Jobs in 3d printing india

186 3d Printing jobs in India (20 new)

Get notified about new 3d Printing jobs in India.

Sign in to create job alert

You've viewed all jobs for this search

79 3d Printing Job Vacancies in India

Ahmedabad ,

Bengaluru / Bangalore

250000 - 1040000 INR

Cam , Cad Design , Mechanical Design Engineer , Design Engineer , Design Engineer Mechanical , Auto Cad , Pro E , Solid Works , Draftsman

Indian scientists plan to build houses in three days using construction 3D printing

Miscellaneous

Construction 3D printing continues to expand its reach and has reached India.

A team of educators from the Indian Institute of Technology Madras is working with tech start-up Tvasta to explore rapid building technology. It is expected that the additive method will allow you to create a box of a one-story house in just three days. A functional prototype is already ready, which has become the first step towards achieving the global goal - to solve the housing problem of the whole country.

Researchers have been studying the application of additive technologies in construction since 2016. Researchers are interested in finding ways to quickly erect a building, in particular, exploring the possibilities of 3D printing in the construction of walls and formwork. As part of the scientific work of the work, the Indian Institute of Technology cooperates with government agencies that are interested in the development of modern technologies. Scientists consider the availability of raw materials, speed of production, automation of labor and savings on the transportation of materials to be the key advantages of the technology.

Scientists consider the availability of raw materials, speed of production, automation of labor and savings on the transportation of materials to be the key advantages of the technology.

“3D concrete printing is perfect for modern architecture. The right combination of binder additives allows the concrete mixture to achieve the desired physical properties: easy extrusion and fast setting,” explains Professor Manu Santanam.

The Government of India is recognizing the need for innovation in construction as the housing shortage becomes more pronounced. According to officials, 3D printing technologies help speed up construction and significantly save resources.

The first 3D printed houses are expected to appear in India later this year.

Subscribe to the author

Subscribe

Don't want

2

Article comments

More interesting articles

70

Subscribe to the author

Subscribe

Don't want

So, after reading all sorts of articles and comments to them, you have finally made a decision to join . ..

..

Read more

ski

Loading

11/13/2022

672

3

Subscribe to the author

Subscribe to the author

Don't want to

Thomas' video post - geek-n#rno about the real wear resistance of the latest generation of E3D Revo ObXidi nozzles ...

Read more

Roman

Loading

03/28/2016

64868

218

Subscribe to the author

Subscribe

Don't want

Treatment with acetone vapor.

I decided to write a post, thus answering the frequently asked ...

Read more

TRUMPF partners with Indian family company Magod Laser to promote 3D printing

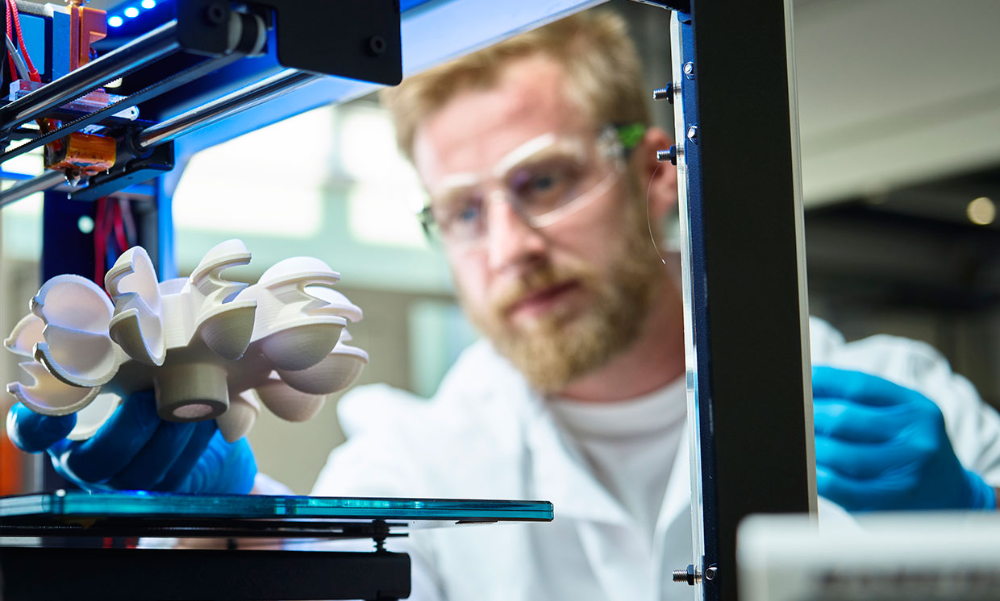

Pictured is Swami Magod, Managing Director of Magod Lasers, aiming to introduce additive manufacturing in India / Image courtesy of TRUMPF

Indian family company Magod Laser has joined forces with TRUMPF, one of the world's largest machine tool and metal 3D printing system manufacturers, to promote 3D printing technology on the Indian continent.

Inspiration from the USA

The story began in 1991 in the USA, where Swami Magod, the current Managing Director of Magod Laser, received his Master's degree in Industrial Engineering. After graduating from university, he continued to work in the USA for several years, and it was here that he first became acquainted with laser technology and heard the name TRUMPF. After gaining extensive experience in the field of laser cutting, he returned to India with the clear goal of saving clients time and cost in sheet metal cutting.

Magoda Laser

Magod Laser headquarters in Bangalore / Image provided: Trumpf

Magod Laser, founded in 1997 in Bangalore, is a synonym for the use of Laser Power technology for industrial . It was the first company in South India to use lasers for sheet metal cutting. With the ultimate goal of making sheet metal cutting faster and more affordable for customers, the company has managed to capture a huge share of the Indian market.

Today Magod Laser has a total of 25 TRUMPF machines - and is a leader in the development of additive manufacturing in India.

plunged into additive production

Magod Lasers now uses TRMPF additive production systems, such as TruPrint 1000 / Image Credit: Trumpf

with the existing preference towards Trumpf and with positive experience with this , Magod Laser purchased the necessary equipment and decided to plunge into additive manufacturing.

Swamy came up with the idea when one of her clients asked the team to weld parts with a laser. Swami explained, “Two of our clients have already used 3D printing and they asked us to laser weld parts together. I realized it was time to print the metal parts myself.”

TRUMPF supplied the necessary equipment in the form of a TruPrint 1000 and Swamy introduced a combined process that took full advantage of the company's expertise. According to Swamy, “There is a limit to the size of parts in 3D printing, so we offer a combination of additive manufacturing and laser welding. To make larger parts, we just weld a few small parts.”

To make larger parts, we just weld a few small parts.”

The main problem in the Indian additive manufacturing market is a lack of knowledge about the technology, but Magod Laser is confident of success. Many companies have reportedly already expressed interest in testing technologies spanning industries from aviation to medical devices.

Above: Swami Magod and his brother Rajendra at their factory in Bangalore / Image credit: TRUMPF

Of course, there are many good reasons to adopt additive manufacturing. The technology opens up previously impossible geometries, paving the way for users to refine and improve their parts. The production of implants for medical purposes is just one example: 3D printed implants are more durable and more successfully fuse with healthy bone tissue. Another advantage of additive manufacturing is that it only applies material where it is really needed, so 3D printed parts are lighter. What's more, any excess powder can be recycled and reused - a much more cost-effective and sustainable approach than traditional processes where up to 80 percent of the material ends up wasted.

Hands-on experimentation is key

Magod's customers share Magod Laser's enthusiasm for experimenting with different geometries and materials to develop new parts. Magod engineers also make prototypes for companies considering 3D printing their own parts.

Seizing the Initiative

Magod Lasers invests in the development of its employees / Image credit: TRUMPF

Educating potential customers and promoting 3D printing in India is an important step and Magod Laser believes it will take the lead. Magod Laser is always happy when potential customers and long-term partners can visit their manufacturing facilities to see 3D printing technology in action. He continues: “We are always on the lookout for new technologies to add to our portfolio because learning new things is a key part of our corporate ethos. We take the professional development of our employees seriously.