Boston 3d printing

Boston Micro Fabrication - Micro-Precision 3D Printers

ULTRA-HIGH RESOLUTION, ACCURACY, AND PRECISION

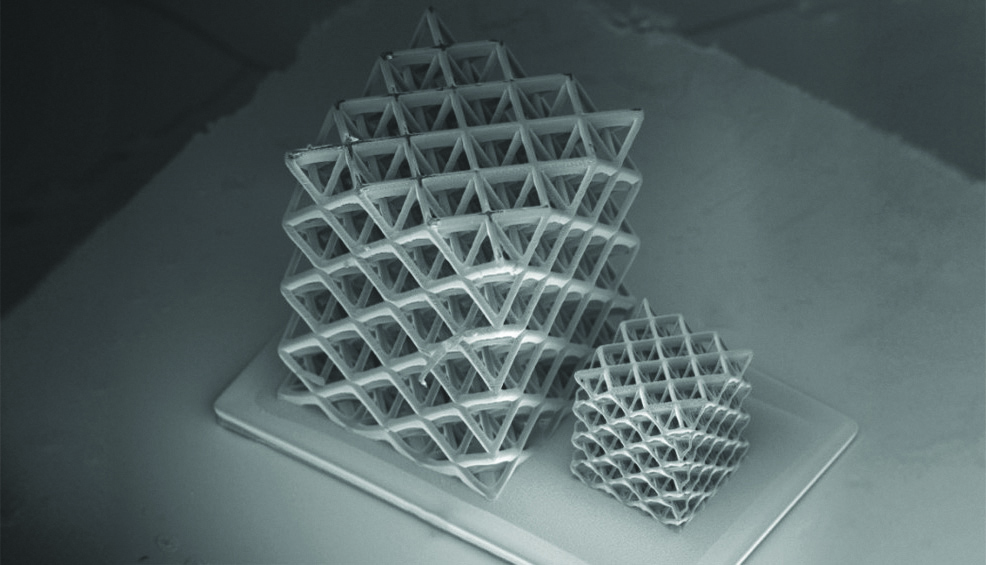

Boston Micro Fabrication is the world leader in micro-precision 3D printers utilizing Projection Micro Stereolithography (PµSL) technology. Many leading companies worldwide are adopting PµSL to 3D print true microstructures with ultra-high printing resolution (2µm~50µm) and printing tolerance (+/- 10µm ~ +/- 25µm).

Micro-precision 3D printing is the optimal manufacturing process for various use cases across a wide variety of industries. The combination of ultra-high resolution, accuracy, and precision allows for more intricate, exact, and replicable parts.

Learn More

Boston Micro Fabrication's microArch S230 wins TCT Award 2022

Boston Micro Fabrication (BMF), the pioneer in microscale 3D printing systems, announced that the microArch™ S230, its most advanced and highest-resolution microscale 3D printer, was recognized as a TCT Awards 2022 winner for the TCT Hardware Award – Polymer Systems category.

Read More

Our Capabilities

News

BMF Raises $43M Series C to Continue Driving Convergence of Additive Manufacturing and Miniaturization

Boston Micro Fabrication (BMF), the pioneer in microscale 3D printing systems, today announced the successful closing of a Series C round of funding, totaling $43 million. The round was led by Shenzhen Capital Group Co., Ltd. (“SCGC”).

Read More

Our Products

Build Size

- 100 × 100 × 75mm

- 19.2 × 10.8 × 45mm

- 3.

84 × 2.16 × 10mm

84 × 2.16 × 10mm - 48 × 27 × 50mm

- 50 × 50 × 10mm

- 50 x 50 x 50mm

- 94 × 52 × 45mm

Layer Thickness

- 10μm~40μm

- 10μm~50μm

- 5μm~20μm

Optical Resolution

- 10μm

- 25μm

- 2μm

Printing Material

- Ceramic

- Photosensitive Resin

Clear Filters

Request a Benchmark Part

We’d be happy to manufacture a benchmark part so you can assess our quality.

Request a Benchmark part

News • May 3, 2022

Using Micro 3D Printing for Short-Run Production

There is considerable R&D focus on how to make parts bigger with additive manufacturing or 3D printing. At the same time, engineers are designing smaller and more complex products, especially in the medical-device and electronics fields. This trend toward miniaturization also requires that the components and assemblies inside these products are also smaller, and often more complex.

Read More

The quality and accuracy of BMF PµSL parts is very unique, and truly mimic expensive micro molded parts, and now we can have parts ready for test within 1-2 days rather than 1-2 months, as well as reducing the huge costs associated with tooling manufacture and reworking as the new products evolve.

We can also explore designs previously out of reach due to manufacturing limitations. Our main focus is to lift our prototyping capabilities to the highest possible level, both in quality and speed. BMF will help us accomplish that.

– Sally van der Most, DSS Manager, Sonion NL

We chose BMF’s microArch 3D Printer due to its ability to replicate critical micro features. Their unique Projection Micro Stereolithography (PµSL) technology prints 3D parts with ultra-high resolution and accuracy, which is key to our business. This is the first 3D printer we’ve encountered that can print micro-precision parts, with the dimensional accuracy and precision that our customers require at this stage of product development. We have put the BMF parts through the same rigorous CT scanning inspection process of our micro molded components and were amazed that dimensionally the parts fell within the tolerances required.

Our customers have been equally amazed.

– Donna Bibber, VP of Business Development, Isometric Micro Molding, Inc.

We have been looking for some time for a machine that can reliably produce parts in this size range as we were at the limits of other machines or would have to sink cost into other manufacturing methods- typical micro injection molding or other micro machining activity that can be expensive and prohibitive to R&D iterations. The ability to rapidly produce these types of parts combined with an open ecosystem is unmatched.

– Sam Wilson, STORM Lab UK, Institute of Robotics and Autonomous Sensing, University of Leeds

The parts say it all. The first time you see a part from a BMF printer you will be amazed. 3D printing, until now, has never been able to produce parts of such precision, and accuracy.

Being able to capture thin walls and fine features at this scale and resolution, with unmatched reliability, is unprecedented from any 3D printing technology. This will absolutely usher in new industries, that have previously ignored 3D printing, to the world of rapid design iteration.

– James Grimm, Senior Business Development Manager, Empire Group

May 12, 2022 • Press Release

Read ArticleMay 4, 2022 • Press Release

Read ArticleCeramic 3D Printing Materials - BMF Boston Micro Fabrication : BMF Boston Micro Fabrication

Material Launch

We are excited to announce the launch of two new ceramic 3D Printing materials available for use on our microArch S200 series – AL Alumina Ceramic and MT Magnesium Titanate Ceramic. Ceramics are great for applications that require hardness and high heat resistance.

Ceramics are great for applications that require hardness and high heat resistance.

In addition, we’ve launched a new high temp material, HT 200 that can can withstand temperatures up to 200°C with high strength and durability, perfect for end use applications.

Alumina AL Ceramic

Our new Alumina Ceramic material is perfect for applications involving tooling, casings and housings, and medical devices – able to withstand high temperatures with high strength properties and chemical resistance.

Key benefits:

- High temp

- High strength

- High stiffness

- Biocompatible

- Chemical resistance

Target applications/industries: Tooling (injection molding), Casings and housings, Medical devices

AL Alumina Ceramic Material Properties

| PURITY (%) | SOLIDS LOADING (vol%) | DYNAMIC VISCOSITY [Pa•s] | THEORETICAL DENSITY (g/cm ) | COMPRESSIVE STRENGTH (MPa) | RELATIVE DENSITY (%) | THREE-POINT BENDING STRENGTH (MPa) | SURFACE ROUGHNESS Ra (μm) | YOUNG‘S MODULUS (GPa) | COEFFICIENT OF THERMAL EXPANSION (ppm/K) | THERMAL CONDUCTIVITY (W/(m•K)) | SPECIFIC ELECTRICAL RESISTIVITY (Ω•cm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PURITY (%) 99. 8 8 | SOLIDS LOADING (vol%) 50 | DYNAMIC VISCOSITY [Pa•s] 10 | THEORETICAL DENSITY (g/cm ) 3.99 | COMPRESSIVE STRENGTH (MPa) 2300 | RELATIVE DENSITY (%) 99 | THREE-POINT BENDING STRENGTH (MPa) 400 | SURFACE ROUGHNESS Ra (μm) | YOUNG‘S MODULUS (GPa) 300 | COEFFICIENT OF THERMAL EXPANSION (ppm/K) 7-8 | THERMAL CONDUCTIVITY (W/(m•K)) 32 | SPECIFIC ELECTRICAL RESISTIVITY (Ω•cm) ≈1014 |

MT Magnesium Titanate Ceramic

The combination of high dielectric constant and low dielectric loss make MT Ceramic suitable for millimeter wave applications such as antennas, wave guides, and other electronic components.

Key benefits:

- Dielectric properties (high constant, low loss) 100x lower than plastic alumina

Target applications/industries: Communications and aerospace, waveguides,

mm wave electronic components (sensors, radar cover, antenna, wave tuning components)

MT Magnesium Titanate Ceramic

| PURITY (%) | SOLIDS LOADING (vol%) | DYNAMIC VISCOSITY [Pa•s] | THEORETICAL DENSITY (g/cm ) | RELATIVE DENSITY (%) | THREE-POINT BENDING STRENGTH (MPa) | SURFACE ROUGHNESS Ra (μm) | RELATIVE PERMITTIVITY (10 GHz) | DIELECTRIC LOSS TANδ (10 GHz) | COEFFICIENT OF THERMAL EXPANSION (ppm/K) | THERMAL CONDUCTIVITY (W/(m•K)) |

|---|---|---|---|---|---|---|---|---|---|---|

| PURITY (%) 99. 5 5 | SOLIDS LOADING (vol%) 49.4 | DYNAMIC VISCOSITY [Pa•s] 6 | THEORETICAL DENSITY (g/cm ) 3.69 | RELATIVE DENSITY (%) 98.5 | THREE-POINT BENDING STRENGTH (MPa) 125 | SURFACE ROUGHNESS Ra (μm) | RELATIVE PERMITTIVITY (10 GHz) 19. 89 89 | DIELECTRIC LOSS TANδ (10 GHz) 2.368*10-4 | COEFFICIENT OF THERMAL EXPANSION (ppm/K) 9-10 | THERMAL CONDUCTIVITY (W/(m•K)) 32 |

Request a Benchmark Part

We’d be happy to manufacture a benchmark part so you can assess our quality.

Request a Benchmark part

Industrial high-precision 3D printing - OFFICIAL REPRESENTATIVE IN RUSSIA

8 (800) 500-33-91

Resolution x Accuracy x Quality

Industrial High Precision 3D Printing

The only “industrial 3D printer” that:

• Provides 2µm print resolution.

• Conforms to the quality of micro injection molding and

micro CNC machining.

• Solves a common problem in 3D printing resin parts

"True to CAD" materials.

Company founded alumni MIT

Boston, Singapore, Tokyo, Shenzhen, London, Moscow

on high-precision 3D printing

500+ companies, are already using technology BMF

3D Printing Capabilities

Boston Micro Fabrication is a world leader in high-precision 3D printers using projection microstereolithography (PμSL) technology. Many leading companies around the world use PμSL to 3D print micro-products with ultra-high print resolution (2μm~25μm).

High-precision 3D printing is the optimal manufacturing process for a variety of use cases across a wide variety of industries. The combination of ultra-high resolution and precision allows you to create more complex parts with incredible repeatability.

TopStanok is the official representative of BMF3D in Russia and CIS countries.

back

Next

High viscosity resin > 1000 cP

Material versatility

Patented BMF technologies allow the use of previously unavailable materials such as high viscosity resins and nano blends. *List of materials constantly expanding

- Open material system

- We will select the material for your tasks

SPIE 2021 Prism Awards Winner

*Best Manufacturing Solution

2-25 µm 3D printers

Products

2MKM Series 3d Printers

- 2 µm XY Resolution

- 5 µm Z Resolution

Application:

- Biomedical Research

- Micromedical Devices

- Microtechnology and microrobots

- Materials Science / R&D

- MEMS and photonics

To get the consultation

10MKM Series 3D Printers

- 10 µm XY Resolution

- 5 µm Z Resolution

Application:

- Prototype molds for micro-injection

- Micro hydraulic devices

- Medical stents

- microstructures

- Microcircuits and microboards

To get the consultation

25MKM Series 3D Printers

- 10 µm XY Resolution

- 5 µm Z Resolution

Application:

- Prototype molds for micro-injection

- Micro hydraulic devices

- Medical stents

- microstructures

- Microcircuits and microboards

To get the consultation

Up to 2µm resolution

Applications by industry

Micro 3D printing is the optimal manufacturing process for various types of 3D printing in a wide variety of industries. The combination of ultra-high resolution, precision and precision results in more complex, precise and reproducible details.

The combination of ultra-high resolution, precision and precision results in more complex, precise and reproducible details.

Medical devices:

Wearable electronics, sensors, implants, needles

Electronics:

Microchips, connectors, microcircuits

Microdynamics:

Gears, valves, motors, actuators, valves

Automotive:

Microswitch, sensor, valve

Photonics:

Transducers, lenses, sensors

Microfluidics:

Chips, adapters

Universities and research institutes:

R&D and research

Photoconverters

• Print time 150 per day

• Total tolerance ± 25 µm

IC socket

• Tolerance +/- 25 µm

• 1500 holes diameter = 0.35 mm / pitch 50 µm

• Print time: 11 hours - 3 pcs. (S140)

Connectors

• Complete production of all designs including thread

• Complex internal cavities

• Hole diameter = 50 µm

LGA chip package

• Approx. 1 PC. (S140)

1 PC. (S140)

Minimally Invasive Syringe Needle

• 0.25 mm inner diameter. syringe

• Rigid enough for a realistic

experiment

• Complex thread and needle structure

Cardiovascular stents

• Flexible material used.

• Rapid production of complex designs

Endoscope base

• Tube diameter = 1.2 mm, length = 4 mm.

• Minimum wall thickness = 65 µm

• Multiple types of complex structures included

• Printing time : 2.5 hours / 1 piece. (P140)

Blood Cooling Heat Exchanger

• Intricate internal heat exchange channels

Connector base

• Accuracy ± 25 µm

• Slits 0.25 mm

• Sharp corners

• Walls 0.2 mm

Filter

• Printed on P130 with

resolution 2 µm

• Rectangular slots

10 µm wide 5 µm wide • 1848 slots per 1 mm² (66x28)

IGOR PONOMAREV

Customer Service Manager

Leave a request, get a free consultation

We will call you within a few minutes

We will consult for free, select the necessary material and make a test 3D print of a sample

By clicking on the "Send request" button, you consent to the processing of your personal data in accordance with Federal Law N152

TopStanok is the official representative of BMF3D in Russia and CIS countries.

Phone:

8 (800) 500-33-91

Working hours:

from 9:00 to 20:00 Moscow time

TopStanok is the official representative office of BMF3D in Russia and CIS countries

Navigation:

Contacts

Moscow, Promyshlenniy pr-d, 7, building 4, office No. 2

topstanok.ru

8 800 500 33 91

[email protected]

Contact us

3 whatsapp

Telegram

Viber

budget 3D-printed analog of the Spot robot from Boston Dynamics

News

Subscribe to the author

Subscribe

Don't want to

11

German and American engineers have created a more affordable alternative to Spot robots - the Solo 8 four-legged open source platform from 3D printed parts and relatively inexpensive, commercially available stuffing. Who needs a headcrab?

Everyone knows about the dog-like Spot robots developed by Boston Dynamics, but not everyone can afford such an assistant: the commercial version of Spot costs from seventy-five thousand dollars. For that kind of money, you can either buy a premium car, or use the robot itself as a vehicle, as Adam Savage did.

For that kind of money, you can either buy a premium car, or use the robot itself as a vehicle, as Adam Savage did.

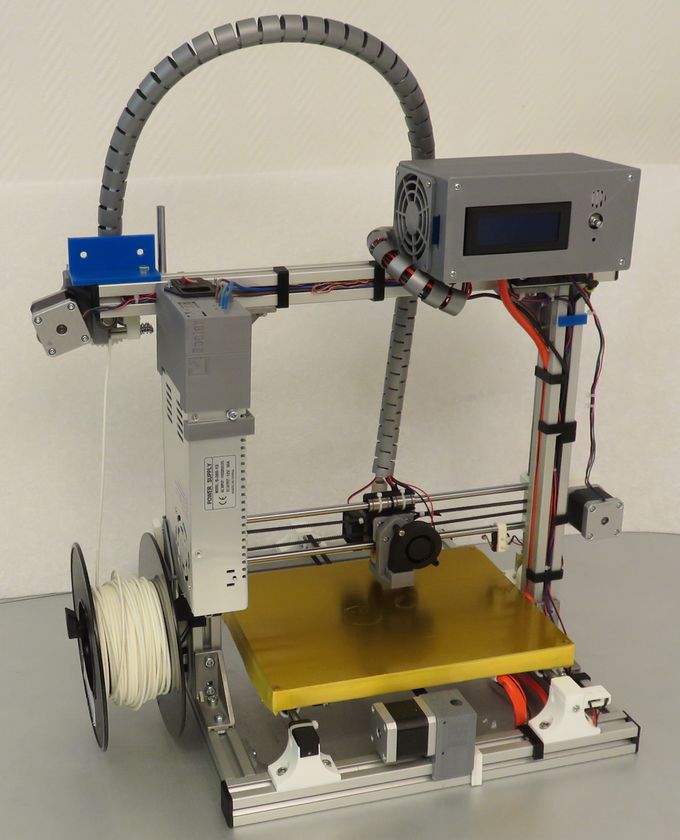

A team of German and American engineers from the Max Planck Institute for Intelligent Systems and New York University was interested in a cheaper version, suitable not so much for beer rides as for laboratory research. The result of the Open Dynamics project was another four-legged robotic system, conceptually similar to Spot and called Solo 8. Technically, this is a much simpler robot, but quite functional and relatively inexpensive. Elements of the supporting structure can be easily reproduced using a household 3D printer, and the filling can be found in stores.

“Developing a robot like this by a research team could easily take four years. In addition, a wide range of knowledge is required. Our platform is a collection of knowledge from several teams. Now any laboratory can go online, download files, print parts on a 3D printer and buy other components. Any user can add additional features within a few weeks,” says German team leader Alexander Badri-Schprovitz.

Any user can add additional features within a few weeks,” says German team leader Alexander Badri-Schprovitz.

Solo 8 weighs just over two kilograms and, thanks to its high power ratio, has good agility. The design of the limbs allows the car to correct itself in the event of a rollover on its back, and the rigidity of the chassis can be changed using a "virtual" suspension, that is, electric motors with adjustable torque. The car runs, jumps and climbs on inclined surfaces, the platform can be equipped with additional stuffing on its own, if desired.

All the necessary documentation for building your own Solo 8 can be found on the official website of the project, and the report of the scientific team can be found at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday.

Learn more