Nanoscribe 3d printer

Nanoscribe 2-Photon Lithography | ORNL

Capability

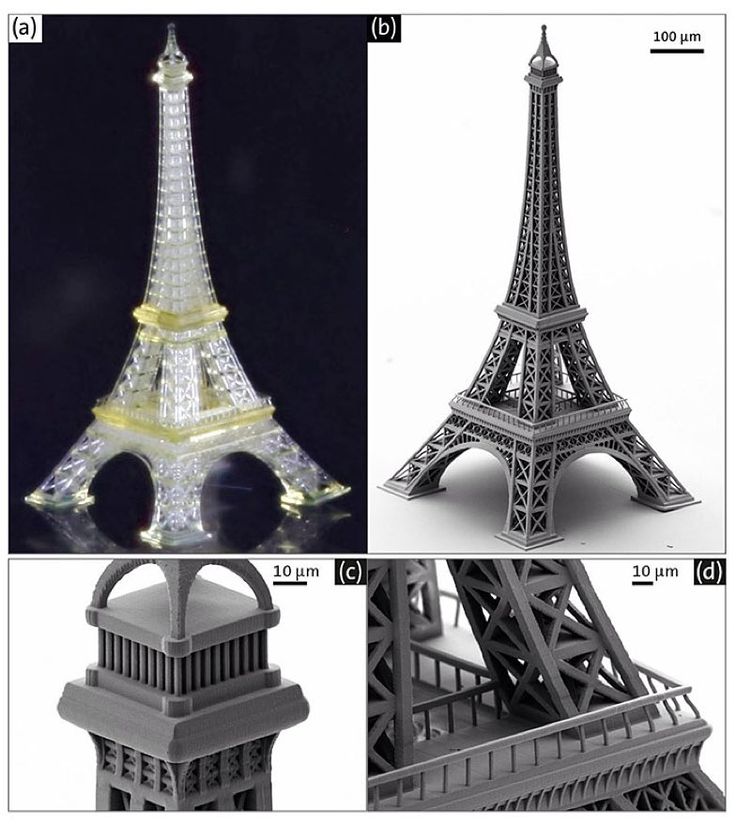

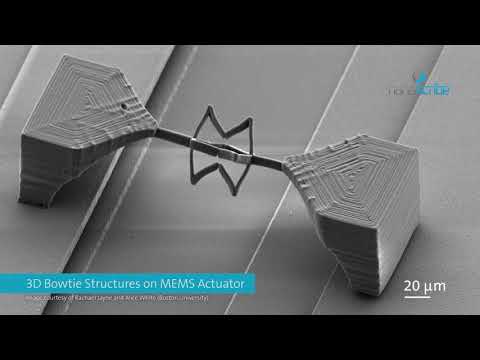

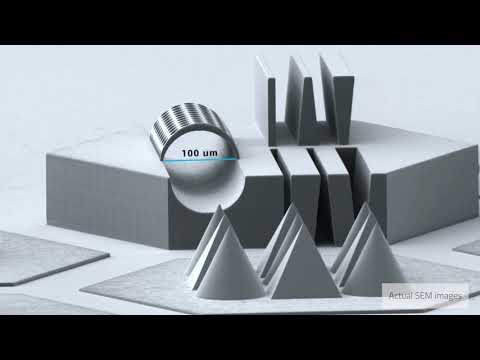

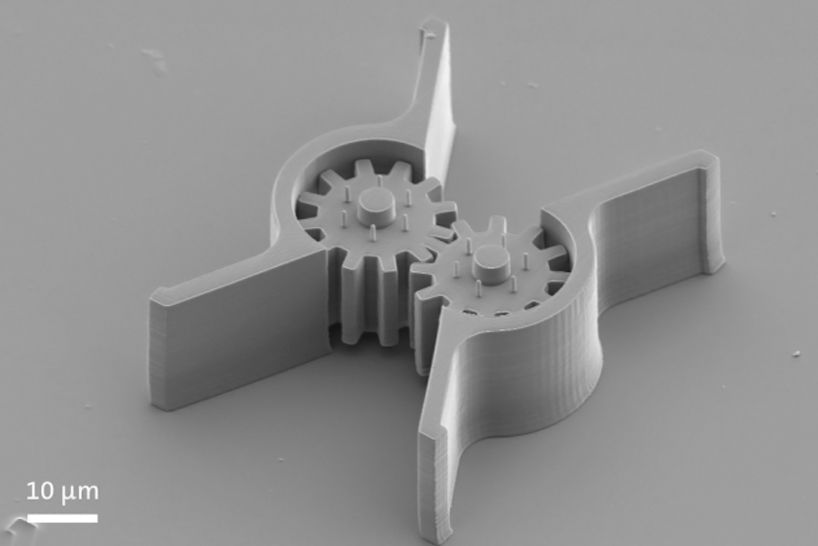

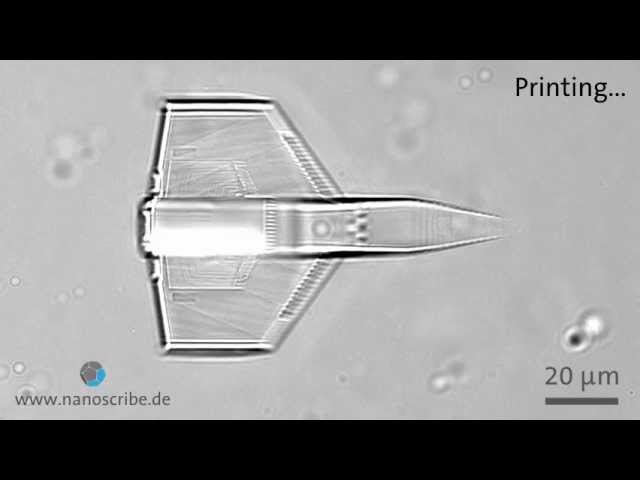

CNMS users and scientists use the Nanoscribe Photonics Professional GT stereolithography system to create intricate 3D micro- and nano-scale structures using principles of additive manufacturing. This tool is uniquely suitable to add 3D structures to on-chip structures already processed using conventional lithographic patterning techniques. Alternatively, this tool enables microscale 3D printing on virtually any flat or arbitrary shaped substrates and allows researchers to create untethered 3D structures.

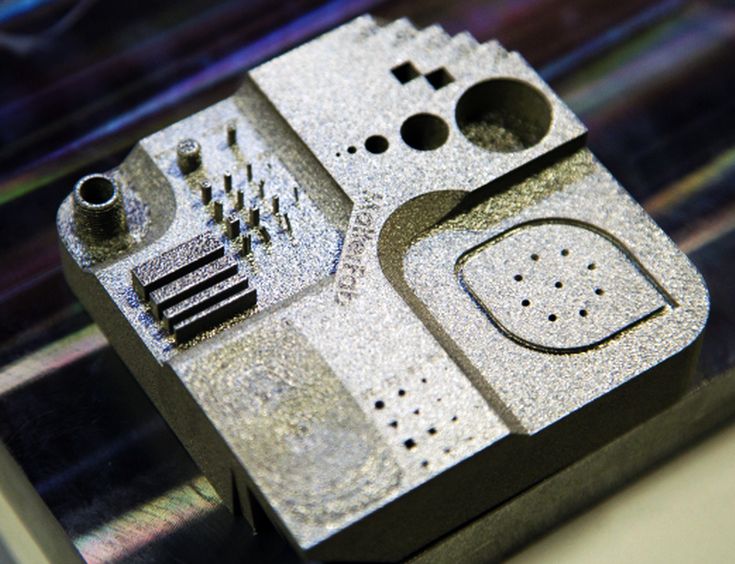

Examples of 3D printed microstructures: (top) a cube with microscale porosity for subsequent modification with a scintillator sensing material; (bottom) an asymmetric texture with unidirectional wettability

Nanoscribe Photonics Professional GT system combines principles of direct laser writing (DLW) and 2-photon polymerization to achieve 3D printing with resolution and fidelity well above those provided by any other commercially available 3D printers. The tool integrates an inverted optical microscope, femtosecond laser, high speed galvo mirror laser scanner and a high precision piezo-stage in a user-friendly computer controlled system that accepts input designs in the industry-standard STL file format. The intuitive interface, optical autofocusing and availability of various sample holders provides a straightforward workflow from the design to implementation of arbitrary complex structures as required by the project goals.

Applications

Micro/nano-scale scale 3D printing is a rapidly evolving enabling technology with applications in many cross-disciplinary areas, such as biomimetic sensing, biomedical devices, soft robotics, active colloids, mechanical metamaterials, nanophotonics and fundamental nanoscience. Examples of recent CNMS user projects that relied on the Nanoscribe tool include 3D printing of asymmetric textures with unusual wetting properties, bioinspired antennas for chemical sensing, porous scintillator media, and carbon electrodes for implantable electrochemical sensors.

Specifications

- Light source: Femtosecond fiber laser (780 nm, up to 40 mW average power, 100 fs pulse duration, 80 MHz repetition)

- Lateral resolution: 160-200 nm (with 63x writing objective)

- Vertical resolution: 500-600 nm (with 63x writing objective)

- Single writing field: up to 300 x 300 x 300 mm3

- Laser scanner beam velocity on the sample surface: up to 50 mm/sec

- Typical printing areas: up to 100 mm2

- Typical printing volumes: up to 1 mm3

- Applicable photoresists: SU8, vendor supplied diacrylate based liquid photopolymers (IP-S, IP-DIP)

- Material of the resulting structures: Cross-linked polymers

- stable up to 100 °C,

- undergoes 20-40% shrinkage between 100-250 °C,

- partially oxidizes at 250-400 °C

- carbonizes above 400 °C

Recent Highlights

Carbon Microelectrodes

Moth-Inspired Antenna

Nickolay V Lavrik

Nanoscribe launches its Quantum X align 3D printer - technical specifications and pricing

0Shares

Insiders and analysts predict the 3D printing trends to watch in our latest series of articles focused on the future of 3D printing.

Nanoscribe, a specialist Two-Photon Polymerization (2PP) 3D printing technology, has announced the launch of its new Quantum X align 3D printer.

Debuted at Photonics West 2022 in San Francisco, the high-precision microprinter is reportedly the first 3D printer capable of printing freeform micro-optical elements directly onto optical fibers and photonic chips. It does this with the help of automatic nano-precision alignment functionality, a feature foreign to other microprinters.

As such, the Quantum X align is designed to enable reliable light coupling via the fabrication of Free Space Microoptical Interconnects (FSMI) between chips and optical fibers.

“With the addition of the new Quantum X align to our industry-proven Quantum X platform, we are enriching Two-Photon Polymerization with powerful alignment technologies that drive the ever-increasing demand in data communications, telecommunications, and sensing applications,” said Martin Hermatschweiler, CEO and co-founder of Nanoscribe. “Our goal is to address the challenges of efficient coupling in photonic packaging and make high-precision 3D printing the technology of choice in integrated photonics.”

“Our goal is to address the challenges of efficient coupling in photonic packaging and make high-precision 3D printing the technology of choice in integrated photonics.”

Down to the nanoscale with Nanoscribe

Nanoscribe was founded in 2007 as a spin-off of the Karlsruhe Institute of Technology (KIT) and specializes in 2PP-based 3D printers. In June 2021, the firm was acquired by bioprinting company BICO Group (formerly CELLINK) in a deal worth €50 million in cash, shares, and earn-outs.

With over 3,000 users at universities, research institutions, and industrial firms around the world, Nanoscribe has made a name for itself in the microprinting space. The company’s product portfolio is a steadily growing one and now includes the Quantum X, Quantum X shape, Quantum X bio, and the Photonic Professional GT2.

To enable applications in microfluidics and micro-optics, Nanoscribe also has its own range of specialist resins on offer. These include the IP Photoresin series for photopolymer parts and the GP-Silica material for silica glass microstructures.

These include the IP Photoresin series for photopolymer parts and the GP-Silica material for silica glass microstructures.

The Quantum X align

Photonic integrated circuits (PIC) are expected to help accelerate the computing power of today’s microelectronics while slashing power consumption to new lows. Unfortunately, the production of PIC devices requires tedious placement and active alignment of the various microoptical elements to form interconnects. Nanoscribe’s latest innovation is designed to address this issue.

The Quantum X align automatically detects the optical interfaces and spatial orientations of photonic chips and fiber cores, enabling it to 3D print freeform microoptics directly in place. The system even takes element tilt into account, eliminating the need for manual active alignment, which is often a costly procedure. Nanoscribe claims the machine can achieve alignment accuracies of down to 100nm in all spatial dimensions.

With a relatively large print area measuring 50 x 50mm, the Quantum X align is versatile in its applications. The system’s capabilities make it well suited to everything from microfluidics and sensor systems to miniaturized medical devices for procedures such as minimally invasive endoscopy.

The system’s capabilities make it well suited to everything from microfluidics and sensor systems to miniaturized medical devices for procedures such as minimally invasive endoscopy.

The Quantum X align is a finalist for the Prism Awards 2022 in the category ‘Manufacturing and Test’.

Different types of fiber to chip Free Space Microoptical Couplers (FSMO) 3D printed on the Quantum X align. Image via Nanoscribe.Technical specifications and pricing

Below are the technical specifications for the Quantum X align 3D printer. Readers interested in purchasing the system should contact Nanoscribe for a quote.

| Print area | 50 x 50mm |

| Alignment precision | 100nm (XY)/500nm (Z) |

| Surface roughness (Ra) | 10nm |

| Shape accuracy (Sa) | 250nm |

| Feature size control | 100nm |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Nanoscribe Quantum X align. Photo via Nanoscribe.

Tags BICO Karlsruhe Institute of Technology Martin Hermatschweiler Nanoscribe Quantum X align Quantum X bio Quantum X shape

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

| 3DNews Technologies and IT market. News printers, print servers, scanners, copiers. The most interesting in the reviews One of the most promising areas in the industry in both the consumer and industrial segments are 3D printers, which open up the prospect of simple and inexpensive prototyping, as well as the production of piece products. Given all the various 3D printing technologies, one can imagine the great possibilities that 3D printers open up for the future of robotics. nine0007 In this regard, it is interesting to learn about the products of Russian developers who work in the Cypriot company Gizmo For You, founded 7 years ago by Dmitry Ruslanovich Zavorotnichenko, a native of the Crimea. The company has almost 4 years of experience in creating 3D printers. Currently, its main products are the Ilios HD kit and the new Ilios Luch 3D printer. Both devices use the principle of stereolithography, which provides for layer-by-layer printing by ultraviolet irradiation of a special liquid, which, as a result, turns into a solid state. The Ilios HD kit is one of the most flexible budget 3D printer solutions available today. It is made on a durable aluminum frame and is able to print fairly large objects with a minimum deviation of 10 microns per 300 mm and a layer thickness of up to 12.5 microns (by standard, the thickness is set to 100 microns). Thanks to the modular design, the size of the printable area can be adjusted to fit small or large objects, up to 28 x 28 x 18 cm. The dimensions of the printer itself are 60 x 50 x 120 cm. The kit comes with a fairly large set of components for modeling the system. In addition, thanks to the support of generic parts, spare parts from other manufacturers can be used. If desired, the user can, for example, install a second projector to increase the working area, as well as more precise motors and alternative electronics to improve the quality of the final result. The resolution of the projector determines the fidelity of the model. Printer software is open source and can be customized for specific engineering needs. Thus, the Ilios HD kit makes it possible to flexibly configure the system for specific user needs. The cost of the device is in the range from 1730 to 4640 euros. The second Ilios Luch 3D printer is a device with a fully automated printing process, including directly from an SD card without a computer. It is made in a metal case measuring 89.2 × 51.2 × 20 cm, which protects the user from contact with materials and chemicals, and also hides all retractable modules at the end of work. They have 5 control buttons and a black and white LCD screen. nine0007 The size of the printed area is an impressive 29.7 × 21.1 × 30 cm. As you can see, the allowable dimensions of the models are larger than the height of the printer itself, which eloquently speaks of the elegance of engineering solutions used in Ilios Luch to achieve maximum compactness . Through the use of cartridges, automation of material distribution, filling and bath cleaning, the user is spared unnecessary printer maintenance. With the help of 10 pumps and a set of sensors, Ilios Luch controls the required amount of material in the bath and adjusts its color by mixing 4 dyes. On the side of the printer there are indicators of the fullness of the cans of coloring (one for 160 ml and three for 100 ml). nine0007 There are also four material cartridges with a capacity of 220 ml each. When the tank is depleted, the user is given the choice to fill it with the remaining material in the bath or install a new cartridge. The cost of 1 kg of hard and durable branded material is 130 euros. One of the cartridges is for a cleaning fluid such as acetone or alcohol used in the automatic system flush procedure. It is allowed to fill containers with materials from other manufacturers and use dyes of the desired color. nine0007 "Ilios Luch" provides reliable retention of the model during printing, and with the help of a special mechanism automatically separates it from the platform at the end of work. At the end of printing, put the model under an ultraviolet lamp or leave it in sunlight for several hours to completely cure the material. For this purpose, Ilios Luch has 4 built-in lamps that illuminate the model from different sides. nine0007 One of the key components of this 3D printer, which is responsible for the quality of printing, is a laser panel that produces UV radiation and forms a model. The panel is very compact and moves on two rails with a high precision servo motor and high quality toothed belt. Such a system does not require as careful observation as the lamp and projector optics. Each layer takes 10-15 seconds to create. The following figures speak of the printing accuracy: layer thickness - 6 microns, part size - from 22 microns, deviation - no more than 10 microns per 300 mm. The Ilios HD kit can also be equipped with a laser irradiation module instead of a DLP projector. The user can purchase the appropriate accessories or initially choose the appropriate ready-made configuration. The cost of the Ilios Luch printer is 12 thousand euros, but this amount is much lower than similar, but less functional third-party solutions. Ilios 3D 3D printers are known for their reliability and durability, as they are all hand-assembled in the company's workshop using the best quality materials to guarantee full performance. nine0007 Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/908880 Headings: News Hardware, printers, print servers, scanners, copiers, MFPs, 3D technologies, Tags: ilios 3d, 3d printing, 3d printers, ilios ray, ilios hd ← В past To the future → |

manufacturing miniatures 28mm, diram, game locations using 3D printer

09. 03.2022

03.2022

Content

-

- How to choose a 3D printer for miniatures 3D printing for the manufacture of miniatures

- FDM

- LCD/DLP

- Printing examples

- Top printer rankings

- FDM

- LCD

- Totals

- How to choose a 3D printer for miniatures 3D printing for the manufacture of miniatures

3D printing finds its application in various fields, not only as a production machine, but also as a reliable hobby assistant.

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history. nine0007

Warhammer 40k miniature soldier

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home. nine0007

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers. nine0007

nine0007

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools. nine0007

Sculpting tool kit

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army. nine0007

Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army. nine0007

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold. nine0007

Metal soldier casting

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully. nine0124

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting. nine0007

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”. nine0007

Warhammer40k universe 3D miniature model

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

nine0007

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time. nine0007

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass. nine0007

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular). nine0007

FDM

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

Working principle of FDM 3D printer

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow. nine0124

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas. nine0007

nine0007

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

How a 3D photopolymer printer works

Pros:

- nine0005 The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc. nine0007

Printing examples

Robot printed on Asiga Pro 4k

Figurine made with Phrozen Sonic Mini 4k

28mm 3D printed miniatures

3D Printed Halloween Miniature

3D printed play models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

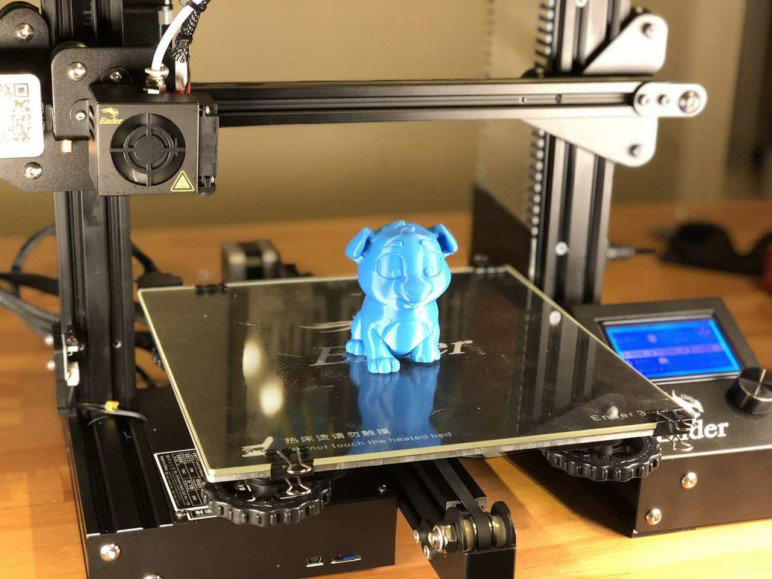

Creality3D Ender 3 Kit

nine0290 Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly. nine0007

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others nine0007

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers. nine0007

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers. nine0007

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others nine0007

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production. nine0007

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production. nine0007

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models. nine0007

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately. nine0007

nine0007

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle. nine0007

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail.

.. Ilios stereolithographic 3D printers...

.. Ilios stereolithographic 3D printers...  nine0007

nine0007  "Ilios HD" has no firmware, supports modern standards and is compatible with many programs, including Mach4. A completely open format allows you to use the best practices of the engineering community. nine0007

"Ilios HD" has no firmware, supports modern standards and is compatible with many programs, including Mach4. A completely open format allows you to use the best practices of the engineering community. nine0007

The bathtub has a durable glass cover. The printer uses stepper motors with optical position sensors for precise movement. All movements, as in Ilios HD, are transmitted through bearings.

The bathtub has a durable glass cover. The printer uses stepper motors with optical position sensors for precise movement. All movements, as in Ilios HD, are transmitted through bearings.  nine0007

nine0007