Peculiarities

High performance

Ability to check up to hundreds of parts per day (even on difficult surfaces). nine0009

nine0009

Complete turnkey solution

No integration required, fully assembled and ready to go.

Multitasking

Maximizes production cycle and productivity by offering simultaneous data acquisition and analysis for a repeatable and uninterrupted flow of measurements.

nine0051 Automatic calibration procedureNo time errors, no downtime and no interruption in equipment operation.

Application

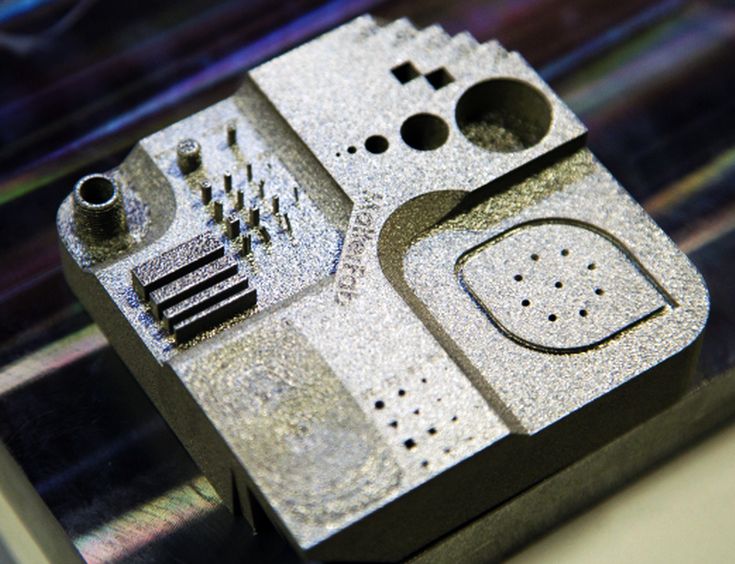

Reverse engineering (reverse engineering)

Product geometry control

nine0051 Creation of digital archivesTechno Print 3D Company

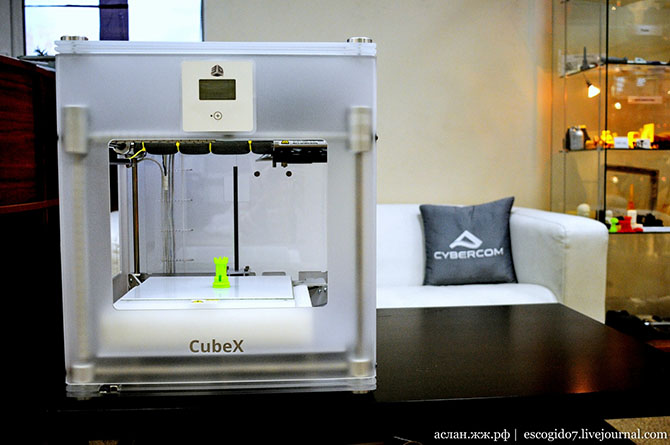

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.