Xjet 3d printing

» About

» AboutXJet provides industry-leading high definition 3D printing solutions that empower companies to create revolutionary products in ceramics and metals.

Manufacturers can now enjoy volume production of true geometric complexities, unlocking a host of applications that have so far been unviable

Renowned Team

We have assembled a world-class team of skilled industry veterans, many of whom helped develop trailblazing inkjet and AM technologies at market pioneers such as Objet, Indigo, Scodix and HP Scitex.

Groundbreaking Technology

Our proprietary NPJ technology empowers the manufacturing of detailed high-quality parts with virtually unlimited geometries – all produced in a safe, convenient and productive manner.

Partner-Driven Approach

With a deep understanding of industry concerns and requirements, we partner with our customers to define, examine and execute new solutions for difficult challenges.

Forward-Thinking Roadmap

Leveraging our robust inkjet technology, we plan to introduce a growing number of metal and ceramic build materials to anticipate evolving industry needs.

Avi Cohen

Executive Chairman of the Board

Avi Cohen

Executive Chairman of the Board

Avi Cohen brings to XJet many years of leadership, accomplishments and experience as a CEO, senior executive and director at private and public companies. Deeply familiar with the capital equipment business for over 25 years, Avi previously served as CEO of RR Media (Nasdaq: RRM) and Orbit Technologies (TASE: ORBI). He also served in executive positions at ECI Telecom and KLA (Nasdaq: KLAC). Since 2008 he has served as a director on the board of Nova Measuring Instruments (Nasdaq: NVMI). He also serves on the boards of multiple other companies including Cortica, FINTICA and CGS Tower Networks. Avi holds B.Sc. and M.Sc. degrees in Electrical Engineering and Applied Physics from Case Western Reserve University.

John Kispert

Industry Expert

John Kispert

Industry Expert

Mr. Kispert has many years of experience as executive in technology companies including 14+ years in capital equipment (KLA) and in the US capital markets. John and Avi Cohen worked together at KLA (Nasdaq: KLAC) and where both members of the executive team for few years.

John was the CFO of the company and later became the President & COO of KLA prior to becoming the CEO of Spansion.

Mr. Kispert is highly respected global business leader and M&A expert with distinguished career infusing corporate vision and successfully driving strategy to execution

Yair Alcobi

CEO

Yair Alcobi

CEO

Yair Alcobi is an accomplished senior executive with rich leadership experience at international technology companies. Prior to his appointment at XJet, Yair served as President of the PCB Division and Vice President at KLA (Nasdaq: KLAC) and Orbotech (Nasdaq: ORBK), where grew the business unit’s market share, revenues and profitability. He previously served as President of Orbotech’s East Asia subsidiary headquartered in Hong Kong, where he directed and expanded its overall operations. Before that, he held numerous key positions at Orbotech, including Senior Vice President of its Asia Pacific subsidiary and Vice President, Sales and Marketing, of its PCB Division. Earlier in his career he held management, marketing and R&D positions at Kulicke & Soffa and ISCAR. Yair holds an Executive MBA from Haifa University and a B.Sc. in Mechanical Engineering from the Technion – Israel Institute of Technology.

He previously served as President of Orbotech’s East Asia subsidiary headquartered in Hong Kong, where he directed and expanded its overall operations. Before that, he held numerous key positions at Orbotech, including Senior Vice President of its Asia Pacific subsidiary and Vice President, Sales and Marketing, of its PCB Division. Earlier in his career he held management, marketing and R&D positions at Kulicke & Soffa and ISCAR. Yair holds an Executive MBA from Haifa University and a B.Sc. in Mechanical Engineering from the Technion – Israel Institute of Technology.

Hanan Gothait

President and Founder

Hanan Gothait

President and Founder

Hanan Gothait is a widely recognized and respected industry expert in the fields of inkjet and 3D printing. An innovative game changer, Hanan co-founded Objet Geometries (later merged with Stratasys), which reinvented the 3D printing space with the introduction of polymer jetting technologies and photopolymer 3D printing systems. Prior to co-founding Objet, he founded Idanit (later merged into HP Scitex), which developed the world’s first wide-format printer. Hanan holds a B.Sc. in Mechanical Engineering from the University of Bridgeport.

Prior to co-founding Objet, he founded Idanit (later merged into HP Scitex), which developed the world’s first wide-format printer. Hanan holds a B.Sc. in Mechanical Engineering from the University of Bridgeport.

Orit Tesler Levy

CFO

Orit Tesler Levy

CFO

Orit Tesler Levy is a senior finance executive with proven experience leading financial activities at global technology companies. Prior to joining XJet, Orit served as CFO of Spectronix-Emerson, where she led substantial transformation in its finance activities and played a central role in integrating Spectronix into Emerson (NYSE:EMR), a global technology and engineering company. She previously served as VP Finance FP&A Business Partnering at Stratasys (Nasdaq: SSYS), a leader in polymer 3D printing solutions. She started her career at Applied Materials (Nasdaq: AMAT), where she rose to serve as CFO of Applied Materials Israel and CFO of the company’s Silicon Segment Group in Silicon Valley, California. Orit earned an MBA (Accounting & Finance) and a BA in Economics from Tel Aviv University.

Orit earned an MBA (Accounting & Finance) and a BA in Economics from Tel Aviv University.

Dror Danai

Chief Business Officer

Dror Danai

Chief Business Officer

Dror Danai brings to XJet a strong track record of over two decades in leading successful business operations at technology-driven companies. As VP Sales & Business Development at Objet (later merged with Stratasys), Dror directed its business operations from a fledgling company to a front-runner in its field. Dror also served as VP Sales & Business Development at Scodix, where he was instrumental in creating a world leader in digital print enhancement. Previously, he was the European Channel Director of CreoScitex as well as the Global Product Manager for the Scitex CTP product line.

Dror holds a B.Sc. in Industrial Engineering (summa cum laude) and an MBA (summa cum laude), both from Tel Aviv University.

Guy Zimmerman

Chief Marketing Officer

Guy Zimmerman

Chief Marketing Officer

Guy Zimmerman brings to XJet diversified expertise in strategy, marketing, and business leadership at leading global companies, together with proven entrepreneurial experience. Prior to joining XJet, Guy served as EVP Marketing & Business Development at Kornit Digital (Nasdaq: KRNT), a leader in the textile and fashion digital printing market, heading its strategy, product, application, and positioning activities. Previously he was VP of Global Sales & BD at Tefron, a manufacturer of seamless intimates and activewear for global retail and fashion brands. Earlier in his career Guy was an Associate Principal at McKinsey & Company, leading global strategic, M&A and operational projects. Guy holds a B.Sc. (summa cum laude) in Industrial Engineering from Tel Aviv University.

Prior to joining XJet, Guy served as EVP Marketing & Business Development at Kornit Digital (Nasdaq: KRNT), a leader in the textile and fashion digital printing market, heading its strategy, product, application, and positioning activities. Previously he was VP of Global Sales & BD at Tefron, a manufacturer of seamless intimates and activewear for global retail and fashion brands. Earlier in his career Guy was an Associate Principal at McKinsey & Company, leading global strategic, M&A and operational projects. Guy holds a B.Sc. (summa cum laude) in Industrial Engineering from Tel Aviv University.

Eduardo Napadensky

Vice President of R&D and Innovation

Eduardo Napadensky

Vice President of R&D and Innovation

Eduardo Napadensky brings to XJet more than 20 years’ experience in additive manufacturing (AM). Eduardo is an experienced executive skilled in the management of interdisciplinary R&D activities and intellectual properties. Prior to joining XJet, he served as Global CTO for Materials at Stratasys, and previously was CTO at Objet. Eduardo started his professional carrier in an elite unit of the IDF Intelligence Corps, where he filled a variety of positions in the fields of chemistry and materials sciences. He is the author or co-author of tens of patents in 3D printing materials and methods. Eduardo holds a Ph.D. in Polymer Sciences and a B.Sc. in Chemistry, both from the Hebrew University of Jerusalem, and an MBA from Tel Aviv University.

Prior to joining XJet, he served as Global CTO for Materials at Stratasys, and previously was CTO at Objet. Eduardo started his professional carrier in an elite unit of the IDF Intelligence Corps, where he filled a variety of positions in the fields of chemistry and materials sciences. He is the author or co-author of tens of patents in 3D printing materials and methods. Eduardo holds a Ph.D. in Polymer Sciences and a B.Sc. in Chemistry, both from the Hebrew University of Jerusalem, and an MBA from Tel Aviv University.

Udi Bloch

COO

Udi Bloch

COO

Udi Bloch is an experienced executive with a long history of leading high-tech companies, including more than 20 years in the printing industry. Prior to joining XJet, Udi served as the COO at Scodix, a company in the digital print enhancement arena. Prior to that, he worked at HP Indigo for well over a decade in several positions including Worldwide Service Manager, Mechanical Engineer, Systems Analyst and Business Development.

Yael Shlomovitz

Vice President of Human Resources

Yael Shlomovitz

Vice President of Human Resources

Yael Shlomovitz is a human resources professional with more than 25 years of experience. Prior to joining XJet as Vice President HR, Yael served as the head of HR at various high-tech and technology-led companies such as ELTA Systems and Teva Israel. Yael earned a B.A. in Psychology from Bar-Ilan University, and an MBA from Boston University (Beer Sheva campus).

XJet delivers its first commercial metal 3D printer to Azoth

0Shares

Israeli 3D printer manufacturer XJet has delivered its first commercial metal 3D printing system to additive manufacturing service provider Azoth.

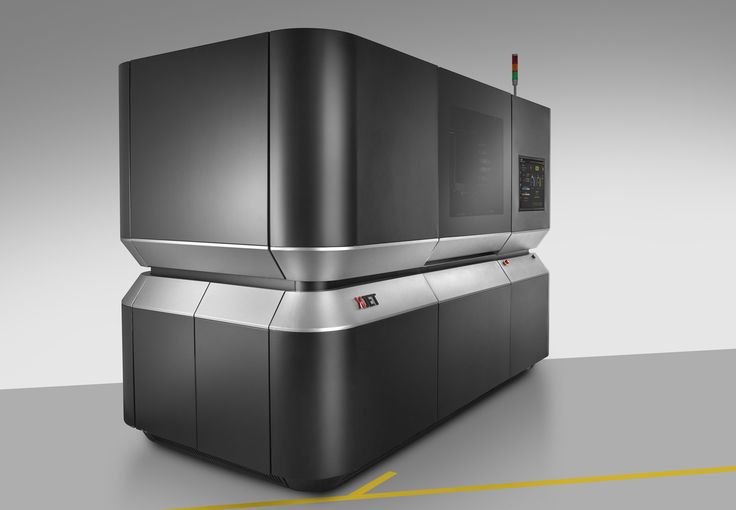

Originally released back in 2019, the Carmel 1400M 3D printer is reportedly the first material jetting system in the world capable of processing both metals and ceramics, combining repeatability and part quality for industrial applications.

Based on XJet’s proprietary NanoParticle Jetting (NPJ) process, the machine features a large-format 500 x 280 x 200mm build tray and can print batches of metal parts with high throughput.

“We have a huge wealth of experience in metal manufacturing – with both additive and subtractive processes. XJet’s metal system delivers capabilities that are in high demand in the market, but are not achievable with other technologies,” said Scott Burk, Azoth’s CEO. “Parts with fine features, high resolution, good surface finish right off the printer – at a level we have not seen before. The ease-of-use and safety working with the XJet system, which does not involve handling powders, is another important factor for us.”

The Azoth team with their new XJet Carmel 1400M 3D printer. Photo via XJet.XJet’s NanoParticle Jetting technology

All of XJet’s 3D printers operate on the company’s NanoParticle Jetting technology. The unique material jetting approach involves spraying nanoparticles embedded in a liquid shell. Once deposited onto a build plate, the liquid outer shells evaporate to leave behind solid, bonded parts made of fused nanoparticles. The resulting components feature high levels of detail, a great surface finish, and dimensional precision.

Once deposited onto a build plate, the liquid outer shells evaporate to leave behind solid, bonded parts made of fused nanoparticles. The resulting components feature high levels of detail, a great surface finish, and dimensional precision.

The firm launched its first NPJ systems, the Carmel 1400 and smaller Carmel 700 3D printers, in 2017. Then in 2019, XJet rebranded the Carmel 1400 to distinguish which models could process ceramics (C) and which could process metals (M).

XJet has since delivered several of its ceramic 3D printers to clients, including a Carmel 1400C to Katholieke Universiteit Leuven (KU Leuven) in Belgium. This was the first XJet system to be implemented at an academic institution within Europe. The company also partnered with dentistry firm Straumann to advance the capabilities of the Carmel 1400C for dentistry applications.

More recently, XJet also launched its Support Material Automatic Removal Technology, or ‘SMART’, post-processing station. Marketed as the “last link in the chain” for automated end-to-end 3D printing, the SMART unit uses intelligent algorithms to automatically remove supports from XJet-manufactured ceramic parts.

Hanan Gothait, CEO of XJet, adds, “We have developed the only metal AM technology available today based on the concept of direct material jetting. After amazing success with the XJet ceramic systems, we are now ready for the bigger dream, bringing to the market our metal solution.”

The Carmel 1400M. Photo via XJet.Commercializing the Carmel 1400M

With Azoth as its latest customer, XJet has now officially commercialized the Carmel 1400M 3D printer. Operating under East West Industrial Engineering (EWIE), Azoth’s background is in high-volume metal manufacturing for major firms such as Ford, Chrysler, and Rolls-Royce. The firm was established when EWIE decided to finally enter the additive manufacturing sector in 2020.

Azoth’s senior leadership came across XJet when it was searching the market for technologies capable of producing small, complex, and high-definition parts that conventional powder bed fusion simply couldn’t manage. Since NPJ prints with very small particles, it allows for tiny layer heights and extremely fine feature details.

Cody Cochran, Azoth’s co-founder and General Manager, explains, “My eureka moment came when we got some test parts through from XJet and I asked the team how they looked, and they responded that they were the best they’d ever seen. What we really liked were the small holes, very sharp corners, and very refined surface finish without needing any post-processing.”

As well as part quality, Azoth also expects to benefit from operational advantages. The Carmel 1400M is suited for both prototyping and end-use production, so the firm will be able to try out various design iterations and take a component to production with the very same machine.

A stainless steel part 3D printed on the Carmel 1400M. Photo via XJet.Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Azoth team with their new XJet Carmel 1400M 3D printer. Photo via XJet.

Tags Azoth Carmel 1400C Carmel 1400M Cody Cochran Hanan Gothait NanoParticle Jetting Scott Burk Xjet

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

XJet to Introduce NanoParticle Jetting at RAPID 2016

News

Israeli company XJet, famous for its Inkjet liquid metal 3D printing technology, will take part in the RAPID 2016: 3D Printing and Additive Manufacturing exhibition, which will be held in Orlando, Florida, USA, May 16-19.

Every year, the RAPID conference brings together all companies related to the field of 3D printing, scanning and additive manufacturing. It is here that XJet is going to demonstrate its NanoParticle Jetting technology to the public for the first time.

It is here that XJet is going to demonstrate its NanoParticle Jetting technology to the public for the first time.

“NanoParticle Jetting technology is the fruit of many years of work by our developers and scientists, including many PhDs,” says Hanan Gotheit, CEO and founder of XJet. – This is an important discovery in the field of additive manufacturing, which has received more than 50 patents. We have managed to overcome many challenges that were previously beyond the power of humanity, and we are extremely proud of the results of our work.”

As the name implies, this technology is based on the use of metal nanoparticles loaded into special cartridges. These cartridges are then inserted into the XJet system and the nanoparticles are passed through the spray nozzles, i.e. 3D printing material does not need to be touched by hands, which means there is no threat of contamination with toxic substances. Liquid metal passes through the nozzles at a rate of 221 drops per second. The finished metal product is lightly sintered and the supporting structures are removed. It is important that this whole process requires almost no operator intervention.

The finished metal product is lightly sintered and the supporting structures are removed. It is important that this whole process requires almost no operator intervention.

The company describes the new technology as follows:

- Details: The particle size and ultra-thin material layers allow the transfer of fine details and the production of thin-walled products.

- Scattering: XJet system printheads deposit ultra-thin layers of liquid droplets of metal nanoparticles. The ink is enclosed in sealed cartridges, which guarantees a high level of safety and ease of handling.

- Design freedom: support materials can be easily removed to create highly intricate designs.

The company guarantees the high quality and speed of its system. With XJet NanoParticle Jetting technology, you can create neat metal products with the smallest details and a perfectly even surface.

“We are excited to show our technology at RAPID,” says Dror Danay, one of the XJet representatives.“The RAPID conference is a great starting point for bringing NanoParticle Jetting to the global market, which is just missing this technology for manufacturing metal parts with complex shapes and fine details.”

Source

Subscribe author

Subscribe

Don't want

4

Article comments

More interesting articles

5

Follow author

Follow

Don't want

Compared to traditional casting, 3D printed sand casting technology has a number of advantages...

Read more

four

Subscribe to the author

Subscribe

Don't want

Scientists of the Arctic Research and Education Center on the basis of the Northern Arctic Federal University. ..

..

Read more

59

Subscribe to the author

Subscribe

Don't want

The 3Dtoday portal, supported by Creality and Bestfilament, invites everyone to participate in...

Read more

SPA used a Xjet 3D printer to print a ceramic piston for the Chaos hypercar

- home

- News AT

- World

- SPA uses a Xjet 3D printer to print a ceramic piston for the Chaos hypercar

Spyros Panopoulos, the founder of SPA, is a pioneer in the use of 3D printing for the automotive industry and the man who developed the world's most powerful internal combustion engine. The new "Chaos" hypercar, which is currently in development, is planned to reach speeds of over 500 km/h with an acceleration from 0 to 100 km/h in 1.

55 seconds. As a result, it will be the highest-revving mass-produced car engine ever, capable of reaching 12,200 rpm and producing an astounding 3,065 horsepower.

55 seconds. As a result, it will be the highest-revving mass-produced car engine ever, capable of reaching 12,200 rpm and producing an astounding 3,065 horsepower. 3D printed ceramic piston

Above: 3D printed ceramic piston for the Chaos hypercar / Source: XJet

required characteristics. Engineer Spyros Panopoulos' patented "Anadiaplasi" design method for additive manufacturing that allows parts to be designed based on Forces Acting on It (CFD), where material is minimized where there are no loads, but added where either reinforcement or thickness reinforcement is required part walls. The design optimized the weight while maintaining the strength and heat resistance of the part, which is important for the new piston when it is used in such a powerful engine. The result was a part with a complex geometry (using bio-design) that was both lightweight, but at the same time with a high level of life cycle in use. This design method was used for all components in the creation of the Chaos hypercar.

After the design was completed, Panopoulos realized that the only suitable technology to produce such a part with complex geometry, accuracy and excellent surface roughness was XJet Nanoparticle Jetting 3D printing. SPA chose XJet Alumina to 3D print the Chaos hypercar piston in collaboration with XJet's Lino 3D partners in Greece due to its extraordinary strength, hardness, light weight and resistance to thermal expansion, making it the ideal material for this part. .

“Ceramic has many advantages over other materials. Harder and stiffer than steel, more resistant to heat and corrosion than metals or polymers, and weighs significantly less than most metals and alloys. The high temperature aluminum oxide parts produced on the XJet will be used in the combustion chamber and moving parts associated with abrasion.”

- Said Spyros Panopoulos, pioneer in the automotive industry, inventor of technology "Anadiaplasi" and founder of SPA

He also added: "XJet 3D printers are unique in 3D printing this part in ceramic, so there are no mistakes in this project. "

" Panopolous, a staunch supporter of additive manufacturing, is using it in the production of the Chaos hypercar, where 78% of the body is reportedly 3D printed, as well as other important parts such as the engine block, camshaft and intake valves. The Chaos ultracar is a marvel in itself. The car will have unrivaled performance like a maximum engine power of 2048 hp, a maximum speed of over 500 km/h and a maximum torque of 1389Nm (Newton meters).

Above: Chaos ultracar SPA Automotive / Source: Spyros Panopoulos Automotive 3D printing with ceramics and design for additive manufacturing (DfAM) is beyond the realm of possibility. We are very proud to be part of such a pioneering project by offering our technologies. Designers and engineers from different branches and industries have new opportunities that are now opening up for them. We expect the 3D printed ceramic piston for the Chaos project to push the boundaries of applications in the automotive industry and beyond.

Learn more