3D printed parts acetone

How To Easily Cold Acetone Vapor Smooth & Finish 3D Prints [Step by Step]

Acetone Polishing (Smoothing) of ABS and ASA – a step-by-step guide

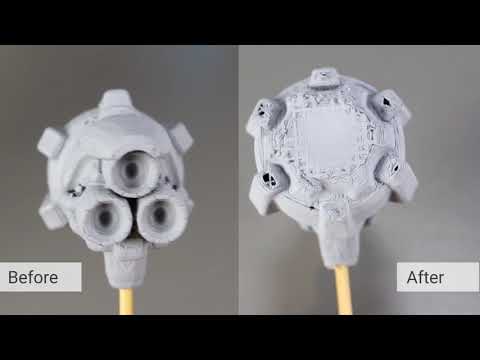

FDM (FFF) 3D printers often produce a final object that while being mechanically sound, tends not to have that ‘professional look’ that you or a customer want to see. You need a reliable, easy method of 3D print finishing.

That’s where the Cold Acetone Vapor Bath process steps in. Finishing 3D printed parts the easy (safe) way. Yes, this was actually 3D printed…

Can I acetone vapor bath my 3D prints?

All ABS 3D prints can be acetone smoothed. Filaments that can be polished using this process are: ABS, ASA, PMMA, HIPS and Polycarbonate.

Other filament types are either unaffected by acetone or are damaged by it. If you’re looking for other 3D printing post-processing techniques, check out our PLA polishing article for details on smoothing out 3D prints that can’t be acetone smoothed.

The following photograph is of a shower tray system consisting of a frame and different color removable trays before ABS Acetone Vapour Smoothing. The frame is made of Black ABS, and all trays are made in ABS of varying colors.

The following photograph show the same system after the ABS Vapour smoothing process.

Not only do the finished parts look better, they now have a higher resistance to water ingress, and they can often be stronger than their non-polished earlier selves once fully hardened.

This is definitely our preferred method when we’re asked how to finish 3D prints – there’s just no better way to easily smooth ABS prints.

SAFETY WARNING!

Before continuing further, please make sure you acquaint yourself with the safety regulations pertaining to acetone (propan-2-one) and its use. It is your responsibility to use this solvent safely.

Obvious things to note for safety are:

- Only use in a well-ventilated area

- NO NAKED IGNITION SOURCES – acetone is extremely volatile and the vapors are Highly Flammable

- *NEVER EVER* heat the acetone!! [See above]

- Avoid breathing the fumes

- Avoid skin contact

- Keep away from animals and children

- Be careful that you do not spill any liquid onto surfaces that might be damaged by acetone – most common household plastics are susceptible to some kind of damage from liquid acetone

The principle behind Vapor Polishing

You can acetone smooth ABS filament & ASA filament, both with acetone liquid or as vapor.

They dissolve readily in the liquid, and a concentrated atmosphere of the vapor will eventually have the same effect. It’s that ‘eventually’ part we are interested in (and not the acetone 3D print mess you’ll be left with if you leave it too long).

We want to melt the surface of the object just enough that the surface tension of the molten plastic smooths out any surface inconsistencies and then halt the process at that point before any structural damage occurs.

In some cases, it is possible to quickly dip an object into acetone liquid to get a polished surface, but this can be very messy and gives inconsistent results.

If you use the vapors instead you have much more control over the ABS smoothing and the final results. As the vapors can get to all exposed surfaces equally, there are fewer areas of uneven melting. There are also no run-off channels or drip marks induced into the surface of the object that direct exposure to acetone liquid may cause.

This is our clear ABS filament, acetone smoothed.

What you will need –

- A well-ventilated area to work that has no exposed ignition sources.

- Wear the appropriate PPE – Safety glasses/goggles, mask, gloves, etc…

- An acetone-proof container (a large glass vase or a tin) big enough to hold the parts you wish to polish – preferably with at least 30mm clearance in ALL directions around the object to be polished – top, bottom, and sides.

- A loose-fitting lid, also acetone-proof. If your lower container is not transparent, you may wish to use a sheet of glass as a lid – this removes the need to keep removing the lid in order to see how the polishing is progressing (and not letting the vapours escape or dust get in).

- A flat, non-porous plate such as glass or metal, to raise the object being polished above any liquid acetone in the bottom of the container – This really needs to be at least 10mm above the surface of any liquid acetone in the container and much larger than the object to be polished as this reduces the chances of liquid acetone creeping up the sides and onto the object itself.

- Some sheets of plastic-free kitchen roll to use as a ‘wick’ for the liquid acetone.

- Somewhere dust-free to allow the surface of the polished object(s) to harden.

- A TIMER! Seriously.

You will walk away, forget it, only to return later to find that amazing print that you were once so proud of has now turned into a hideous misshapen lump of plastic, or at worst some kind of acetone ABS mess.

It might not happen this time or the next, but it will.

Getting started

Make sure your container is free from contaminants (this will be your acetone bath), then place a few sheets of the kitchen roll up the side and along the bottom of the container. This will allow the liquid acetone to wick up the kitchen roll, helping to produce a strong concentration of vapor at all levels within the container.

Find somewhere to work that has surfaces and materials that will not be damaged by acetone or the fumes. Acetone is a superbly-powerful solvent – you don’t want it dissolving things that you’d rather keep. It is a low-density liquid that has very little surface tension, so it splashes and ‘wets’ surfaces very easily.

Acetone is a superbly-powerful solvent – you don’t want it dissolving things that you’d rather keep. It is a low-density liquid that has very little surface tension, so it splashes and ‘wets’ surfaces very easily.

To hold the kitchen roll sheets in position, place your metal support (plinth) onto them. Make sure that you arrange the kitchen roll in such a way that when it gets wet with liquid acetone it cannot fall down onto your printed objects, as that will destroy any chances of achieving an acceptable finish.

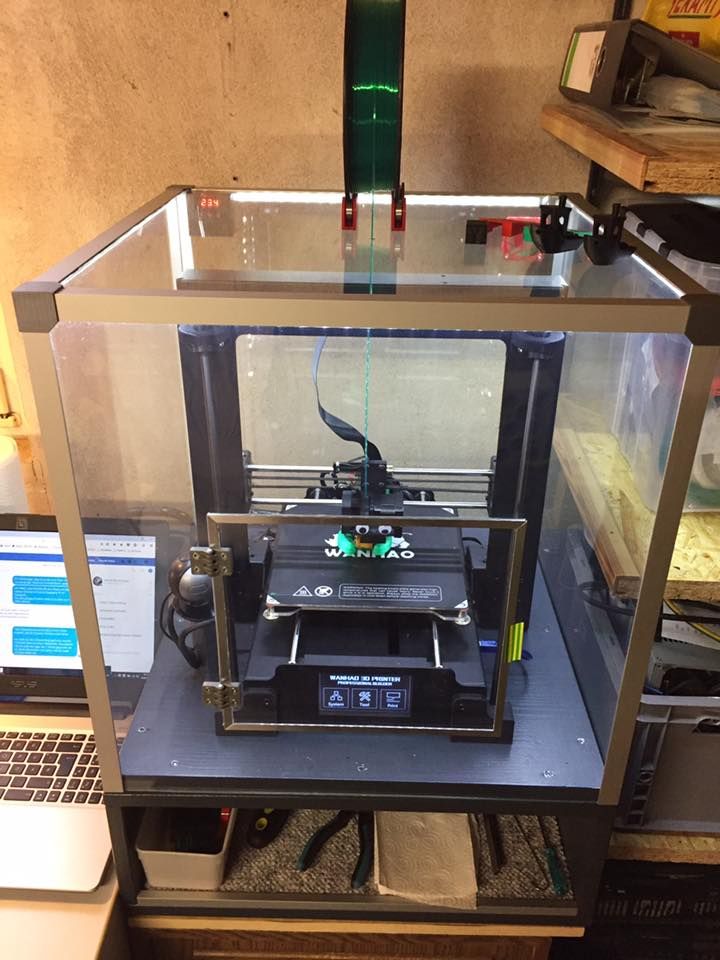

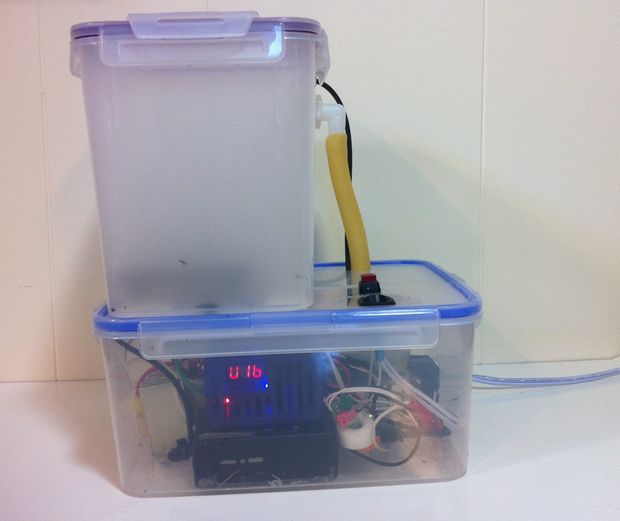

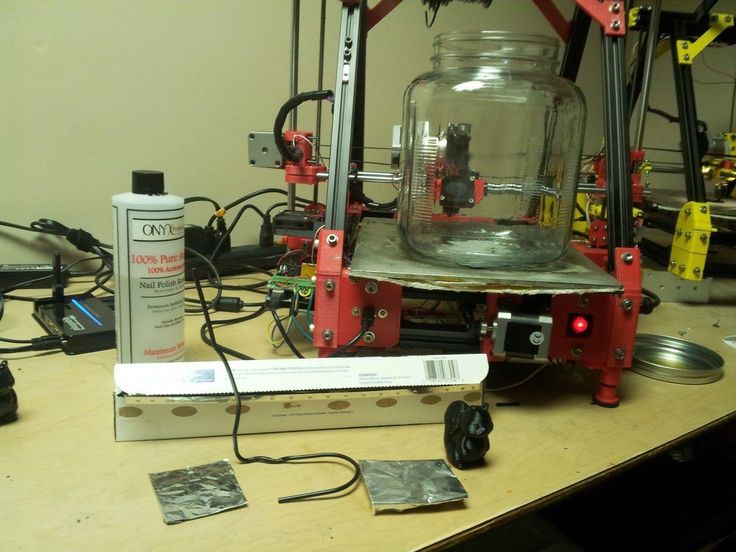

The following photograph shows the setup used in the acetone bath ABS of the soap trays seen above.

The soap dish is sitting on top of a plinth made from a small piece of glass stood on three 22mm diameter copper plumbing joints – an arrangement that stops any chance of liquid acetone reaching the dish via capillary action (or surface-wetting).

Things to consider about the process of 3D printing acetone finishing itself

Not all filaments are the same, even from the same supplier. For instance, due to secondary effects from the pigments that go to make up the colors of ABS filaments, different colors polish at different rates. This means you will need to monitor the polishing of different colored objects so that you can remove them at the correct time.

For instance, due to secondary effects from the pigments that go to make up the colors of ABS filaments, different colors polish at different rates. This means you will need to monitor the polishing of different colored objects so that you can remove them at the correct time.

The polishing process not only softens the surface of the object, the fumes also penetrate into the body of the object. Depending on the period of exposure, you will need to ‘air’ the object for a period of time that is commensurate with the time that the object was exposed to acetone vapour.

Usually, this takes a few days. However, in some cases, the full mechanical strength of the object may not be realized until a significant time has passed – for high-density objects, this can take weeks, or even longer!

The polishing process continues for a while after you remove the object from the container – usually for about ten minutes. So don’t be tempted to leave it in too long.

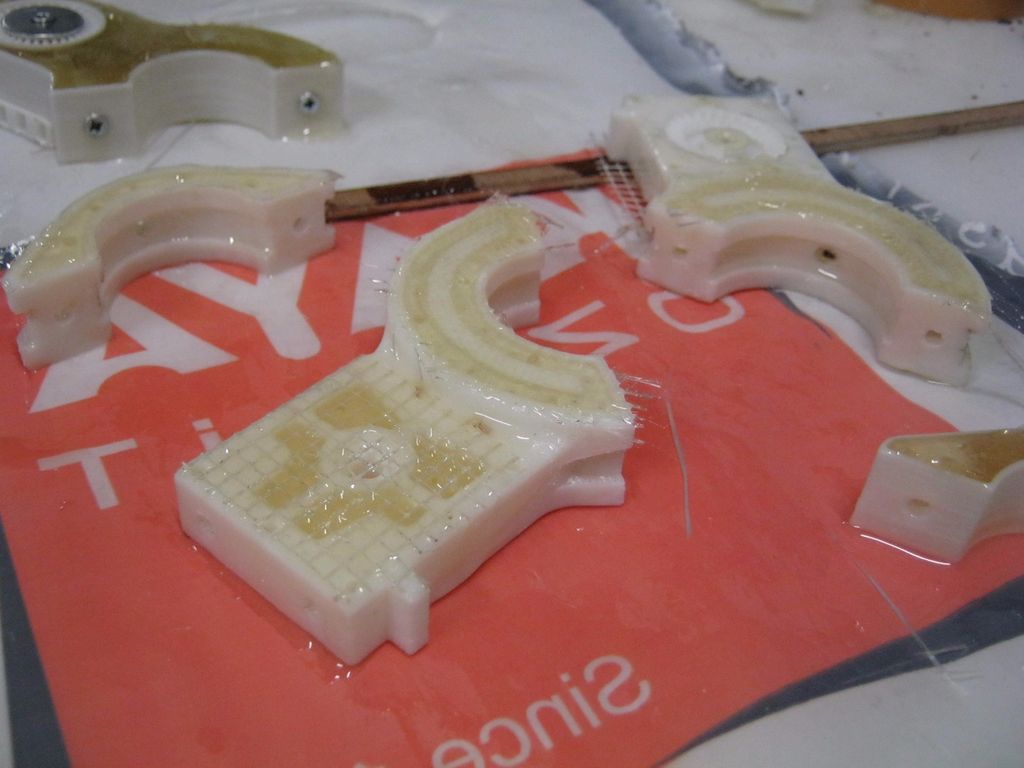

The following photograph shows what happens to a part when exposed to the fumes for an extended period.

The hole in the center at the bottom is supposed to be round, and the lower edges are all supposed to be straight.

The ambient temperature affects the speed of the process – you are evaporating a volatile liquid after all.

- Too cold and it can take ages.

- Too warm, and the process goes too fast.

- Too hot, and you may be looking for a new place to work/eyebrows, so NEVER apply heat.

Finally – you need to have somewhere totally dust-free to place the polished object while the surface hardens. If you don’t, any dust that falls onto the surface will become embedded in it. Permanently.

Polishing

This is the really easy part.

- Without getting any on your plinth, pour the acetone over the kitchen roll sheets you placed up the side of the container. You need to have enough acetone to cover the bottom of the polishing container to a depth of a millimeter or two.

- Ensure that there is no liquid acetone present on your plinth.

- Make sure that you have a fool-proof way of removing the object from the container after polishing without the need to touch it, or you will leave marks all over the surface where you make contact.

- Quickly place the object in the center of the plinth – try not to touch it again – you have just a few seconds to adjust the final position. The polishing process has already started – it is that quick! You don’t really want to leave fingerprint impressions on your work, do you?

- Place the lid on the container and start your countdown timer. I personally set the timer to 15-minute intervals for finely-detailed objects, and 30 for large solid objects.

Depending on how rough the surfaces of the object are, and how polished you want the object to be, the process can take from around 15 minutes to several hours.

There is ALWAYS a trade-off between the required surface finish and the loss of fine details. Only you can decide what is acceptable.

Once you are satisfied that the polishing is almost complete, carefully remove the object to a totally dust-free environment that has good ventilation. This stops most of the ever-present dust particles that are suspended in the air from falling onto the semi-molten surface of the object.

This stops most of the ever-present dust particles that are suspended in the air from falling onto the semi-molten surface of the object.

Note: The reason you remove the object from the container at the point just before you get the surface finish you require as the polishing process continues for a short while even after the object has been exposed to fresh air.

You can always put it back in the chamber later if you are not satisfied, but once the process has gone too far, the damage is irreversible.

After about 30 minutes, a ‘skin’ will have formed on the polished object that will stop dust particles from becoming embedded in the surface of the object.

Remove the object from your dust-free chamber without touching it, and put it somewhere that has good ventilation to allow the acetone to further leach out of the object. The object at this point has little to no structural integrity so be careful how you do this.

Depending on the solidity and size of the object, the process of removing the acetone can take from a few hours to many weeks before the full strength of the object has been regained.

Once you are certain that a good skin has formed on the object, you can speed up this process of solvent evaporation considerably by using a fan continuously blow air across the surface of the object – smoothing 3D printed parts effortlessly.

Summary

To recap, the filaments that can be polished using this process are: ABS, ASA, PMMA, HIPS and Polycarbonate.

Other filament types are either unaffected by acetone or are damaged by it.

Acetone vapor baths & other ways to remove layer lines

As a low-cost 3D printing material, ABS is one of the most popular filaments among FDM 3D printer users, beginners and experts alike. Although it has its disadvantages — such as a strong smell when printing and a dependence on heated print beds — it creates durable parts that are resistant to fairly high temperatures.

For many casual 3D printing users, the decision often comes down to PLA, PETG, or ABS filament. PLA has a low melting point and environmental credentials, while PETG is highly impact-resistant. But ABS has one unique advantage over its low-cost competitors: it can be easily dissolved with acetone, which means printed objects can be post-processed to give them an exceptionally smooth surface. While other thermoplastics can be dissolved with other solvents, no combination is quite as effective as acetone on ABS.

PLA has a low melting point and environmental credentials, while PETG is highly impact-resistant. But ABS has one unique advantage over its low-cost competitors: it can be easily dissolved with acetone, which means printed objects can be post-processed to give them an exceptionally smooth surface. While other thermoplastics can be dissolved with other solvents, no combination is quite as effective as acetone on ABS.

That being said, smoothing 3D printed parts made of ABS requires a certain level of skill. Acetone is highly flammable and an irritant to the skin and eyes, so it must be handled with extreme caution. Fortunately, this guide explains exactly how you can safely carry out ABS acetone smoothing, as well as part smoothing via other post-processing methods like sanding and polishing.

One of the major disadvantages of FDM 3D printing is that it produces visible layer lines — ridges on the surface of a part — as a result of moving from one layer to the next along the Z axis. Layer lines are especially pronounced when using a greater layer height (lower Z-axis resolution) and when printing curved parts.

Layer lines are especially pronounced when using a greater layer height (lower Z-axis resolution) and when printing curved parts.

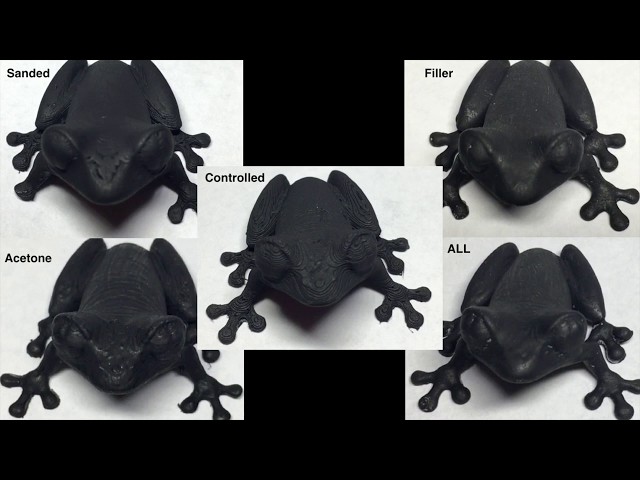

Smoothing your ABS parts is a way to eliminate the appearance of visible layer lines and change the surface texture of the part from matte to glossy. The process is generally carried out for cosmetic reasons, but it can also have functional benefits: smooth, frictionless parts may be required for mechanical reasons or to facilitate the assembly of multiple components.

You should smooth your ABS prints if you want to maximize the aesthetic quality. However, you should exercise caution when smoothing if the part needs to meet strict dimensional tolerances; this is because smoothing takes away a small amount of surface material and consequently alters the dimensions of the part.

Recommended reading: ABS print temperature considerations: Nozzle, bed, enclosure

If you’re looking to eliminate the appearance of layer lines on your ABS parts, your best bet is to invest in some acetone. This section explains how acetone smoothing works and examines four common methods of applying the solvent to printed parts.

This section explains how acetone smoothing works and examines four common methods of applying the solvent to printed parts.

Acetone is a solvent found in nail polish remover

How does smoothing with acetone work?

Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. As with all polymers, ABS is resistant to certain substances and vulnerable to others.

When it comes to smoothing, the most relevant fact about the chemical makeup of ABS is its solubility in esters, chloroform, ethylene dichloride, and various ketones, of which acetone is one. Substances like chloroform and ethylene dichloride are toxic and require extensive safety precautions, but acetone is milder and much easier to handle in non-controlled environments. It is an active ingredient in nail polish remover, for instance.

So, chemically speaking, why does acetone dissolve ABS? The short answer is that because ABS is soluble in ketones, the presence of acetone causes the ABS (the solute) to dissolve into the acetone (the solvent), forming a sort of soup or slurry (the solution) on the surface of the plastic.

This means that when you apply a small amount of acetone to a 3D printed ABS part, the surface of the part will dissolve. When this is done in a controlled manner, it is possible to dissolve just enough ABS to eliminate imperfections like layer lines, leaving behind a smoother (and fractionally smaller) version of the part. Some researchers have even suggested that acetone smoothing can improve the strength of ABS parts by increasing interlayer adhesion.[1]

So what is the best way to smooth ABS with acetone? There are different methods for applying acetone to ABS parts in a controlled manner, and we will explore four of them here, noting which ones we recommend and which we don’t.

Safety measures

Acetone is a highly flammable substance that can irritate the skin and eyes, so it must be handled with extreme care. The following safety precautions should be followed with all acetone application methods:

Always store acetone in a cool, well-ventilated area away from direct light, fire, and any other potential ignition sources

Only open your acetone container in a well-ventilated area, wearing a protective mask to avoid inhalation of fumes

It is recommended to wear eye protection and non-nitrile gloves to prevent potential eye and skin irritation

Method 1: Brush application

The simplest way to achieve a fairly smooth finish on ABS parts is to apply liquid acetone to a 3D printed part with a brush. Deposit a small amount of liquid acetone into a shallow container, then dip the brush into it and apply a very thin coating over the surface of the part.

Deposit a small amount of liquid acetone into a shallow container, then dip the brush into it and apply a very thin coating over the surface of the part.

This method is not highly recommended as it uses a large amount of acetone and produces uneven results: the surface may appear streaked or unevenly smoothed. By applying acetone with a brush, it is also easy to apply too much of the solvent, potentially causing permanent deformation to the part or fully dissolving thin walls.

Method 2: Acetone bath

Another way to achieve a smooth surface finish on ABS parts is to create an acetone bath. This method involves fully submerging the part in a polypropylene (PP) container of liquid acetone for a short period of time, allowing the entire surface of the ABS part to come into contact with the solvent.

This method is not recommended as it requires a very large amount of acetone and can excessively dissolve the ABS part or cause it to warp and twist. Furthermore, removing the part from the acetone requires one of two difficult procedures: either removing the part from the bath (and therefore touching it, potentially causing surface deformations) or draining the liquid into a container underneath (requiring a more complex, multi-container setup).

Furthermore, removing the part from the acetone requires one of two difficult procedures: either removing the part from the bath (and therefore touching it, potentially causing surface deformations) or draining the liquid into a container underneath (requiring a more complex, multi-container setup).

Method 3: Acetone vapor smoothing

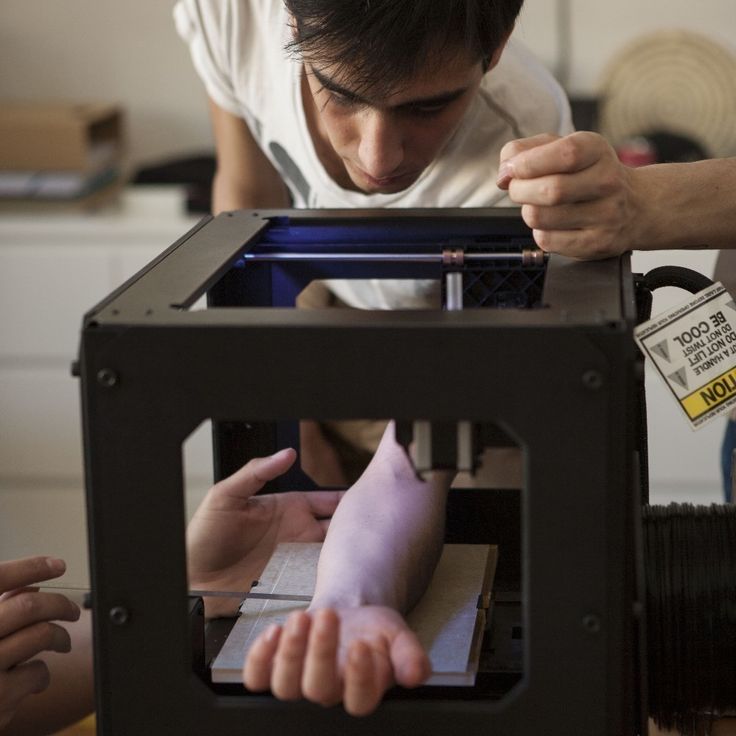

A much more effective means of ABS smoothing is the creation of an acetone steam bath or vapor bath. This method does not involve the direct application of liquid acetone to the ABS part, but instead allows acetone fumes to slowly penetrate the surface of the part. This can be achieved by keeping the part and the acetone within a container.

This is the most highly recommended method, both for its safety and effectiveness, and we will explain how to do it with step-by-step instructions.

Create a smoothing box

The vapor smoothing method requires a partially enclosed container to keep the acetone fumes close to the printed part and prevent them from escaping into the room (though the container should not be airtight).

For small ABS parts, you could use a glass container such as a glass jar. For larger parts, or to smooth several parts at once, it is better to use a transparent polypropylene (PP) storage container; these are cheap, available in various sizes, and will not dissolve upon contact with the acetone.

A PP container can function as a smoothing box for vapor smoothing

Place a raised platform in the box

Your ABS parts should not touch the bottom of the smoothing box. You will therefore need a small raised platform on which to place your ABS parts. This platform should not be made from a material that is soluble in acetone, or it will dissolve. Metal works best, and a regular plate coated in aluminum foil is one option.

Soak tissue paper in acetone

Instead of pouring liquid acetone directly into the smoothing box, you need only soak some tissue or paper towels in the solvent before adding the paper to the edges of the smoothing box, either by pressing them firmly against the walls of the container or attaching them with magnets (one inside and one outside the box).

Leave at least a small window of uncovered wall surface so you can see the part while it is being smoothed.

Close up the smoothing box

The vapor smoothing will only work if the smoothing box is closed off, as this prevents the acetone fumes from escaping. If you are using a jar or a storage container with a snap-on lid, lay the lid gently on top of the container without sealing it, and make a few small holes in the lid.

It is critical that the smoothing box is not fully sealed, as this can cause a dangerous amount of pressure buildup.

Let the vapor smoothing take place

The ideal amount of vapor smoothing could take between 10 minutes and an hour. We therefore recommend observing the process through the transparent smoothing box, at least until you have an idea of how long you will need for future prints.

Once the desired smoothness has been attained, you can remove the lid from the box and safely dispose of the acetone-soaked paper. Leave the parts untouched for as long as possible, as their surface will still be soft from the acetone.

Leave the parts untouched for as long as possible, as their surface will still be soft from the acetone.

Add heat and air circulation (optional)

Once you are comfortable with the basic vapor smoothing process, you can improve its efficacy in two ways: by placing the smoothing box on a warm (not hot) surface or by putting a small fan within the box. However, be careful with electronics, as an errant spark could ignite the acetone and cause a fire.

Method 4: Automated acetone vapor smoothing

A much safer and more consistent method of vapor smoothing can be carried out when using a dedicated post-processing machine such as the Zortrax Apoller. Such machines distribute the solvent fumes evenly while maintaining constant air circulation and gentle heat, resulting in the best possible surface finish and meeting strict safety requirements.

Unfortunately, these machines are much more expensive than the DIY method outlined above. Also note that the popular Polymaker Polysher device will not work with ABS and acetone, as it is only compatible with the company’s proprietary smoothable filaments and solvents.

Also note that the popular Polymaker Polysher device will not work with ABS and acetone, as it is only compatible with the company’s proprietary smoothable filaments and solvents.

Advantages | Disadvantages | |

Brushing | Requires minimal equipment | Uneven application Uses more acetone than necessary Easy to damage printed parts |

Bath | Even application | Uses more acetone than necessary |

Vapor smoothing | Even application | Hard to maintain even smoothing with larger parts |

Auto vapor smoothing | Most even application | Expensive |

Sanding

The most common method for smoothing 3D printed parts, sanding, does not require the use of chemicals. Sandpaper is applied manually to the part, and its rough surface removes a small amount of material from the part surface.

Sandpaper is applied manually to the part, and its rough surface removes a small amount of material from the part surface.

When sanding ABS parts, start with coarse sandpaper (80-grit, for example), then gradually move to finer grit (120 and 240). Finally, use a very fine-grit sandpaper (1000) with water to make the parts as smooth as possible. Try to apply even coverage right across the surface of the part. Note that while powered sanders can rapidly speed up the sanding process, the heat generated by these machines can adversely affect printed parts. If you have time, we recommend manually sanding ABS parts.

Sanding is safe and easy to do, but it can be difficult to reach deep crevices in the part and to apply an even amount of pressure over the entire surface.

Sandpaper is a safe and simple alternative to acetone smoothing

Polishing

If you don’t want to deal with a strong solvent like acetone, it is possible to create a high-shine finish for your ABS parts by applying a liquid polish (Brasso, for example) with a piece of cloth. This should be done after sanding, when the surface of the parts is already fairly smooth.

This should be done after sanding, when the surface of the parts is already fairly smooth.

Apply the polish-soaked cloth firmly, making circular motions over the surface of the part until it is fully glossy.

Methods to avoid

Some smoothing methods that work for other thermoplastic filaments won’t work with ABS. For example, isopropyl alcohol (IPA) works just like acetone when printing PVB, but won’t cut through the surface of your ABS parts. Another common smoothing agent is d-lemonene, but this only works for HIPS 3D printed parts. We would also advise against using very strong chemicals like chloroform as a solvent, since acetone is less toxic and just as effective.[2]

Recommended reading: Smoothing PLA 3D prints with sandpaper, solvents, and more

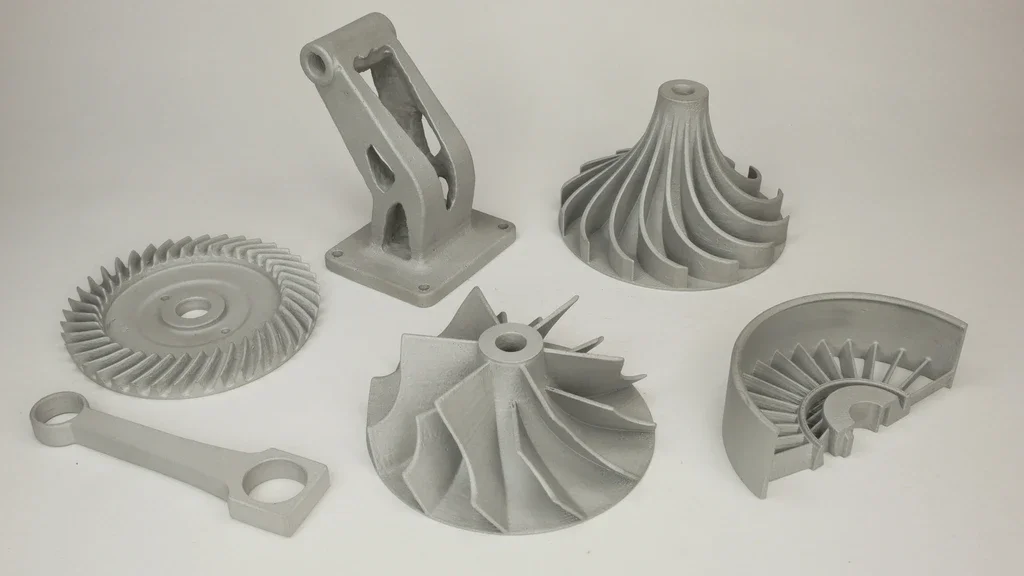

After support removal, smoothing is possibly the most important post-processing technique for FDM 3D printed parts. Smoothing removes unsightly layer lines, giving printed parts the appearance of high-quality injection moldings, and the process can be carried out on a small budget.

Of all common 3D printing materials, ABS is perhaps the best suited to smoothing. Its solubility in acetone provides printer users with an easy route to smooth and glossy parts, making it a highly suitable filament for cosmetic parts such as display prototypes, models, and figurines. In fact, smoothed ABS parts more closely resemble molded or stereolithography parts than as-printed FDM parts.

However, as we have mentioned, acetone smoothing should be carried out with caution. Although less dangerous than other smoothing agents like chloroform, acetone poses risks to human safety, the most significant of which are its flammability and its potential to irritate the skin and eyes. Newcomers to the acetone smoothing process should familiarize themselves with the necessary precautions, investing in a mask and gloves and only carrying out the process in a well-ventilated area.

If these safety precautions are followed, printer users will find acetone smoothing to be a highly effective means of improving the visual quality of their ABS parts.

[1] Gao H, Kaweesa DV, Moore J, Meisel NA. Investigating the impact of acetone vapor smoothing on the strength and elongation of printed ABS parts. Jom. 2017 Mar;69(3):580-5.

[2] Joshi DR, Adhikari N. An overview on common organic solvents and their toxicity. J. Pharm. Res. Int. 2019 Jun;28(3):1-8.

Acetone vapor treatment.

Acetone vapor treatment.

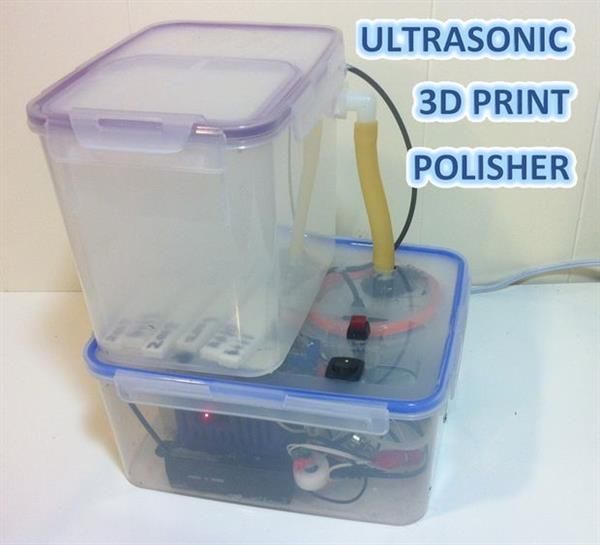

I decided to write a post, thereby answering the frequently asked questions of customers who purchased a “bath” from me, and for those who cannot decide on the volume of the “bath” container or want to make it on their own.

Bath construction.

"Bath" consists of a container, a system of forced mixing of acetone vapors and a bowl-heating element, a heating element for filling with acetone.

Which container to choose? I am using three different containers. 2 liter sealed for parts up to 90 mm high, 3 liter sealed for parts up to 220 mm long, 5 liter unsealed for parts up to 200 mm high. Most often I use a 2-liter - 90% of the total number of printed parts. The container must be made of polyethylene with transparent walls and airtight; an unsealed container can also be used, but with a tight-fitting lid. As practice has shown, for chemical processing, the use of containers with these dimensions covers approximately 99% of all parts printed by me in two years.

Most often I use a 2-liter - 90% of the total number of printed parts. The container must be made of polyethylene with transparent walls and airtight; an unsealed container can also be used, but with a tight-fitting lid. As practice has shown, for chemical processing, the use of containers with these dimensions covers approximately 99% of all parts printed by me in two years.

These are my three "baths" for 2, 3 and 5 liters.

This is a three liter bath.

Forced mixing system acetone vapor consists of a micromotor, bearing assembly and fan. All parts that come into contact with acetone vapor must be made from PLA. Anyone who has design skills can design this knot himself. If someone does not have such an opportunity or desire to make a “bath” himself, then you can buy from me both a finished product and a set of parts for self-assembly.

Heating element , heater. From my experience, the power of the heating element should be 2 - 3 watts, for containers of large capacity (10-15 liters) up to 5 watts is possible. If you use more power, the process will be less controllable. Using Ohm's law, you can calculate and manufacture the heating element yourself. The boiling point of acetone is 56.1 °C, and a heating element with a power of more than 5 watts in hot summer weather can exceed this temperature. From the point of view of explosiveness, there is nothing terrible in this, but intensive vaporization in a closed volume creates fog and fogging of the container walls, which completely excludes the visualization of the process. Of course, with the acquisition of skills, visual observation is no longer required, and for experienced users, increasing the power of the heating element will speed up the process.

If you use more power, the process will be less controllable. Using Ohm's law, you can calculate and manufacture the heating element yourself. The boiling point of acetone is 56.1 °C, and a heating element with a power of more than 5 watts in hot summer weather can exceed this temperature. From the point of view of explosiveness, there is nothing terrible in this, but intensive vaporization in a closed volume creates fog and fogging of the container walls, which completely excludes the visualization of the process. Of course, with the acquisition of skills, visual observation is no longer required, and for experienced users, increasing the power of the heating element will speed up the process.

The amount of acetone depends not only on the surface area of the workpiece, but also on the volume of the container. For identical parts, the larger the volume of the container, the more acetone is needed, and for a large part, more acetone is needed than for a small part with the same container volume. How much acetone is needed - this parameter is selected empirically and depends on the area of the workpiece, on the ambient temperature, on the chemical composition of the ABS plastic (filament manufacturer), on the tightness of the container and on the grade, concentration of acetone. You also need to keep in mind that acetone is well diluted with water and an unscrupulous seller or manufacturer of acetone can easily take advantage of this. In order not to spoil the part, you must start with a small dose of acetone and if the treatment is insufficient, simply repeat the process one or two more times. It should be borne in mind that when refilling with acetone, all vapors from the first filling will evaporate, and additional acetone will be required for the required concentration of vapors in the container. If anyone does not understand the meaning of the last phrase, I explain that when a satisfactory result is obtained in several approaches and when moving to a single stage, the amount of acetone used in two or three approaches must be added up and taken 75% of the amount.

How much acetone is needed - this parameter is selected empirically and depends on the area of the workpiece, on the ambient temperature, on the chemical composition of the ABS plastic (filament manufacturer), on the tightness of the container and on the grade, concentration of acetone. You also need to keep in mind that acetone is well diluted with water and an unscrupulous seller or manufacturer of acetone can easily take advantage of this. In order not to spoil the part, you must start with a small dose of acetone and if the treatment is insufficient, simply repeat the process one or two more times. It should be borne in mind that when refilling with acetone, all vapors from the first filling will evaporate, and additional acetone will be required for the required concentration of vapors in the container. If anyone does not understand the meaning of the last phrase, I explain that when a satisfactory result is obtained in several approaches and when moving to a single stage, the amount of acetone used in two or three approaches must be added up and taken 75% of the amount. It is clear that the figure of 75% is not an absolute value, but an approximate value and is a recommendation.

It is clear that the figure of 75% is not an absolute value, but an approximate value and is a recommendation.

Processing time depends on the same parameters listed above in the paragraph "amount of acetone". Visually, the process is monitored through the transparent walls of the box, but the main difficulty of visual control is that the end of the chemical treatment process will occur after the installation is ventilated, after some time. This is due to the fact that the surface of the part exposed to the vapor becomes viscous fluid, and this fluidity occurs as long as there are active elements in this layer, saturated ketones of acetone vapor. The neutralization of saturated ketones occurs by the quantitative absorption of these molecules by molecules of acrylonitrile butadiene styrene (ABS) and by ordinary ventilation, that is, if you guess with the amount of acetone filled into the device, the process of vapor exposure to plastic will stop itself and will not spoil the part. Otherwise, after a certain period of time, it is necessary, without turning off the device, to open the lid of the box, while the part will have an unfinished look and cannot be touched, and ventilate for 10-20 minutes. After this time, the part will take on an almost final form, the flow process will slow down significantly, and the part can be picked up. Finally, acetone vapor will “come out” of the part after 5 to 7 days. If the part is structural and must experience stress, it is advisable to use it after two to three days. To speed up the process of “exit” of vapors, the part can be heated to 50 ° C, but not earlier than after 1-2 hours of cold ventilation. It is advisable to carry out all work in a ventilated room, if work is carried out at home, then it is better to do this in bathrooms with forced exhaust or on the balcony. Acetone is a flammable liquid, and acetone vapor at a certain concentration explosive .

Otherwise, after a certain period of time, it is necessary, without turning off the device, to open the lid of the box, while the part will have an unfinished look and cannot be touched, and ventilate for 10-20 minutes. After this time, the part will take on an almost final form, the flow process will slow down significantly, and the part can be picked up. Finally, acetone vapor will “come out” of the part after 5 to 7 days. If the part is structural and must experience stress, it is advisable to use it after two to three days. To speed up the process of “exit” of vapors, the part can be heated to 50 ° C, but not earlier than after 1-2 hours of cold ventilation. It is advisable to carry out all work in a ventilated room, if work is carried out at home, then it is better to do this in bathrooms with forced exhaust or on the balcony. Acetone is a flammable liquid, and acetone vapor at a certain concentration explosive .

Appearance of processed products immediately after opening the container.

This is the product after airing for 30-40 minutes. These parts required 9-10 cm3 of acetone and 50-60 minutes of time at a room temperature of 25°C in a two-liter container. The outer surfaces of these products were not subjected to mechanical processing. The area of all surfaces exposed to vapors is -406 cm2. Dimensions of one part (LxWxH) -100x55x22 mm.

Next, I will show different products and processing modes.

Bust of Putin - 3 pieces, box - 5 liters, the total area of all treated surfaces of three busts - 1188 cm2. The amount of acetone is 18 cm3, the processing time is 80-90 minutes. The air temperature in the room is 25 ° C. The dimensions of one bust (LxWxH) are -75x65x132 mm.

Honeycomb with stand - 1 piece, box - 2 liters, surface area - 810 cm2, amount of acetone - 6 cm3, processing time - 40 minutes. Air temperature in the room - 22 ° C. Dimensions (LxWxH) - 79x79x80 mm.

Tower, box - 5 liters, surface area - 750 cm2, amount of acetone - 18 cm3, processing time - 110 minutes. The air temperature in the room is 18° C. Dimensions (LxWxH) - 56x100x128 mm.

Porsche Cayenne headlight bracket, box - 2 liters, surface area - 151 cm2, amount of acetone - 6 cm3, processing time - 50 minutes. The air temperature in the room is 18° C. Dimensions (LxWxH) - 91x80x18 mm.

Body part, box - 3 liters, surface area - 690 cm2, amount of acetone - 12 cm3, processing time - 60 minutes. Air temperature in the room - 18 ° C. Dimensions (LxWxH) - 178x109x34 mm.

Professor Yoda, box - 2 liters, surface area - 140 cm2, amount of acetone - 6 cm3, processing time - 40 minutes. The air temperature in the room is 20° C. Dimensions (LxWxH) - 60x80x65 mm.

All parts shown above have been virtually unmachined.

Next, I will show the parts, the surface of which was completely machined - sanded.

Parts green, blue and red, processed 1 piece, box - 5 liters, surface area - 380 cm2, amount of acetone - 15 cm3, processing time - 90 minutes. The air temperature in the room is 20° C. Dimensions (LxWxH) - 70x70x120 mm.

Blue part, box - 2 liters, surface area - 230 cm2, amount of acetone - 8 cm3, processing time - 50 minutes. The air temperature in the room is 20° C. Dimensions (LxWxH) - 70x70x50 mm.

What part should be? Design, printing layer thickness, machining.

Workpiece design . Not every detail can be processed in the "bath". If the part design has very thin walls or bridges less than 1 mm thick, then they will melt and lose their shape before the rest of the part surfaces are processed. The way out is either to increase the wall thickness, or to protect one side, let's say the inside, with masking tape or carry out light processing.

The thickness of the print layer affects the final quality, but not very much. Due to the penetration of acetone vapor into the microslits of the interlayer gaps, additional sintering and gluing of the layers occurs, which strengthens the part, making it more monolithic. It is clear that with a layer thickness of 0.1 mm, there will be more microgaps than with a layer with a thickness of, for example, 0.2 mm. This means that a part with a layer of 0.2 mm should turn out to be more monolithic, so to speak, and a part with a layer of 0.1 mm more beautiful. Probably, a layer of 0.15 mm will be optimal for both solidity and appearance.

Due to the penetration of acetone vapor into the microslits of the interlayer gaps, additional sintering and gluing of the layers occurs, which strengthens the part, making it more monolithic. It is clear that with a layer thickness of 0.1 mm, there will be more microgaps than with a layer with a thickness of, for example, 0.2 mm. This means that a part with a layer of 0.2 mm should turn out to be more monolithic, so to speak, and a part with a layer of 0.1 mm more beautiful. Probably, a layer of 0.15 mm will be optimal for both solidity and appearance.

Machining parts . In most cases, printed parts require machining with needle files, sandpaper, or other tools such as Dremel engraver attachments. After machining, the surface is rough and visually lighter than the rest of the body. Before such parts are placed in an acetone bath, it is necessary to pre-treat with acetone the places that have been machined. To do this, take any non-fluffy cloth, moisten it in acetone and wipe these places with one or two movements. The movements must be quick so that the fabric does not stick to the part. If it is not possible to wipe the entire surface in one or two times, then you need to wait 20-30 seconds and repeat the procedure. If this is not done or treated not with a cloth, but with a brush, then after processing the part in the “bath”, these places will be rough to the touch and visually not very shiny.

The movements must be quick so that the fabric does not stick to the part. If it is not possible to wipe the entire surface in one or two times, then you need to wait 20-30 seconds and repeat the procedure. If this is not done or treated not with a cloth, but with a brush, then after processing the part in the “bath”, these places will be rough to the touch and visually not very shiny.

Thank you for your attention, write comments, criticism of the case is accepted, if something is not clear, ask.

How to smooth 3D printing?・Cults

Objects created with a 3D printer don't always look as good as they should. Even if visualization of 3D printed parts is usually acceptable, this may not be enough if the object is for sale or display. Some people just want a perfectly smooth and shiny surface for 3D printing. Fortunately, it is possible to achieve this level of perfection with the help of some suitable tools. This guide will show you how to smooth out ABS and PLA 3D prints for the best results.

The FDM 3D printer opens up endless possibilities for creating PLA 3D prints. However, parts may be printed with bad layers that need to be removed. If you want to give your 3D printed parts a shinier look, there are some easy ways to align your 3D printed PLA.

Use spray paint and polyurethane

The sanding method used to be the most common technique for leveling 3D printed PLA. Today there are new alternatives. You can use spray paint mixed with polyurethane to line up 3D printed PLA parts. To do this, you need to purchase the right tools:

- spray paint,

- polyurethane,

- fan for drying parts.

The smoothing process is one of the simplest. First of all, it is necessary to clean the product so that dust or other dirt does not linger on the surface of the object. Use a spray can to cover the 3D print with a layer of paint. Then a layer of polyurethane can be applied to the part. Be very careful and place the freshly coated 3D print under a fan to speed up the drying process .

After a few minutes, you will find that the mixture of polyurethane and paint starts to fill in unwanted holes and imperfections on your PLA 3D print. Once completely dry, the part can be recoated with mix to remove any remaining surface imperfections. This method is less tiring than sanding.

Opt for XTC-3D Clear Epoxy

Although highly effective, using a mixture of paint and polyurethane to line a room can be too messy for some people. There are other alternative methods for anti-aliasing PLA 3D printing. Transparent epoxy resin XTC-3D has been specifically designed to align PLA 3D parts for an optimal finish . The product consists of two bottles that need to be mixed for 3D printing.

Remember to mix the product well and follow the instructions correctly. Using a brush, apply the resin to the printed parts. The dried product will harden into a smooth transparent layer. PLA 3D printing becomes smoother and shinier. XTC-3D can also be mixed with dyes and stains if you wish to color your parts. You can also add effects such as metallic highlights or palettes.

XTC-3D can also be mixed with dyes and stains if you wish to color your parts. You can also add effects such as metallic highlights or palettes.

Use 3D Gloop

This adhesive has been specially developed for smoothing PLA 3D prints. 3D Gloop can be used for various purposes. To smooth out a 3D print with this product, simply apply it to the printed part with a brush. It works like the XTC-3D, except it only has one bottle. This is a great advantage if you only want to use a small amount of glue. However, 3D Gloop is not without flaws. The product contains a number of toxic components. It should be used in a well ventilated area.

Acetone is a chemical stripper used by professionals to sand and clean certain materials. Due to its high toxicity, it should be handled with care in a well-ventilated area. Acetone can be used to level ABS 3D printing. The process does not require a lot of equipment. All that is required is metal or glass container .

/91f3dfd02cdc286.s.siteapi.org/img/70095ab103eae1c6a64808b85496f592e398cf55.jpg)