Kickstarter 3d laser printer

Boost your Kickstarter Campaign using 3D Printing!

3D Learning Hub

See all categories

Contents:

- Introduction

- Why you should choose 3D printing to create your prototype

- Your next step: Production using additive manufacturing!

- Why using a 3D printing service could help your Kickstarter campaign?

Introduction

Why you should choose 3D printing to create your prototype

Create the perfect 3D printed prototype

Additive manufacturing could totally help you to create a prototype or a proof of concept for your project. Indeed, while creating a new project with a startup, one of the main priorities is to minimize the costs, but also to create a project with great quality. It has to look quite promising to attract backers. How could 3D printing help you with that exactly?

3D printing could make your prototyping process easier. Indeed, you will just need a 3D model and then 3D print it with the 3D printing material of your choice. First, this prototyping technique is quite convenient, because if you need to modify your prototype, you will just need to modify your 3D file directly and make any iteration your need from it. During your market validation process, the possibilities offered by this cutting-edge technology will definitely help you create the perfect proof of concept or prototype!

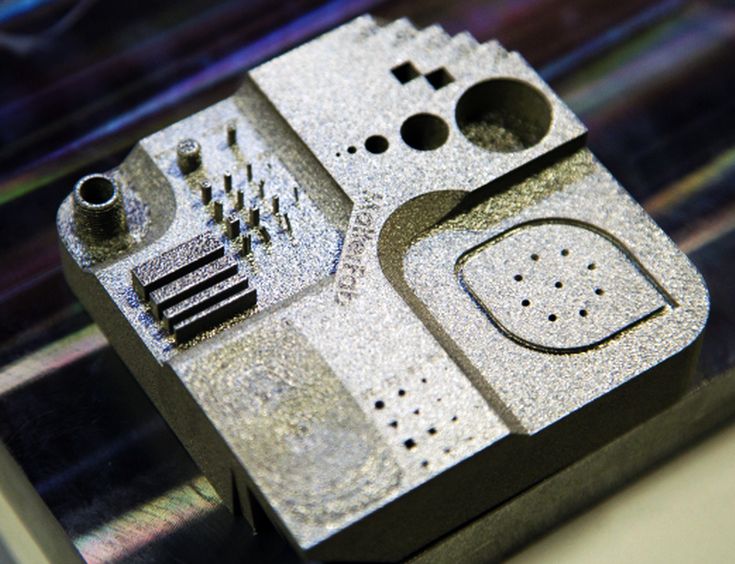

Using technologies such as Selective Laser Sintering (SLS) will allow you to create really good looking parts, even for your prototype, which could be a huge advantage for the launch of your Kickstarter campaign!

Having a functional prototype and a demonstration to launch your campaign will definitely help people to invest in your project. What are you waiting for?

What are you waiting for?

How does it allow you to minimize your costs?

3D printing is a convenient manufacturing method, allowing you to print small batches which is perfect for a prototype development. Additive manufacturing, contrary to other traditional manufacturing methods is really cost-effective when it comes to small batches, that is why it is helping companies in their prototyping process.

Moreover, the choice of 3D printing material will affect the price of your printing process. Some materials are offering pretty good properties at a low price. For example, our Multi Jet Fusion PA12, in its raw version, is our cheapest material, perfect for the development of your product. The Multijet Fusion PA12 objects printed through Sculpteo are created from a fine polyamide powder. The material is characterized by good elasticity and high impact resistance! Do you want to try it right now? Upload your STL file right here and get a quote of your 3D printed part using the Multi Jet Fusion technology.

Your next step: Production using additive manufacturing!

Now, here is the next step. You have the prototype of your product, you got some orders through your successful Kickstarter campaign. How could you fulfil your first production run? Once again, 3D printing could help you with that. While using it as a manufacturing method for your final project, 3D technology allows you to create the exact number of parts you need, when you need it. It is a way to avoid inventory and high minimum order quantities for injection molding and become a real revolution for your storage thanks to a digital inventory.

But can 3D printing really create finished parts? Absolutely, yes! Thanks to the wide range of 3D printing materials you will be able the choose the material perfectly fit to the nature of your project, and add great finishing. In a lot of people’s mind, additive manufacturing is only good for prototyping, but they are totally wrong. This technology is more and more used by companies for their production process.

Are you looking for a plastic material or are more interested in metal 3D printing? Do you need a heat resistant part? A rigid or a flexible one? Check out our 3D printing materials catalog and make your choice. For more info, don’t hesitate to contact our sales team and explain your project to us!

Why using a 3D printing service could help your Kickstarter campaign?

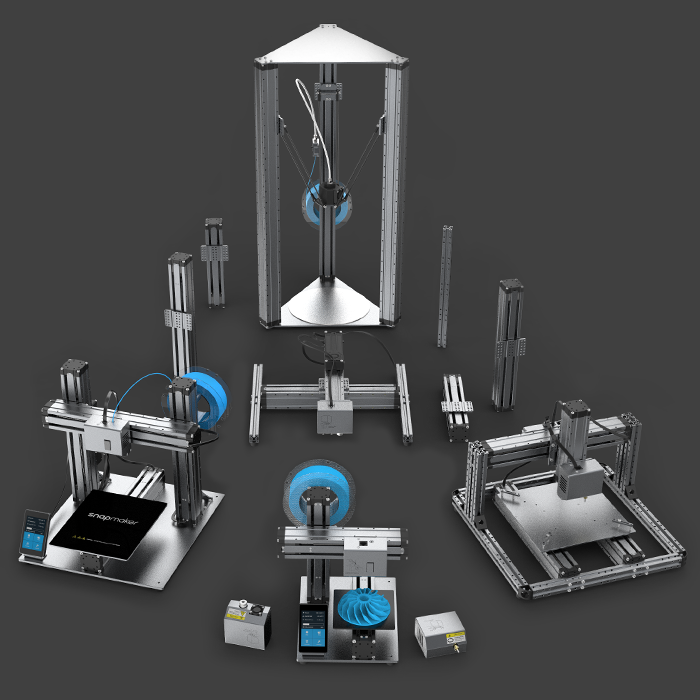

Investing in 3D printers can be really expensive, especially for a startup just launching its project. It can also be quite risky if you are looking for the quality of parts printed with industrial 3D printers.

Using a 3D printing service such as Sculpteo will allow you to get access to a whole 3D printing material catalog, this way, you can use, test and make the most of different technologies for your project. The only thing you have to do is to upload your 3D model on our online 3D printing service, and you will get a instant quote of your project, regarding the technology you decided to choose.

You will also be able to control the amount of parts you order and receive parts when you need them, making it more cost efficient than ordering ten thousand or more parts from offshore manufacturers.

We hope this blog post helped you to see how 3D printing could be a major advantage for your Kickstarter or Indigogo campaign. You could use it from your proof of concept to your final production process.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

LumiPocket LT Launches on Kickstarter-3D Printer Also Offers Laser Engraving & PCB Etching - 3DPrint.com

The first thing you should know about plunking down the LumiPocket LT on your desktop is that it’s going to look great. So if style is a requirement, that’s covered. We’re assuming you want much, much more than just looks though, and so does Lumi Industries, a forerunner in 3D printing solutions, based in Italy. They’ve just launched a Kickstarter campaign, although they at Lumi are veterans of participating in crowdfunding campaigns, as we’ve reported previously regarding the predecessor of the LT, with the LumiPocket, which was funded and very well received on Indiegogo. With this launch, many early bird perks abound for those who pledge.

So if style is a requirement, that’s covered. We’re assuming you want much, much more than just looks though, and so does Lumi Industries, a forerunner in 3D printing solutions, based in Italy. They’ve just launched a Kickstarter campaign, although they at Lumi are veterans of participating in crowdfunding campaigns, as we’ve reported previously regarding the predecessor of the LT, with the LumiPocket, which was funded and very well received on Indiegogo. With this launch, many early bird perks abound for those who pledge.

“This will be one of the first campaigns on Kickstarter based in Italy, since only a few months ago they have opened up to campaigns from our country,” said Davide Marin, founder of Lumi Industries.

Lumi Industries was founded by makers who have a passion for 3D printing, and they’re able to carry that over into an understanding of what their client base is searching for in products. And the LumiPocket LT may very well fit into your technological wishlist–as well as your budget.

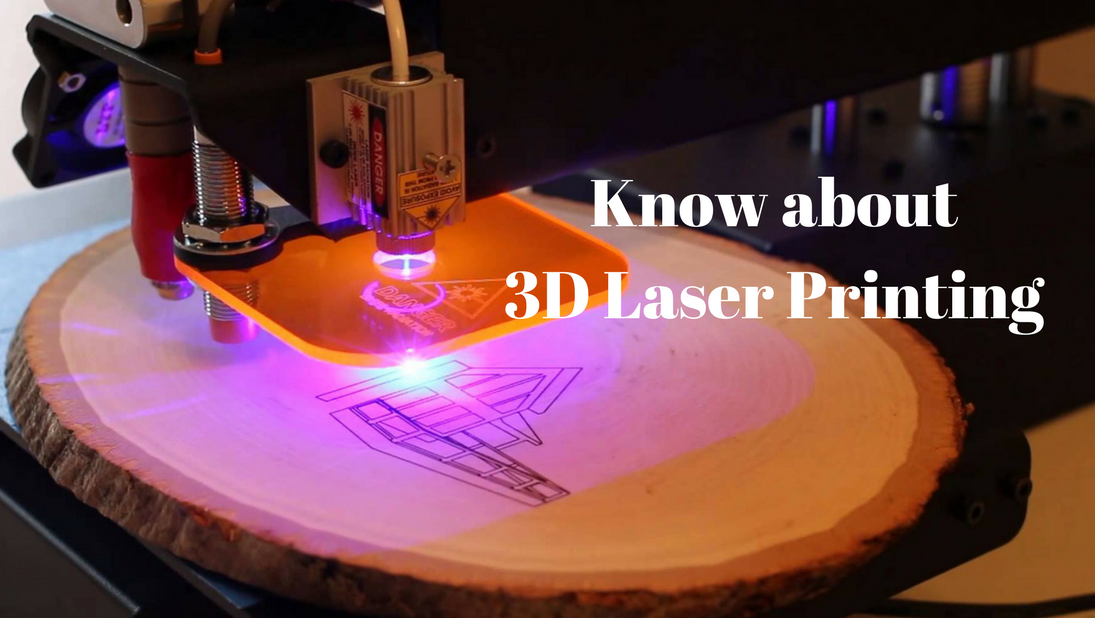

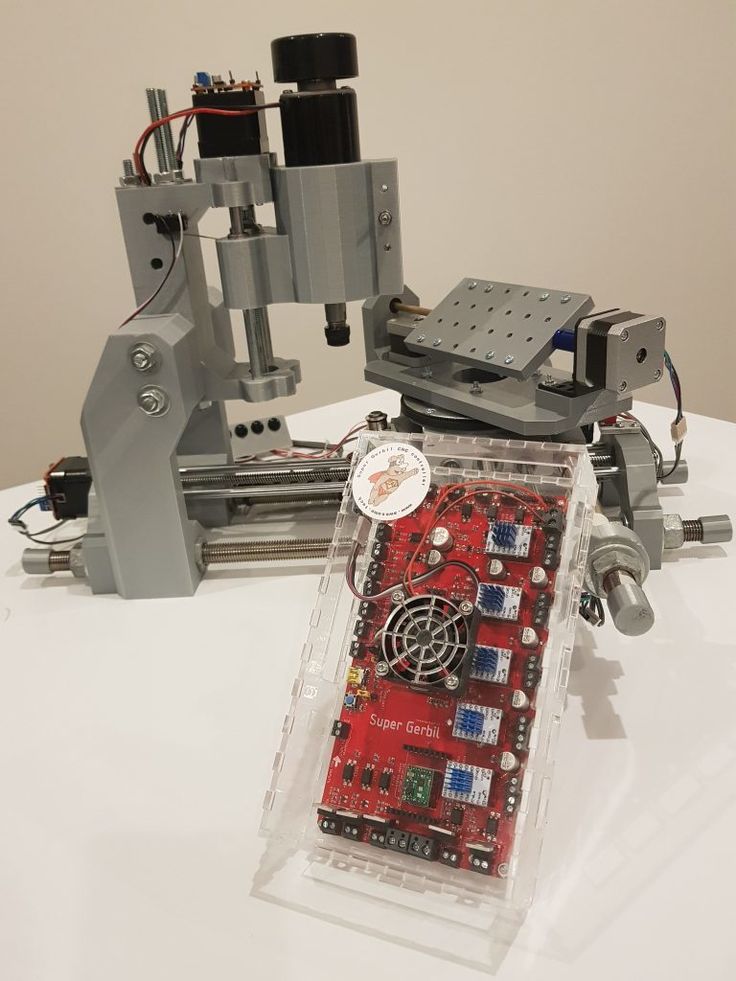

Looking to add as many capabilities as possible without breaking the bank or letting go of quality, Lumi has produced another small resin SLA 3D printer that also acts as a compact laser marker and engraver and a fast PCB etcher.

The LumiPocket LT is a multi-tasking, standalone machine that allows you to experience the wonders of SLA 3D printing and take your 3D printing projects to a new and enhanced level. As a hobbyist, the sky is the limit for coming up with new creations, gifts, and inventions–but if you are coming to 3D printing from the entrepreneurial angle, here’s your chance to add to your menu of offerings substantially.

“Last year we launched LumiPocket, an affordable, high quality resin based 3D printer. We have learned a lot during this year, and listened to the feedback from our users,” said Marin. “We wanted to create a new 3D printer that was not relying on an external videoprojector. We tested almost every solution for UV image creation, and finally decided to design an alternative version of the Scara arm.

”

“This allowed us to have a very compact image generation unit that can be mounted on the top of LumiPocket. We wanted to expand its possibilities further, so we added laser engraving and PCB etching capabilities to the software we designed. Now LumiPocket LT is also standalone and it does not need a PC connection, so it is even more versatile.”

Just beginning with using a resin 3D printer opens up numerous options as well as the chance to look forward to precision, high resolution 3D prints. It operates with the specialized LumiReact 3D printing resin, but the Lumi team has also tested it completely successfully with FunToDo, Makerjuice, and SpotA resins.

The LumiPocket LT employs a light-curing process to offer the best quality possible in 3D printing, and offers up to 50 microns on the Z axis and 100 microns on the XY axes. With the accompanying software you are able to slice and complete your 3D model and save the file on an SD card. After that, just plug it in to your LumiPocket and watch the little 3D printer go.

With the laser marker and engraver, you can make use of 8bit grayscale and both raster and vector modes. Here’s a great way to add to all your 3D prints right off the bat–plus the Lumi team invites you to use it for producing items like laser etched business cards, QR codes, coasters, and more–all from your home desktop, which may soon be turning into your mini-factory. So far, the Lumi team has tested heavy cardboard, wood, expanded PVC, leather, and more for use. Speed can be expected at 25mm/s depending on which materials you use.

PCB Etching

For etching PCBs, you can eliminate all the hassle of traditional processes by just placing the board inside the included tray, importing the files, and letting LumiPocket etch the PCB, ready for development. Presensitized boards are used, with an average etching time of 30s to 1m, depending on the number of traces.

“I believe that the LumiPocket LT can be a really innovative device in the existing 3D printer market,” said Marin.

“Its custom designed Scara arm allows for high quality in a small footprint, and having a multifunctional machine that can do resin 3D printing, PCB etching, and laser engraving at the cost of a traditional FDM 3D printer is amazing.”

Today’s world is busy, bustling, and puts a high value on efficiency and the ability to multi-task. Style in both the office and home, as well as the home workshop, tends to have a contemporary minimalist approach these days, with not a lot of counter space. If you are engaged in 3D printing and want to do more but don’t really have the space to add equipment, here’s a great way to add functionality without having to purchase an entire lineup of machines to get your projects completed.

Are you looking for increased functionality in your office or home workshop area? Do you see this machine as being able to help you increase creativity levels, or add to your small business offerings? Discuss in the LumiPocket LT 3D Printer & More forum thread over at 3DPB. com.

com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: kickstarter • laser engraver • Lumi Industries • lumipocket • LumiPocket LT • PCB etching • resin 3D printer • sla 3d printer

Please enable JavaScript to view the comments powered by Disqus.

Is thePeachy Printer another kickstarter 3D printer or a new player on the market? / Sudo Null IT News

Articles about new 3D printers appear on Habré regularly and promptly, but so far (two days have passed since the start of the campaign) there has been nothing about this printer. I'll fill this gap, so:

Peachy Printer is the most affordable ($100) 3D printer and scanner.

Watch the introductory video, which reveals the principle of operation and explains where this cheapness came from.

Peachy does not refer to the already familiar printers operating with the melting of ABS / PLA rods, but to printers using Laser stereolithography

(I note that printers with stereolithography used to be on kickstarter, for example, a year ago www.kickstarter.com/projects/formlabs /form-1-an-affordable-professional-3d-printer - but what was called "affordable professional 3D printer" sold for more than $2000)

In our case, laser stereolithography implies that there is a liquid photopolymer (or as it is usually called, resin - "resin") and there is a UV laser that controls the curing process and layer by layer "grows" the model we need. nine0003

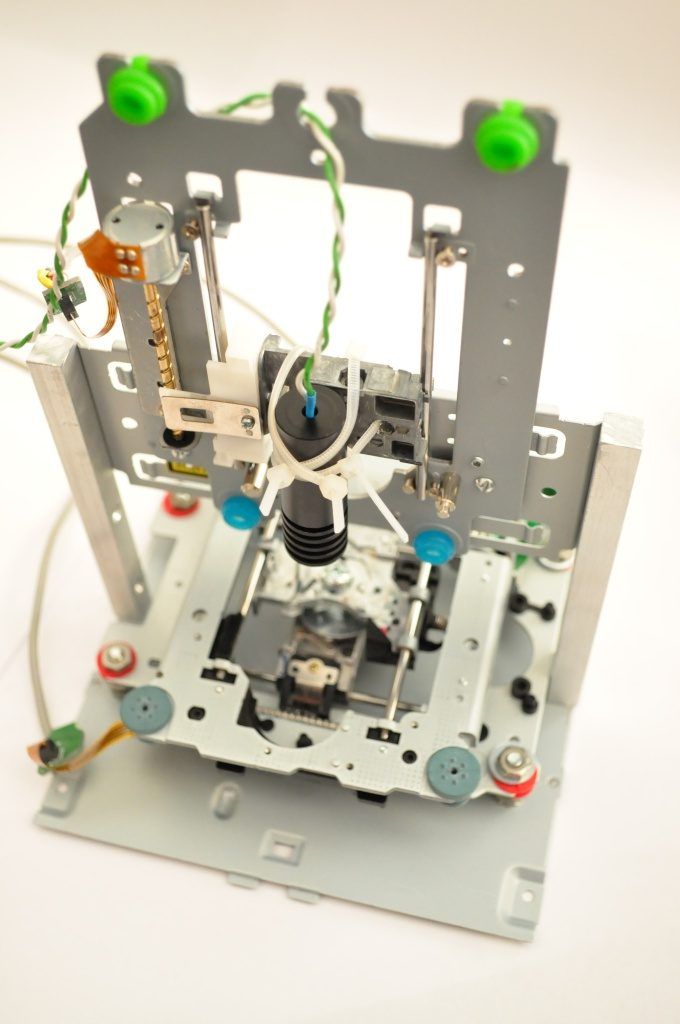

The Peachy printer uses some surprisingly simple yet (seemingly) effective ways to cut costs:

no separate (except for the laser module itself) electronic components. All control of the module is through the output of the computer's sound card, and feedback is through the microphone input. The printer needs two containers, in the upper one - a water-salt solution, in the lower one - a photopolymer. Water drips drop by drop into the lower tank (on the way it closes the contacts that transmit liquid level data to the microphone input), and thereby raises the photopolymer layer higher and higher. The software, in the form of a module for the Blender 3D modeling program, translates the model in the form of instructions for deflecting mirrors that control the laser. nine0003

Water drips drop by drop into the lower tank (on the way it closes the contacts that transmit liquid level data to the microphone input), and thereby raises the photopolymer layer higher and higher. The software, in the form of a module for the Blender 3D modeling program, translates the model in the form of instructions for deflecting mirrors that control the laser. nine0003

Wikipedia on stereolithography

Sample work Peachy

unsightly views of the Module-Mirror and Laser

Create www.peachyprinter.com zealously took up promotion and launched two crowdfunding campaigns at the same time.

www.kickstarter.com/projects/117421627/the-peachy-printer-the-first-100-3d-printer-and-sc

www.indiegogo.com/projects/the-peachy-printer-the-first-100-3d-printer-scanner

Kickstarter has already collected $32,000 out of $50,000 (actually Canadian dollars, but this is approximately the same as in US dollars)

They started on indie later and haven't collected anything yet.

There is no doubt that the required amounts will be collected, but there is a considerable fly in the ointment in our (or rather, in their) barrel of photopolymer:0006! Yes, there will be five more new printers in ten months!

I didn't write anything about “and the scanner”, as they promise to publish details about this a little later. nine0003

Update:

One Google+ user posted a link to a video that was on peachy's official channel but has since been removed from it. Presumably because of the quality of the video (and also because there is a lot of smoking on that video). There you can see the operation of the module in more detail. (from the second minute)

There you can see the operation of the module in more detail. (from the second minute)

P.S . About the photopolymer - the author writes that a special modification of the photopolymer sold on makerjuice.com is being developed for them, the specifications of the original polymer can be read at makerjuice.com/docs/SubG-MSDS.pdf

P.P.S I assume that the name Peachy is derived from Pitch - http://en.wikipedia.org/wiki/Pitch_(resin) perhaps somehow sideways and peach (peach) kissed. And if, as they suggest, look into a banal dictionary, you can find out that "Peachy" → "A slang word for 'thats great'".

Creality Pipeline 3D Printer Goes Kickstarter

News

Subscribe author

Subscribe

Don't want

11

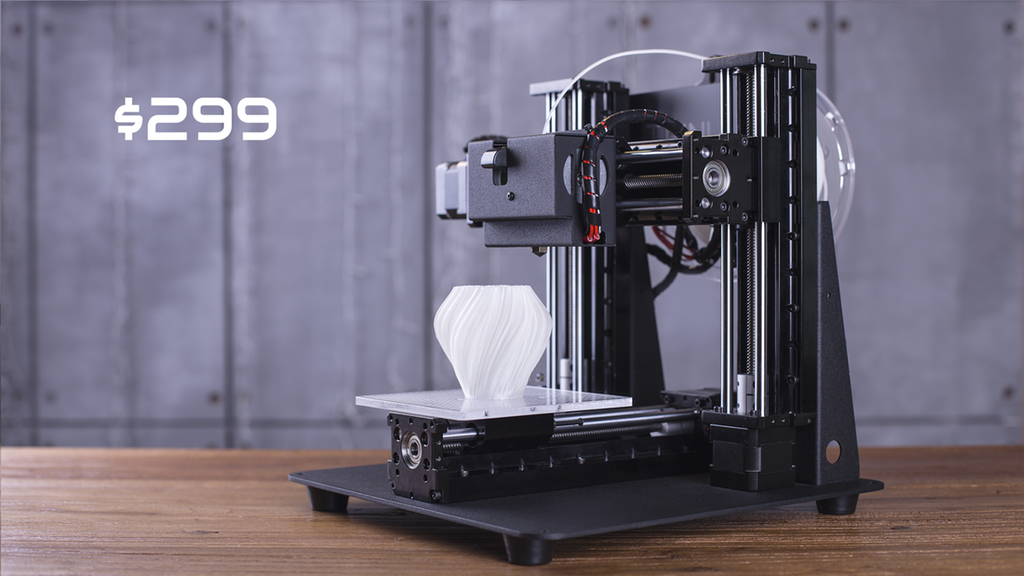

Creality is preparing to accept orders for the 3DPrintMill 3D conveyor belt printer with unlimited plot area on the Z axis. products, and small-scale additive manufacturing.

This 3D printer has already been featured in several reviews under the designation CR-30. In the additive community, the idea of conveyor 3D printers has been floating around for a long time, at least twelve years, but commercial versions have only recently begun to appear: Blackbelt in 2017, Powerbelt Zero in 2019, from the open source versions, the White Knight project can be mentioned. Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

It was only a matter of time before an analogue appeared in the assortment of leading Chinese manufacturers of 3D printers, and already on November 18, everyone will be able to apply for Creality's system, called 3DPrintMill. The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538. nine0003

nine0003

As you can see in the illustrations, the distinguishing features of these 3D printers are the guides mounted at an angle of 45 ° to the surface along the X and Y axes, as well as the conveyor belt. You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window. nine0003

Alternatively, this 3D printer can be used for in-line production, printing one part after another and allowing the models to separate themselves from the tape at the end and fall into a container. From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

Polylactide, PET-G, and TPU are listed as consumables, but there is a heated platform in the work area under the belt. The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt. nine0003

Specifications of 3DPrintMill 3D printer (CR-30):

- Print technology: FDM

- Number of extruders: 1

- Construction area size: 200x170x∞ mm

- Printing accuracy: ±0.

Learn more