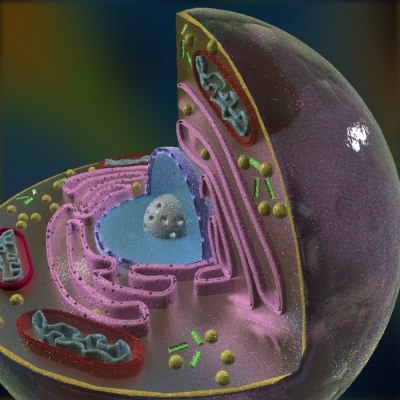

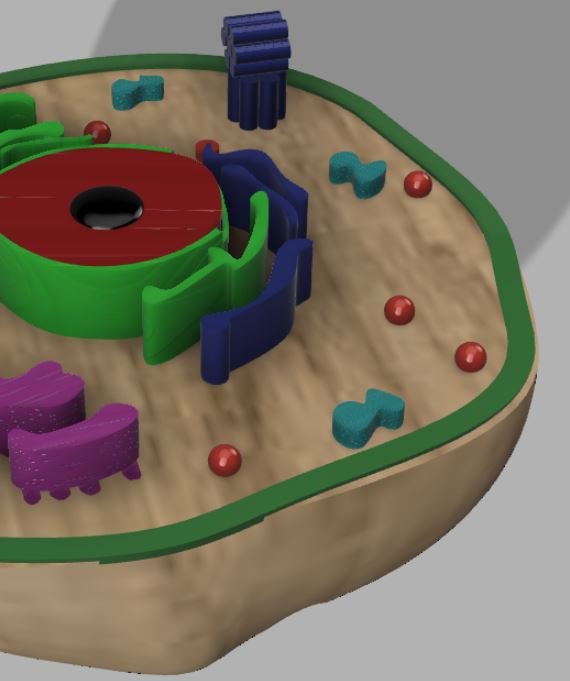

Animal cell 3d print

▷ animal cell 3d models 【 STLFinder 】

Porte-clé cellule animale - animal cell key ring

thingiverse

Porte-clé cellule animale - animal cell key ring

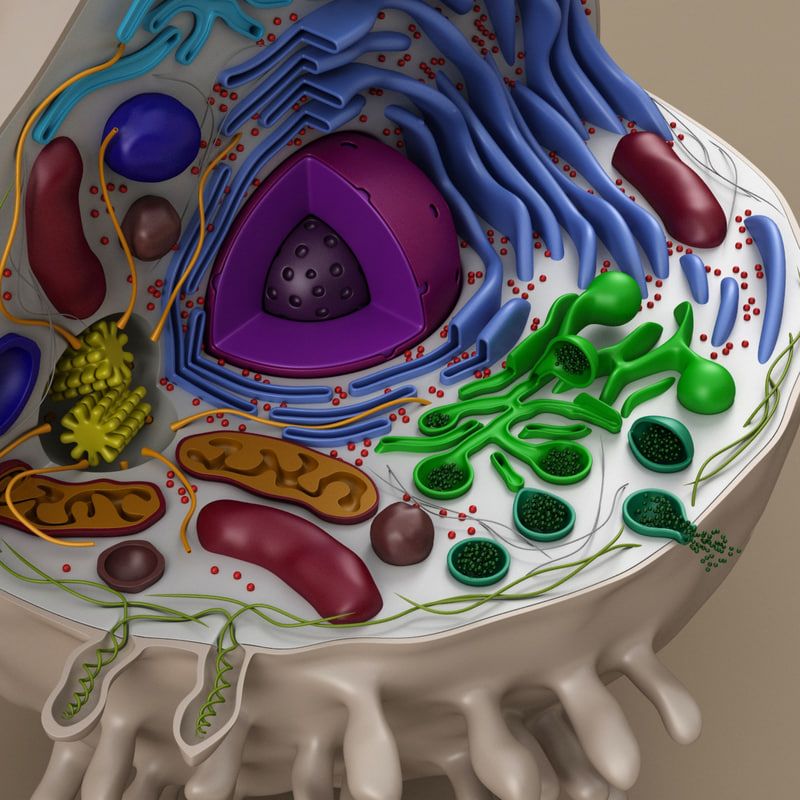

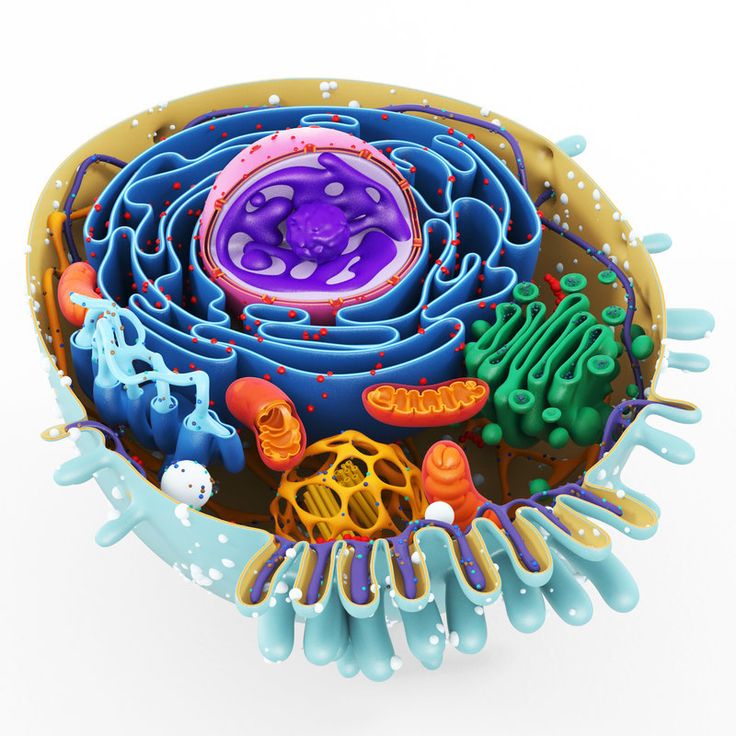

animal cell

pinshape

animal cell

Animal Cell

thingiverse

A 3D Animal Cell

animal cell

thingiverse

Animal cell for biology

Animal Cell

sketchfab

Animal cell made by me.

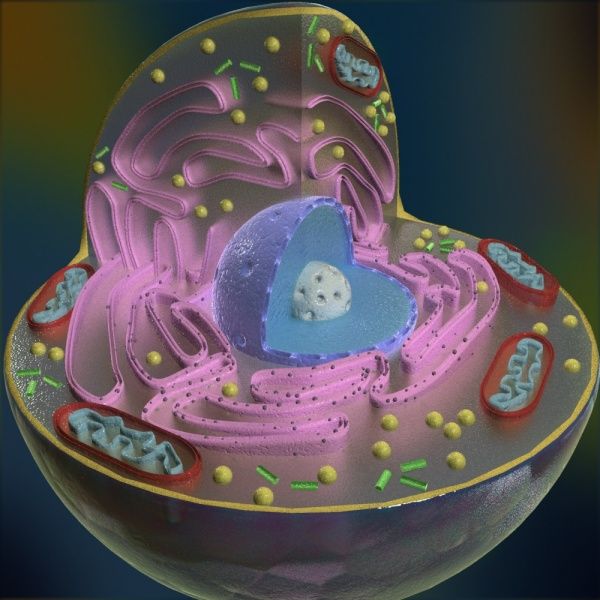

Animal Cell

thingiverse

Model of Animal Cell for teachers, students and educators. ...Enjoy

Animal Cell

sketchfab

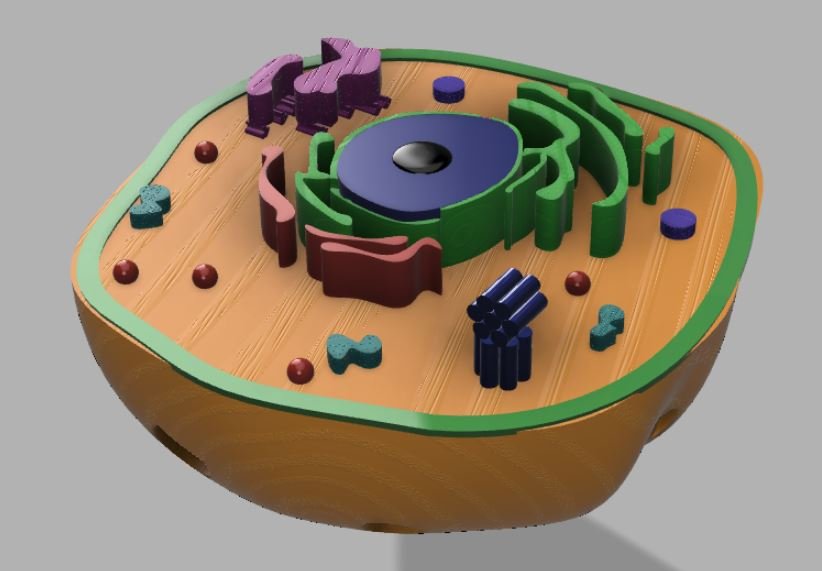

Model of an animal cell created in Tinkercad.

Animal Cell

thingiverse

A large scale Animal Cell... ...more info to follow

Animal Cell

pinshape

It is a model of an animal cell

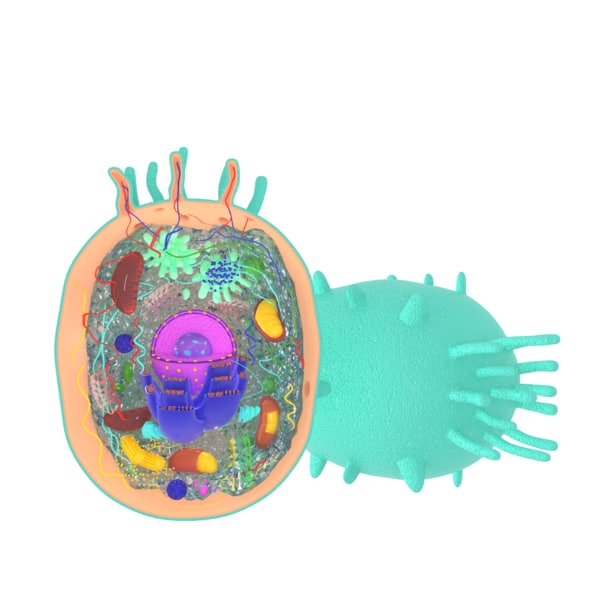

Animal Cell

thingiverse

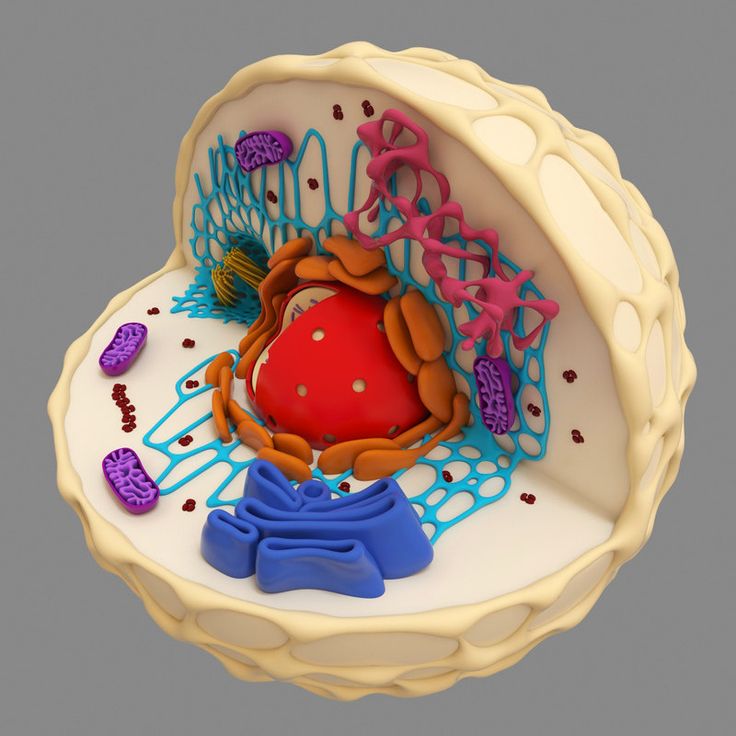

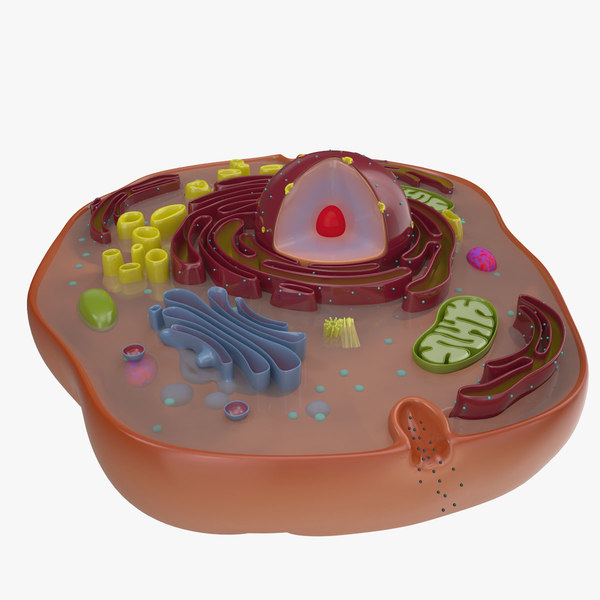

This is a model of an animal cell, enjoy it Standards NGSS CCSS Overview and Background Model of an animal cell Lesson Plan and Activity Discover the parts of a cell Materials Needed just print it !!!

Animal Cell

sketchfab

This is an Animal Cell for A presentation on my school

Animal Cell

thingiverse

A Edited 3D designed animal cell by Dalton S. ...from MyMiniFactory.com Instructions Print It.

...from MyMiniFactory.com Instructions Print It.

Animal Cell

myminifactory

Model of Animal Cell for teachers, students and educators. Enjoy! ... paleos.it [email protected]

Animal cell

pinshape

Animal Cell model for 3D printng. ... Units: millimeters Length: 265 mm Width: 265 mm Height: 127 mm

Animal Cell

thingiverse

Animal Cell with "Vacuole" spelled correctly and added a Centriole and a Nucleolus. ...My son remixed this for his High School project.

...My son remixed this for his High School project.

animal cell

thingiverse

This is a animal cell you can use it for school This is a remix from https://www.thingiverse.com/thing:398515

Animal Cell

thingiverse

... my classes, I was put to work to recreate a tool that would be able to be used as a biology tool during one of the classes. ...Although, my creative side wasn't activated, I decided to do an Animal Cell which provides all the organelles within a cell.

animal cell

thingiverse

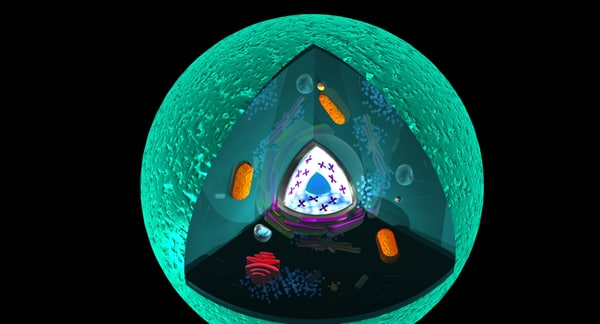

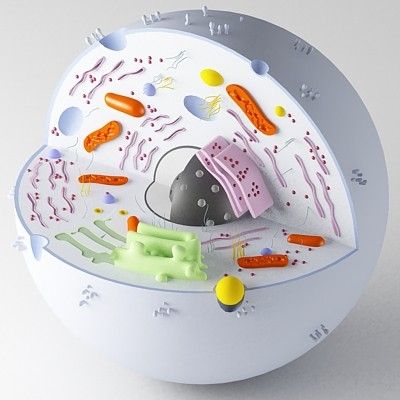

It`s a simplified model of animal cell. Ther are a cell nucleus, an endoplasmic reticulum,a Golgo apparatus,some ribosomes and some mitochondrions.This model you can put on the support and place it on the cupboard.

Prosty model komórki...

Ther are a cell nucleus, an endoplasmic reticulum,a Golgo apparatus,some ribosomes and some mitochondrions.This model you can put on the support and place it on the cupboard.

Prosty model komórki...

Animal Cell

thingiverse

So far, I've only done the nucleus, but future updates will show the other parts of the cell (organelles). UPDATE: I've finished making all the organelles. Version 1.0 is just a waaaaaayyyyyy bigger version, while 2.0 is M3D printable size and the...

Animal Cell

thingiverse

It is an animal cell model that I designed myself. I designed it for my project. A model with all organelles. They are not together. All the pieces are in individual large shapes.

If you want, you can divide the lysosome into two and print it, it...

All the pieces are in individual large shapes.

If you want, you can divide the lysosome into two and print it, it...

Animal Cell

pinshape

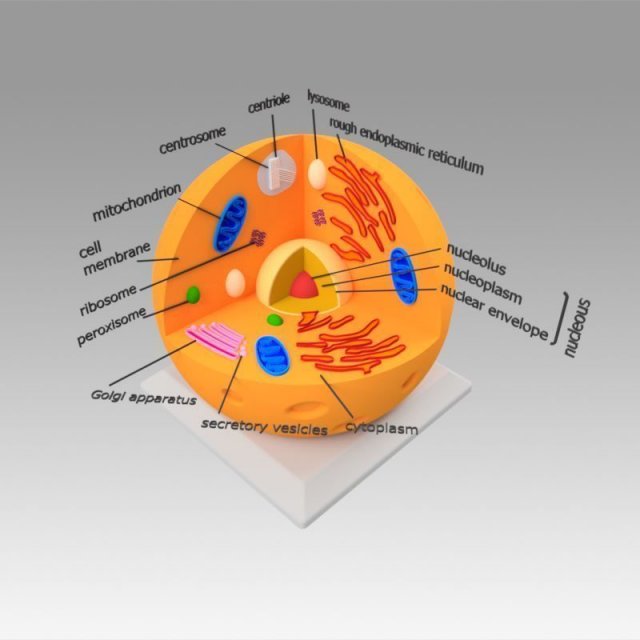

-Added callouts for the names of parts of the animal cell. Letters are executed by volume. If necessary, they can be turned off from the model. -Model does not include any backgrounds or scenes used in preview images. -Units: mm Thank you for coming...

Animal cell

cults3d

-Added callouts for the names of parts of the animal cell. Letters are executed by volume. If necessary, they can be turned off from the model. -Model does not include any backgrounds or scenes used in preview images. -Units: mm File Formats: .obj ...

-Units: mm File Formats: .obj ...

Animal cell

thingiverse

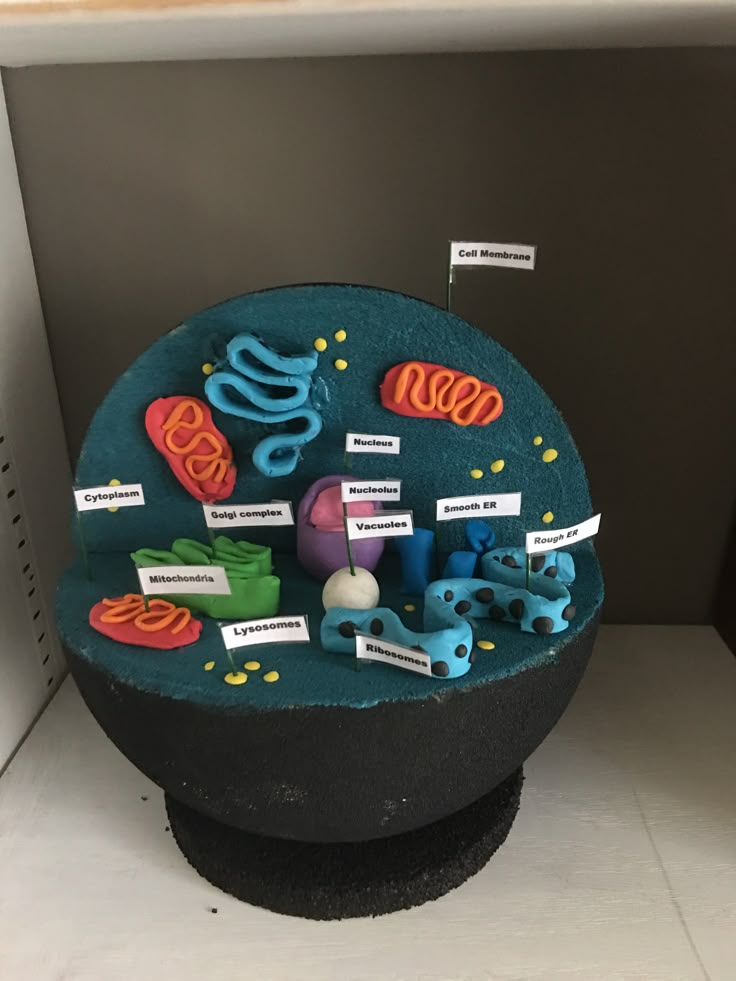

The STL files above are printable parts that successfully when put together create a full model of an animal cell . Suitable for any biology , anatomy or aquatic science class to teach students about parts of a cell. Some key things to remember for...

Animal Cell School Project

thingiverse

Animal cell model for school

Animal Cell Stand

thingiverse

Stand for an animal Cell model

Animal Cell V5

sketchfab

Animal cell model for 7th grade project

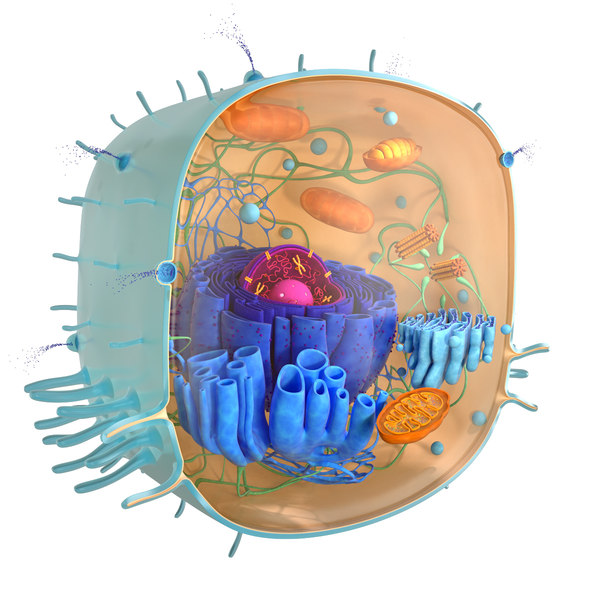

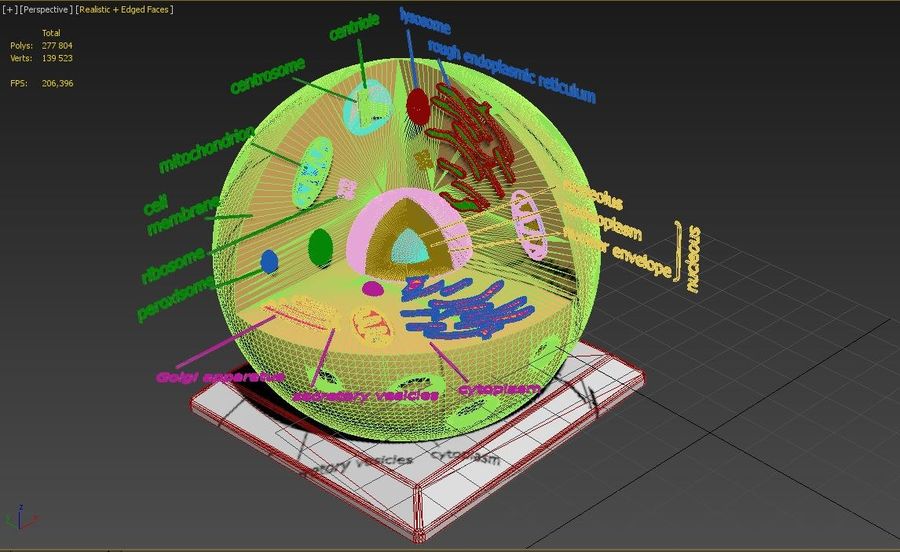

Animal Cell 3D model

cgtrader

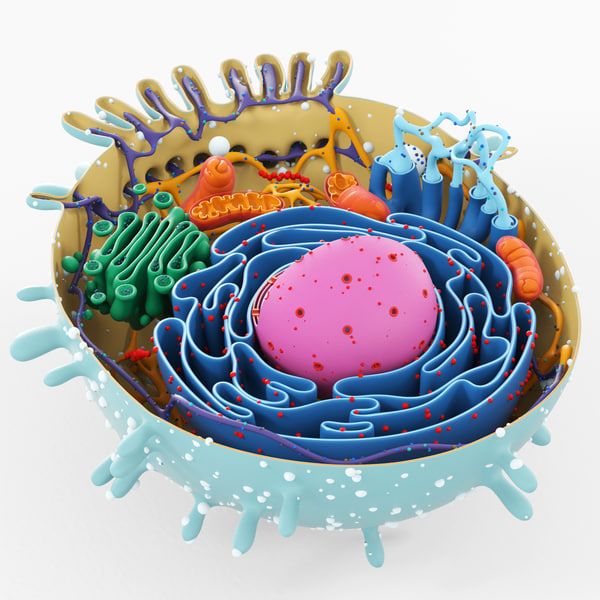

Animal Cell 3d Model 3D Typical Animal Cell's model Animal Cell structure And uncut cell 1-5 images are Renders, others_ screenshots Best model for 3D print The Model Consists of: Cell Envelope_Cell coat, Cell Membrane Cytoplasma Secretory Vesicle. ..

..

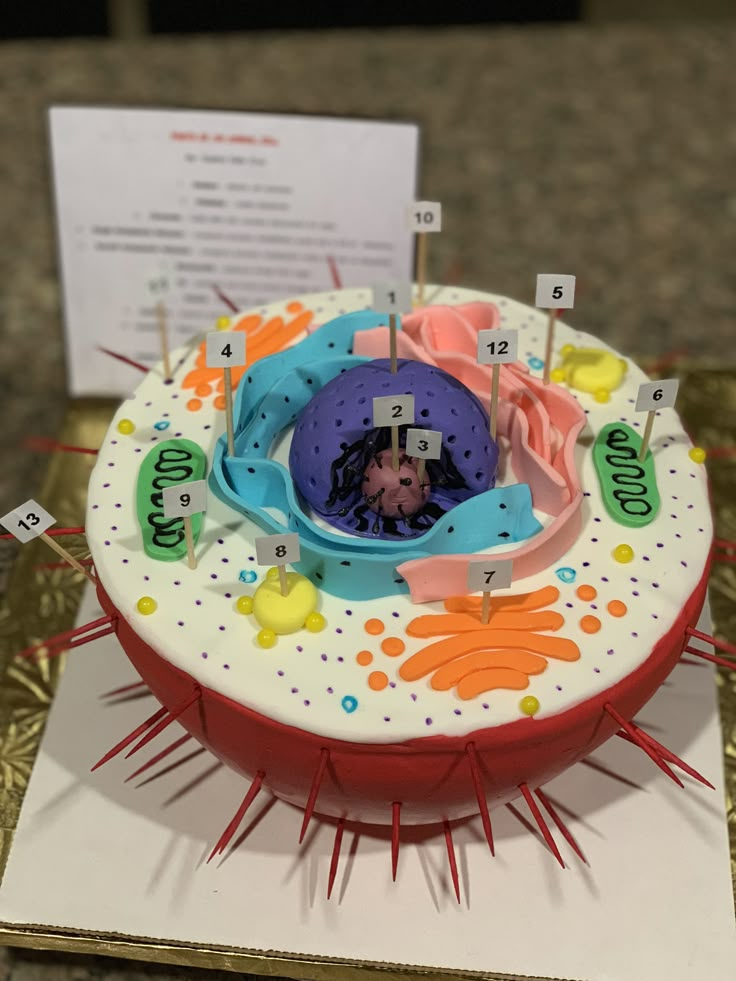

Animal Cell Model

thingiverse

A simple animal cell with labeled parts with numbers.

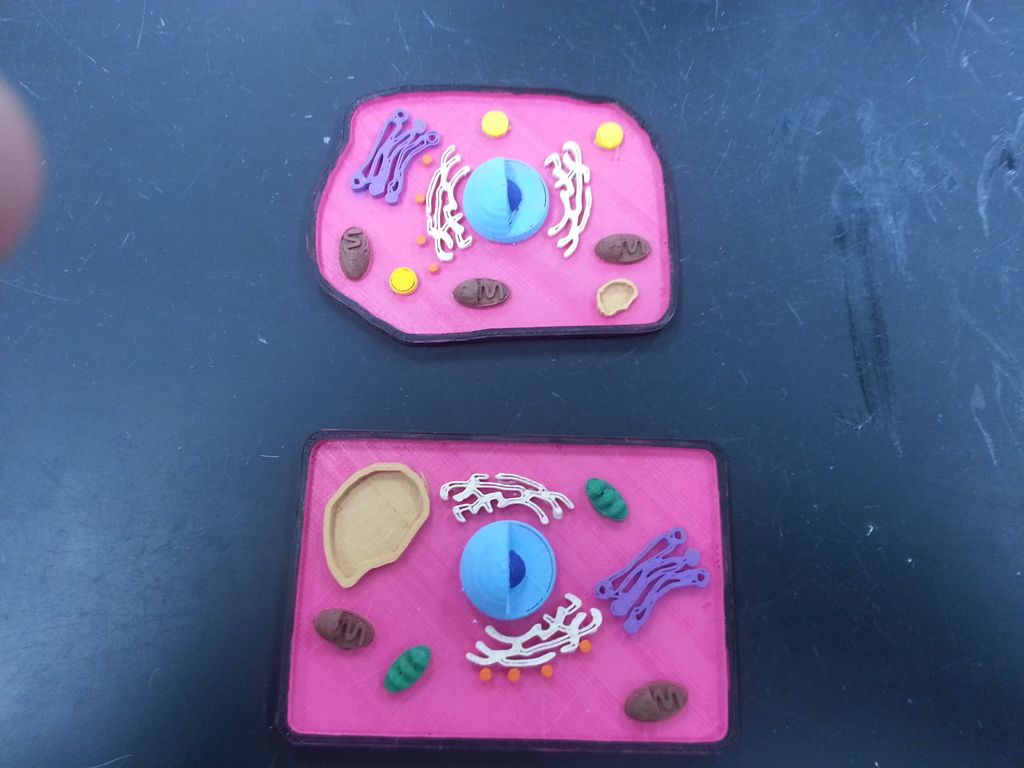

Plant and Animal Cell

thingiverse

A plant and animal cell designed in Minecraft.

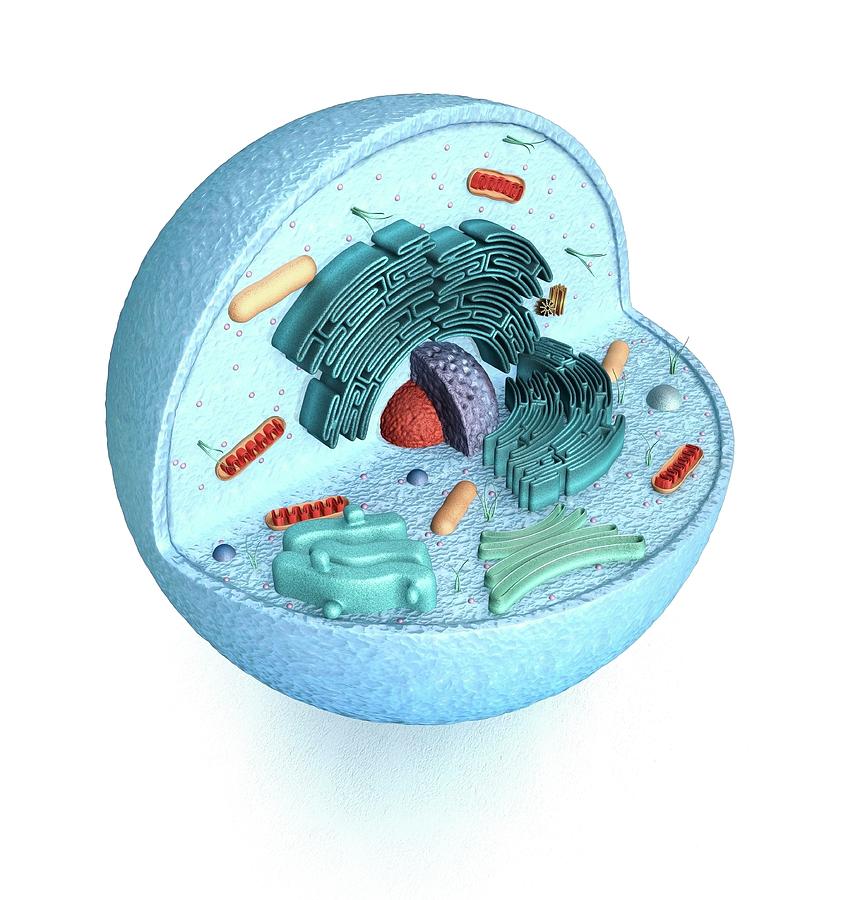

Animal Cell 3D model

cgtrader

... nucleus and specialized structures called organelles that carry out different functions. Animal cells do not have plant-specific organelles like cell walls, which support the plant cell, or chloroplasts, the organelle that carries out photosynthesis

Animal and Plant Cell Construction Kit

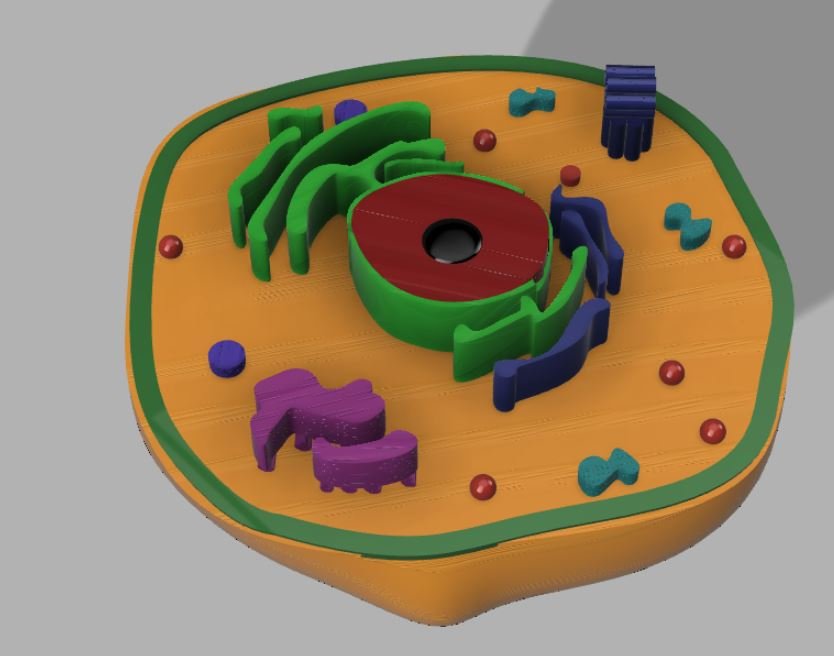

Animal and Plant Cell Construction Kit by mfritz is licensed under the Creative Commons - Attribution license.

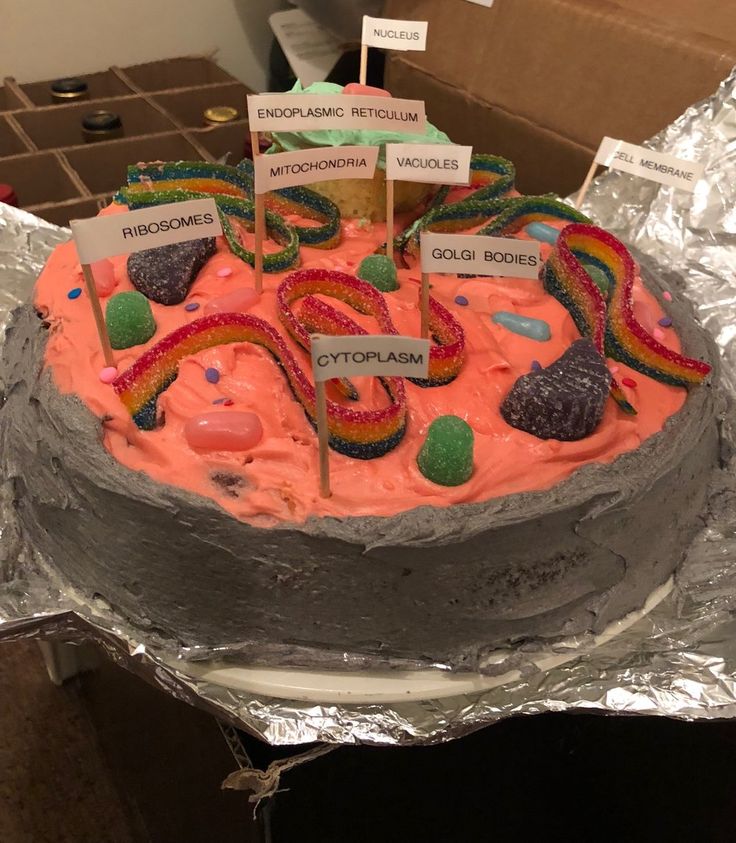

Make a model of an animal or plant cell.

Making models of animal and plant cells is a common middle school science activity. Now you can 3D print your cell model. Customize or remix as you please, put a hole in it and make a keychain, whatever you like.

Open the file Animal and Plant cell Construction Kit on Tinkercad.com and you'll have all the parts you need. Or download the parts individually and put them together in your favorite cad program.

https://www.tinkercad.com/things/4Pc42eJLU5Y

The easiest way for students to build their cells is to search for and open the file Animal and Plant Cell Construction Kit on Tinkercad.com https://www.tinkercad.com/things/4Pc42eJLU5Y. All the parts are in that file and students just need to move them into the correct position and then delete the extra pieces to have a printable model.

Students will want to use the arrow keys to help them move parts into the correct position. They will not need to resize the pieces or lift them off the workplane. They can copy or duplicate to make extra copies of the organelles, and they can be rotated to add some variety to the lay out.

They can copy or duplicate to make extra copies of the organelles, and they can be rotated to add some variety to the lay out.

NGSS

Make a model of an animal or plant cell.

Making models of animal and plant cells is a common middle school science activity. Now you can 3D print your cell model. Customize or remix as you please, put a hole in it and make a keychain, whatever you like.

Open the file Animal and Plant cell Construction Kit on Tinkercad.com and you'll have all the parts you need. Or download the parts individually and put them together in your favorite cad program.

https://www.tinkercad.com/things/4Pc42eJLU5Y

- Go to Tinkercad.com and find the Animal and Plant Cell Construction Kit file and open it https://www.tinkercad.com/things/4Pc42eJLU5Y

- Choose either the animal cell or plant cell. Lock it in place and delete the one you don't want

- Drag and drop the organelles into position in the cytoplasm

- Use Copy or Duplicate to make extra copies of organelles

- You can use rotate to reposition the organelles

- Delete all the extra pieces and labels

- Print your cell model

- Optional: You can use paint or markers to color the organelles

Objective

Students will design and print a 3D model of an animal or plant cell, or both.

Audience

This project is intended for an 8th grade class but could be used for grades 6 - 8.

Preparation

Students should have a basic understanding of the cell, it's parts and their functions. The 3D design process using Tinkercad is relatively easy and would be a good project for beginners.

Steps

- Go to Tinkercad.com and find the Animal and Plant Cell Construction Kit file and open it https://www.tinkercad.com/things/4Pc42eJLU5Y

- Choose either the animal cell or plant cell. Lock it in place and delete the one you don't want

- Drag and drop the organelles into position in the cytoplasm

- Use Copy or Duplicate to make extra copies of organelles

- You can use rotate to reposition the organelles

- Delete all the extra pieces and labels

- Print your cell model

- Optional: You can use paint or markers to color the organelles

Results

This project was completed as described with two 8th grade classes. The students were able to create both an animal cell and plant cell during one 45 minute class period.

The students were able to create both an animal cell and plant cell during one 45 minute class period.

A few students accidentally shifted pieces above or below the workplane, so make sure they check for that before attempting to print models.

Biomaterial for 3D printing of temporary human bones created / Sudo Null IT News Photo: Adam E. Jakus

Attempts to create materials for 3D printing of temporary human bones (osteoregenerative biomaterials) have been made repeatedly. Unfortunately, they still suffer from a number of shortcomings. Among them are the inability to quickly and accurately reproduce a new bone, high cost and limited production capabilities, and the complexity of processing during a surgical operation.

The new biomaterial is devoid of all these shortcomings. If all tests are successful, then in a few years people will be able to get strong, superelastic and cheap artificial bones that will biodegrade in the body in a few years (they are gradually replaced by natural bone tissue). The most interesting thing is that the material extrusion process at room temperature, theoretically, allows printing bones even on home printers.

The most interesting thing is that the material extrusion process at room temperature, theoretically, allows printing bones even on home printers.

As the scientists write, the new material HB (from hyperelastic “bone”) consists of 90% by weight from hydroxyapatite and 10% from polycaprolactone.

Hydroxylapatite Ca 10 (PO 4 ) 6 (OH) 2 is the main mineral constituent of natural human bones. In most bones, it is about 50% of the total mass, and in tooth enamel - 96%. In medicine, a synthetic analog has long been used in traumatology, orthopedics, and bone surgery as a filler that replaces parts of a lost bone. In dentistry, it is also used in toothpastes as a remineralizing element that strengthens tooth enamel.

But polycaprolactone (PCL) is not found in biological materials. It is a biodegradable polyester, which is used in industry for the production of polyurethanes. It is made into biodegradable bags. In medicine, PCL is also used as a suture material and as a self-absorbable long-acting thermal implant (filler), which has the ability to stimulate the growth of fibrous tissue and replenish volume due to its own components. Many tablets are produced in PCL capsules, they are absorbed in the body. In addition, PCL is used in mass 3D printing as a material for prototyping. By its properties, viscous PCL is similar to a natural resin like gutta-percha.

Many tablets are produced in PCL capsules, they are absorbed in the body. In addition, PCL is used in mass 3D printing as a material for prototyping. By its properties, viscous PCL is similar to a natural resin like gutta-percha.

Experiments have shown that artificial bones of this composition can be quickly printed at room temperature at a speed of up to 275 cm 3 /hour by extrusion, that is, by forcing a viscous melt of material or a thick paste through a forming hole. A special solvent is used to create a viscous mixture that is loaded into the printer.

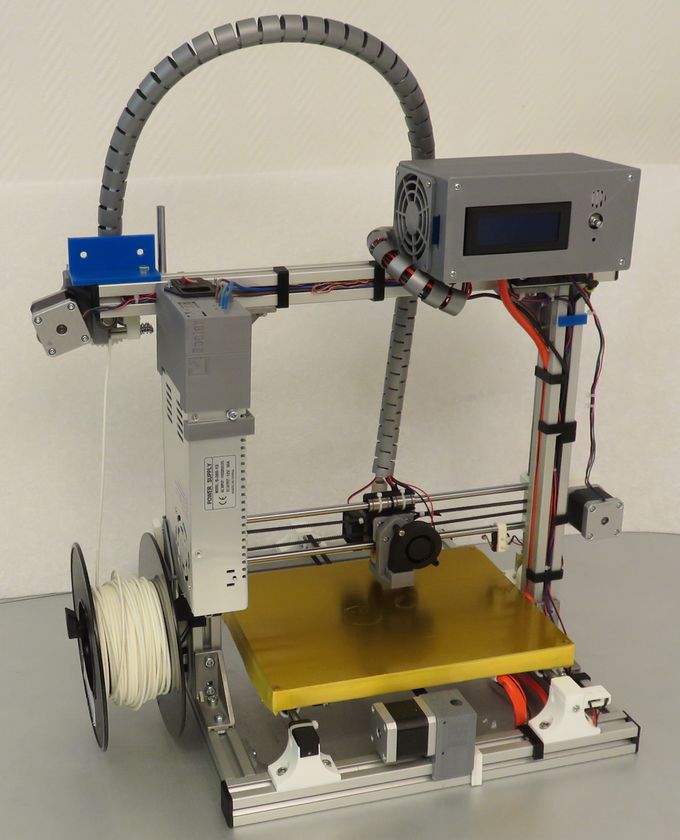

Printing an implant with traditional extrusion at room temperature is a big advantage because other bone implants are created at high temperature using lasers, explains Ramille Shah, lead author and research team leader at Northwestern University ( USA). During the experiments, the researchers themselves used a commercially available 3D-Bioplotter System printer manufactured by EnvisionTec. This device can be purchased for between $250,000 and $300,000.

Of course, in the household, such a printer would be too expensive. But every hospital or surgical center can afford it. In principle, even private individuals can buy such printers and print new bones for themselves or pets if necessary (of course, it is advisable to turn to a professional surgeon for the operation).

EnvisionTEC 3D-Bioplotter

Artificial bones demonstrate good mechanical properties: strain to failure from 32% to 67%, elastic modulus from 4 to 11 MPa. Thus, it is an elastic and durable material. It is also characterized by high absorbency (porosity 50%), supports the viability and spread of living cells. Tests have shown that the material does not interfere with the formation of bone marrow cells from mesenchymal stem cells.

So far, the biocompatibility of HB has only been tested in laboratory animals, but these experiments have proven very promising. Subcutaneous implants in mice did not cause rejection within 7-35 days. In rats, a bone graft was placed in the posterolateral part of the spine (posterior lateral fusion) for 8 weeks, and new bone formation was recorded. We also conducted an experiment on a primate with skull damage (4 weeks).

In rats, a bone graft was placed in the posterolateral part of the spine (posterior lateral fusion) for 8 weeks, and new bone formation was recorded. We also conducted an experiment on a primate with skull damage (4 weeks).

During all experiments, HB did not cause a negative reaction of the immune system. At the same time, normal vascularization (formation of blood vessels) was noted, the artificial bone quickly integrated into the surrounding tissues, quickly ossified and supported the growth of new bone tissue without additional intervention. It is assumed that as the material biodegrades, its place will be taken by living natural bone tissue with blood vessels.

It is important to note that for all its strength and elasticity, the new material is not brittle or brittle like many other implants. That is, the surgeon can cut off a piece of artificial bone without splinters, a common problem with other implants.

Researchers hope to get approval to start human trials within five years. No 3D printing material is currently approved by regulators as a regenerative bone material in the US. HB may be the first.

No 3D printing material is currently approved by regulators as a regenerative bone material in the US. HB may be the first.

Scientific paper published on September 28, 2016 in the journal Science Translational Medicine (doi: 10.1126/scitranslmed.aaf7704).

3D printing of human organs / Sudo Null IT News Submitted to their corporate blog. Questions can be addressed directly to them.

This is from the new Organ 3D Printing Lab. An impressive microscope is in front, and two medical engineers behind AutoCAD are visible further – they are making a mock-up of a site for the formation of tissue spheroids.

A laboratory for 3D organ bioprinting (Invitro project) has recently opened here. Some kind of fierce extravaganza of misunderstanding of what is being done is going on around her. In general, although I am not a microbiologist, I became interested. I made my way to the developer - V.A. Mironov. It was he who invented the organ printing technology and patented it in the USA, participated in the development of three modifications of bioprinters, and it was he who was the “chief in science” in the new laboratory in Moscow:

V. A. Mironov (M.D., Ph.D., professor with 20 years of experience in microbiology, in particular, on the border with IT) - in the process of explaining the essence of the technology to me for an hour and a half, he painted a bunch of paper.

A. Mironov (M.D., Ph.D., professor with 20 years of experience in microbiology, in particular, on the border with IT) - in the process of explaining the essence of the technology to me for an hour and a half, he painted a bunch of paper.

In a nutshell, he could not tell about printing, because first you need to understand some of the history of the issue. For example, why it was necessary to discard the bright idea of growing an embryo without a head in a surrogate mother, and then removing a kidney from it and placing it in a bio-solution for accelerated maturation.

In the meantime, the main thing. Do not rush to drink everything that burns: a new liver is still very far away . Go.

Evolution of methods

So, first there was gene therapy : the corresponding complexes were introduced to the patient. Certain cells were isolated, the necessary genes were introduced into them, then the cells were placed in the human body. There was not enough insulin - here is the gene that produces its creation. We take a cellular complex, modify it, inject it into the patient. The idea is excellent, though with one fundamental drawback: the patient is cured immediately, and there is no need to buy anything after the operation. That is, guess who it was across the throat. The case was difficult, and then one of the patients died - and a wave of lawsuits and bans, characteristic of the United States, began, as a result of which the research had to be curtailed. As a result, there is a method, but it has not really been tested.

There was not enough insulin - here is the gene that produces its creation. We take a cellular complex, modify it, inject it into the patient. The idea is excellent, though with one fundamental drawback: the patient is cured immediately, and there is no need to buy anything after the operation. That is, guess who it was across the throat. The case was difficult, and then one of the patients died - and a wave of lawsuits and bans, characteristic of the United States, began, as a result of which the research had to be curtailed. As a result, there is a method, but it has not really been tested.

The next trend was cell therapy - the use of embryonic stem cells. The method is excellent: "universal" cells are taken, which can be developed to any required by the patient. The problem is that in order to get them somewhere, you need an embryo. The embryo in the process of obtaining cells is obviously consumed. And this is already a moral and ethical problem that caused the ban on the use of such cells.

Next - tissue engineering - this is when you take a base, put cells on it, put it all into a bioreactor, and at the output you get the result (organ) that the patient needs. Like a prosthesis, only alive. Here is an important point: the main difference from the prosthesis is that the prosthesis is originally from inorganic matter, and is unlikely to ever be integrated into the body “like a native”. You can't scratch a wooden leg.

Methods of tissue engineering are scaffold - when a leached (de-livered) cadaveric organ is used, which is then "populated" with the patient's cells. Other scientific groups have tried to work with porcine organ protein scaffolds (human donors are not needed, but immunocompatibility rises to its full potential). Frames are artificial - from different materials, some scientific groups even experimented with sugar.

Mironov himself practices frameless technology (using hydrogel as a base). In his method, the base polymer rapidly degrades, leaving only cellular material as a result. In other words, first a frame made of neo-boundaries with placed cells is inserted, and then the frame “dissolves”, and the cells of the already grown organ take over its functions. For scaffolds, the same material is used as for surgical sutures: it easily and simply degrades in the human body.

In other words, first a frame made of neo-boundaries with placed cells is inserted, and then the frame “dissolves”, and the cells of the already grown organ take over its functions. For scaffolds, the same material is used as for surgical sutures: it easily and simply degrades in the human body.

The main question here is why 3D printing is needed. To understand this, let's dig a little deeper into the available tissue engineering methods.

Approaching the goal

In general, the idea of inserting a pre-grown organic organ into a person is excellent. Let's look at three options for the development of technology:

- You take an inorganic framework, seed it with cells, and you get a finished organ . The method is crude, but working. It is about him that we are talking about in most of those cases when they say "we printed the organ." The problem is that somewhere you need to take the "building material" - the cells themselves.

And if they are, then it is foolish to use some kind of external frame when it is possible to simply assemble an organ from them. But the most painful problem is incomplete endothelialization. For example, for bronchi made like this, the level is about 70%. This means that superficial vessels are thrombogenic - by curing a patient, you immediately bring him a new disease. Then he must live on heparin or other drugs, or wait for a blood clot and embolism to form. And here, US lawyers are already looking forward to playing back according to the old scenario. And the problem of endothelialization has not been solved yet. A possible option is to isolate bone marrow progenitor cells by mobilization with special preparations and homing on the organ, but this is still a fantasy far from practice.

And if they are, then it is foolish to use some kind of external frame when it is possible to simply assemble an organ from them. But the most painful problem is incomplete endothelialization. For example, for bronchi made like this, the level is about 70%. This means that superficial vessels are thrombogenic - by curing a patient, you immediately bring him a new disease. Then he must live on heparin or other drugs, or wait for a blood clot and embolism to form. And here, US lawyers are already looking forward to playing back according to the old scenario. And the problem of endothelialization has not been solved yet. A possible option is to isolate bone marrow progenitor cells by mobilization with special preparations and homing on the organ, but this is still a fantasy far from practice. - The second method is extremely original and very pleasing with its cynicism . We take a cell (fibroblast) of the patient, add 4 genes. We put the resulting cell into a blastocyst (animal embryo) and begin to grow the animal.

It turns out, for example, a pig with a human pancreas - the so-called chimera. The organ is completely “native”, only the entire infrastructure around – blood vessels, tissues, and so on – is from a pig. And they will be rejected. But nothing. We take a pig, cut out the desired organ (the pig is completely consumed), and then remove all the pig tissues with the help of special processing - it turns out, as it were, an organic frame of an organ that can be used to grow a new one. Some researchers have gone further and proposed the following life hack: let's replace the pig with a surrogate mother. Here's how: in addition to 4 genes, another one is added to the cell, which is responsible for acephaly (lack of a head). A surrogate mother is hired to carry our mutual embryo friend. It develops without a head, acephalus is good at it. Then - an ultrasound, finding out that the child is defective, and a legally permitted abortion. There is no head - there is no person, which means that we did not kill anyone.

It turns out, for example, a pig with a human pancreas - the so-called chimera. The organ is completely “native”, only the entire infrastructure around – blood vessels, tissues, and so on – is from a pig. And they will be rejected. But nothing. We take a pig, cut out the desired organ (the pig is completely consumed), and then remove all the pig tissues with the help of special processing - it turns out, as it were, an organic frame of an organ that can be used to grow a new one. Some researchers have gone further and proposed the following life hack: let's replace the pig with a surrogate mother. Here's how: in addition to 4 genes, another one is added to the cell, which is responsible for acephaly (lack of a head). A surrogate mother is hired to carry our mutual embryo friend. It develops without a head, acephalus is good at it. Then - an ultrasound, finding out that the child is defective, and a legally permitted abortion. There is no head - there is no person, which means that we did not kill anyone. And here - time! - we have here a theoretically legal biomaterial with undeveloped organs of the patient. Implant them fast! Of the obvious disadvantages - well, except for the moral side - organizational complexity and possible legal complications in the future.

And here - time! - we have here a theoretically legal biomaterial with undeveloped organs of the patient. Implant them fast! Of the obvious disadvantages - well, except for the moral side - organizational complexity and possible legal complications in the future. - And finally, there is a third method, about which we are talking about . It is also the most modern - three-dimensional printing of organs. And that is what they are doing in the new laboratory. The meaning is this: no inorganic scaffolds are needed (cells hold themselves perfectly), no need to take organs from someone. The patient gives a little of his adipose tissue (everyone has it, only skinny Japanese complained during the experiments), from which the necessary structural elements are obtained by sequential processing of cells. A three-dimensional model of an organ is created, converted into a CAD file, then this one is given to a 3D printer that can print with our cells and understands at what point in three-dimensional space it needs to “lay” a specific type of cell.

The output is a tissue construct, which must be placed in a special environment until problems with hypoxia begin. In the bioreactor, the tissue construct "ripens". Then the organ can be "transplanted" to the patient.

The output is a tissue construct, which must be placed in a special environment until problems with hypoxia begin. In the bioreactor, the tissue construct "ripens". Then the organ can be "transplanted" to the patient.

Obvious complexities of the method are as follows:

- Obtaining a model of an organ. You need to get a diagram from somewhere. It's pretty simple.

- Obtaining the cells themselves. Obviously, we need material to print the organ.

- Assembling a printer so that cells can print (a lot of problems with the formation of an organ structure).

- Hypoxia (lack of oxygen) during organ creation.

- Realization of nutrition of the organ and its maturation to readiness.

So, a 3D printer is only a piece of the organ fabrication line: it needs to be provided with a drawing, material, and then the resulting organ model must be grown from cells. Now let's see step by step how all the tasks described above are solved.

Now let's see step by step how all the tasks described above are solved.

Organ Model

So, a CAD file is taken (now in stl format) with a model of an organ. The easiest way to get a model is to make a 3D scan of the patient himself, and then modify the data by hand. Now the current constructs are modeled in AutoCAD.

Modeling visible. The 3D structure is like that of a regular part, only instead of plastic there will be fabric spheroids.

Material

The material is taken - tissue spheroids, which will be used for printing. As a basis, a hydrogel is used, which acts as a connecting structure. The 3D printer then prints the organ from these tissue spheroids.

The first experiment confirming that a whole organ can be assembled from pieces: scientists cut the heart of a chicken into fragments and spliced it again. Successfully.

Now the question is where to get cells for this material. The best are human embryonic stem cells, which can be used to make cells for any tissue by sequential differentiation. But, as we know, you can't touch them. But you can take iPS - induced pluripotent stem cells. They can be made from bone marrow, dental pulp, or a patient's normal adipose tissue, and are made by various companies around the world.

The best are human embryonic stem cells, which can be used to make cells for any tissue by sequential differentiation. But, as we know, you can't touch them. But you can take iPS - induced pluripotent stem cells. They can be made from bone marrow, dental pulp, or a patient's normal adipose tissue, and are made by various companies around the world.

The scheme is as follows: a person goes to the clinic, undergoes liposuction, the adipose tissue is frozen and placed in a repository. If necessary, they get it, the necessary cells are made from it (ATDSC, there is one such complex in Russia) and then differentiated according to their intended purpose. For example, iPS can be made from fibroblasts, from them - the renal epithelium, and then - the functional epithelium.

Machines for the automatic production of such cells are manufactured by General Electric, for example.

Centrifuge. The first stage of separation of material from adipose tissue.

Balls are formed from these cells in special micropits on the solid material. A cell suspension is placed in the recess on the mold, then the cells are fused, and a ball is formed. More precisely, it is not a very smooth spheroid.

A cell suspension is placed in the recess on the mold, then the cells are fused, and a ball is formed. More precisely, it is not a very smooth spheroid.

Block processing

The next problem is that the cells in the carddig are eager to grow together. Tissue spheroids must be isolated from each other, otherwise they will begin to fuse prematurely. They need to be encapsulated, and for this, hyaluronic acid, obtained from blood serum, is used. It needs very little - just one very thin layer. It also quickly "leaves" after printing.

Seal

The head of the 3D printer has three extruders: two nozzles with gel and a device that produces tissue spheroids. Thrombin is in the first nozzle with the gel, fibrinogen is in the second one. Both gels are relatively stable until they touch. But when the fibrinogen protein is cleaved by thrombin, a fibrin monomer is formed. It is to them, like concrete, that tissue spheroids are fastened. With a layer depth corresponding to the diameter of the spheroid, one can sequentially apply the material row by row - they made a layer, fixed it, and moved on to the next one. Then fibrin is easily degraded in the medium and washed out during perfusion, and only the desired tissue remains.

With a layer depth corresponding to the diameter of the spheroid, one can sequentially apply the material row by row - they made a layer, fixed it, and moved on to the next one. Then fibrin is easily degraded in the medium and washed out during perfusion, and only the desired tissue remains.

This is how the tubes will be printed

The printer prints in layers of 250 micrometers: this is a balance between the optimal block size and the risk of hypoxia in the spheroid. In half an hour, you can print a tissue-engineering structure 10x10 centimeters - but this is not yet an organ, but a tissue-engineering structure, “snot” in jargon. For a structure to become an organ, it must live, have a clear form, and carry out functions.

A microscope with a huge focal length looks at a glass cube with a 3D printer.

Print head. So far, tests of the complex on plastic are underway. The printer now prints consumables, plastic molds for creating spheroids. In parallel, tests are underway on a sterile box for a 3D printer with a working electronic device.

In parallel, tests are underway on a sterile box for a 3D printer with a working electronic device.

Post-processing

The main question is that it would be good for cells to have access to oxygen and nutrients . Otherwise, they begin, roughly speaking, to rot. When the organ is thin, there are no problems, but already from a couple of millimeters it is important. True, an elephant, for example, has cartilage up to 5 millimeters - but they are built in where a lot of pressure is created due to the mass of the rest of the elephant. So, in order for the printed organ not to deteriorate during the fabrication process, microcirculation is needed. This is done by printing real vessels and capillaries, plus with the help of the thinnest perfusion holes made by inorganic instruments (roughly speaking, the structural blocks arrive on a polymer "skewer", which is then removed).

Tissue compaction

Tissue union of several cell types without mixing

The future organ is placed in a bioreactor. This is, greatly simplifying, a jar with a controlled environment, in which the necessary substances are supplied to the inputs and outputs of the organ, plus accelerated maturation is ensured due to exposure to growth factors.

This is, greatly simplifying, a jar with a controlled environment, in which the necessary substances are supplied to the inputs and outputs of the organ, plus accelerated maturation is ensured due to exposure to growth factors.

Here's what's interesting - the architecture of an organ is usually similar to the usual encapsulated object in OOP - an inlet artery, an outlet vein - and a bunch of functions inside. It is assumed that the bioreactor will provide the desired input and output. But this is still a theory, it has not yet been possible to collect a single one. But the project has been worked out to the stage “you can assemble a prototype”.

Hanging in the laboratory. You can see the first stage: obtaining the basic elements, the second - a 3D printer with three extruders, the third - moving from a prototype to an industrial model, then testing on animals, then going to an IPO and installation for people.

Complete line - cell sorter, tissue spheroid fabricator, printer, perfusion unit

Markets

Now who needs all this at the stage, while there are no organs themselves.

The first major customers are the military . Actually, as you might guess, DARPA visits all scientists involved in this topic. They have two applications - testing (a lot of things cannot be tested on living people, but you want to - a separate organ would be very useful) and therapeutic. For example, a fighter of democracy tears off his arm, and it takes a day to crawl to the hospital. It would be nice to close the hole, relieve the pain, give him the opportunity to shoot another 5 hours, and then come to the nurse on his own two feet. In theory, either robots are possible that will collect all this in place, or patches from human tissues, which are already seriously thinking of putting on burns.

Second client - Pharma . There, drugs are tested for 15 years before entering the market. As the Americans joke, it's easier to kill a colleague than a mouse. On the mouse you need to collect a bunch of documents in your hand thick. Certified mice are very expensive as a result. Yes, and the results on the animal are different from human ones. Existing test models in flat cell models and in animals are not sufficiently revalent. I was told in the lab that about 7% of the world's new drug formulas don't make it to clinical trials due to nephrotoxicity detected in preclinical testing. Of those that have reached, about a third have problems with toxicity. That is why, by the way, one of the first tasks is to test the functionality of nephrons made in the laboratory. Tissues and organs from the printer will significantly accelerate the development of drugs, and this is a lot of money.

Yes, and the results on the animal are different from human ones. Existing test models in flat cell models and in animals are not sufficiently revalent. I was told in the lab that about 7% of the world's new drug formulas don't make it to clinical trials due to nephrotoxicity detected in preclinical testing. Of those that have reached, about a third have problems with toxicity. That is why, by the way, one of the first tasks is to test the functionality of nephrons made in the laboratory. Tissues and organs from the printer will significantly accelerate the development of drugs, and this is a lot of money.

The third client is hospitals. The US kidney transplant market, for example, is $25 billion. At first, it is supposed to just sell 3D printers to hospitals so that the patient can get what they need. The next (theoretical) step is the creation of complexes for printing organs directly inside the patient. The fact is that it is often much easier to deliver a miniature printhead inside a patient than a large organ. But this is still a dream, although the necessary robots exist.

But this is still a dream, although the necessary robots exist.

This is how it should work

Yes, there is another important topic here: in parallel, research is being conducted on the control of tissue spheroids due to magnetic levitation. The first experiments were simple - iron “nano-sawdust” was thrust into the fabric, and the spheroids really flew as they should in the magnin field and were delivered to the place. But differentiation suffered. With sawdust it is difficult to perform the necessary functions. The next logical step is the metal in the encapsulating layer. But even cooler are microsuits with magnetic particles. These spacesuits cover the spheroid and can also act as a connector frame that snaps into place right away, which gives a huge scope for the rapid printing of organs.

Links

— Company at Skolkovo

— About the Russian conference on regenerative medicine that this team did

A bunch of links in English that talks about gradual progress:

www. ncbi.nlm.nih.gov/pubmed/12679063

ncbi.nlm.nih.gov/pubmed/12679063

www.ncbi.nlm.nih .gov/pubmed/11500808

www.ncbi.nlm.nih.gov/pubmed/20603872

www.ncbi.nlm.nih.gov/pubmed/21419621

www.ncbi.nlm.nih.gov/pubmed/18423666

www .ncbi.nlm.nih.gov/pubmed/16805712

www.ncbi.nlm.nih.gov/pubmed/15174961

www.ncbi.nlm.nih.gov/pubmed/18333793

www.ncbi.nlm.nih.gov/pubmed/18194071

www.ncbi.nlm.nih .gov/pubmed/18154465

www.ncbi.nlm.nih.gov/pubmed/14981244

www.ncbi.nlm.nih.gov/pubmed/20811099

www.ncbi.nlm.nih.gov/pubmed/19176247

www .ncbi.nlm.nih.gov/pubmed/12740943

A pile of paper that Mironov drew during the story. Handwriting like a doctor :)

Important facts

- No 3D printed organ has yet been implanted in humans. But there are about a dozen different cases of successful "installation" of such organs in animals.

- Mironov has already assembled three operating 3D bioprinters: 2 in Canada, one in Brazil.

The new one in Russia should be better than all the existing ones.

The new one in Russia should be better than all the existing ones. - When spheroids are spliced together, the tissue becomes compacted - for example, a kidney will have to be printed three times more than it will be inside the patient - already at the last stage of fabrication it will become a normal size.

- Now we have learned how to make basic things, for example, tubes from different types of fabric. After checking the functionality of the cells, complex designs can be made. For example, a nephron is easily obtained from tubules, and a kidney is easily obtained from many nephrons.

- Robots are needed. In the bronchi, for example, there are 10 orders of branching - it is somewhat tiring to collect this with your hands, and the patient is not ready to wait thousands of years. The future of fast printing technology is microfluidic extruders that make up to 10,000 drops per second. Together with a fast robot, they can give a great effect.

- Printed organs are immediately athrombogenic - for example, vessels are immediately lined from the inside with endothelium.

Learn more