3D printing wave bonding

What is Wave Bonding in 3D Printing? The Complete Guide

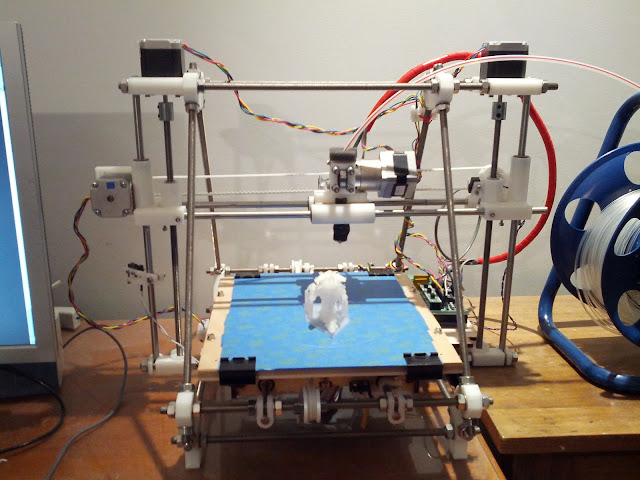

If you’re printing with an M3D or other printer that supports wave bonding, you’re probably wondering what it is. The good news is, wave bonding is relatively simple, easily fits to specific project types, and doesn’t require any special knowledge or skill to use. And, while it can be used in addition to rafting, is often ideal for large prints, which might warp or peel without the added support. If you’re using an M3D printer, wave bonding is a built-in feature, which you can turn off and on at will.

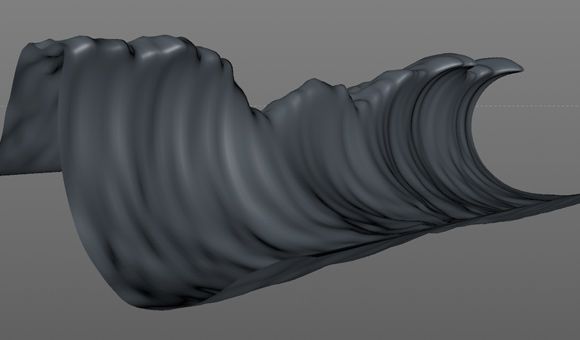

Wave bonding uses anchor points every 5mm of the print to ensure the print model sticks to the surface. This bonding method is often used as an alternative to rafting, or a horizontal latticework of filament underneath the print.

Understanding Wave Bonding Feature

If you have an M3D printer, you can access wave bonding under “more options” from the print menu. From there, you can turn on additional options, like wave bonding, rafts, etc. Wave bonding is a support structure designed to offer added structural support for larger prints. Here, the M3D wave bonding is literally just the process of creating anchor points every 5mm. When the model is printed, it sticks to the anchor points. This then prevents warping and peeling.

For example, if you print a larger model and it starts to peel up – wave bonding could solve the issue. That’s also true if you’re seeing the base warp for larger prints.

Wave Bonding vs Raft When to Use What

Your M3D printer offers multiple structural support options including raft and wave bonding. Both are good options to use – but in different scenarios.

It’s also often pointless to use both at once, because they have some overlap in function.

Raft

Raft printing is a way to create a stabilizing base for prints. It’s primarily used to prevent warping and to ensure good bed adhesion. And, while it’s necessary if your bed isn’t level, a well-levelled bed doesn’t always need it. Rafts consist of a latticework frame which is printed on the bed first. If any slipping is done, it’s by the raft. This ensures that the model itself stays firm, doesn’t slip, and has a better chance of a secure build.

Rafts consist of a latticework frame which is printed on the bed first. If any slipping is done, it’s by the raft. This ensures that the model itself stays firm, doesn’t slip, and has a better chance of a secure build.

Eventually, rafts are a good choice if you’re using any heat sensitive material. For example, ABS. If you want extra security on a model that keep slipping, it’s also a good idea. And, if you’re having issues with warping with smaller models, rafts can be a good call.

Wave Bonding

Wave bonding is an alternative support structure which you can choose to use instead of or in addition to rafts. If you’re printing very large objects, raft separation is common. Wave bonding prevents this, because the anchors are built into the model as part of the first layer. Here, the printer creates a base layer of anchors every 5mm. Wave bonding was designed for printing larger structures that might otherwise warp or peel. And, while it was originally designed for flexible materials like ABS, it’s usable with PLA as well. However, most experienced printers recommend sticking to blue painters’ tape instead as a faster, cheaper alternative.

However, most experienced printers recommend sticking to blue painters’ tape instead as a faster, cheaper alternative.

Wave bonding is also suitable for some smaller prints. That’s ideal if you want to streamline finishing the model. It’s significantly easier to file down anchor points than it is to file down a full lattice. That can save you significant time when finishing the model. However, you should always experiment, so consider using PLA sheet in the print bed.

Some people also consider using both together. However, this isn’t recommended. Both wave bonding and rafts function to provide an anchor and to prevent peeling. Doubling up doesn’t actually add to the effect. However, it does increase the technical difficulty of the print and of removing the print from the raft. Why? Wave bonding is on the first layer. Anchor points are printed on the base. Then if you print a latticework over it, the full base layer can be very deep. Therefore, you might also have to offset the printer nozzle height to avoid pushing the model off the print bed. Some users recommend a 0.5mm adjustment. However, you should check and experiment with yours if you intend to use both.

Some users recommend a 0.5mm adjustment. However, you should check and experiment with yours if you intend to use both.

FAQs

If you still have questions about 3D printing or your M3D printer, this FAQ should help.

What is M3D?

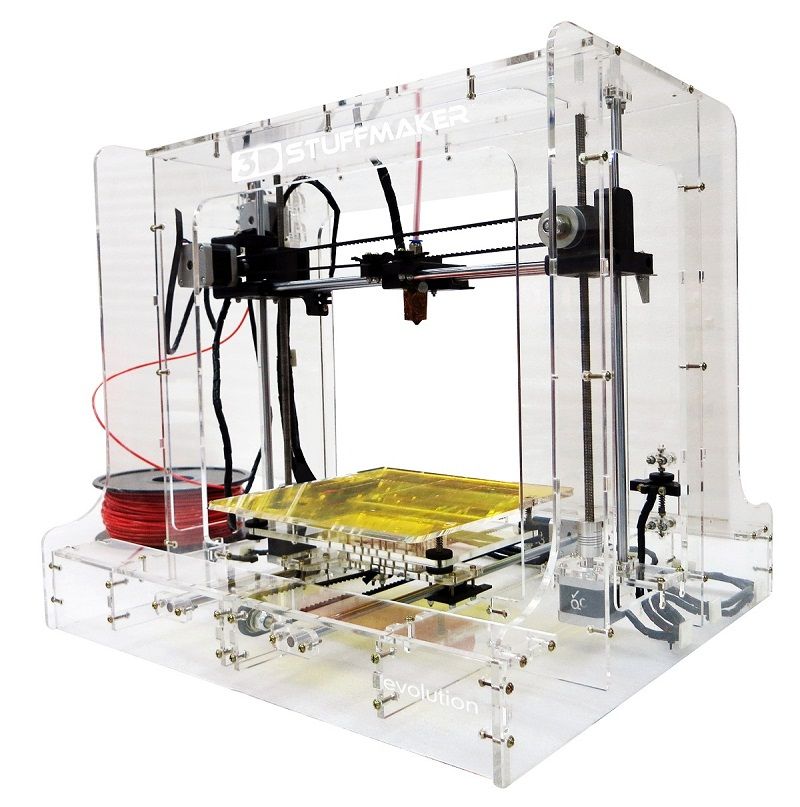

M3D is a small, consumer-oriented 3D printer brand. The brand launched its first 3D printer in 2014, with the Micro 3D printer. It was also the most-funded 3D technology in the world at the time. Today, M3D has revolutionized several trends including color 3D printing, lower noise printing, and multi-filament heads. That makes M3D one of the leaders in home 3D printers – especially with its smaller Micro series.

What is model on model support?

Model on model support normally refers to using support structures to prevent a 3D print from collapsing before it cools. Here, you print arches, pillars, or other supports to support prints with overhang while they are being printed. Lattice supports and newer features like wave bonding may also count.

What is Micro Printer?

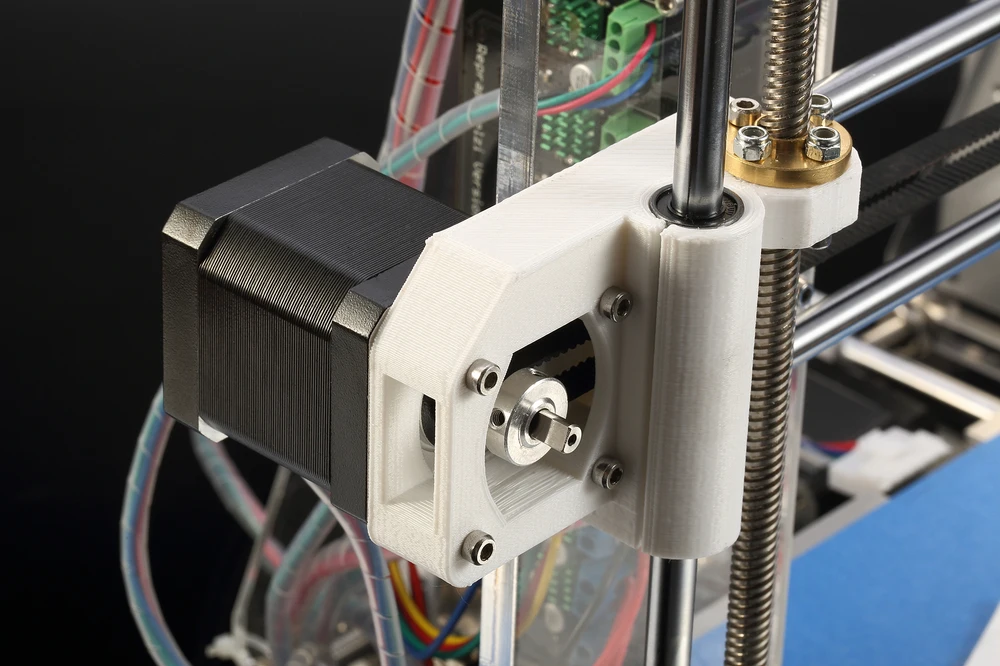

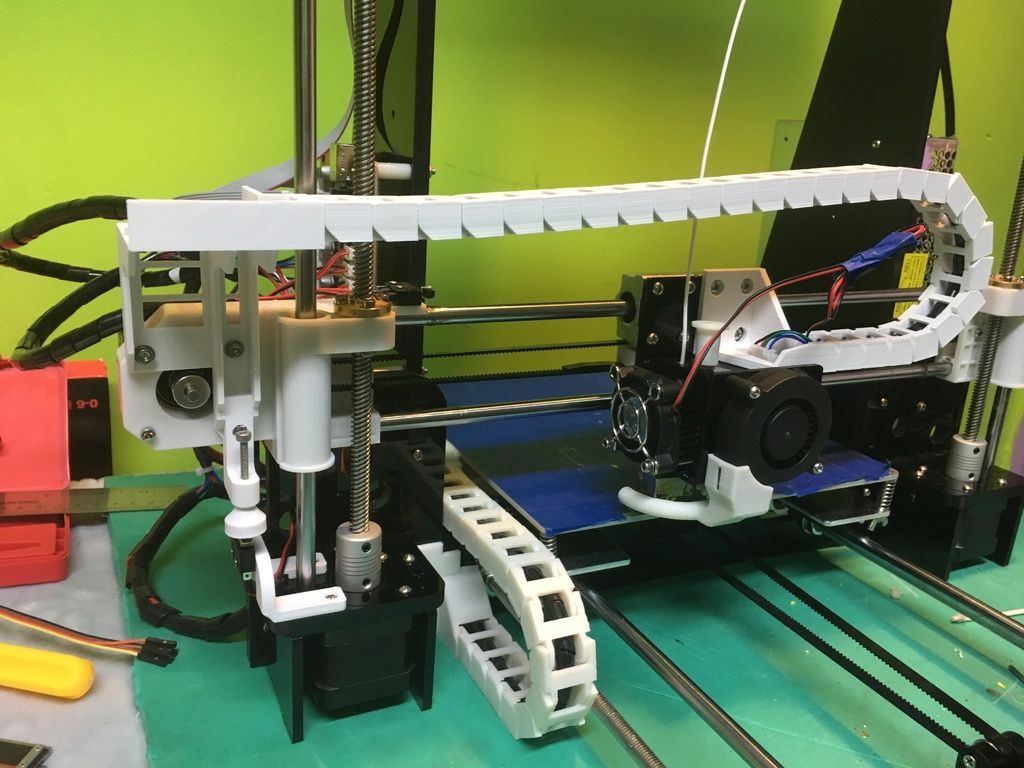

Micro is M3D’s core line of printers. This small line of cube-shaped printers was also one of the first home-use 3D printers on the market. In most cases, they’re small, designed to fit into any space, and designed or smaller builds. However, M3D also sells a range of models that you can build yourself with different bed sizes. In most cases the Micro + is intended for beginner printers who want something small, accessible, and stable.

Final Thoughts

Wave bonding is a somewhat new feature on M3D printers. It’s intended as a structural support option and an alternative to rafts or using tape. It’s also a great choice for larger models because it prevents issues like peeling and warping. At the same time, it doesn’t come with the same inherent risks of separation that you get when using rafts on a larger model. Essentially, it’s perfect for larger ABS builds.

Hopefully, this guide has helped you decide what to do with wave bonding on your printer.

When should I use a raft, when should I use a brim?

Asked

Modified 1 year, 7 months ago

Viewed 81k times

$\begingroup$

Taken from the answer provided by @EricJohnson,

When should I use a raft, and when should I use a brim? What advantages does each have over the other?

Raft

Brim

- rafts

- brims

$\endgroup$

$\begingroup$

A raft will allow for better adhesion for the whole print as the raft attaches to the printing surface and the print attaches to the raft. Rafts go all the way under the print and consist of multiple layers, whereas a brim is only 1 layer and on the outside of the print. Rafts are normally harder to remove than brims because of the increased contact with the print.

Rafts are normally harder to remove than brims because of the increased contact with the print.

From my own experiences, the brim does not help a lot with layer adhesion as it is only 1 layer. I normally use a raft when I need a nice looking 1st layer that is not on the bed or when there are not enough contact points.

$\endgroup$

1

$\begingroup$

A raft is used to prevent warping. Instead of printing directly on the build surface, parts are built on top of it. You remove and dispose of a raft post-print. The raft is larger than the part and so has more adhesion. Rafts are primarily used with ABS to help with bed adhesion. Rafts are also used to help stabilize models with small footprints (e.g. a pole), or to create a strong foundation on which to build the upper layers of a model. If your only concern is bed adhesion it is better to use a brim.

If your only concern is bed adhesion it is better to use a brim.

A brim is attached to a model and extends outward. Brims typically have several outlines and may be a few layers tall. Brims are often used to stabilize small parts of a model, such as legs of a table, because brims help these areas stay connected to the print bed.

TL;DR

The brim is only around a model and attached to its first layer, a raft is also under it.

$\endgroup$

$\begingroup$

A raft helps when the part has few points of contact with the print bed, and doesn't therefore adhere well at points within and without the part.

A brim helps when the part doesn't adhere well around the perimeter of the part.

There are very rare situations where you'll need both, but typically you'll only use one or the other.

$\endgroup$

$\begingroup$

I have been favoring brims recently; I am tired of the rafts becoming an integral part of my print, impossible to remove.

$\endgroup$

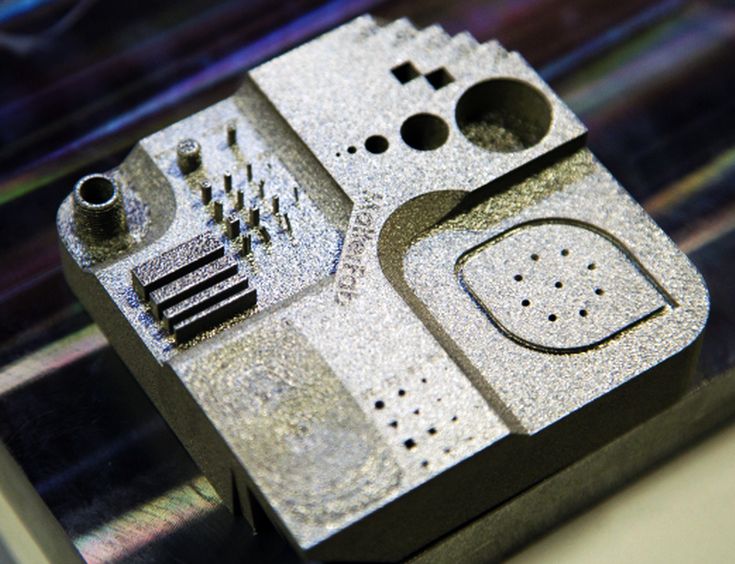

Ways to Bond FDM 3D Printed 3D Models

Overview

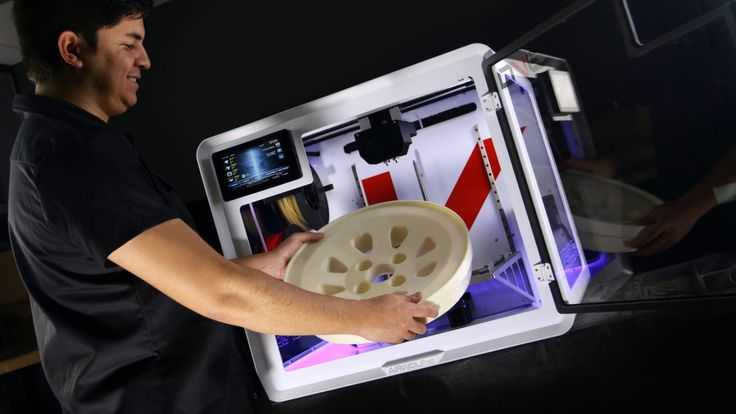

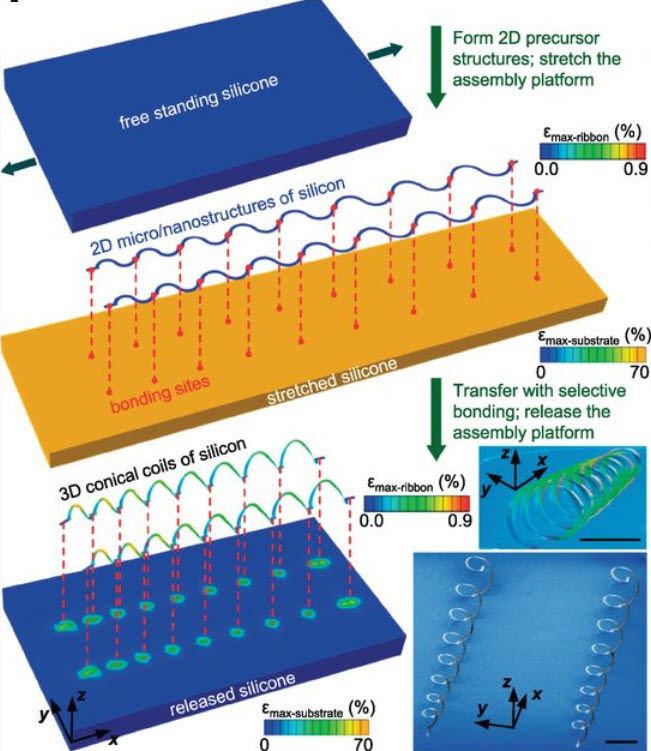

Create models that are larger than your 3D printer chamber, or bond 3D printed parts to other components.

Bonding FDM 3D parts

For models that don't fit on the 3D printer's build tray, for faster build times using less support material, or for models with small features, sectioning and then bonding FDM parts this is a great solution. There are many methods and even more materials for fastening parts. nine0005

The main considerations when choosing a bonding method are bond strength and compatibility with FDM materials. To obtain strength data, Stratasys conducted laboratory tests at the University of Texas EI Paso, which measured the tensile strength. Other criteria - including time, cost, complexity of operations, part configuration and overall performance - were also taken into account. The accuracy of the fastened parts, however, depends on many factors. For example, adhesion characteristics such as viscosity will affect accuracy. The skill of the operator, the method of connection and the type of fastening will have an even greater impact. nine0005

For example, adhesion characteristics such as viscosity will affect accuracy. The skill of the operator, the method of connection and the type of fastening will have an even greater impact. nine0005

To help you select the bonding method that is best for you, below is a brief evaluation of the simple ways to bond parts made from various FDM materials.

Adhesive (epoxy)

Two-component epoxy is commonly used to bond FDM parts. The components are mixed and then applied with dispensers, brushes or infiltration. The thickness of the layer can range from thin (as in caulking) to thick (as in putty), so epoxy application methods will vary. After applying the resin, the parts to be bonded are fixed or clamped until the adhesive has hardened. nine0005

Epoxy formulations vary in curing time, material properties and bond strength. They have very good mechanical strength, good thermal and chemical resistance. The curing process is long, so you have 20 to 70 minutes for minor adjustments after the parts have been joined. The disadvantage of the process is a long hardening time. Curing at room temperature lasts from one to five days, and parts cannot be processed for many hours. Heat curing can greatly speed up the process. nine0005

The disadvantage of the process is a long hardening time. Curing at room temperature lasts from one to five days, and parts cannot be processed for many hours. Heat curing can greatly speed up the process. nine0005

Glue (cyanoacrylate)

Cyanoacrylate is commonly known as super glue. It is a fast curing adhesive that can be used for quick repairs and for easy bonding of parts. Super glue is simply applied to the mating surfaces and the parts are held together. The adhesive connection is established in a few minutes. The specific tensile strength of FDM parts glued with super glue is higher than when glued with epoxy glue. However, its resistance to high temperatures, chemical attacks and solvents is worse. Therefore, bonding parts with super glue may degrade the performance of FDM parts. Thus, cyanoacrylate is recommended for concept models and assembly test prototypes rather than for functional prototypes or finished products. nine0005

Solvent

Solvent bonding works by chemically melting the plastic on the bonding surfaces. The solvent can be brushed onto the mating surfaces, after which the parts are pressed and held together. The solvent can also be injected into pre-fitted and connected parts or existing cracks. A thin, fluid layer of solvent spreads over all surfaces of the part, which improves bond strength. Various solvents can be used, but Micro-Mark's SAME STUFF is recommended. nine0005

The solvent can be brushed onto the mating surfaces, after which the parts are pressed and held together. The solvent can also be injected into pre-fitted and connected parts or existing cracks. A thin, fluid layer of solvent spreads over all surfaces of the part, which improves bond strength. Various solvents can be used, but Micro-Mark's SAME STUFF is recommended. nine0005

The method produces joints that are much stronger than many adhesive joints. Like superglue bonding, the process is very simple and bonding takes place in seconds. Another similarity is that the solvent can be applied to hard-to-reach areas because the solvent penetrates well into the seam or crack.

The advantage over super glue and epoxy is that after bonding, the bonded parts will only contain FDM material. Even though bonding takes place in seconds, the parts must be cured for at least 8 hours. It should also be noted that if the part is heated above 80 degrees, the surface may begin to bubble. Solvent bonding is not suitable for bonding PPSF or ULTEM9 parts085. These FDM materials have high chemical resistance, so they are poorly soluble in solvent.

These FDM materials have high chemical resistance, so they are poorly soluble in solvent.

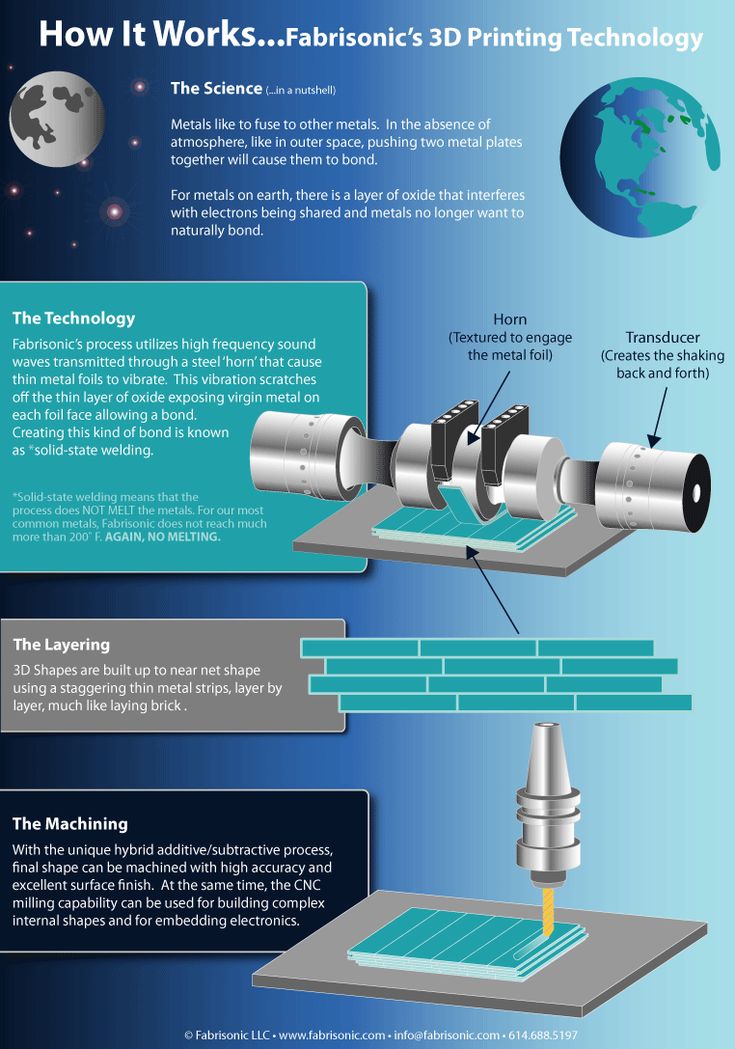

Hot air welding of plastics

Hot air welding of plastics is similar to oxy-acetylene welding of metal. However, a hot air stream is used instead of a flame, and an FDM filament is used instead of a filler wire. To fasten the parts, a hot air tool is slowly passed along the joint. The heat melts the thread, which then fills the seam. This method produces a stronger bond than all other methods. It's also fast and inexpensive. nine0005

Parts can be used immediately after they have cooled down to a temperature where they can be handled. Because the bonding material is a small piece of FDM plastic, the cost is negligible. Another benefit of using an FDM material as a bonding medium is material continuity. The fastening area has the same properties and characteristics as the part itself. For best results, hot air welding should not be used on thin wall sections. Also, the process requires some skills, so the results depend on the experience and technique of the operator. nine0005

nine0005

Ultrasonic Spot Welding

This technology is widely used in manufacturing processes to create permanent bonds between plastic parts. An ultrasonic welding tool uses sound waves to fuse the spot areas of a joint. With the availability of a manual ultrasonic welding machine, this method can be used in the manufacture of small batches of prototypes or in direct digital production. Compared to other bonding methods, there are a few small disadvantages of ultrasonic welding, without taking into account the need to purchase a welding machine. The welded areas are stronger than the surrounding material, while the tensile strength is not as high as in hot air welding or the parts themselves. The tip of the welding machine and nozzles are often interchangeable. A large number of tips and welding nozzles are available, which determine the thickness of the materials to be welded, the diameter of the weld, as well as its type. nine0005

Since there is no filler material that is introduced into the joint area, the accuracy of the parts and their properties do not undergo significant changes. This makes ultrasonic welding ideal for medical applications where the quality of parts is important as well as their suitability for contact with human tissue.

This makes ultrasonic welding ideal for medical applications where the quality of parts is important as well as their suitability for contact with human tissue.

When higher strength is required, ultrasonic welding can be used in combination with other methods. Technological seam of individual parts to fix their position and then the use of adhesives, solvents or other bonding methods. This approach is especially useful for bulky and awkward builds. Ultrasonic welding is a fast and very inexpensive process. As soon as the welding process is completed, the part can be immediately used in the work. Since no consumables are required, the cost of the process includes only direct labor costs. nine0005

Fastening (mechanical connection)

Although this approach is not a fastening method, but a connection method, it can be an effective alternative. There are a large number of mechanical fastening methods and fixtures that can be used when joining FDM parts. One unique way to mechanically connect sections is to insert fasteners into the FDM part during the build process. When it is removed from the Fortus, the fixtures are already integrated inside the part. nine0005

When it is removed from the Fortus, the fixtures are already integrated inside the part. nine0005

quick tips for moving from a CAD model to a printed object / Sudo Null IT News was withdrawn from publication due to a technical error. Please be understanding. Thank you!

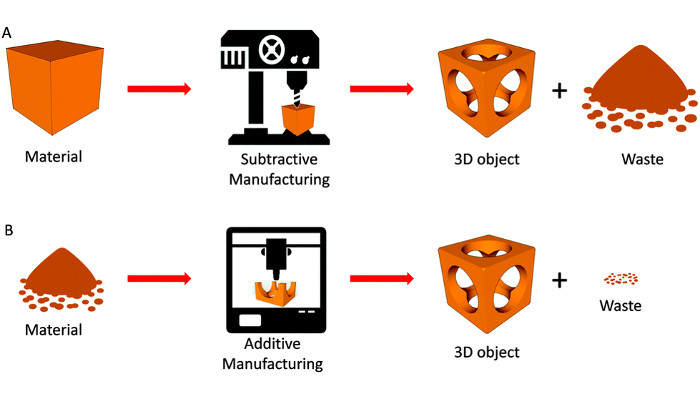

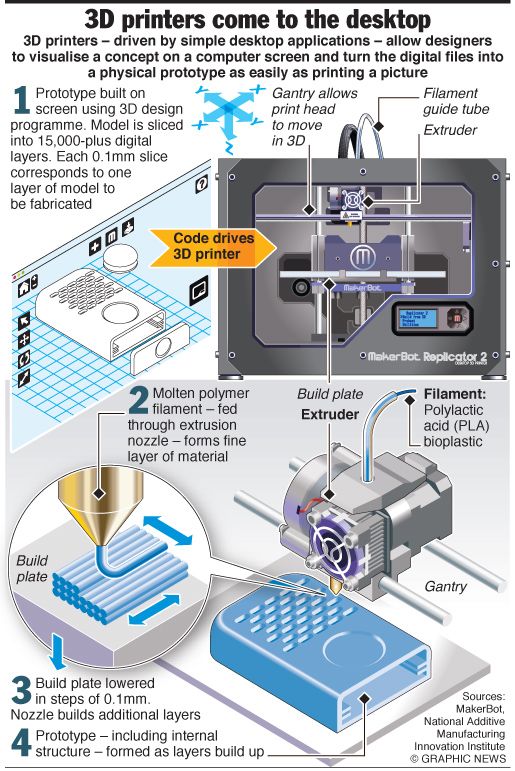

Whether it's just a hobby or a source of income, 3D printing is always based on product design. Those accustomed to traditional technologies will have to rethink the entire approach to product design and manufacture. nine0005

When the project is ready, a number of additional operations are performed: setting the orientation of the model and other parameters that ensure the proper printing process. In addition, it is necessary to take into account the fact that most 3D printers allow you to choose the degree of filling the model with cellular structures. The correct choice of this parameter provides protection of the object from deformation and destruction during the printing process, as well as significant savings in material and reduction in production time.

Finally, the last factor influencing the success or failure of the 3D printing process is the strength of the connection between the model and the table. If the workpiece is separated from the table during printing, then all the work will go down the drain.

Here, we'll walk you through the 3D printing process and provide some simple guidelines for using additive manufacturing in the design phase. In addition, we will dwell on the methods of preparing a finished project for printing, and also consider ways to securely fasten the workpiece to the table. nine0052

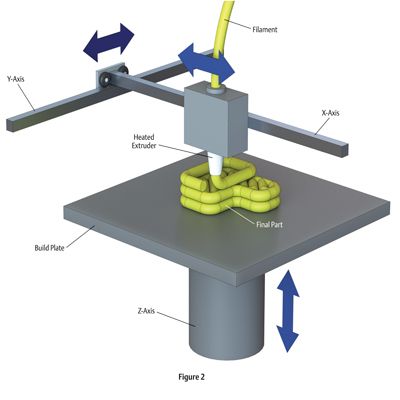

These guidelines apply primarily to Fused Deposition Printers (FDM) printers, but may apply to other types of printers as well. The process of obtaining a finished part by 3D printing is basically the same regardless of the method used.

Designing an object

Any 3D printing starts with construction. If you are developing a product yourself, then you need to build a 3D model of it in a computer-aided design (CAD) system to turn the designer's idea into reality. In this case, the object can be both very simple and very complex. However, too thin and too small models should be avoided. nine0005

In this case, the object can be both very simple and very complex. However, too thin and too small models should be avoided. nine0005

3D-CAD from Siemens from this article for 49900r (90% discount), the promotion is valid until March 20, 2020. Read more>>

Saving the file in a special format for printing

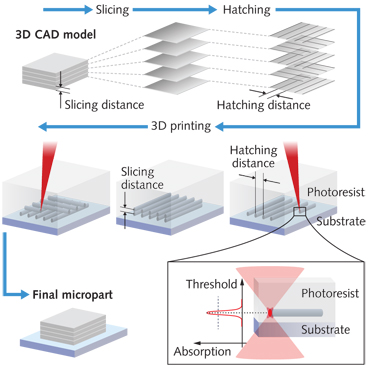

To print an object, its model must be saved in a special file format - for example, STL, which has become the de facto standard in the world of 3D printing. In this format, model surfaces are represented as a grid of triangles. Simple surfaces are broken down into a small number of triangles. The more complex the surface, the more triangles you will need. Today, other formats are used in 3D printing, in particular, the 3MF format developed by Microsoft. But the most common is still STL. nine0005

CAD systems make it very easy to save the model in the desired format: just click the Save As command. To improve print quality, it is desirable to set a number of settings for saving to the STL format - for example, the tolerance during transformation and the angle of the plane. The lower the conversion factor and the better the angle, the smoother the printed part will be.

The lower the conversion factor and the better the angle, the smoother the printed part will be.

Opening the file in the slicer program

Most, if not all, 3D printers come with their own slicer software. The slicer loads the STL file created in the CAD system and cuts it into layers, and then creates a control program for the printer. nine0005

Place the model correctly in the print space

After entering the print settings, the model (or several models) needs to be placed on the printer table. You can print many objects on one table at once. At the same time, compared to printing a single object, the time slightly increases, but in general it still turns out to be less. Here are some tips for choosing the right model orientation.

Set parameters

In the slicer program, the user sets parameters such as print speed, material consumption, nozzle and desktop temperatures. Most slicers have simple settings for beginners. In this case, most often there are also advanced settings so that experienced professionals can achieve optimal results. Advanced settings include percentage infill, amount of backing material, and type of backing or raft (this is a small, thin base that keeps the printed part stable. The backing is removed when it's finished). The number of options is truly endless. Specific settings vary depending on the brand of printer. It's easy enough to set them up. nine0005

Most slicers have simple settings for beginners. In this case, most often there are also advanced settings so that experienced professionals can achieve optimal results. Advanced settings include percentage infill, amount of backing material, and type of backing or raft (this is a small, thin base that keeps the printed part stable. The backing is removed when it's finished). The number of options is truly endless. Specific settings vary depending on the brand of printer. It's easy enough to set them up. nine0005

Sending the control program to the printer

After setting the print settings, the placement of future objects on the table, their orientation and quality, it's time to finally start the printer. It is enough to press the Print button and find something to do while the production is in progress. Depending on the complexity of the design, the process takes from several minutes to several hours.

Finishing

Finishing includes removing the printed part from the table, as well as removing the support material by melting, mechanical separation or dissolution (depending on the design of the printer). The part may require some light sanding or polishing, but overall a properly printed object looks good from the start. Other types of finishing are placing plastic parts in a container with acetone to smooth out surface roughness, gluing (if the dimensions of the structure exceed the dimensions of the 3D printer or individual elements of the object must have different orientations), drilling holes and painting. nine0005

The part may require some light sanding or polishing, but overall a properly printed object looks good from the start. Other types of finishing are placing plastic parts in a container with acetone to smooth out surface roughness, gluing (if the dimensions of the structure exceed the dimensions of the 3D printer or individual elements of the object must have different orientations), drilling holes and painting. nine0005

3D printing process

3D printer design considerations

Eliminate sharp corners

If the direction of the surfaces changes abruptly (for example, a vertical wall intersects with a horizontal overlap), then such a model is difficult to print. The printer will build excessive inner surfaces, wasting too much material. There are two easy ways to prevent this: add chamfers to smooth out where the surfaces meet, or round the corners so the printer gradually builds a vertical surface. In addition, rounding will increase strength, since destruction most often occurs at sharp corners. nine0005

In addition, rounding will increase strength, since destruction most often occurs at sharp corners. nine0005

Elimination of thin walls and small geometries

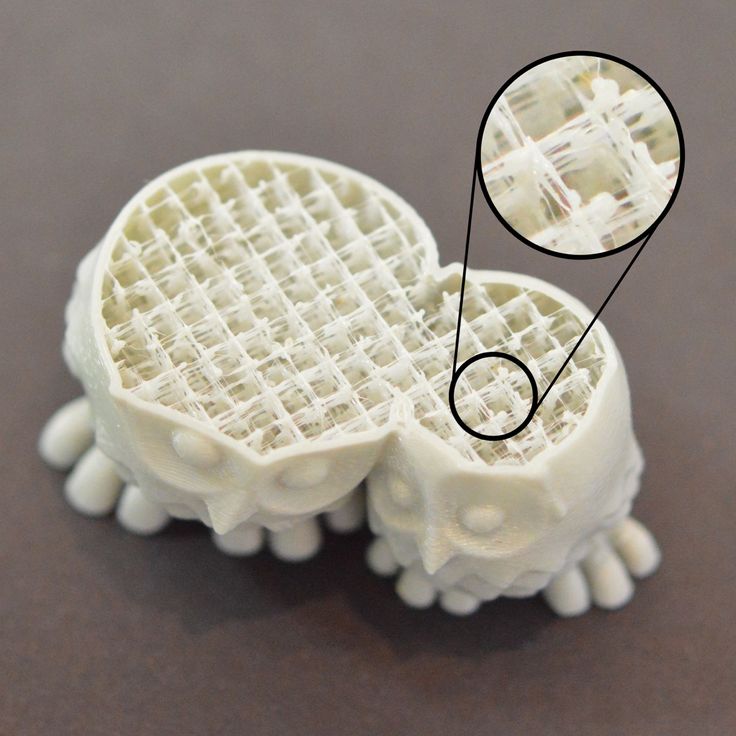

Layer by layer fusing technology consists in supplying hot plastic through a nozzle with the formation of a printed object layer by layer. The thickness of the extruded plastic layer cannot be made smaller than a certain limit, depending on the diameter of the nozzle and the speed of the print head. Excessively thin-walled details are difficult to print - often the result is a chaotic weave of fibers. If the part can be printed, it is very fragile and breaks easily. nine0005

Too thick walls - also bad

On the other hand, if the walls are too thick, they become brittle and crack easily. This is especially important when printing from materials other than resins, as excess thickness during the manufacturing process leads to internal stresses in the part. Even when printing from plastics, material is wasted on walls that are too thick and time is wasted.

Even when printing from plastics, material is wasted on walls that are too thick and time is wasted.

Removing large overhangs

3D printers allow you to create amazing shapes and surfaces, but they are not capable of printing directly in the air. If there is a void in the part with material above it, additional support material must be used. Most slicers add material automatically, but require you to specify the orientation and volume of the support structure. Printers with a single nozzle create an array of thin columns, which then have to be broken off. The result is an uneven surface. Therefore, it is recommended to avoid large overhanging elements whenever possible in order to reduce the need for support material. nine0005

If such an element is unavoidable, you can try to flip the object. Most printers are capable of printing overhanging elements with an angle of about 45 degrees. At a certain height, the edge of such an element may sag somewhat. The actual capabilities of a particular printer are determined by trial and error.

The actual capabilities of a particular printer are determined by trial and error.

Holes shrink

Remember that the part is made of heated plastic. As it cools, it inevitably shrinks. Therefore, holes and other critical structural elements have to be made larger so that after shrinkage their size is as close as possible to the required one. nine0005

However, if you need to make a tight tolerance hole, it is better to print it with a smaller diameter and then ream it with a suitable tool. This is especially true for holes whose axis is parallel to the printer table.

Increasing the footprint

If the area of contact between the object and the base is small, the part may separate from the table during printing. To prevent this from happening, wide bases are added to the model legs, which are installed on the printer table. In general, the closer to the table, the more material must be added to the support. There are other ways to securely fasten the part to the table, which we will discuss a little later. nine0005

There are other ways to securely fasten the part to the table, which we will discuss a little later. nine0005

Special moves

The right approach to design makes printing easier. In addition, there are special post-processing techniques that are important to be aware of.

Place round surfaces vertically

The model should be oriented so that the minimum amount of support material is used. Ideally, it should rest on the table with a large flat edge. In addition, circular geometry must be placed so that the circular faces are vertical. If we look at the printer table from above, we should see a round silhouette of the object. In this case, the part comes out as symmetrical as possible with the formation of a solid round structure. nine0005

Place voids and holes vertically

If there are voids in the model (for example, it is a rectangular pipe), it is desirable to place such voids vertically in order to reduce the volume of the support material. If you print the pipe in a horizontal position, you will have to provide support for the entire interior. If you put the pipe on the end, then no support is required at all.

If you print the pipe in a horizontal position, you will have to provide support for the entire interior. If you put the pipe on the end, then no support is required at all.

The same is true for holes: to get a hole with a straight axis, it is best to print it vertically - in the form of a stack of rings, which avoids warping or deforming a round hole into an oval one. nine0005

Set print quality settings

Proper selection of print parameters, such as STL conversion tolerance and slicer software settings, allows parts to be produced with a surface quality that matches that of cutting. However, this entails an increase in print time. When choosing quality parameters, one should proceed from the purpose of the object: is it a finished product or a prototype? Will the part be visible or hidden? nine0052 The quality parameters also affect the shape of the holes in the part. In CAD files, holes are represented as a set of straight lines at an angle to each other. The higher the quality of the model in the saved STL file, the less the circle looks like a polygon.

The higher the quality of the model in the saved STL file, the less the circle looks like a polygon.

Reducing the layer thickness

To obtain the best quality, especially when using layer-by-layer deposition technology, it is necessary to reduce the thickness of the layers. It does increase the print time, but the end result is worth it! nine0005

Optimizing the filling with honeycomb structures

In terms of strength, objects do not have to be solid. Similar to a honeycomb, printers can create a honeycomb infill that balances strength and saves expensive polymer material. However, if the printed part serves as a prototype for strength testing, and the serial product will be manufactured by traditional methods, and also if the part is subjected to certain types of mechanical stresses and pressures, a solid design will be preferable. nine0005

Choosing material

The success of printing largely depends on the correct choice of material. Materials have different properties. For example, the melting point of thermoplastic polyurethane (TPU) and polylactic acid (PLA) is lower than that of acrylonitrile butadiene styrene (ABS). In addition, the material is taken into account when choosing the type of support structures. For an object made of polylactic acid, supporting elements can be made from the same polylactic acid, since it will be quite easy to separate them from the finished part. If the part is printed from ABS plastic, then the support elements must be made from a different material, and it is better not to use such elements at all in thermoplastic polyurethane parts. nine0005

Materials have different properties. For example, the melting point of thermoplastic polyurethane (TPU) and polylactic acid (PLA) is lower than that of acrylonitrile butadiene styrene (ABS). In addition, the material is taken into account when choosing the type of support structures. For an object made of polylactic acid, supporting elements can be made from the same polylactic acid, since it will be quite easy to separate them from the finished part. If the part is printed from ABS plastic, then the support elements must be made from a different material, and it is better not to use such elements at all in thermoplastic polyurethane parts. nine0005

Cellular filling

A solid body is not always the best choice for 3D printing. Printing solid parts has its advantages, but the internal honeycomb structure saves both expensive material and time.

Creating objects with a specified degree of filling with honeycomb structures is a unique opportunity for 3D printing. Moreover, it is not required to design such a structure: this is done by the slicer program. As a rule, it is enough to set only the percentage of filling (the closer it is to 100, the more solid the object will turn out) and select the type of cells, if the printer has such an opportunity. nine0005

Moreover, it is not required to design such a structure: this is done by the slicer program. As a rule, it is enough to set only the percentage of filling (the closer it is to 100, the more solid the object will turn out) and select the type of cells, if the printer has such an opportunity. nine0005

In addition to saving time and material, the internal honeycomb structure has many other advantages.

Cellular filling prevents warpage

Printing large objects as a single piece introduces a danger of warpage. By reducing the infill percentage, the air during printing passes through the part, providing more uniform cooling and eliminating warping.

Cellular filling does not lead to loss of strength

Printing cells instead of solid material does not reduce the strength of the part. In many cases, a honeycomb part is strong enough for the chosen application, but lighter and less material intensive. nine0005

nine0005

The function determines the choice of cell geometry

Most slicers support a wide variety of cell geometries. The optimal option is determined by the functional purpose of the object. Standard box padding simplifies printing, while hexagonal and triangular boxes add strength. Wave fill allows the object to bend or twist.

How do I choose the right filling percentage?

In general, the strength of an object increases as the percentage of infill increases. Most printers have a default infill percentage of 20, which is optimal in some cases but too high or too low in others. Consider mechanical stresses in the printed object and increase the percentage of infill in areas where greater strength is required. If high strength is not required, choose the lowest possible filling. This saves material and speeds up printing. Most often, the selection of the optimal percentage of filling is done by trial and error. nine0005

nine0005

Ways of fastening the workpiece to the table

“Rafts”, “brims”, “skirts” – these terms sound funny, but they just refer to the three main ways of attaching a 3D printed part to a printer table. Let's take a look at each of these methods and their areas of application.

Skirt

The skirt involves creating a few rings around the object at the beginning of the print to make sure the plastic is extruded normally. The skirt is not in contact with the object at all. It surrounds the printable area and helps start the fusing process. When creating a skirt, a large volume of hot thermoplastic polymer passes through the nozzle. This prepares the printer for printing the part itself. This guarantees good adhesion to the table and obtaining smooth surfaces of the object. nine0005

Brim

The brim is a wide, flat area connected to the main object as a support base (think of a brim of a hat). It is very similar to a skirt, but connected to the model. In addition to all the advantages of a skirt, the brim keeps the edges of the object being made on the table.

It is very similar to a skirt, but connected to the model. In addition to all the advantages of a skirt, the brim keeps the edges of the object being made on the table.

When printing, the outside of an object often cools faster than the middle, causing the edges to curl. Brim prevents this phenomenon by holding the edges.

Raft

A raft is a detachable base, made in the form of a thin mesh platform, located under the entire object (which lies on the raft). To create a raft, the printer first prints a flat plate in two or three layers, and then begins to manufacture the object. nine0005

The rafts provide excellent adhesion to the table surface and also provide a strong print base. This is especially useful when making small and oddly shaped parts that do not fit well on the table, as well as thin-walled objects.

After printing is completed, in most cases the raft will separate easily from the part.

If the printer does not have a heated desktop function

Rafts are used if the printer does not have desktop heating. In this case, excessive adhesion becomes a problem. nine0005

In this case, excessive adhesion becomes a problem. nine0005

An alternative method is to apply adhesive paper tape to the printer bed, with the edges down if possible (this protects the bed itself). You can also use packing tape, but it is usually more expensive.

If buckling does occur or the object separates from the table, apply a dissolvable glue stick to the adhesive tape. This will enhance adhesion.

Find out the features of a specific 3D printer and take them into account when preparing your model

3D printing is not only a science, but also an art. Effective design for subsequent 3D printing requires an understanding of the technological process, taking into account its features and the purpose of the future object. This will greatly improve print performance. nine0005

Using Solid Edge in 3D printing

Not all CAD systems are suitable for 3D printing

The capabilities of the applied system should not limit the designers. Our Solid Edge system is designed with the latest 3D printing technologies in mind. Various 3D printers and 3D printing services are supported.

Our Solid Edge system is designed with the latest 3D printing technologies in mind. Various 3D printers and 3D printing services are supported.

Take it to the next level with specific techniques for designing 3D printed parts

Generative modeling in Solid Edge opens up new possibilities: the designer selects a specific material, sets the design space, allowable loads, restrictions and target mass of the part, and the system automatically calculates the desired geometry. As a result, 3D printing methods can produce the most complex shapes.

In addition, when building models, the use of the results of three-dimensional scanning is provided. Solid Edge successfully combines the traditional boundary representation of solid models (B-Rep) and the representation of surfaces in the form of a grid of triangles, which avoids time-consuming transformations that are fraught with errors. nine0005

If you've already downloaded an STL file for printing, our unique synchronous technology allows you to quickly and easily edit your imported models in Solid Edge in preparation for the process.