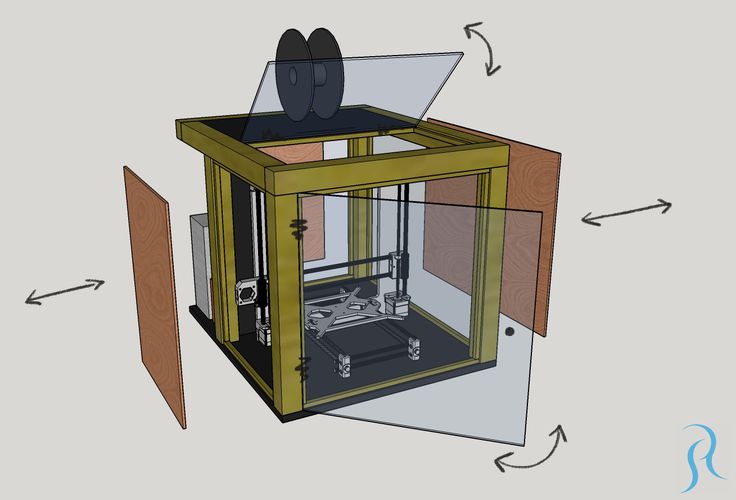

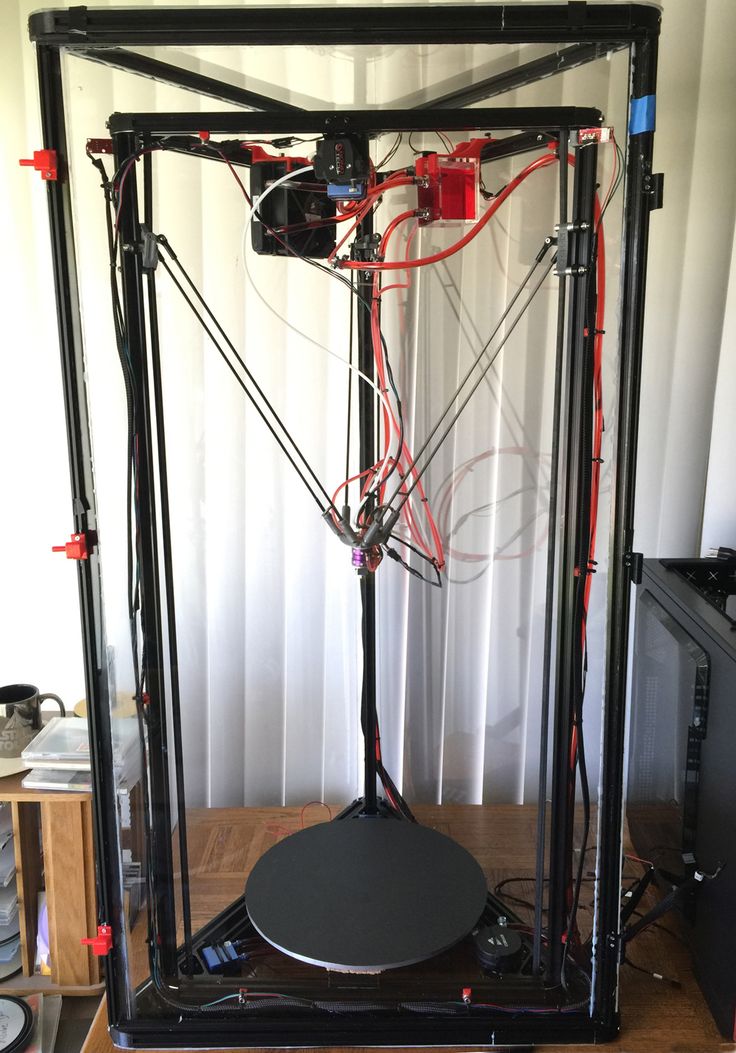

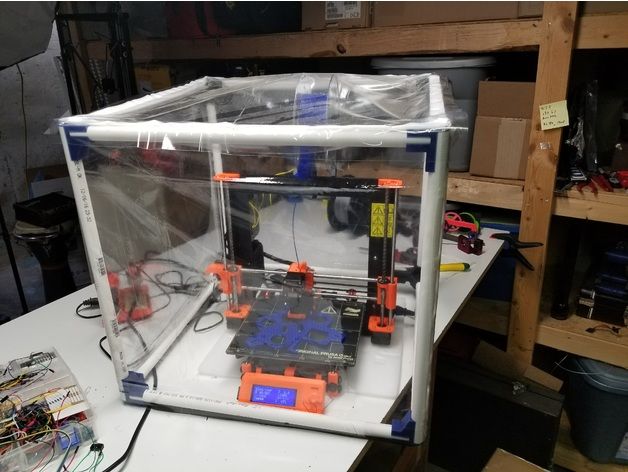

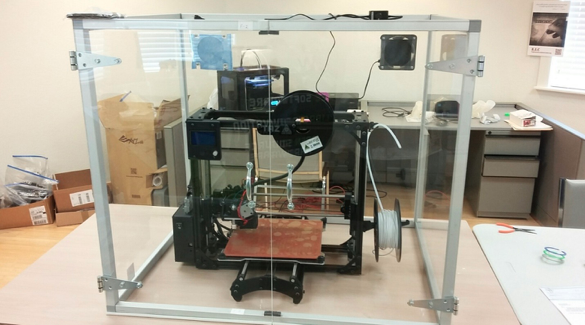

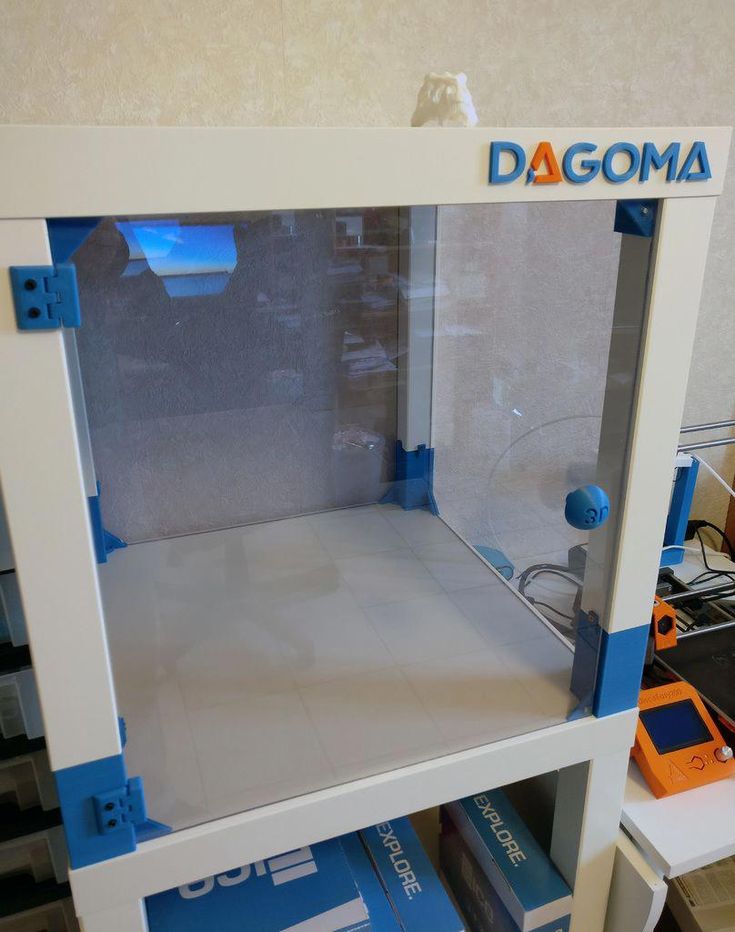

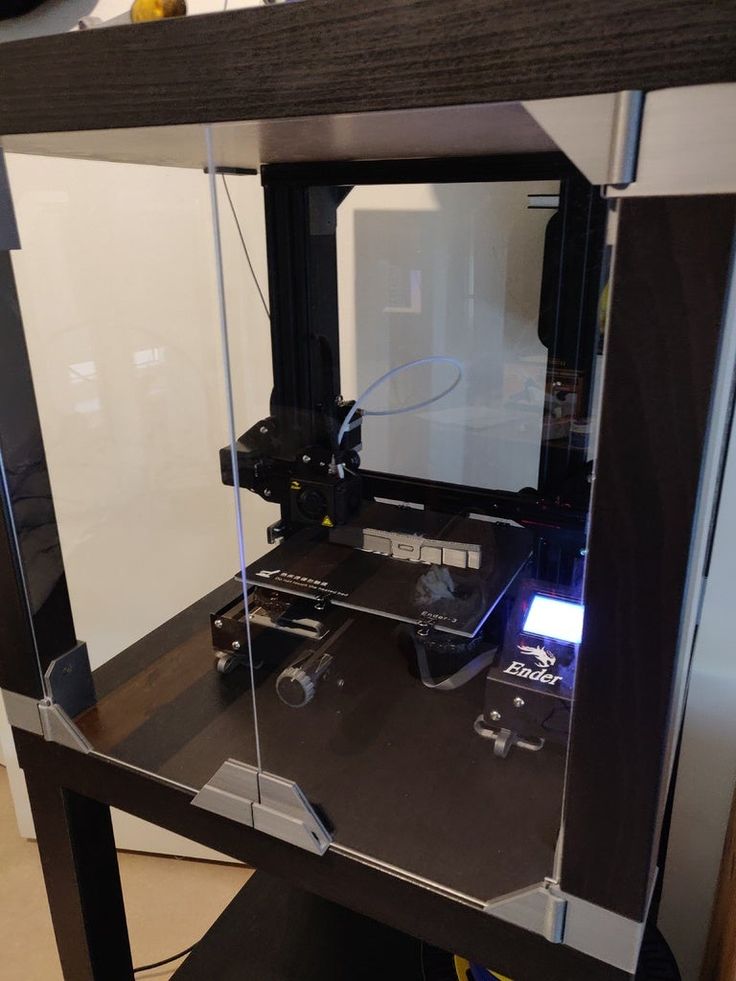

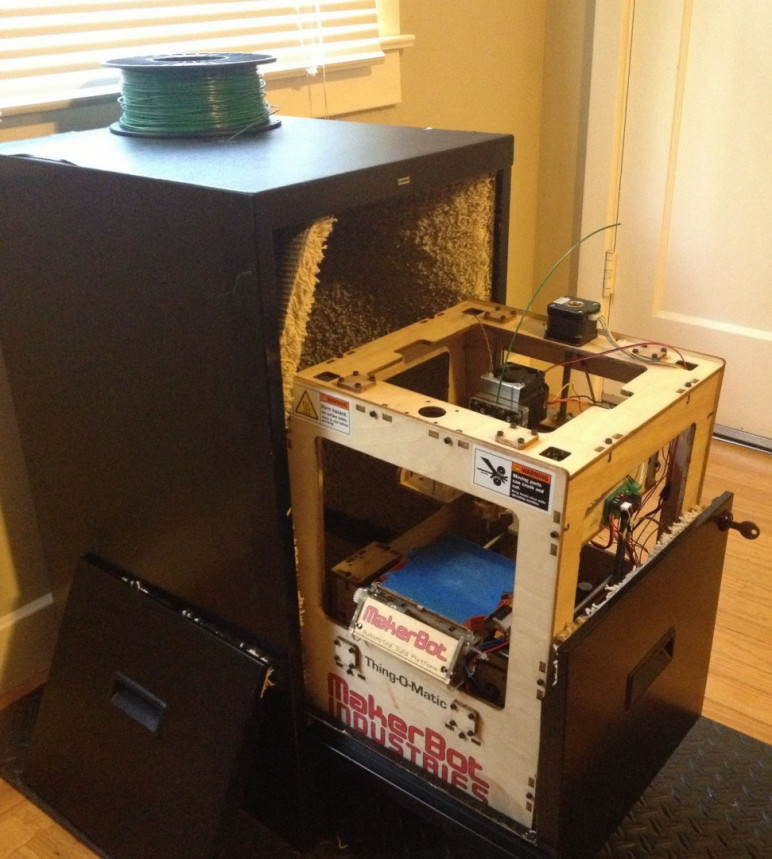

3D printer with enclosure

The 9 Best Enclosed 3D Printers (2022) – Clever Creations

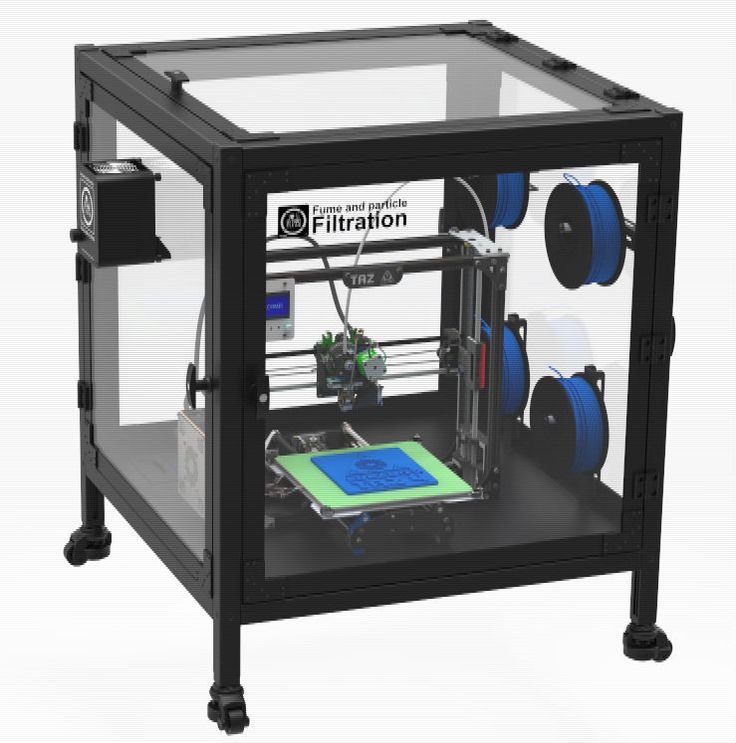

There are many benefits to using an enclosed 3D printer. For example, it provides a much higher level of safety than an open-frame printer, as it contains all the heated components within the printer enclosure. This helps to keep fumes and particles from escaping, which makes using it safer for both the user and the environment.

In addition to their safety, 3D printers with enclosures come in a neat boxy design, have premium features, and give better print results with high-temperature filaments than open-frame printers do. With choices ranging from simple Flashforges to the high-end Ultimakers, however, choosing the best enclosed 3D printer for your needs might be difficult.

To help narrow down your selection, we have compiled a list of the best enclosed 3D printers available right now. No matter your budget, we’ve got you covered.

| Enclosed 3D Printer | Category | Build volume | Price (~) | Best Offer |

|---|---|---|---|---|

| Flashforge Adventurer 3 | Best under 500 | 150 x 150 x 150 mm | $370 | Flashforge |

| QIDI TECH X-Pro | Best under 500 | 230 x 150 x 150 mm | $469 | Banggood |

| Elegoo Saturn | Best under 500 | 192 x 120 x 200 mm | $499 | ELEGOO |

| Flashforge Creator Pro 2 | Best under 1000 | 200 x 148 x 150 mm | $649 | Flashforge |

| Flashforge Adventurer 4 | Best under 1000 | 220 x 200 x 250 mm | $799 | Flashforge |

| Creality CR-5 Pro | Best prosumer | 300 x 225 x 380 mm | $1079 | Creality3D |

| Dremel DigiLab 3D45 | Best prosumer | 255 x 155 x 170 mm | $1600 | MatterHackers |

| Raise3D Pro2 | Best professional | 305 x 305 x 300 mm | $3999 | MatterHackers |

| Ultimaker S5 | Best professional | 330 x 240 x 300 mm | $6355 | MatterHackers |

Best 3D printers with enclosure in 2022

Flashforge Adventurer 3

Best under 500

Check Price

AmazonFlashforgeBanggood

The Flashforge Adventurer 3 is an easy-to-use, budget-friendly, enclosed 3D printer. Aimed towards beginners in 3D printing, the Adventurer 3 gets the basic features right and provides a hassle-free 3D printing experience.

The Adventurer 3 comes with a detachable nozzle system that quickly lets you swap between different nozzles. By default, the 3D printer comes with a 0.4 mm nozzle that can be heated up to 240 °C. This is sufficient to let you 3D print with PLA, ABS, and PETG with ease.

At its low price point, you can expect several downsides. Some of its most significant are the small build volume and proprietary software. Its relatively small print area is enough only for small-to-medium-sized objects and limits what you can 3D print without splitting your models. The proprietary software (Flashprint) has limited features compared to what you can find on more open-source printers.

The Flashforge Adventurer 3 is still an excellent enclosed 3D printer on a budget, excelling in use in classrooms or for other educational purposes. Both its ease of use and safety are great for these scenarios, and the printing quality is more than sufficient for typical classroom models.

Standout Features

- Detachable nozzle

- Flexible, removable heated bed

- Wi-Fi connectivity

Technical Details | |

|---|---|

| Build volume | 150 x 150 x 150 mm |

| Max. hot end temperature | 240 °C |

| Max. heated bed temperature | 100 °C |

| Bed leveling | Manual |

| Connectivity | USB stick, Wi-Fi, Ethernet, FlashCloud, PolarCloud |

| Compatible materials | PLA, ABS, PETG |

What We Like

- Easy to use

- Portable design

- Remote 3D printing

Could Be Better

- Small build volume

- Limited material compatibility

Find Flashforge Adventurer 3 at

AmazonFlashforgeBanggood

QIDI TECH X-Pro

Best under 500

Check Price

AmazonBanggood

The QIDI Tech X-Pro is a budget-friendly, dual extruder, fully enclosed 3D printer. While it is not high on features, a decent build volume of 230 x 150 x 150 mm is enough to print most small-to-mid-sized objects. It comes with a flexible aluminum print bed that can reach up to 120 °C. Enough for 3D printing with ABS or PETG.

While it is not high on features, a decent build volume of 230 x 150 x 150 mm is enough to print most small-to-mid-sized objects. It comes with a flexible aluminum print bed that can reach up to 120 °C. Enough for 3D printing with ABS or PETG.

The QIDI Tech X-Pro uses a proprietary QIDI Print slicer remarkably similar to the earlier versions of Ultimaker Cura. You can use the inbuilt Wi-Fi of the X-Pro to print remotely. The sturdy aluminum body of the X-Pro ensures long-term durability, while the 4.3 full-color touchscreen provides an intuitive user experience.

Everything considered the QIDI Tech X- Pro is a great dual extruder 3D printer. It is a good choice for getting started with dual extrusion 3D printing in classrooms or even in a semi-professional setting.

Standout Features

- Dual extruder setup

- Wireless 3D printing

- LCD Touchscreen

Technical Details | |

|---|---|

| Build volume | 230 x 150 x 150 mm |

Max. hot end temperature hot end temperature | 250 °C |

| Max. heated bed temperature | 120 °C |

| Bed leveling | Manual |

| Connectivity | USB, Wi-Fi, Ethernet |

| Compatible materials | PLA, ABS, and PETG |

What We Like

- Beginner friendly

- Great printing quality

- Reliable company support

Could Be Better

- Limited slicer features

Find QIDI TECH X-Pro at

AmazonBanggood

Elegoo Saturn

Best under 500

Check Price

AmazonELEGOOMatterHackers

Even though all resin 3D printers come in enclosed designs, only a few of them are as good as the Elegoo Saturn. The Saturn 3D printer is the big brother of the Elegoo Mars line of resin 3D printers and delivers excellent printing results with consistent performance.

It features a 4K monochrome LCD that cures resin layers under 2-3 seconds and promises great 3D printing speed. The high-resolution screen ensures an XY accuracy of 50 microns, leading to highly detailed and smooth 3D printed models.

The high-resolution screen ensures an XY accuracy of 50 microns, leading to highly detailed and smooth 3D printed models.

The Saturn 3D printer also features dual linear rails on the Z-axis, ball-bearing leveling for the build platform, and an aluminum resin vat. The double linear railing and the ball-bearing leveling system ensure smooth and stable printing, reducing the chances of print failures.

This is one of the best resin 3D printers in its price range, because of its large build volume and excellent 3D printing quality. If you want high-detail 3D prints at a budget price, the Elegoo Saturn is a great choice.

Standout Features

- 4K LCD monochrome screen

- Dual-linear rails on Z-axis

- UV LED Matrix

Technical Details | |

|---|---|

| Build volume | 192 x 120 x 200 mm |

| XY-axis resolution | 0.05 mm |

| Bed leveling | Automatic |

| Connectivity | USB, Ethernet |

| Materials | 405 nm UV resin |

What We Like

- Fast printing speed

- Large build volume

- Excellent value

Could Be Better

- No air filtration

Find Elegoo Saturn at

AmazonELEGOOMatterHackers

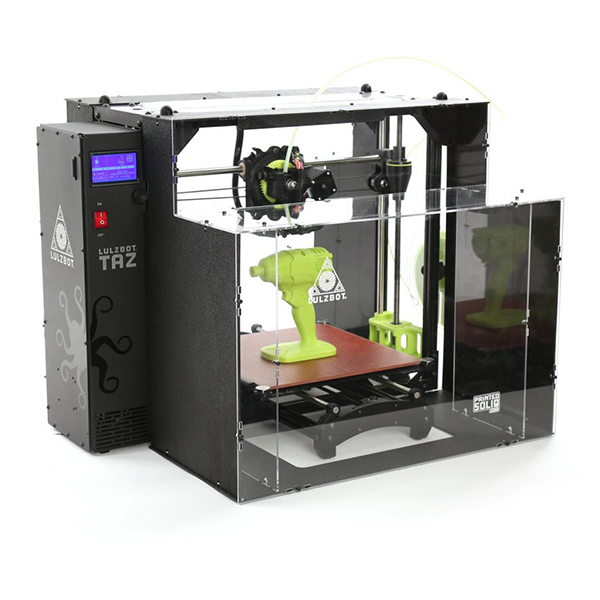

Flashforge Creator Pro 2

Best under 1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

The Flashforge Creator Pro 2 is the successor to the first Creator Pro and improves upon many aspects of its predecessor. With the Creator Pro 2, Flashforge aims to deliver an easy-to-use 3D printer that can print reliably and offers a great 3D printing experience.

With the Creator Pro 2, Flashforge aims to deliver an easy-to-use 3D printer that can print reliably and offers a great 3D printing experience.

The Creator Pro 2 features an Independent Dual EXtruder (IDEX) setup. This lets you 3D print with two individual extruders simultaneously. To get the most out of the IDEX setup, you get different 3D printing modes such as the mirror mode, duplicating mode, and multi-material printing mode.

With its multi-material mode, this 3D printer lets you print with multiple filaments at a time. This is useful if you plan to 3D print complex structures that need soluble supports. Simply use one extruder for your regular filament, and the other for water-soluble PVA filament.

Other than the IDEX feature, the Creator Pro 2 comes with excellent features for its price category. You get a 3.5-inch touch screen, a fully enclosed body, a removable top cover, and a heated bed. The print quality out of the box is good, and with a bit of calibration, you can get consistent high-quality 3D prints.

The Creator Pro 2 is a great 3D printer for hobbyists, semi-professionals, and printing farm users alike. It is compatible with a wide variety of materials, and the IDEX feature is one that is not commonly encountered in this price range. If you’re looking to get started with multi-material 3D printing, the Creator Pro 2 is a superb 3D printer to start your journey.

Standout Features

- IDEX system

- Fully enclosed design

- Touchscreen interface

Technical Details | |

|---|---|

| Build volume | 200 x 148 x 150 mm |

| Max. hot end temperature | 240 °C |

| Max. heated bed temperature | 120 °C |

| Bed leveling | Manual |

| Connectivity | SD card, USB |

| Compatible materials | PLA, ABS, PETG, TPU |

What We Like

- Multi-material 3D printing

- Beginner friendly

- Community support

Could Be Better

- Limited build volume

- Limited to Flashprint software

Find Flashforge Creator Pro 2 at

AmazonFlashforgeGeekbuyingAliExpress

Flashforge Adventurer 4

Best under 1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

The Flashforge Adventurer 4 is a solid upgrade over its previous generations, and if you’re willing to spend a little more, it is a superb 3D printer for the price.

Like the Adventurer 3, you get a detachable nozzle system that quickly lets you swap nozzles. The Adventurer 4 comes with a high temp nozzle that can reach 265 °C. This enables you to print with a lot more materials. To accompany that, you get a flexible, removable heated metal build plate to remove your 3D prints easily.

The rest of the improvements are in the build volume, Y-axis and Z-axis, and its HEPA filtration system. The build volume is now 325% more than its predecessor, and it offers a dual Y-axis design with a reinforced Z-axis for a stable and higher quality 3D printing experience.

The Adventurer 4 is feature-rich and provides good quality prints consistently. The ease of use, well-built quality, and reliability of Flashforge make it an excellent choice for beginners, hobbyists, and professionals alike.

Standout Features

- HEPA 13 air filter

- Quick-release nozzle

- Sturdy build quality

Technical Details | |

|---|---|

| Build volume | 220 x 200 x 250 mm |

Max. hot end temperature hot end temperature | 265 °C |

| Max. heated bed temperature | 110 °C |

| Bed leveling | Semi-automatic |

| Connectivity | USB stick, Wi-Fi, Ethernet |

| Compatible materials | PLA, ABS, PC, PETG, PLA-CF, PETG-CF |

What We Like

- Supports many materials

- Remote 3D print monitoring

- Convenient nozzle system

Could Be Better

- Poor camera quality

- Expensive nozzle replacements

Find Flashforge Adventurer 4 at

AmazonFlashforgeGeekbuyingAliExpress

Creality CR-5 Pro

Best prosumer

Check Price

AmazonCreality3DComgrow

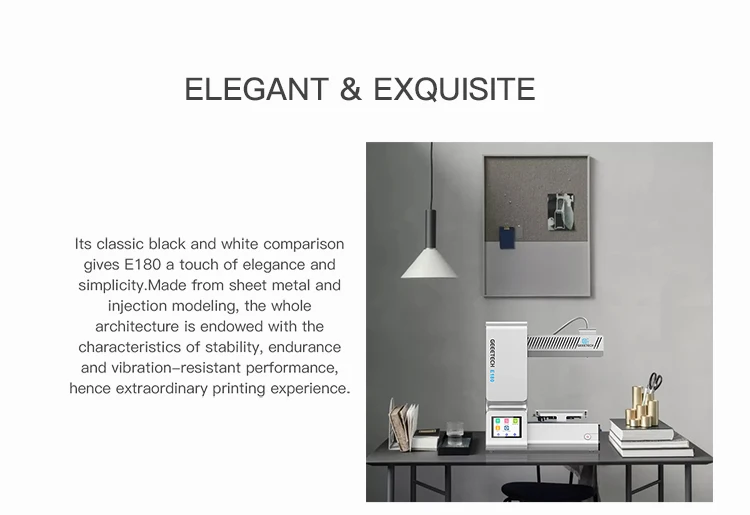

The Creality CR-5 Pro is a premium design 3D printer by Creality 3D, which offers a decent printing quality with a nice enclosed all-in-one design. The boxy white body and the open-end top closely resemble the Ultimaker S5 mentioned above.

Other than that, the CR-5 Pro has a 300 x 225 x 380 mm print volume to let you print more oversized objects with ease. The PTFE-lined hot end can reach only up to 240°C, however, which means you’re limited to printing with only PLA, ABS, and PETG. For an “industrial-grade” 3D printer, these materials are pretty basic.

The print quality on the CR-5 Pro is consistent and reliable, and you can definitely get some very nice-looking 3D printed parts. Considering the high price point of $1199, it is certainly not your average Creality 3D printer. It is aimed towards prosumers, schools, and professionals looking for a reliable desktop 3D printer that delivers high-quality 3D prints without any hassles.

Standout Features

- Large build volume

- Carborundum glass bed

- Intuitive touchscreen UI

Technical Details | |

|---|---|

| Build volume | 300 x 225 x 380 mm |

Max. hot end temperature hot end temperature | 240 °C |

| Max. heated bed temperature | 100 °C |

| Bed leveling | Manual |

| Connectivity | SD card, USB |

| Compatible materials | PLA, ABS, PETG, and TPU/TPE |

What We Like

- Easy to set up and use

- Silent operation

- Sturdy body

Could Be Better

- Poor quality control

- Costly

Find Creality CR-5 Pro at

AmazonCreality3DComgrow

Dremel DigiLab 3D45

Best prosumer

Check Price

AmazonMatterHackers

The Dremel Digilab 3D45 is a fully enclosed 3D printer aimed at educational use but is still equally suitable for professional applications. It is manufactured by the renowned toolmaker Dremel and features a sturdy built with premium quality design.

The Digilab 3D45 has a large footprint with a 255 x 155 x 170 mm rectangular build volume. It features an all-metal hotend that can reach up to 280 °C with a direct drive extruder to let you print with advanced as well as flexible filaments.

It features an all-metal hotend that can reach up to 280 °C with a direct drive extruder to let you print with advanced as well as flexible filaments.

It has an automatic bed leveling sensor designed to level your printing area before beginning your 3D prints. One nice touch is the addition of an active carbon filter to filter out harmful 3D printing fumes and VOCs emitted during the printing process. As the 3D printer is fully enclosed, and considering that it’s designed for use in classrooms, the carbon filter is a great feature to have.

The heated bed and high-temperature nozzle allow ABS, Nylon, and even Polycarbonate printing. Regardless of whether you are considering the Digilab 3D45 for your hobby or your small business, it is capable of living up to your demands.

That is, you can justify paying the high price. Its high cost is not easy to justify for everyone.

Standout Features

- Industrial design

- All metal hotend

- Active carbon filter

Technical Details | |

|---|---|

| Build volume | 255 x 155 x 170 mm |

Max. hot end temperature hot end temperature | 280 °C |

| Max. heated bed temperature | 100 °C |

| Bed leveling | Semi-automatic |

| Connectivity | USB stick, Wi-Fi, Ethernet |

| Compatible materials | PLA, PETG, Nylon, ABS |

What We Like

- Advanced material support

- Consistent, high-quality 3D prints

- Educational support

Could Be Better

- High price

Find Dremel DigiLab 3D45 at

AmazonMatterHackers

Raise3D Pro2

Best professional

Check Price

AmazonMatterHackers

The Raise3D Pro2 is an industrial-grade 3D printer designed with professionals in mind. Its premium build quality, use of high-quality materials, and smooth workflow with proprietary 3D slicer make 3D printing on the Pro 2 a breeze.

The Raise3D Pro2 has a dual extrusion system and retracting hot ends that can reach a maximum temperature of 300 °C. Not only does this let you print with multiple materials at a time, but the high temperature ensures that you can easily print with advanced plastics as well.

Not only does this let you print with multiple materials at a time, but the high temperature ensures that you can easily print with advanced plastics as well.

Pro 2 comes with a HEPA filtration system to filter toxic particulates and fumes. Ideal when working with filaments like ABS and Nylon.

Similarly, its heated bed allows for stable printing of the same filaments. And because the printer is enclosed, there is little need to worry about warping.

On the electronics side, the Raise3D Pro2 offers a powerful 32-bit motion control board and Wi-Fi to monitor and control your 3D prints remotely. Its 7-inch touchscreen has a neatly laid out UI and feels intuitive to use.

With its rich feature set, Raise 3D Pro 2 does not disappoint and consistently delivers excellent, high-quality 3D prints. Even though its capabilities are well-suited for both beginners and advanced users, its price suggests that it is more oriented towards the latter.

Standout Features

- Large build volume

- High temperature hotends

- Wi-Fi and camera

Technical Details | |

|---|---|

| Build volume | 305 x 305 x 300 mm |

Max. hot end temperature hot end temperature | 300 °C |

| Max. heated bed temperature | 110 °C |

| Bed leveling | Automatic |

| Connectivity | SD card, USB, Wi-Fi |

| Compatible materials | PLA, ABS, PETG, TPU, Nylon, ASA, HIPS, PC |

What We Like

- Advanced materials support

- Ideamaker slicer integration

- Premium build quality

Could Be Better

- Large footprint

- High price

Find Raise3D Pro2 at

AmazonMatterHackers

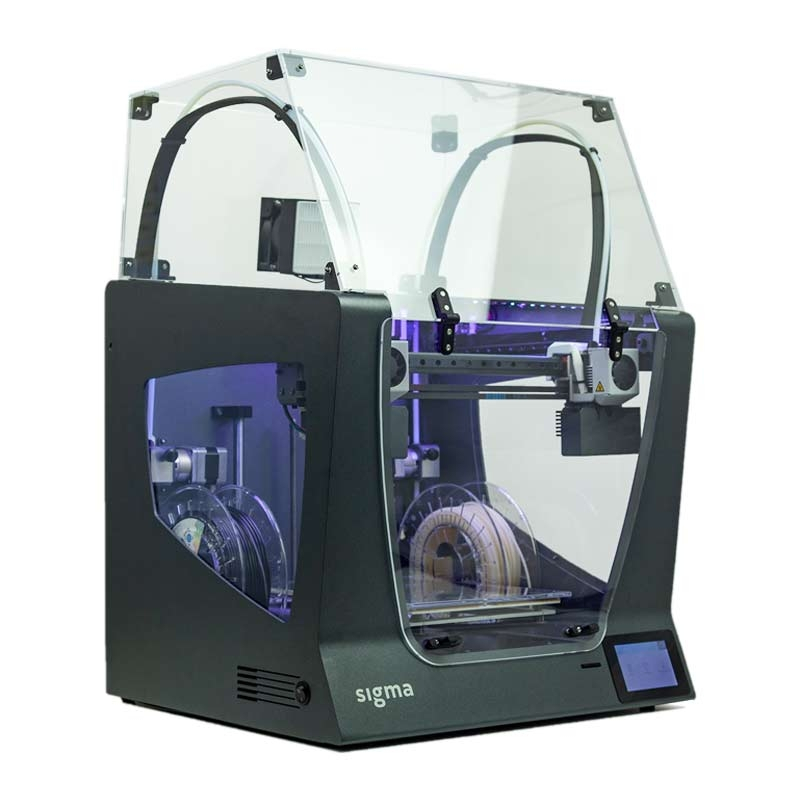

Ultimaker S5

Best professional

Check Price

AmazonMatterHackers

The Ultimaker S5 is a premium 3D printer with an excellent track record of delivering outstanding 3D prints. Its large white boxy design houses a dual extruder setup capable of printing two filaments simultaneously.

Note that his is not the same as an IDEX setup of the Flashforge Creator Pro 2. Instead, the S5’s dual extruder setup is mainly designed to print with multiple materials, such as soluble supports for complex designs.

Instead, the S5’s dual extruder setup is mainly designed to print with multiple materials, such as soluble supports for complex designs.

The dual extruders come with swappable print cores. These are specifically designed for Ultimaker 3D printers and help increase productivity while printing with different materials. A dual gear feeder system grips the filament on both sides increases reliability when for 3D printing with flexible materials, such as TPU filament.

With the Ultimaker S5, you also get access to the Ultimaker Digital factory, a wide range of Ultimaker materials, and premium support. With a price tag of $6355, it is certainly not for everyone. However, if you’re looking for a professional and reliable 3D printer for your next business, the Ultimaker S5 is the top choice.

Standout Features

- Dual extrusion system

- Automatic bed leveling

- Intuitive touchscreen interface

Technical Details | |

|---|---|

| Build volume | 330 x 240 x 300 mm |

Max. hot end temperature hot end temperature | 280 °C |

| Max. heated bed temperature | 140 °C |

| Bed leveling | Advanced active leveling |

| Connectivity | USB, Wi-Fi, Ethernet |

| Compatible materials | Ultimaker PLA, Tough PLA, ABS, Nylon, CPE, CPE+, PC, PP, TPU 95A, PVA |

What We Like

- Premium printing experience

- Quick swappable nozzles

- Support for 200+ materials

Could Be Better

- High price

- Not recommended for beginners

Find Ultimaker S5 at

AmazonMatterHackers

Buyer’s Guide

What to look for when buying an enclosed 3D printer?

Now that we’ve looked at some of the best enclosed 3D printers, it is time to understand what to look out for when buying one. This section will go over the most important features that you need to look at when buying an enclosed 3D printer.

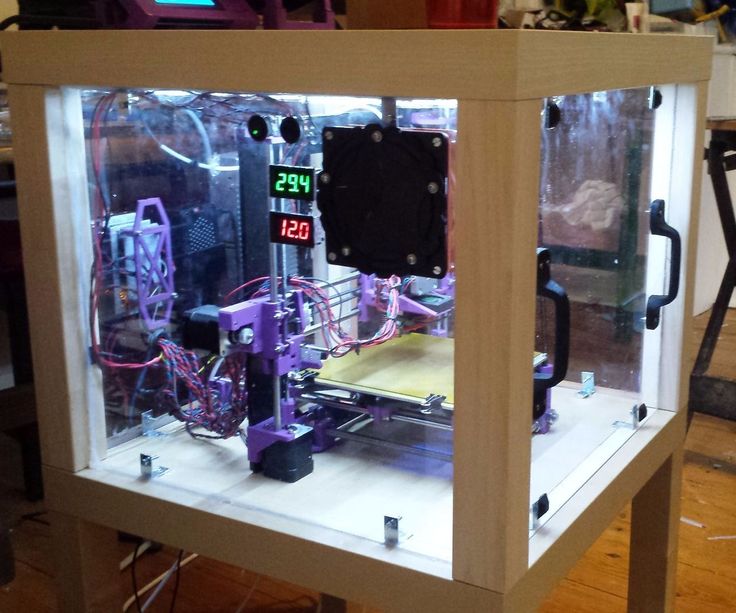

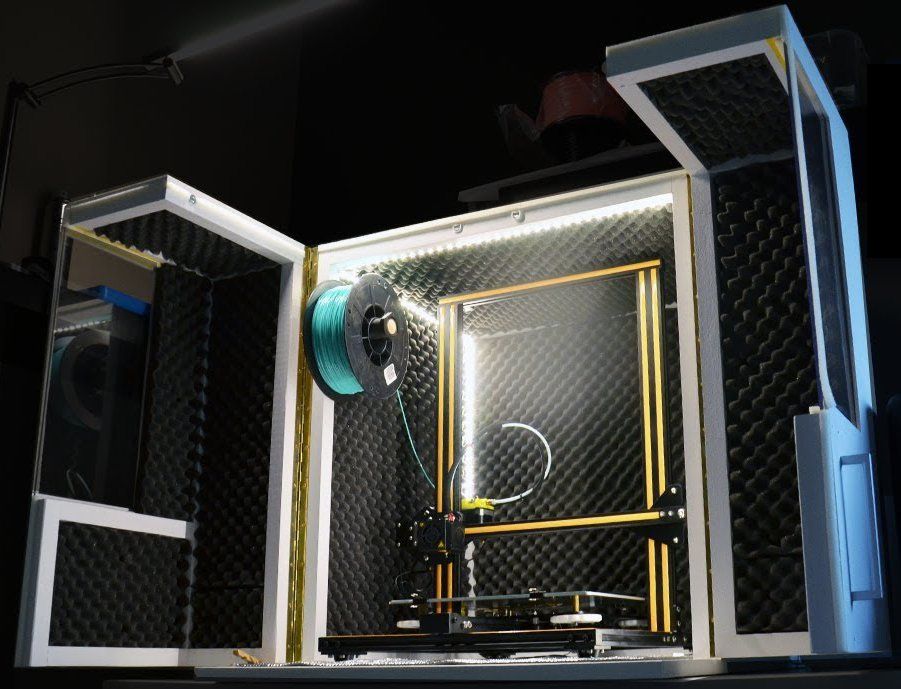

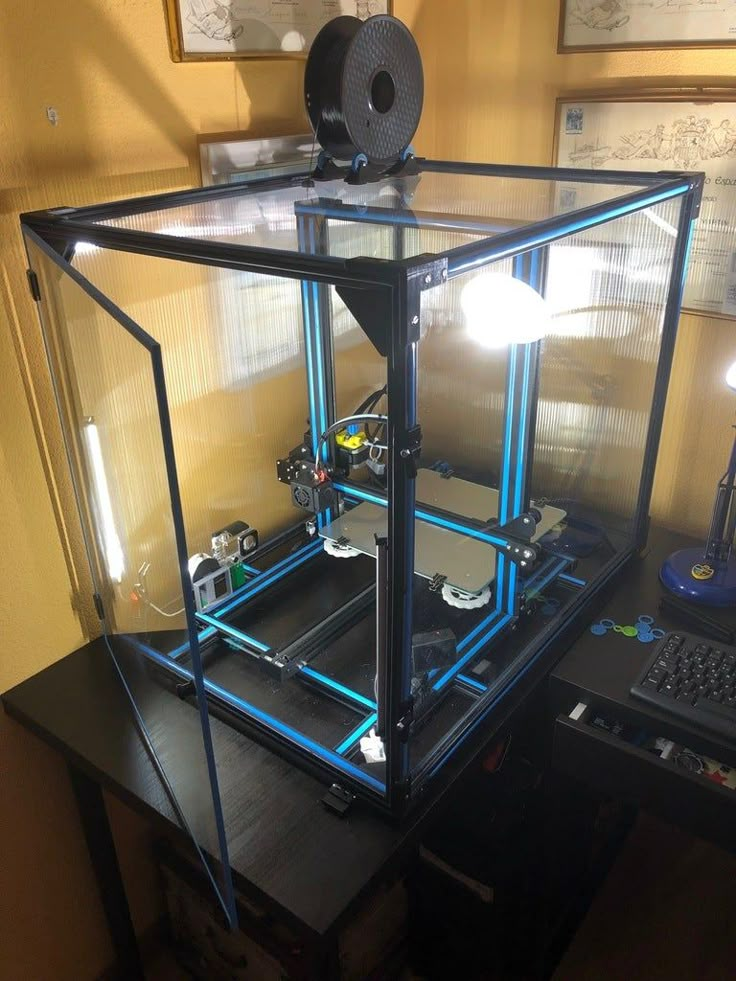

Fully vs partially enclosed

You’ll find that some 3D printers like the Raise 3D Pro 2, Flashforge Adventurer 3, and Adventurer 4 are fully enclosed. This helps maintain a stable printing temperature and protects the 3D prints from air drafts. 3D printer enclosures also reduce stepper motor noises and contain potentially harmful 3D printing fumes from non-PLA filament.

Having a fully enclosed 3D printer basically enhances the overall 3D printing experience and improves the printing quality.

In comparison, 3D printers like the Ultimaker S5 and the Creality CR-5 Pro have a partially enclosed open-top design. While all the electronics are housed well within the body, the filament spool and the Bowden tubes are exposed. The temperature in the printing area in open-top 3D printers can fluctuate greatly and its exposed print area means that it is impossible to include an air filtration system.

HEPA and Carbon Filters

3D printing releases toxic fumes and particulates in the atmosphere during the printing process. These 3D printer fumes consist of harmful Volatile Organic Compounds (VOCs) and Ultra Fine Particles (UFPs). Long-term exposure can cause headaches, nausea, and even respiratory disorders in extreme cases.

These 3D printer fumes consist of harmful Volatile Organic Compounds (VOCs) and Ultra Fine Particles (UFPs). Long-term exposure can cause headaches, nausea, and even respiratory disorders in extreme cases.

HEPA filters are designed to absorb 99.97% of particulates with a 0.3 microns (µm) size. This filters out most of the toxic VOCs. With a built-in active carbon filter, you can get rid of any smell and even the UFPs. If you’re printing in a home environment or around children, it is crucial to consider a 3D printer with a HEPA filtration system.

Build Volume

In open-frame 3D printers, you don’t have to account for the extra space required for the panels, top cover, and the entire enclosure. The build volume to footprint ratio of an open 3D printer is more than that of an enclosed one. Enclosed 3D printers have extra body panels, spool holders, electronics, and some even have extended top covers.

To put things into perspective, the enclosed Flashforge Adventurer 4 has a build volume of 220 x 200 x 250 mm, while the overall footprint of the 3D printer is 500 x 470 x 540 mm. The open-frame Creality Ender 3, which has a similar printing area, only has a 440 x 410 x 465 mm footprint.

The open-frame Creality Ender 3, which has a similar printing area, only has a 440 x 410 x 465 mm footprint.

You should be aware that enclosed 3D printers can take up a lot of space on your desktop and still have a limited printing area. If you want a bigger build volume and an enclosure, be prepared to give up some of your precious desktop real estate.

Heated Print Bed

A heated print bed in a 3D printer lets you print with a wide variety of 3D printing materials. It is a necessity if you want to 3D print with Nylon, ABS, PETG, Carbon fillers, and Polycarbonate.

Especially when you consider that a heated bed in an enclosed 3D printer serves as an excellent way to warm up the printing area and keep it at a stable temperature, it improves the printing quality with specific materials. It helps negate the side effects caused by temperature fluctuations, such as warping and peeling of layers.

Open-source vs closed ecosystem

Some 3D printer manufacturers like end-to-end control over their 3D printers to deliver an optimal 3D printing experience. This closed ecosystem is designed to give you the best software, filaments, and custom-tailored solutions specific to your 3D printer.

This closed ecosystem is designed to give you the best software, filaments, and custom-tailored solutions specific to your 3D printer.

3D printers like Flashforge, Ultimakers, and the Raise 3D have proprietary slicers and filaments. Everything is designed for your specific 3D printer, from the software to the hardware, and you can guarantee consistent quality 3D printing results. These are the printers you start to encounter in the ‘3D printers under $1000‘ and higher segments.

The closed ecosystem is excellent if you want a hassle-free 3D printing experience and do not want to fiddle with too many settings. However, these 3D printers tend to have a higher 3D printer price because of their extra development costs. Similarly, their materials and replacement parts tend to be on the costlier side.

With open-source 3D printers, you have complete control and a wide range of options to choose from. You can select your favorite slicer, your favorite filament manufacturer and are not limited to what the 3D printer manufacturer can provide. Open-source printers are great if you like to tinker with your machines and do not want to spend a premium on replacement parts and filaments.

Open-source printers are great if you like to tinker with your machines and do not want to spend a premium on replacement parts and filaments.

Filament Support

Most enclosed 3D printers come with a heated bed, and some even have dual extruder designs.

Besides the regular PLA filament, ABS, and PETG, some enclosed 3D printers can easily print with Nylon, PVA, and HIPS. The enclosed design helps maintain a warm temperature in the build chamber, crucial for these materials.

Price

Enclosed 3D printers tend to be more expensive than open-frame 3D printers. The extra body materials, sophisticated design, proprietary software, and enhanced user experience are pricey.

Some of the best enclosed 3D printers, such as the Ultimaker S5 and the Raise 3D Pro 2, can go upwards of $4000. Even cheaper enclosed 3D printers, like the Flashforge Adventurer 3, can cost around $400.

This is more than a similar level of open-frame 3D printer, like the Creality Ender 3 v2. If you are looking for a 3D printer under $300, an enclosed printer is unlikely to be an option.

If you are looking for a 3D printer under $300, an enclosed printer is unlikely to be an option.

FAQ

What does a 3D printer enclosure do?

An enclosure protects your 3D prints from external elements. It lowers the stepper motor noise, contains the 3D printer fumes, and prevents air drafts. This enhances the overall print quality. In terms of safety, an enclosure protects the hot elements like the hot end and the heated build platform from children and pets.

What are the downsides of an enclosed 3D printer?

Enclosed 3D printers tend to cost more than open-frame 3D printers. Most of these 3D printers use proprietary software, components, and filaments which also increases the overall cost of the 3D printer.

It is also difficult to access the various elements of an enclosed 3D printer. The enclosed design makes it hard to reach the different components of the 3D printer and affects the repairability of the machine.

Conclusion

3D printers with enclosures are essential if you want to protect yourself from 3D printing fumes or want to work with advanced or high-temperature materials that are prone to warping. To help you pick the best enclosed 3D printer, we have a variety of recommendations depending on your budget.

To help you pick the best enclosed 3D printer, we have a variety of recommendations depending on your budget.

If your budget is $500 or less, the best option is Flashforge Adventurer 3. With its low price, very easy setup, and enclosed printing process, the Adventurer 3 is a great option for beginners in 3D printing.

If you have a bit more to spend for an enclosed 3D printer, say up to $1000, our recommendation is the Flashforge Adventurer 4. The Adventurer 4 offers more advanced features than the Adventurer 3 at an affordable price. Most notably, it offers a significantly larger build volume and a HEPA filtration system.

For serious hobbyists or small businesses with up to $2000 to spend for a 3D printer with enclosure, you can’t go wrong with the Dremel DigiLab 3D45. It is one of the best 3D printers on the market today with its wide material compatibility, large build volume, and filtration system. It does come with a pretty hefty price tag, so you need to be serious about its benefits and features to justify spending that much money on it.

Lastly, for the professionals out there that are more concerned with reliability than price, there is the Ultimaker S5. The S5 is one of the best 3D printers in the world and it doesn’t come cheap with a $6355 price tag. However, its excellent performance, wide material compatibility, and massive build volume make it perfect for serious implementations such as professional prototyping or small business use.

Recommended:

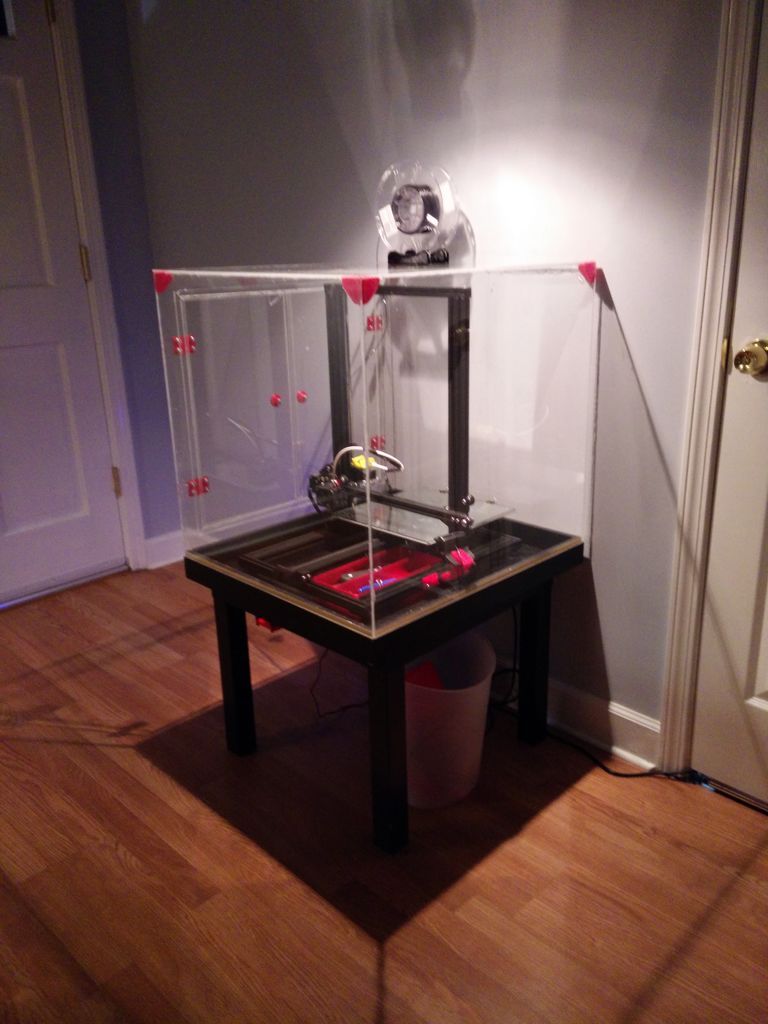

9 Amazing DIY 3D Printer Enclosure Ideas

8 Best Enclosed 3D Printers 2022 (All Price Ranges)

Enclosed 3D printers keep the cool air from getting to your print, causing warping or other issues. For basic filaments like PLA, 3D printer enclosures don’t make all the difference, but for trickier filaments like ABS and Nylon, they’ll save you time and time again.

Most cheap 3D printers are open 3D printers — they have no frame or enclosure (you can sometimes buy them separately) and print in the open air. Almost all 3D printer kits, like the Ender 3 and CR-10, are open air 3D printers (though you can buy Ender 3 enclosures).

However, this can cause problems. ABS, a commonly used 3D printer filament, warps when not cooled slowly. Moreover, enclosed 3D printers keep the hot and dangerous-to-touch 3D printer parts away from yours and anyone else’s prying hands. This is especially important around children, making enclosed 3D printers some of the best 3D printers for kids.

Best 3D printers with enclosures

| Name and brand | Build Volume (mm) | Price | Where to buy | Alternative purchase option |

|---|---|---|---|---|

| Monoprice Voxel | 150 x 150 x 150 | $449 | Amazon here | Matterhackers here |

| Qidi Tech X-Pro | 230 x 150 x 150 | $499 | Amazon here | 3DJake UK & Europe |

| Bibo 2 | 216 x 187 x 160 | $679 | Amazon here | |

| Flashforge Creator Pro / Max | 227 x 148 x 150 | $699 / $879 | Amazon here | 3DJake UK & Europe |

| Dremel 3D45 | 254 x 152 x 170 | $1,599 | Matterhackers here | Dynamism Store here |

| Raise3D E2 | 330 x 240 x 240 | $3,499 | Matterhackers here | Dynamism Store here |

| Raise3D Pro2 / Pro2 Plus | 305 x 305 x 300(600) | $3,999 / $5,999 | Matterhackers here | Dynamism Store here |

| Ultimaker S5 | 330 x 240 x 300 | $5,995 | Dynamism Store here | Matterhackers here |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

Best enclosed 3D printers under $1,000

Flashforge Adventurer 3 Lite – cheapest enclosed 3D printer

- Price: $339 — Available at Flashforge Official store here / Available at Amazon here

- Build volume: 150 x 150 x 150 mm

The Flashforge Adventurer 3 Lite is a compact and quiet, fully enclosed beginner-friendly printer that offers frictionless out-of-the-box printing. There’s minimal setup involved, bar a well-guided five-point assisted calibration process, which makes it a top choice for first-timers or students looking to cut their 3D printing teeth free of hassle.

It’s modeled almost exactly on the full-fat Adventurer 3, minus a built-in camera and filament run-out detector. These minor features don’t detract significantly from the easy printing experience on offer here.

Aside from the sleek enclosed design, the Flashforge Adventurer 3 Lite has everything you need to work with thorny materials like ABS: a flexible, heated bed with a top temperature of 100°C and a max nozzle temperature of 240°C. With these features, you can also dabble in more exotic heat-sensitive filaments such as metal-fill, wood-fill, and others.

With these features, you can also dabble in more exotic heat-sensitive filaments such as metal-fill, wood-fill, and others.

It also has a robust selection of connectivity options, including Wi-Fi and remote print monitoring, thanks to FlashForge’s 3D Cloud Print. A 150 x 150 x 150 mm build volume makes for a tight print area, one of the few complaints that stick when assessing the Flashforge Adventurer 3 Lite. You won’t have much luck printing bulky, towering parts, but this is easily remedied by printing in parts instead.

It’s also worth pointing out that the filament bay mounted on the side of the printer, while practical, isn’t geared to accommodate all types and brands of filament. You may need to fashion an external holder if your third-party filament of choice won’t fit.

Key points:

- Enclosed chamber

- Reliable, beginner-friendly printer

- Wi-Fi connectivity

- Materials: PLA, ABS, Ultra Strong PLA, PLA Color Change, Metal-Filled, Wood, and High Speed PLA

- Price: $449 — Available on Amazon here / Available on Matterhackers here

- Build volume: 150 x 150 x 150 mm

The cheapest enclosed 3D printer we recommend, the Monoprice Voxel is one of the best 3D printers for beginners. It’s super simple to set up (within 10 mins!), is easily operable via the touchscreen, can print via WiFi, and comes with 8GB onboard memory for storing 3D printer files. It comes with a few 3D models on file as well as some filament to get you started, so you can really go from unboxing to printing in minutes.

It’s super simple to set up (within 10 mins!), is easily operable via the touchscreen, can print via WiFi, and comes with 8GB onboard memory for storing 3D printer files. It comes with a few 3D models on file as well as some filament to get you started, so you can really go from unboxing to printing in minutes.

If you’re brand new to 3D printing and not too technical, the assisted leveling reduces expertise to just a tap. It also comes fully assembled so you don’t need any DIY skills, surprising considering most printers in this price range are 3D printer kits. It can also connect to the Polar Cloud, allowing you to remotely control and monitor your printer, and even do so for multiple printers simultaneously.

Key points:

- Cheap enclosed 3D printer

- Beginner friendly

- WiFi printing and touchscreen on an affordable machine

- Materials: ABS, PLA, PETG, Flexibles

- Price: $500 — Available on Amazon here / Available on 3DJake UK & Europe here

- Build volume: 230 x 150 x 150 mm

One of the most popular low cost 3D printers of the last year, the Qidi Tech X-Pro offers reliability, accuracy, dual extrusion, and an effective enclosed printing area, all at $500.

Layer thicknesses start at 0.05mm, and the printer can print at speeds between 30 and 150mm/s — though at these high speeds print quality will noticeably deteriorate. It’s Mac and Windows compatible, and can print via WiFi, as well as via USB or ethernet connections.

The flexible, removable build plate makes for easy print removal with minimal damage, and it comes with Qidi Tech’s own QidiPrint 3D slicer. Overall, it’s one of the best enclosed 3D printers for $500.

Key points:

- Large 4.5 inch touchscreen for ergonomic printing

- Flexible build plate

- WiFi printing and dual extrusion for $500

- Materials: ABS, PLA and PETG

Flashforge Creator Pro 2 – Top Affordable IDEX Printer

- Price: Available at Flashforge Official store here / Check price on Amazon here

- Build volume: 200 x 148 x 150 mm

A well-tooled refresh of the classic Creator Pro, the Flashforge Creator Pro 2 offers all the balmy goodness of an enclosure with features you wouldn’t expect in the $600 to $700 range. We see it as a perfect second printer for a maker that’s already tackled that initial learning curve on a budget FDM kit and is now looking for something more versatile and feature-rich.

We see it as a perfect second printer for a maker that’s already tackled that initial learning curve on a budget FDM kit and is now looking for something more versatile and feature-rich.

While the Flashforge Creator Pro 2 features a sturdy, well-built enclosed print chamber suitable for both ABS and PLA thanks to the removable acrylic top cover, it’s the independent dual extruder system that sets it apart from the other best enclosed 3D printers out there.

An IDEX system is almost unheard of at this price, giving makers the possibility to spice things up with mirror prints, duplicate prints, soluble support structures, and even printing multiple materials or colors simultaneously. It’s one for complex prints with vertiginous overhangs or an ideal tool to help a teacher pump out as many student-designed prints as fast as possible.

These two central points aside, the Flashforge Creator Pro 2 rounds off the offering with a touchscreen interface, a 200 x 148 x 150 mm build volume, and compatibility with PLA, Pearl PLA, ABS, ABS Pro, PVA, and HIPS materials.

It’s worth noting that Flashforge made the unfortunate choice of anchoring the Creator Pro 2 to its in-house FlashPrint slicer. It does the job well enough but doesn’t have the versatility of an open-source software kit like Cura. Not necessarily a deal-breaker, especially for 3D printing newcomers or educators that want straightforward software and pre-loaded settings specifically tuned to work with the Creator Pro 2 from the get-go.

Key points:

- Affordable independent dual extruder system

- Fully-enclosed print chamber

- Materials: PLA, Pearl PLA, ABS, ABS Pro, PVA, and HIPS

- Price: $679 — Available on Amazon here

- Build volume: 216 x 187 x 160 mm

Full of character and affordable for hobbyist makers, the Bibo 2 offers 50-micron accuracy, dual extrusion, and WiFi printing, all at well under $1,000.

Though not an IDEX printer, this enclosed 3D printer still offers copy printing modes for printing two of the same objects simultaneously. It has an easy to use touchscreen — not a given in this price range — and has filament run out detection to avoid ruining prints.

It has an easy to use touchscreen — not a given in this price range — and has filament run out detection to avoid ruining prints.

As well as a 3D printer enclosure for effective ABS and Nylon 3D printing, the Bibo is built in a stable and strong aluminium frame, minimizing unwanted vibrations that can slightly affect performance and print quality. Overall, for the price it’s a great enclosed 3D printer — and it can also come with a laser engraver kit.

Key points:

- WiFi printing, dual extrusion, and a touchscreen, all for just over $500

- 50-micron minimum layer heights

- Claims to be able to print Polycarbonate, but also says max temperature is 270C

- Materials: PLA, ABS, HIPS, flexible filaments, PETG, Nylon, PC, Carbon fiber

Best prosumer enclosed 3D printers

Dremel 3D45- Price: $1,599 — Available on Matterhackers / Available on Dynamism / Available on Amazon

- Build volume: 254 x 152 x 170 mm

Accurate, versatile and perfect for teaching 3D printing in schools, the Dremel 3D45 builds on almost a century of Dremel manufacturing excellence. Boasting up to 50-micron accuracy, connectable via WiFi as well as by USB or ethernet cable, and compatible on Mac or Windows computers as well as iPads, the Dremel Digilab 3D45 perfectly complements any school or business prototyping environment.

Boasting up to 50-micron accuracy, connectable via WiFi as well as by USB or ethernet cable, and compatible on Mac or Windows computers as well as iPads, the Dremel Digilab 3D45 perfectly complements any school or business prototyping environment.

The heated plate means it can print Nylon and Eco-ABS, and the built-in HD camera makes for easy remote monitoring of print progress, which can be easily done via their cloud 3D printing software.

If you do run into any problems, Dremel’s USA-based support are on hand to help you. Overall, it’s a reliable and accurate enclosed 3D printer that offers good build volume and results for the price.

Key points:

- Effective auto leveling system

- Highly-rated customer support

- Versatile

- Materials: PLA, PETG, Eco-ABS, Nylon

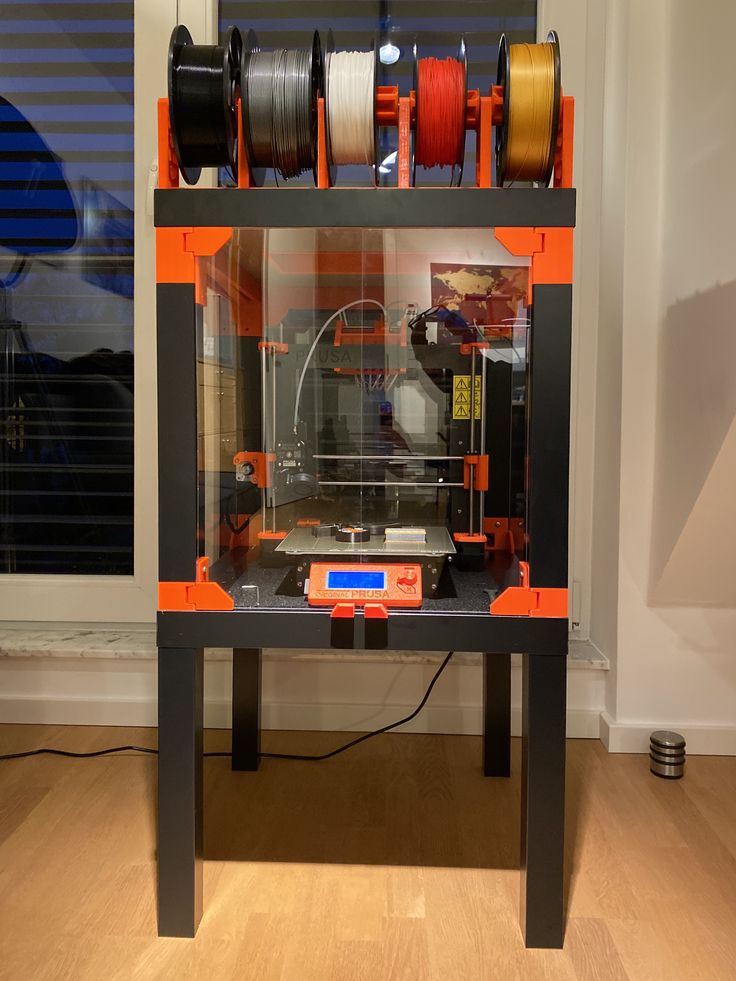

- Price: $3,499 — Available on Matterhackers / Available on Dynamism / Available on Amazon / 3DPrima Europe here

- Build volume: 330 x 240 x 240 mm

Raise3D’s large, enclosed 3D printer brings IDEX dual extruder 3D printing to their already impressive 3D printing range. IDEX 3D printer extruders can move independently, greatly increasing print speeds and efficiency, especially for printing multiple similar or identical parts.

IDEX 3D printer extruders can move independently, greatly increasing print speeds and efficiency, especially for printing multiple similar or identical parts.

The E2 features two main modes:

- Mirror mode: 3D prints inverted mirror versions of your model, for example a left and right-footed shoe sole, simultaneously.

- Duplication mode: uses both extruders in synchrony, printing two identical objects at the same time and doubling printing efficiency.

The E2’s 3D printer enclosure keeps the heat in, and everything else out. If the door is opened during printing, progress is immediately paused to ensure nobody is burned or harmed by the extruder or heated bed. The E2 also has an effective air filtration system, removing melted plastic particles and aromas, as well as filament run out sensors and power outage recovery features.

Key points:

- Build volume drops to 295 x 240 x 240 mm if using the dual extruder

- Useful Mirror & Duplication modes

- Built-in safety measures

- Materials: PLA, ABS, HIPS, PC, TPU & TPE, PETG, Nylon, PP, ASA, PVA, Glass-infused, Metal-filled, Carbon fiber-filled, and wood-filled filaments

Best upper-range 3D printers with enclosures

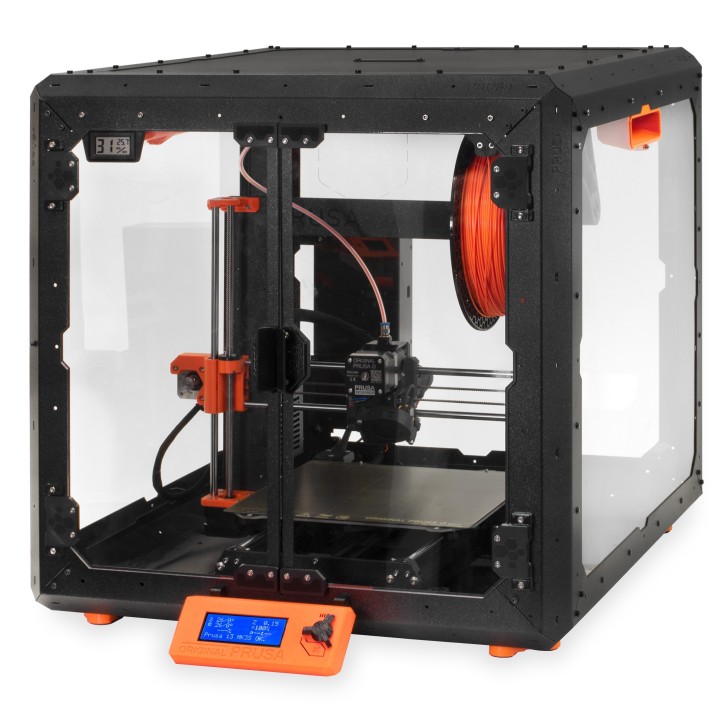

Raise3D Pro2 / Pro2 Plus- Price: $3,999 / $5,999 — Available on Matterhackers here / Available on Dynamism here / Available on Amazon here

- Build volume: 305 x 305 x 300 (605) mm

A true workhorse 3D printer with full enclosure, the Raise3D Pro2 range offer incredible accuracy, material compatibility, great workflow, and a host of other key features.

The standard Pro2 already features a very large build area, with the Pro2 Plus expanding the z-axis range up to up 605 mm tall parts. The extruders can reach 300C for even the toughest filaments like PC, and the dual extruders make for effective soluble support printing as well as 3D printing multiple colors.

With minimum layer heights of 0.01mm possible, the Pro2 enclosed 3D printers can print incredibly crisp and intricately detailed parts. Switch out the nozzle for a smaller nozzle, and zone in on small details for a fantastic finish. The built-in camera makes monitoring prints easy, and the 7-inch touchscreen offers data and a simple to use overall workflow.

Key points:

- Dual extruder build volume: 280 x 305x 300 mm

- Complete printer: accurate, reliable, enclosed, versatile.

- Materials: PLA, ABS, HIPS, PC, TPU, Nylon, ASA, PETG, PVA, Glass, Carbon fiber, Wood

- Price: $5,995 — Available at Dynamism here / Available on Matterhackers here / 3DPrima Europe here

- Build volume: 330 x 240 x 300 mm

Capable of 3D printing industrial-grade parts with up to 20-micron layer resolutions, it doesn’t get much better than the Ultimaker S5. An enclosed 3D printer that becomes even more effective and safe with the S5 Pro Bundle, the S5 offers reliable and repeatable dual extrusion, at astonishing accuracy, even with abrasive filaments like glass and carbon fiber filaments.

An enclosed 3D printer that becomes even more effective and safe with the S5 Pro Bundle, the S5 offers reliable and repeatable dual extrusion, at astonishing accuracy, even with abrasive filaments like glass and carbon fiber filaments.

Though Ultimaker make their own filaments, the S5 is open and can be used with any 2.85mm filaments. It prints via WiFi as well as a variety of other methods, and can be monitored remotely via the built-in camera.

If you purchase the S5 Pro Bundle, you gain access to 24/7 automated material handling, air filtration and heat control for up to 6 filaments, as well as the Air Manager which further encloses the 3D printer.

Key points:

- Excellent precision and print quality

- Reliable and effective with many materials

- Pro Bundle makes it an even more effective enclosed 3D printer

- Materials: PLA, CPE, NYLON, ABS, Glass, Carbon fiber, PC, PVA, PP, TPU

Buyer’s Guide – What To Consider

Fully or Partially-Enclosed Chamber

Partially-enclosed printers are somewhat of an oddity as they don’t offer the ideal environment for printing either of the two main filament types, ABS and PLA. However, they provide an extra layer of safety, useful for education or makers with children. We recommend a fully-enclosed chamber if you plan to print using ABS and an open design if PLA is your filament of choice. If you’re looking to print with ABS and PLA, choose an enclosed printer with removable covers.

However, they provide an extra layer of safety, useful for education or makers with children. We recommend a fully-enclosed chamber if you plan to print using ABS and an open design if PLA is your filament of choice. If you’re looking to print with ABS and PLA, choose an enclosed printer with removable covers.

Build Volume

Build volume represents the printable area available to you on an enclosed printer. In other words, it’s a measure of the size and type of prints you can make. If you plan on making large prints or multiple copies, we recommend printers with large volumes, such as the Ultimaker S5.

Material Compatibility

By design, an enclosed 3D printer offers compatibility with a broader range of material types due to the capacity to maintain a higher temperature around prints and keep cool air out. ABS is by far the most common filament type for enclosed chambers, but you’ll also find printers that can tackle nylon, PC, and other heat-sensitive materials. PLA is also a possibility as long as the printer’s covers are removable as the material requires cooler ambient temperatures for the best results.

PLA is also a possibility as long as the printer’s covers are removable as the material requires cooler ambient temperatures for the best results.

Heated Bed

Given that the whole point of an enclosed chamber is to provide a stable thermal environment to print trickier filament like ABS, a heated bed is a must-have. It helps provide an additional heat source directly below the print, which helps with layer adhesion and slows the cooling rate, which avoids unwanted imperfections like warping and curling.

Connectivity

Connectivity determines how you interact with the printer, whether sending sliced prints or fine-tuning settings. An SD card reader is more or less standard, as is USB in many cases, but for ease of use, nothing beats Wi-Fi connectivity and, by extension, cloud-based printing and monitoring.

Layer Resolution

Layer resolution indicates the lowest layer height a print can produce. Opt for a printer with a lower layer resolution for parts with more detail, such as the 20 microns on the Ultimaker S5. On an enclosed FDM printer, a 100-micron layer resolution is relatively standard and allows you to create a wide range of parts.

On an enclosed FDM printer, a 100-micron layer resolution is relatively standard and allows you to create a wide range of parts.

Filters

If you’re buying an enclosed chamber, chances are ABS is part of your printing plans. ABS is not just odorous but also produces potentially harmful fumes. Having a printer equipped with filters, either carbon or HEPA, helps extract the most toxic elements from the fumes. Additionally, we also recommend working with ABS in a well-ventilated space.

Touchscreen

For convenience, we recommend an enclosed 3D printer with a touchscreen. After all, we’re all accustomed to scrolling and swiping on our phones, so it makes sense to want the same functionality and familiar interface when working with a 3D printer. Most modern printers feature a touchscreen as standard.

Price

Enclosed printers tend to bump up the price as you pay for the extra manufacturing and design involved. But, with the ever-growing popularity of the race-to-the-bottom budget category, enclosed chamber printers are more affordable than ever before. You can easily buy a reliable enclosed 3D printer for under $400. Naturally, if you have the budget, new professional-grade printers priced in the thousands of dollars hit store shelves each year, too.

You can easily buy a reliable enclosed 3D printer for under $400. Naturally, if you have the budget, new professional-grade printers priced in the thousands of dollars hit store shelves each year, too.

Advantages of Enclosed 3D Printers

✅

Better ABS and Nylon 3D printingEnclosures can cool parts down more slowly, and maintain more consistent and high heats within the build chamber. This reduces warping and splitting during the printing process.

✅

Much safer3D printer enclosures keep hot parts like the nozzle and heated bed away from kids if you have family at home, or if 3D printing at schools.

✅

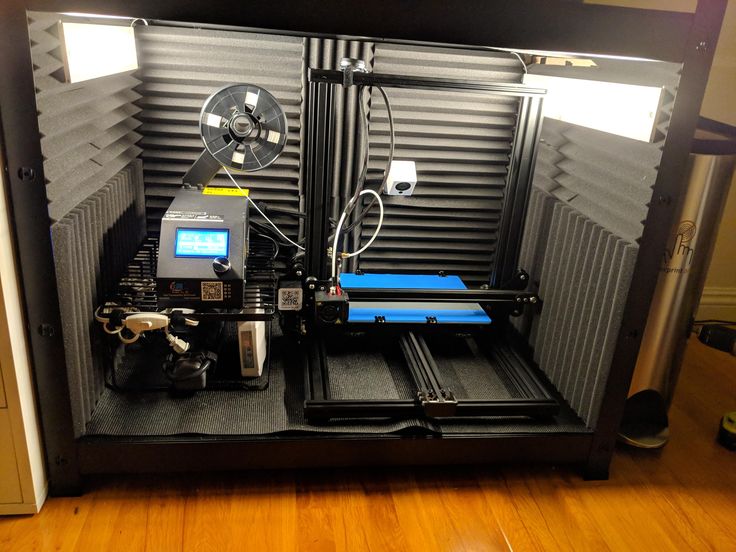

QuieterThe enclosed area keeps noise in, making them ideal quiet 3D printers. Enclosures contain the whirring and buzzing of the printing process, a genuine boon if you’re printing at home or in a confined space with bad acoustics likely to amplify noise levels.

✅

Sturdier and more reliableEnclosed 3D printers are typically built with a sturdy cuboid structure, with four walls that prevent vibrations and other factors from worsening print quality.

✅ Noise Reduction

enclosures help keep noise levels down by containing the whirring and buzzing of the printing process, a genuine boon if you’re printing at home or in a confined space with bad acoustics likely to amplify noise levels.

Disadvantages of Enclosed 3D Printers

More expensive – 3D printers with enclosures cost more than open FDM printers. The logic is evident here; manufacturers have to spend more on raw materials and the assembly process, costs that invariably trickle down to consumers.

Difficult maintenance and troubleshooting – Due to the enclosed design, maintenance is much harder on an enclosed 3D printer. Cleaning, replacing, troubleshooting, or upgrading parts is far more troublesome than an open-design 3D printer.

FAQs

What Does a 3D Printer Enclosure Do?Enclosures help enhance printing performance by keeping hot air in and cold air/drafts out. For heat-sensitive materials like ABS, a stable higher temperature environment is crucial for proper layer adhesion and to reduce the chances of warping, curling, and other issues. Similarly, an enclosure helps keep dust and dirt away from the printer’s parts and the print itself; essential for successful printing as impurities can affect adhesion and print quality.

Similarly, an enclosure helps keep dust and dirt away from the printer’s parts and the print itself; essential for successful printing as impurities can affect adhesion and print quality.

Yes. An enclosure keeps hot and moving parts away from curious fingers and hands, lessening the likelihood of injury compared to open-design printers where all the parts are exposed and readily accessible. If you live with children or work in an educational setting alongside younger students, an enclosed 3D printer provides peace of mind. Additionally, the filters often mounted in enclosed printers rid fumes of toxic elements.

How to Maintain an Enclosed 3D Printer?Enclosed 3D printer maintenance is identical to what’s involved in keeping an open-design printer in tip-top shape: regular cleaning of the bed and nozzle, firmware updates, routine inspection of parts for wear and tear, and bed leveling/calibration at regular intervals.

If you’re looking to print with ABS, yes. An enclosure provides the right, sustained ambient temperature for ABS to thrive. On the other hand, if you plan to print with PLA, an open-design printer stands as a better option. PLA requires plenty of cool air and ventilation to flourish.

preview / 3D Printers, Machine Tools & Accessories / iXBT Live

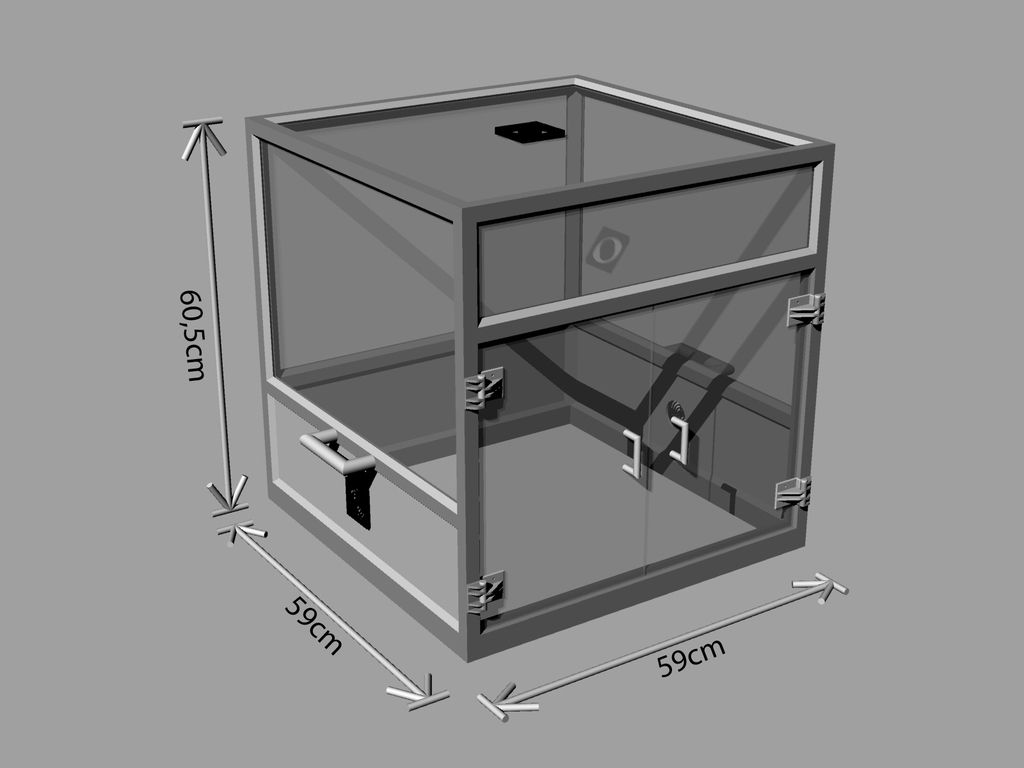

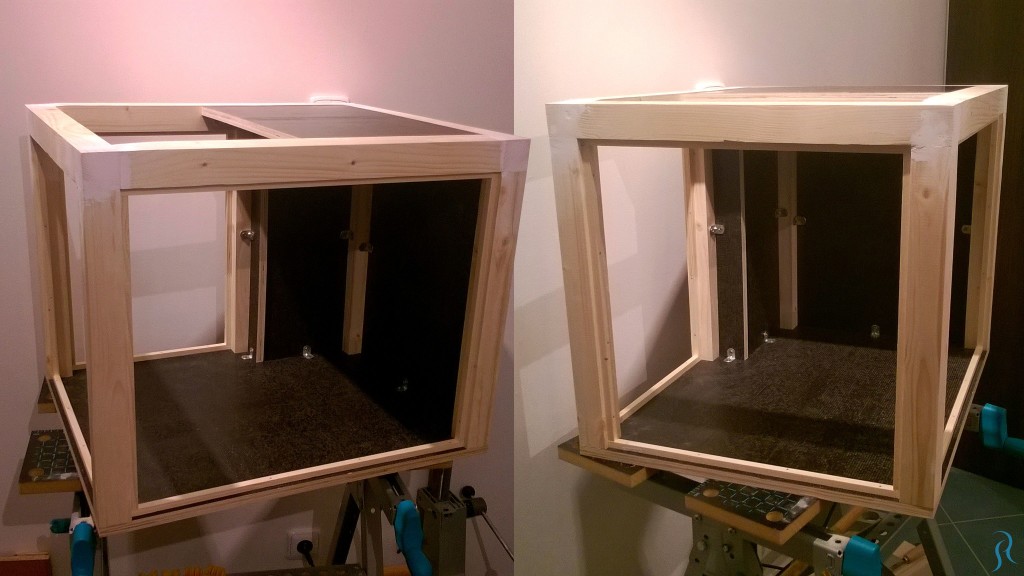

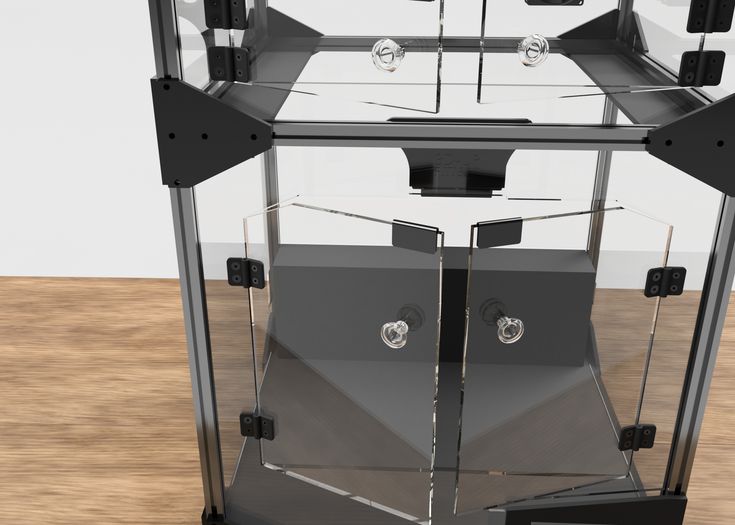

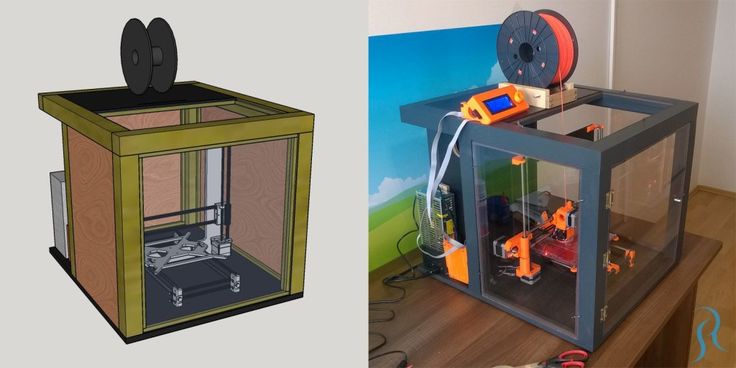

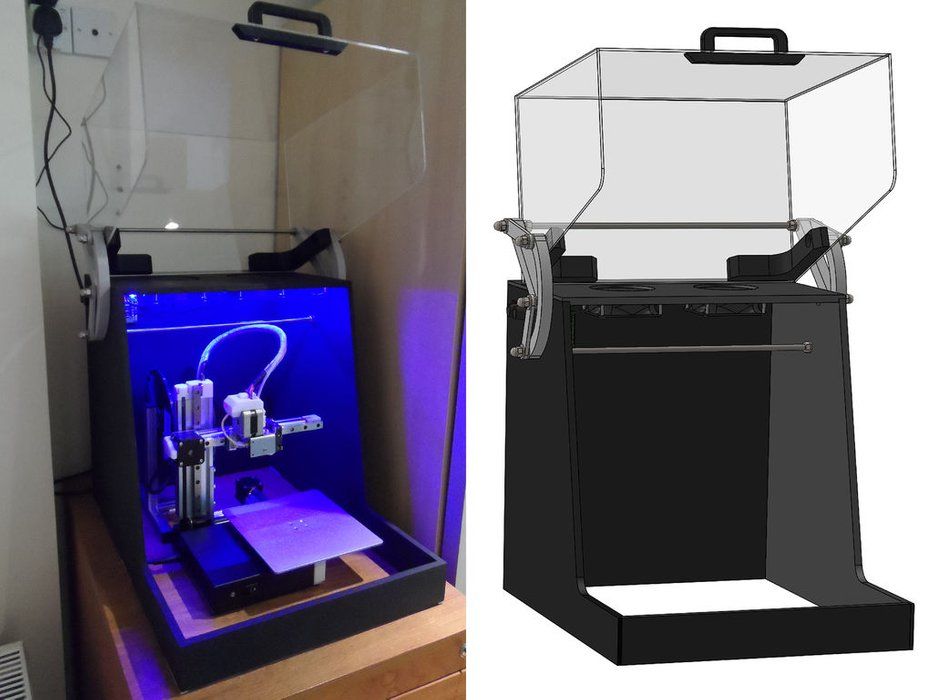

The B&R 3D project is growing and a PRO version of the kits is now available. Sets of body parts for self-assembly are universal and allow you to assemble a 3D printer both on H-bot and Core XY kinematics. The B&R PRO versions of the kits have received a number of changes in a positive way and have received larger “Plus” versions of the kits. Now this is one of the most affordable ways to assemble a steel printer, which outperforms its brethren with a plywood case or an aluminum profile frame in all respects.

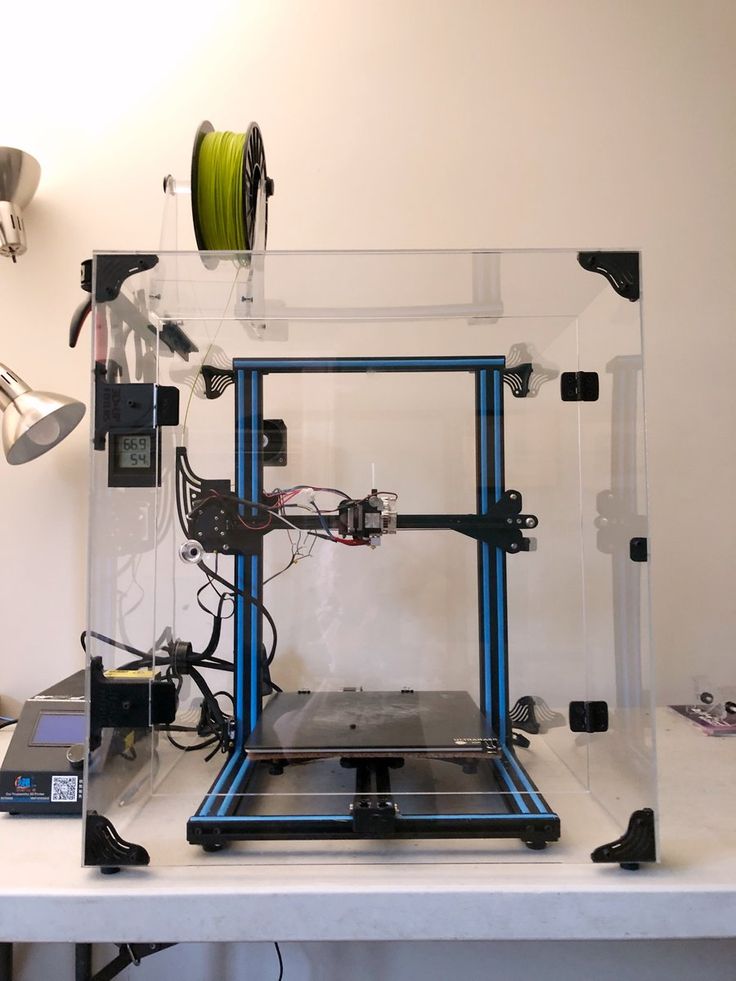

Such a 3D printer allows you to assemble a fairly budget-friendly structure from metal, and not from plywood / profile. The side walls are sheathed with acrylic panels (if necessary). The design allows the installation of a direct feed (direct extruder) of plastic, as well as dual extruders for color printing.

The side walls are sheathed with acrylic panels (if necessary). The design allows the installation of a direct feed (direct extruder) of plastic, as well as dual extruders for color printing.

The range includes three new B&R Pros and two basic build kits:

- The B&R PRO 3030 kit has a printable area of 300 x 300 x 350 mm. Overall size 615 x 471 x 481 mm with a set weight of 19kg.

- Kit "B&R PRO 3030 plus" has an enlarged print area of 320 x 320 x 350 mm. Overall size 615 x 496 x 501 mm with a set weight of 23 kg.

- Kit "B&R PRO 2525 plus" has a print area of 270 x 270 x 300 mm. Overall size 615 x 450 x 450 mm with a set weight of 19 kg.

- The B&R 3020 basic kit has a print area of 300 x 200 x 300 mm. Overall size 570 x 455 x 370 mm with a set weight of 15 kg.

- B&R 2020 basic kit has a printable area of 200 x 200 x 300 mm. Overall size 570 x 405 x 370 mm with a set weight of 14 kg.

A heavy printer is good. The massive body well dampens excess vibration when working at high print speeds. The body itself is rigid, made of thick stamped steel with a powder coating. There are holes for installing a touch display (diagonal options are possible), holes for installing encoders, switches, USB panels. The electronics compartment is located under the "floor" of the device. I covered the nuances of assembling the basic kit for assembling a B&R 3D printer in a separate article.

The massive body well dampens excess vibration when working at high print speeds. The body itself is rigid, made of thick stamped steel with a powder coating. There are holes for installing a touch display (diagonal options are possible), holes for installing encoders, switches, USB panels. The electronics compartment is located under the "floor" of the device. I covered the nuances of assembling the basic kit for assembling a B&R 3D printer in a separate article.

The peculiarity of the project is not only the openness and availability of information, but also the possibility of implementing a moving scheme both in the form of CoreXY and in the form of H-Bot. The top panel provides for the installation of one of two versions of kinematics.

Assembly of B&R kits is quite simple - fastening panels in turn, setting up a table, assembling guides (shafts, rails), motors, connecting electronics. It should be noted that only steel painted panels are included in the B&R kit. Additional components are purchased by the user according to the list based on his own preferences. There is both an opportunity to save money and a path to assembling the most advanced 3D printer.

There is both an opportunity to save money and a path to assembling the most advanced 3D printer.

The advantage of 3D printers with a large printable area is that you can create large models without cutting into pieces and without subsequent gluing. An example of a complex layout mechanism is shown in the images below.

The B&R kit is one of the most affordable and smart options for DIY 3D printer assembly. Detailed information on assembling and setting up the printer can be found both in the official B&R group and in the project's telegram chat.

Source : B&R 3D printer official chat

News

Publications

or not, you can just not respond. And the good ones are usually bad. limited time. I just had time to tune in - how is everything...

Public transport fares are going up since the new year, but there is a way to save a lot and make your life more comfortable. From 1.1.2023 the cost of a trip in public...

Disclaimer: I have no financial education. I share my observations. If there are errors in the article, please do not hate, but correct in the comments. Based on today's realities. Cyber attacks...

I share my observations. If there are errors in the article, please do not hate, but correct in the comments. Based on today's realities. Cyber attacks...

The 1More Aero headphones deliver surround sound and accentuate the channel depending on which way the head is turned. I liked the music in the model due to the deep working of the instruments, which is the case with others...

I love high-tech household devices, which are able to simplify and even automate some routine tasks. The Smart Robot Vacuum Cleaner has become an obvious bargain for me since...

During construction, there is always something interesting to be found. In the Italian city of Marino, they discovered a very entertaining road laid in the days of Ancient Rome. Now everyone can...

how to optimize design and speed up production

Rapid prototyping

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Benefits of 3D Printed Cases | Developing custom electronics cases: what material to choose for 3D printing? | How to design enclosures for 3D printing | Access to components | The strength of the 3D printed case | Quality and precision | Order a 3D printing service

Implementing additive manufacturing can bring more value to your business than you might think. The production of electronics requires a lot of effort, but thanks to 3D printers, this process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

The production of electronics requires a lot of effort, but thanks to 3D printers, this process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

Scalable Electronics Manufacturing

The manufacture of electronic devices is associated with certain difficulties. How can the creation of electronics cases affect the success of related projects and business as a whole?

See the benefits of scalable and adaptable enclosures. When designing electronic devices, you must keep pace with changing market demands, including record-breaking project turnaround times. This is made possible by an optimized and scalable manufacturing process. Implementing Just-In-Time principles in part manufacturing can also be a huge business benefit.

In the electronics industry, additive manufacturing opens up many opportunities. Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design.

Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design.

iQB Technologies Experts Recommend Article: 14 Frequently Asked Questions About FDM Production Printing

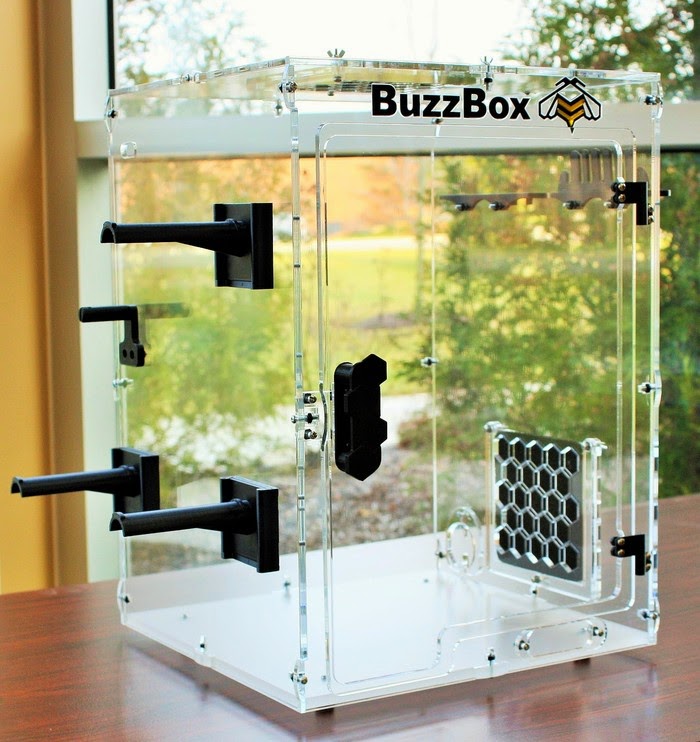

Benefits of 3D Printed Cases

Adaptability

Additive manufacturing provides almost limitless freedom of action. In the manufacture of cases on a 3D printer, it is possible to provide for latches, locking connections, threaded connections and flexible hinges. Thanks to thoughtful functionality, the case will become more versatile.

3D printing provides design flexibility not available with injection molding. Indeed, it is almost impossible to make changes to the design of the finished mold. If you want to change the project, you will have to start all over again.

With 3D printing, everything is different: you just need to make changes to the 3D file, which will not stop the manufacturing process for a minute. The ability to quickly adjust workflows increases production agility at no extra cost. Thanks to 3D files, there is no need to worry about the service life of the body structure or other part. Changes can be made at any time as needed.

Another significant advantage of additive manufacturing is mass customization. You can customize the work files according to the client's needs. Making several iterations of the case on a 3D printer will not increase the cost of production!

Prototype laser housing 3D printed by TWIZE

3D printer: ProtoFab SLA600 DLC

Material: photopolymer Formula W

Layer thickness: 100 microns

Print time: 12 hours

The result of the work: a laser body suitable both for checking the assembly and as a master model for casting in silicone

Want to try 3D printing prototypes or functional products? Test service is free!

Order 3D printing service

Innovations

Additive manufacturing provides an opportunity to innovate and improve designs. With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology.

With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology.

You can take into account all the functional features of the part and integrate them directly into the device.

Acceleration of production processes

Speeding up processes drives business growth. When creating an electronic device, the design and ergonomics of the case are just as important as its performance. This requirement is easily implemented due to the ability to create complex forms very quickly. 3D printing is the fastest prototyping technology: unique prototypes can be produced without a mold, resulting in low part cost.

With 3D printing, the price does not depend on the number of parts, but on the amount of material used. By making multiple iterations of the same case, 3D printing will be a much more sustainable and sustainable manufacturing method than traditional ones. Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements.

Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements.

3D printing is ideal for making plastic cases. Whether you need to customize a product or follow Just-In-Time principles, the benefits of this technology for your business are undeniable.

iQB Technologies Experts Recommend Article: From Aircraft Prototype to Biomedicine: Sharebot Unleashes New Opportunities

Development of customized electronics enclosures

Which 3D printing material to choose?

What is the best material for case making? To develop a project and start 3D modeling, you must select the material and take into account the design parameters.

Plastic enclosures for electronics can be developed through additive manufacturing using adapted materials. Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products.

Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products.

How to design enclosures for 3D printing

Before you start modeling a case, it is recommended that you start designing with the components that it will contain. This way you can place components and make sure everything fits, as well as provide clearance for connectors or cables. To ensure that all components will fit, we recommend leaving a gap of 0.5mm between the components and the 3D printed elements.

Access to components

The first thing to think about when designing a case is what to put in it and how to access it later. If access to the components is not required, you can design special fasteners or use adhesive during assembly of the case to completely seal it.

If access to the components of the case is necessary, the following mechanisms can be used:

-

semi-rigid eyelets;

-

sliding panels;

-

screws;

-

conventional and flexible hinges;

-

prefabricated structures.

Eyelets, slots and flanges help with assembly and alignment of parts. In addition, if the minimum dimensions of these elements are observed, they can increase the strength of the hull.

Durability of 3D printed case

The main thing to consider is the thickness of the walls of the case. This parameter determines the weight, stiffness, strength and possible applications of the hull. Even if the 3D printer is capable of printing small parts and thin walls, we recommend keeping the minimum wall thickness of 2mm. This value provides structural strength while keeping the weight of the part light. The optimum thickness can also be determined using the design guide for the material used.

However, be careful, because depending on the length of the casing, the 2 mm thick walls can bend, which can lead to some shrinkage.

Corner rounding is a key feature of 3D printing because hard corners can be printed poorly. Roundings are necessary both inside the case and outside.

Roundings avoid sharp corners and reduce stress

For external corners, a slight rounding (1 or 2 mm) can be used on the housing surface.

Inside the case, the corners can be reinforced with thickenings and roundings. A very small radius simplifies 3D printing and reduces stress concentration at corners.

Thickening and rounding inside the body reduce stress around the hole

3D printed housing: quality and precision

If the design contains gaps or holes for fasteners, select a material that provides the desired accuracy. 3D printing plastic provides high precision, but we recommend drilling or punching holes after printing with special tools.