Macewan 3d printing

About 3D Printing | Library Website

Search

Library Resources

Keyword

- Keyword

- Title

- Author

- Subject

Search Tips

- "Quotes" for phrases/titles:

- "social media" "Life of Pi"

- AND for different concepts:

- Indigenous AND Canada AND decolonization

- OR for similar concepts/synonyms:

- teenagers OR adolescents OR youth

- Asterisk(*) for truncation:

- divorc* = divorce divorced divorcing divorcee

- Parentheses to combine different and similar concepts:

- (teenagers OR adolescents) AND depression

3D Printing

Vinyl Cutting

Programming

Loanables

Welcome to 3D Printing!

Remote access

Log in with your MacEwan ID to upload your file to our print queue.

Drop-In access in 6-203

Stop by and the Student Makerspace Tech Tutors will introduce you to 3D printer basics. Come make with us!

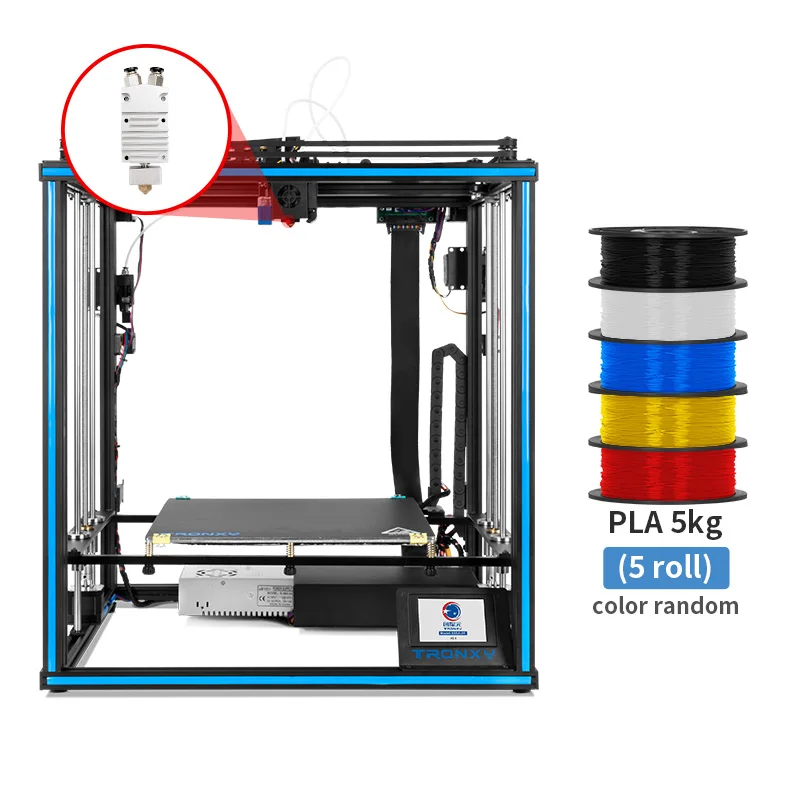

6 Ultimaker 3D Printers

- 2 x Ultimaker S3 (build volume 9" x 7.4" x 7.9")

- 2 x Ultimaker 3 (build volume 9" x 7.4" x 7.9")

- 2 x Ultimaker 2 (Extended build volume 8.77" x 8.77" x 12")

- Full Specifications

Printing an Object

Detailed instructions (PDF)

Service Limitations

To provide equitable access, users can submit two 3D prints/mo, and print times are limited to 24 hrs for each print job.To request a print job outside these parameters, please contact the Makerspace at [email protected].

When submitting 3D prints remotely:

- If your job fails due to an issue with the file and how it is sliced, you will receive instructions from Tech Tutors for improving the file and/or slicing via the system

- If it fails a second time, you will be asked to come into the Makerspace so the Tech Tutors can help you to improve your file and it's slicing so it will print properly.

We are not able to 3D print using filament other than the what is provided by the makerspace.

3D Printing Policy

MacEwan University Library reserves the right to refuse any print request.

We may not be able to print your submission due to the following reasons:

- The file is not viable to print. It may contain elements or be designed in such a way that printing it could damage the 3D printer.

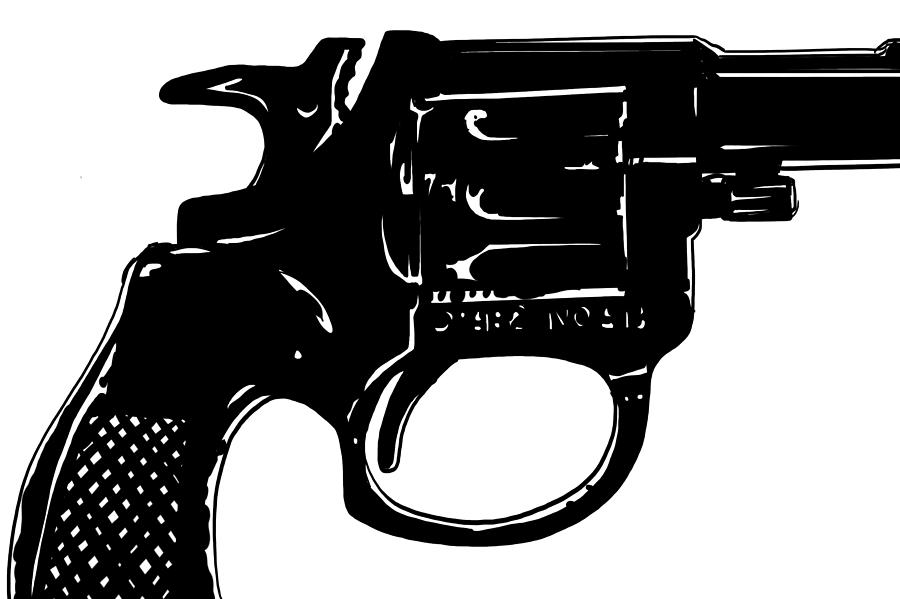

- Prohibited by local, provincial, or federal law. No guns or functional weaponry. Props or costume items will be evaluated on a case-by-case basis.

- The file violates intellectual property or copyrights including objects or aspects of such that are registered trademarks or patents.

- Commercial use, the service is not intended to provide objects for commercial purposes. However, prototyping is encouraged.

- Multiples will have to be approved on a case-by-case basis, due to print time restrictions, only one object can be requested at a time.

Class sets can be printed, other requests for limited amounts of multiple copies for non-commercial use will be considered and accommodated where possible.

Class sets can be printed, other requests for limited amounts of multiple copies for non-commercial use will be considered and accommodated where possible.

Our printers are in an open and visible part of the library, please keep this in mind.

In summary, print jobs should not pose a risk to the printer, be prohibited by law, for commercial use, or violate intellectual property or copyright.

Contact

To request longer prints, or for any 3D printing questions, advice or object design help, email [email protected].

This work is subject to a Creative Commons Attribution-NonCommercial 4.0 International License. For exceptions, see the Library Copyright Statement.

Need Help?

Chat with us!3D Printing Policy | Library Website

Search

Library Resources

Keyword

- Keyword

- Title

- Author

- Subject

Search Tips

- "Quotes" for phrases/titles:

- "social media" "Life of Pi"

- AND for different concepts:

- Indigenous AND Canada AND decolonization

- OR for similar concepts/synonyms:

- teenagers OR adolescents OR youth

- Asterisk(*) for truncation:

- divorc* = divorce divorced divorcing divorcee

- Parentheses to combine different and similar concepts:

- (teenagers OR adolescents) AND depression

MacEwan University Library reserves the right to refuse any print request.

We may not be able to print your submission due to the following reasons:

-

The file is not viable to print. It may contain elements or be designed in such a way that printing it could damage the 3D printer. See preparing your 3D print file.

-

Prohibited by local, provincial, or federal law. No guns or functional weaponry. Props or costume items will be evaluated on a case-by-case basis.

-

The file violates intellectual property or copyrights including objects or aspects of such that are registered trademarks or patents.

-

Commercial use, the service is not intended to provide objects for commercial purposes. However, prototyping is encouraged.

-

Multiples will have to be approved on a case-by-case basis, due to print time restrictions, only one object can be requested at a time. Class sets can be printed, other requests for limited amounts of multiple copies for non-commercial use will be considered and accommodated where possible.

Our printers are in an open and visible part of the library so we can not keep your print private. However, your personal information provided in the print request will be kept confidential.

In summary, print jobs should not pose a risk to the printer, be prohibited by law, for commercial use, or violate intellectual property or copyright.

With thanks to U of A, NAIT and EPL for sharing their 3D printing policies.

How to tell if a file is licensed for re-printing, modifying or sharing?

See the licensing and copyright for 3D prints.

Have questions?

You can ask specific questions regarding a print job in the notes section when you submit your print request. General inquiries can be sent to [email protected] where you will be contacted by one of our technicians, you can also ask in our library.

This work is subject to a Creative Commons Attribution-NonCommercial 4. 0 International License. For exceptions, see the Library Copyright Statement.

0 International License. For exceptions, see the Library Copyright Statement.

Need Help?

Chat with us!Project "Perspectives and possibilities of 3D printers" | Project on informatics and ict (grade 7) on the topic:

Slide 1

Prospects and opportunities for 3 d printers

Slide 2

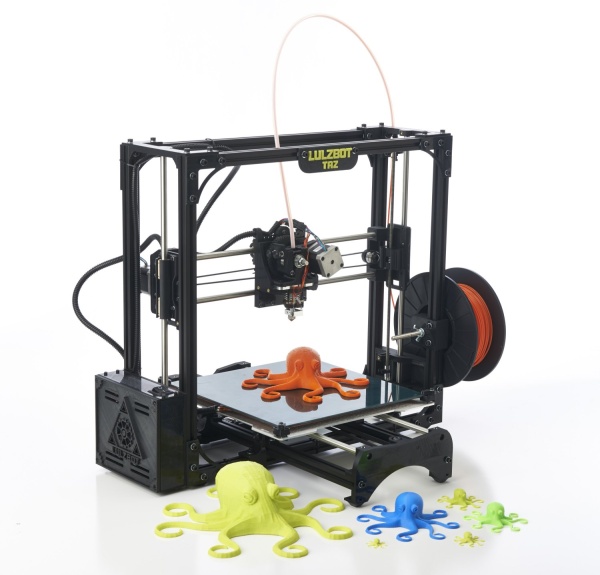

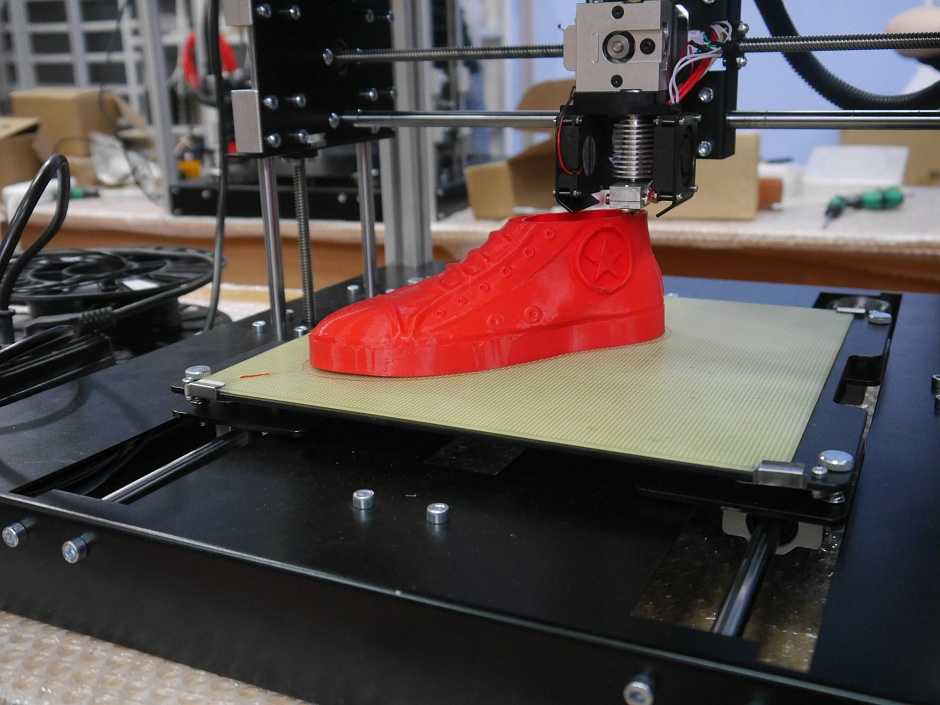

History of 3d printer technologies Work on the creation of three-dimensional printers began in the eighties of the last century, the term itself " three-dimensional printing "appeared only in 1995 in the bowels of the Massachusetts Institute of Technology. Until 2008, any 3D printer could only work using one type of consumable - ABS plastic. This is one of the best consumables for 3D printing. Now the number of materials has exceeded one hundred. Today, materials such as acrylic, concrete, hydrogel, paper, gypsum, wood fiber, ice, metal powder, chocolate, etc. can be used. The main feature of 3D printers is that all the resulting models are solid and are applied in layers, layer by layer. And, if only a paper version is obtained on a simple printer, then on a 3D printer you can create a children's toy, a souvenir figurine, plastic utensils, fabric for tailoring, as well as implants for use in medicine, and a car. The possibilities of new generation printers are almost limitless.

And, if only a paper version is obtained on a simple printer, then on a 3D printer you can create a children's toy, a souvenir figurine, plastic utensils, fabric for tailoring, as well as implants for use in medicine, and a car. The possibilities of new generation printers are almost limitless.

Slide 3

Education The use of 3D printing in education makes it possible to easily and quickly obtain a variety of visual aids for students, which can be distributed in secondary and higher educational institutions. Equipping educational institutions with 3D printers can help increase the return on the educational process and the rapid assimilation of the material by students. Thanks to 3D printing, students can work with real physical models, manipulating them in every possible way. Almost any layouts or visual aids can be drawn on a computer in a program, and then brought to life. Scope of 3D printers

Slide 4

3D printing is finding its way into high fashion and design. With 3D printers, designers can quickly develop models or exclusive pieces. Some fashion designers have already mastered this direction and present their collections of clothes printed on a 3D printer. For example, at the Paris Fashion Week, fashion designer Iris Van Herpen has already presented such a unique collection called "Tension". However, the clothes printed on the printer can only be seen at fashion parties and shows. Design and production of clothes

With 3D printers, designers can quickly develop models or exclusive pieces. Some fashion designers have already mastered this direction and present their collections of clothes printed on a 3D printer. For example, at the Paris Fashion Week, fashion designer Iris Van Herpen has already presented such a unique collection called "Tension". However, the clothes printed on the printer can only be seen at fashion parties and shows. Design and production of clothes

Slide 5

Architecture A construction 3D printer uses extrusion technology in its work, in which each new layer of building material is squeezed out of the printer on top of the previous layer. 3D printing makes it possible to obtain unique concrete forms without formwork, while significantly reducing the cost of human labor and the time it takes to commission an object. The use of these printers in construction will make it possible to move away from traditional building forms and create irregularly shaped houses with curved contours and lines. With the help of 3D printing, you can build luxurious creative houses with unique structural elements. Imagine something that is aesthetically perfect and yet built in just a few hours without the potential danger to builders.

With the help of 3D printing, you can build luxurious creative houses with unique structural elements. Imagine something that is aesthetically perfect and yet built in just a few hours without the potential danger to builders.

Slide 6

Medicine The use of 3D printers in medicine, in some situations, becomes the only way to save a human life. For example, by recreating the elements of the patient's skeleton to practice the techniques necessary for a successful operation. The University of Missouri is developing technologies that allow clots of cells of a given type to be applied to a special bio-gel. The development of this technology is the cultivation of full-fledged organs. 3D printers are also widely used in dentistry and prosthetics. Digital production of crowns and prostheses is much faster than classical production.

Slide 7

Several successful attempts have been made to produce fully functional weapons. For example, a development team led by Cody Wilson defiantly chose the most popular weapon in the United States (M-4) for cloning to demonstrate the promise of 3D printing technology and their availability for almost any purpose. Military

Military

Slide 8

Food Industry 3D printers have been used with varying degrees of success in many food-related processes. For example, manufacturers of equipment for the food industry print dummies of fruits in order to calibrate the operation of mechanisms without spoiling real vegetables and fruits. Food printers are being developed that create beautiful products with complex shapes and help automate routine actions in the kitchen. However, the penetration of 3D printing in cooking is taking place without much haste. Perhaps because people are not aware enough about the quality of printed food. According to social surveys, 77% of people, without any reason, consider products prepared using printers to be inedible.

Slide 9

Last story An injured turtle gets the world's first 3D printed shell When a turtle named Freddy was found in one of the burning bushes during a fire in Brazil, his chances of survival were slim. But thanks to a group of pioneering doctors, Freddie not only survived, which was already an ordeal, but he also became the proud owner of the world's first 3D printed shell! A turtle named Freddie was very lucky when he survived after severe burns received as a result of a fire. His shell was badly damaged. In this state, Freddie would hardly have lasted long. But luckily, a group of resourceful doctors made him a new 3D printed shell!

His shell was badly damaged. In this state, Freddie would hardly have lasted long. But luckily, a group of resourceful doctors made him a new 3D printed shell!

Slide 10

Freddie's new carapace looks great, but it lacks a bit of color The artist has hand-painted the carapace to look as natural as possible.

Slide 11

The artist hand-painted the shell to make it look as natural as possible.

Slide 12

Now Freddy would definitely have the Teenage Mutant Ninja Turtles on his team!

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc.), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

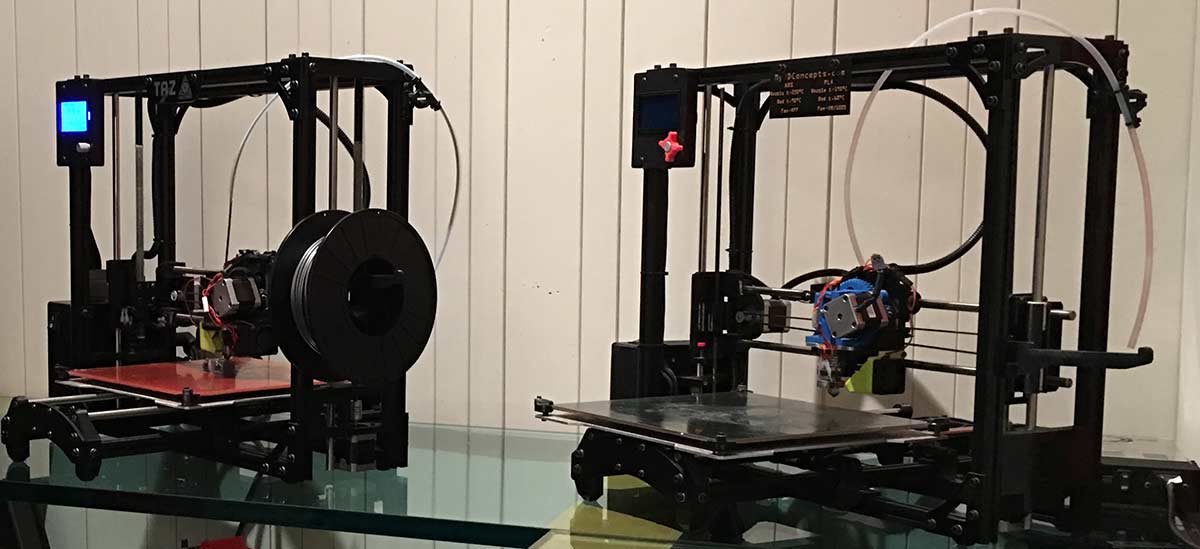

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

First of all, it is worth mentioning the MakerBot company, which started as a startup, took RepRap ideas as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.