3D print slide fire stock

What Is and Can You 3D Print a Bump Fire Stock in the US? » 3D Printing Media Network

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Before the horrific Las Vegas shooting, I suspect most people had never heard of a bump stock or bump fire stock, which can replace the standard stock that comes with semi-automatic assault weapons.

They are made so that there is a gap between the stock and the body of the weapon. When the weapon is fired, the operator holds the trigger finger in a stationary position. Upon firing, the recoil causes the body of the weapon and trigger to move backward, compressing the gap between the stock and the weapon. The recoiling weapon then bumps off of the stock and moves forward, gliding the trigger to the finger. When the trigger hits the finger, it fires again, repeating the process, which simulates automatic fire, achieving a rate-of-fire of 400 to 800 rounds per minute. A bump fire stock can retail in the low hundreds of dollars.

Soon after the shooting, Congress started talking about enacting a law to ban the sale of bump fire stocks and the NRA may even support regulating such devices. On the assumption that anything can be 3D printed, would such a law prevent people from making their own bump fire stock?

Bluy Prints Available OnlineA Google search of “3D printed bump fire stock” revealed exactly what I expected: a YouTube video of the test firing of a 3D printed bump fire stock posted by SilkyDionysus4 in April of this year.

On October 10, 2017, gun rights advocate, The Jack News, published an article called “Here’s How to 3D Print Your Own Bump Stock Before Congress Bans Them.” The article links to a collection of FOSSCAD digital blueprints for a variety of AR-15 parts, including a bump-fire stock.

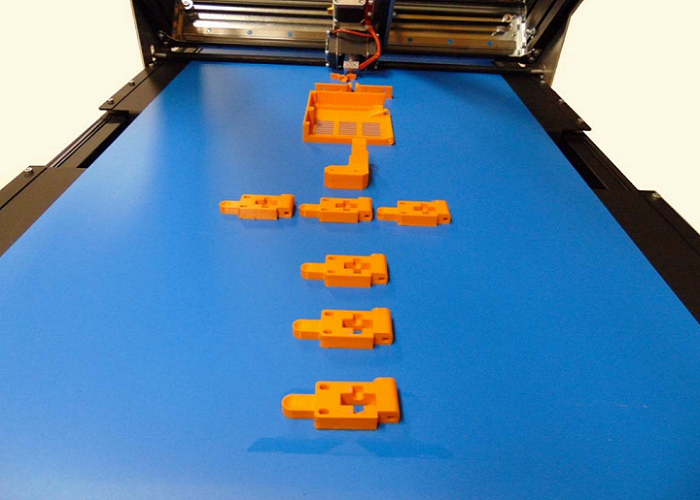

These digital blueprints supposedly can be used to 3D print a bump fire stock. According to the article, this device can be printed in a 3D printer with at least an 8” x 8” build chamber. A smaller chamber could be used if the device is built in pieces.

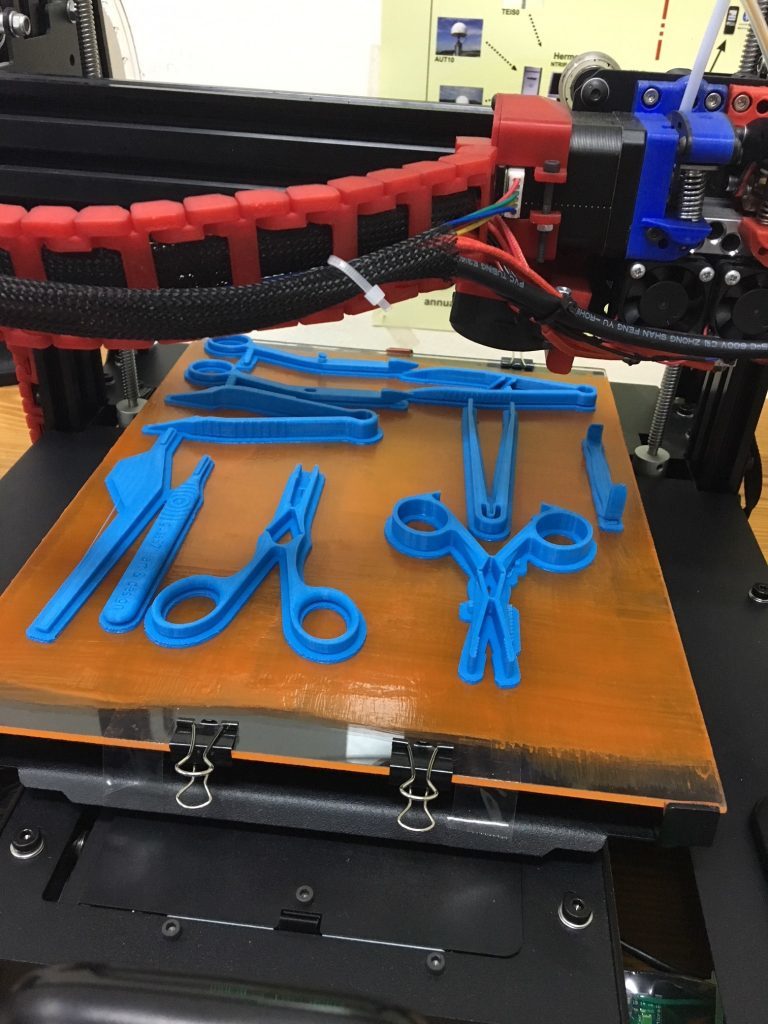

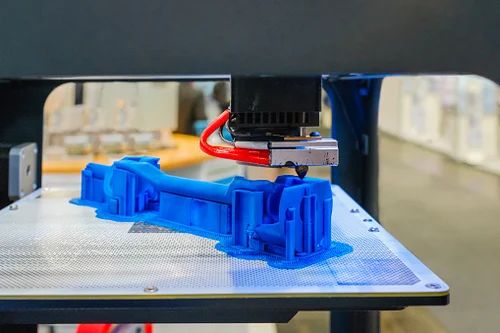

Although the type of 3D printer is not specified, the bump fire stock in the video appears to have been printed on a material extrusion machine. This is the most basic and least expensive type of 3D printer, starting at a few hundred dollars. A bump fire stock can be 3D printed in cheap plastic and have no moving parts.

A Google search also yielded a link to digital blueprints for a bump fire stock posted by Disruptive Solutions in October 2013. Online forums show that some people in the gun community are shifting into high gear to create and mass-distribute digital blueprints for bump fire stocks before any government ban takes effect. I believe the idea is that if the blueprints are distributed widely, the cat cannot be put back into the bag.

Bump fire stock digital blueprints will soon be available on the Dark Web, if they are not already there. The Dark Web is at least 20 times larger than the World Wide Web. There is no bag big enough to hold all of the cats that could roam there.

Desgined from ScratchAlthough the idea of trying to control the digital dissemination of bump fire stock design files suggests a lack of understanding of the power of the Internet, anyone who wants to 3D print a bump fire stock doesn’t really need the Internet at all.

In addition to bump fire stocks and their digital blueprints becoming available on the Black Market, if they are banned, you can design and make your own digital blueprints.

Bump fire stocks are simple devices that almost duplicate the original gun stock. Anyone with even a little design talent could design a bump fire stock from scratch (or tweak the digital blueprint for a legal, aftermarket gun stock), using any one of a number of 3D design programs, and could even customize the design. Then all you need is an inexpensive 3D printer ($500 to $1000) and some plastic filament.

Then all you need is an inexpensive 3D printer ($500 to $1000) and some plastic filament.

Although I have read comments suggesting that the high cost of 3D printers will dissuade people from 3D printing their own bump fire stocks, this is silly. Anyone who spends hundreds or thousands of dollars on weapons can and will spend hundreds of dollars, if not more, for a machine that provides allows them to make things “away from control.”

Away from control means the ability to make things without anyone knowing about it or being able to control it. I also discuss in my book, 3D Printing Will Rock the World, that the cost of 3D printers can easily be shared in what I call “friends networks.” Why wouldn’t a bunch of like-minded people pool their resources to be able to make things away from control, or simply to make things so they don’t have to buy them? And by pooling resources, they could buy a better 3D printer than any one of them could afford alone.

3D ScanningThere is also another way to create a digital blueprint without the Internet: 3D scanning. Anyone of a hundred inexpensive 3D scanners can be used to scan either a friend’s bump fire stock or the weapon’s original, legal gun stock. The scan is then tweaked in a 3D design program to make it a bump fire stock, which can then be 3D printed.

Anyone of a hundred inexpensive 3D scanners can be used to scan either a friend’s bump fire stock or the weapon’s original, legal gun stock. The scan is then tweaked in a 3D design program to make it a bump fire stock, which can then be 3D printed.

So this brings me back to the original question: Would banning the sale of bump-fire stocks prevent people from making their own? The answer is, probably not.

If my underlying message is not obvious, here it is: the law enforcement community needs to educate itself on 3D printing and its potential illegal uses, and plan accordingly.

About the author

John Hornick, the author of the award-winning book, “3D Printing Will Rock the World,” offers educational programs to the law enforcement community on the dark side of 3D printing, and on how 3D printing can be used to aid law enforcement. Contact him at [email protected].

Related Articles

▷ ar15 bump fire stock 3d models 【 STLFinder 】

AR15 Stock Extension

thingiverse

Extension for a AR15 stock

Collapsible AR15 Hex Stock

thingiverse

It fits a standard Ar15 buffer tube, you might have to scale it by a percent or two for that perfect fit, I have included a sliced part of the stock so you can test fit. I used the old bolt, spring and nut from my original stock. Hatchbox bronze PLA...

I used the old bolt, spring and nut from my original stock. Hatchbox bronze PLA...

Collapsible AR15 Stock Blank

thingiverse

It fits a standard Ar15 buffer tube, you might have to scale it by a percent or two for that perfect fit, I have included a sliced part of the stock so you can test fit.I used the old bolt, spring and nut from my original stock. ...Edit 4/6/17 Added...

Airsoft AR15 Stock Adapters

thingiverse

https://www.facebook.com/3DprintedAirsoft I was asked to make these so why not to share them, one adapter is for buffer tubes with thread and one is with ris rail for stock from sig etc. ... It require stock mount only 10mm height, you may need to cut.

... It require stock mount only 10mm height, you may need to cut.

ar15 style stock

thingiverse

this was done on an ender 5+ this was printed standing upright ( butt plate down ) this stock was designed just for something to prove I could do it and work as a functional stock, works with standard lower and buffer tube as long as square at the...

AR15 ARC Stock

thingiverse

You might need to elongate the grip screw hole in the stock for proper fit.

UPDATED 12/21/2018: Fill 1mm gap forward of grip, relocated selector spring hole and grip screw, added ambi selector lever cutouts, and narrowed grip mount. Please post a. ..

..

AR15 Thumbhole Stock

thingiverse

You might need to elongate the grip screw hole in the stock for proper fit. UPDATED 01/07/2019: Corrected outer contours. Additional 0.5mm gap fill at grip and shifted selector detent spring hole. Enlarged selector lever cutout. Grip screw hole...

AR15 Dry Fire Device

thingiverse

Inserts into AR15 bolt carrier and permits resetting the trigger with a 1/4" inch pull on the charging handle for dry fire practice. Do not insert into a hot weapon! ... Check out Revere's Riders for top-notch, affordable rifle marksmanship training:...

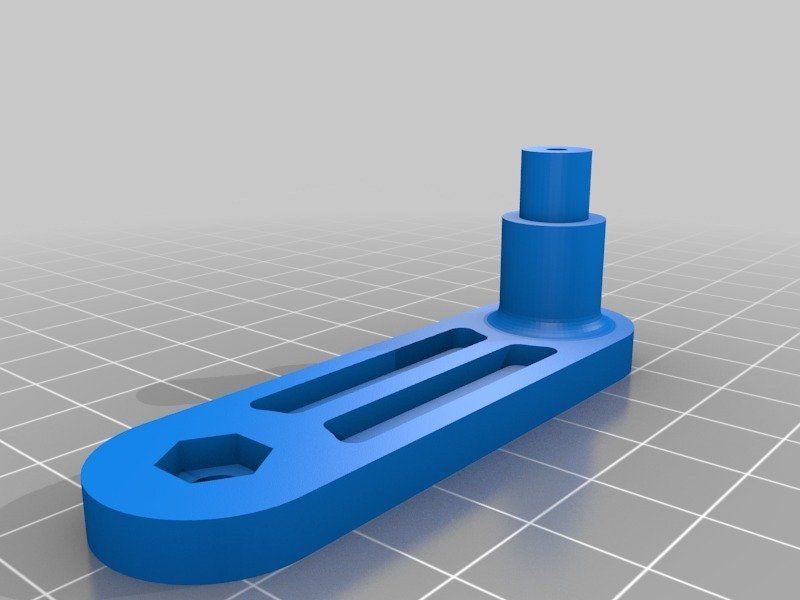

WRENCH STOCK TUBE M4 / AR15

cults3d

Key for stock tube M4/AR15. If you like it, you can find my other creations here : https://cults3d.com/fr/utilisateurs/AT_Eleven_3D/cr%C3%A9ations My facebook page: https://www.facebook.com/ATEleven3D Unless otherwise stated, all creations...

If you like it, you can find my other creations here : https://cults3d.com/fr/utilisateurs/AT_Eleven_3D/cr%C3%A9ations My facebook page: https://www.facebook.com/ATEleven3D Unless otherwise stated, all creations...

M4 or AR15 Airsoft Stock

thingiverse

Modeled this in preparation to modify it to move the battery into the stock. Nothing special, just an exact copy of the stock that comes with the gun. ... In addition to the STL file, I also uploaded the native SolidWorks 2018, STEP, and IGES files...

AR15/M4 Mil-spec stock

thingiverse

Re-designed Mil-spec stock from Grabcad. Can fit big batterys. Work-in progess, but useable as it is.

...

Thank you if you support my work.

Work-in progess, but useable as it is.

...

Thank you if you support my work.

M4/AR15 Compatible Airsoft Lightweight Stock

thingiverse

... BUILD THIS ! Code : HA3D-016 Model : Hornet_Standard_Stock Designer : Hornet Test done with Tianse PLA and TPU. ... FOLLOW THIS PROJECT AND MANY OTHERS IN "HORNET AIRSOFT" YOUTUBE CHANNEL : https://www.youtube.com/channel/UCjG2fck4nwnPs5ap3ZqGF_w

Nerf Stryfe AR15 / M4 Carbine Extendable Stock

thingiverse

FYI i printed AR15-main_stock.STL You can then print the latch AR15-stock_latch. STL If you want you can print AR15-stock_swivel.STL and AR15-stock_swivel_screw.STL for some more eye candy. However i haven't printed these yet and it's unlikely they...

STL If you want you can print AR15-stock_swivel.STL and AR15-stock_swivel_screw.STL for some more eye candy. However i haven't printed these yet and it's unlikely they...

Turbo Fire Stock

thingiverse

This is a stock attachment point for the XShot Turbo Fire that connects to a 3/4 pipe for any custom stock.

Ruger 1022 stock replacement part ar15 stock housing V4

thingiverse

Ruger 10/22 ar style stock. ...Uses ar15 collapsible butt and pistol grip. 11" to 14.5" lop (length of pull). ...Finer threads for a tighter fit.

Ruger 1022 stock replacement part ar15 stock housing

thingiverse

The standard ar15 buffer tube dimensions were used except the threading. the tube was canted 10 degrees down. No known issued yet. It has not been printed and tested for fit yet.

... Find the latest updated version here...

the tube was canted 10 degrees down. No known issued yet. It has not been printed and tested for fit yet.

... Find the latest updated version here...

Customizable M4 / AR15 stock travel limiter

thingiverse

A small and simple device you can use on your buffer tube to limit the stock's travel.

Airsoft stock for M4/AR15 - 2

thingiverse

Hi, Made this stock but never try to print it. The fixation system is made with one M6 bolt. enjoy, Iron. ...

Airsoft stock for M4/AR15 - 1

thingiverse

Hi, Some custom stock i made few month ago. The fixation is made with one M6 screw and a M6 nut.

...

enjoy,

Iron.

The fixation is made with one M6 screw and a M6 nut.

...

enjoy,

Iron.

Airsoft stock for M4/AR15 - 3

thingiverse

Hi, Here is the first stock i made. I guess something is wrong with this one but couldn't say what. ...So if you find out, i would like to know :) enjoy, Iron.

Airsoft stock for M4/AR15 - 4

thingiverse

Hi, Here is another stock for m4. The printing volume should fit with a 200mm x200mm.

You normaly don't need to make support (not 100% sure)

Feel free to tell me if it's printing well.

...

enjoy,

Iron.

Nerf AR15 Stock remix plus shoulder pad

thingiverse

I decided to remix but cutting out the center to open up and lighten the appearance of this nerf stock. I am currently printing it now, so I am unable to comment on the rear fitment. I also designed a shoulder pad that can be glued after it is...

ar15

grabcad

ar15

AK - Stock - AR15 Adapter Low-poly 3D model

cgtrader

AR15 Adapter for AK74/AKM it allows to attach AR15 Stocks to the AK 2K Textures \ Specular | Metallic All Parts can be attached easily. ...

...

AR15/M4/16 STOCK

thingiverse

Designed up this dealer button to use in home games or have just as something laying around for any poker fan. It was inspired by a dealer button in Pokerstars VR. Printing: Ring - Infil to add weight, supports needed for spade inset. Letter...

AR15 stock mil spec

thingiverse

Uses m5 hardware

AR15 Sniper Stock

grabcad

just playing around.

M4/AR15 crane stock adjustment peice with retaining nut.

thingiverse

This peice/peices are for the cranestock adjustment for the standard ar15/m4 and other compatible crane stocks. These ARE NOT the correct scale at the moment and will take a little figuring out to be correct. I will post the actual sized ones here...

AR15

grabcad

AR15 built from picked up parts

(remix)Airsoft AR15 Stock Adapter with QD points

thingiverse

Remix of the original stock adapter,i removed the branding and put quick detach sling mounts

3D printing and 3D printer presentation, report

3D printing and 3D printer

Presentation authors: Salatina E. A., Salatin S. A.

A., Salatin S. A.

3D printer

is a peripheral device that uses the layer-by-layer method of creating a physical object from a digital 3D model. In foreign literature, this type of device is also called fabber, and the 3D printing process is called Rapid Prototyping.

What is a 3D printer?

The principle of operation of a 3d printer is based on the principle of gradual (layered) creation of a solid model, which, as it were, is “grown” from a certain material. The advantages of 3D printing over the usual, manual methods of building models are high speed, simplicity and relatively low cost.

Technologies

There are various technologies for 3D printing. The difference between them lies in the way the product layers are applied.

The most common are SLS (selective laser plexus), HPM (molten material overlay) and SLA (stereolithiography).

Stereolithography or SLA is the most widely used technology due to the high speed of building objects.

SLA technology

The technology works like this: a laser beam is directed at a photopolymer, after which the material hardens.

The photopolymer is a translucent material that deforms when exposed to atmospheric moisture.

Once cured, it can be easily bonded, machined and painted. The working table (elevator) is in a container with a photopolymer. After the laser beam passes through the polymer and the layer hardens, the working surface of the table moves down.

SLS technology

Laser beam sintering of powder reagents - aka SLS - is the only 3D printing technology that is used in the manufacture of molds for both metal and plastic casting.

Plastic models have excellent mechanical properties, which make them suitable for making full-featured items. SLS technology uses materials that are similar in properties to the brands of the final product: ceramics, powdered plastic, metal.

The 3D printer device looks like this: powder substances are applied to the surface of the elevator and sintered under the action of a laser beam into a solid layer that corresponds to the parameters of the model and determines its shape.

DLP technology

DLP technology is new to the 3D printing market. Stereolithographic printers are positioned today as the main alternative to FDM equipment. This type of printer uses digital light processing technology. Many people wonder what the 3d printer of this sample prints with?

Instead of a plastic filament and a heating head, photopolymer resins and a DLP projector are used to create three-dimensional figures.

Despite the intricate name, the device is almost indistinguishable from other desktop printers. Its developers, represented by

QSQM Technology Corporation, have already launched the first samples of high-tech equipment into a series. It looks like this:

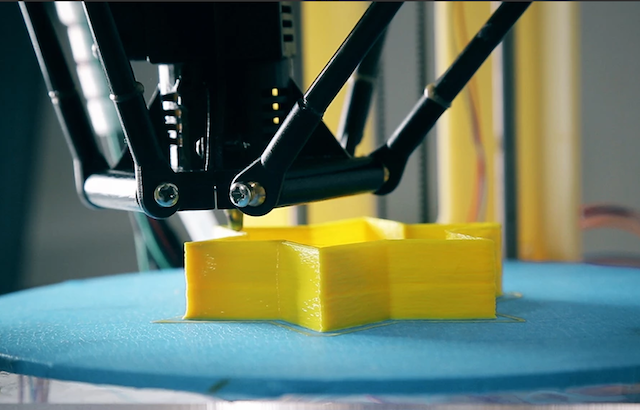

HPM technology (FDM) HPM

Allows you to create not only models, but also final parts from standard, structural and high-performance thermoplastics. It is the only technology that uses production grade thermoplastics to provide unparalleled mechanical, thermal and chemical strength to parts.

HPM printing stands out for its cleanliness, ease of use and suitability for office use. Thermoplastic parts are resistant to high temperatures, mechanical stress, various chemicals, wet or dry environments.

Soluble auxiliary materials allow the creation of complex multi-level shapes, cavities and holes that would be problematic to obtain with conventional methods. HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths.

HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths.

When the 3D printer completes the creation of the part, it remains to separate the auxiliary material mechanically, or dissolve it with detergent, after which the product is ready for use.

3D pens

Hand-printing pens are also popular these days. Moreover, it would be correct to call them not printing devices, but pens for drawing three-dimensional objects.

The pens are made in the same way as fusing printers. The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle.

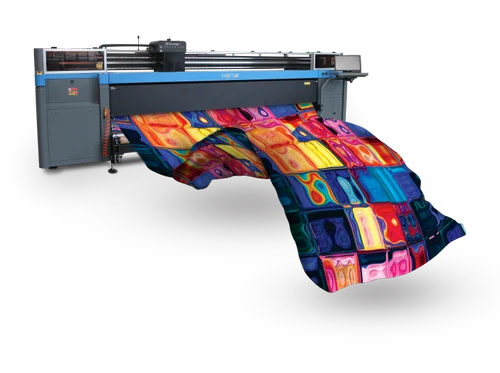

Applications of 3D printing

3D printing has opened up great opportunities for experimentation in areas such as architecture, construction, medicine, education, fashion design, small-scale production, jewelry, and even in the food industry. In architecture, for example, 3D printing allows you to create three-dimensional models of buildings, or even entire microdistricts with all the infrastructure - squares, parks, roads and street lighting.

In architecture, for example, 3D printing allows you to create three-dimensional models of buildings, or even entire microdistricts with all the infrastructure - squares, parks, roads and street lighting.

Thanks to the cheap gypsum composite used, the cost of finished models is low. And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

3D printer: application in the field of construction

In construction, there is every reason to believe that in the near future the process of erecting buildings will be much faster and easier. Californian engineers have created a 3D printing system for large objects. It works on the principle of a construction crane, erecting walls from layers of concrete. Such a printer can build a two-story house in just 20 hours. After that, the workers will only have to carry out finishing work.

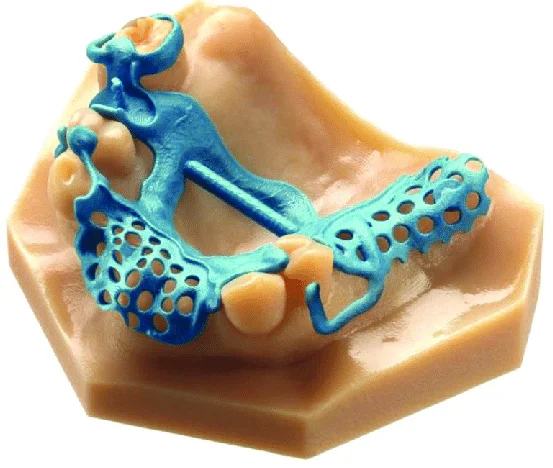

Medical Applications

In medicine, thanks to 3D printing technologies, doctors have been able to recreate copies of the human skeleton, which allows them to more accurately practice techniques that increase the guarantees of successful operations.

3D printers are increasingly being used in the field of prosthetics in dentistry, as these technologies allow much faster production of prostheses than traditional manufacturing.

Not so long ago, German scientists developed a technology for obtaining human skin. In its manufacture, a gel obtained from donor cells is used. And in 2011, scientists managed to reproduce a living human kidney.

3D printing. Future and prospects. (Part 1) presentation, report

3D printing technology

Part 1

3D printing.

Future and prospects.

Do you all know what a 3D printer is for?

Formulate an interesting proposal for creating a 3D model

Answer the maximum number of questions

and get a 3D model as a gift!

or a certificate for a master class in 3D printing.

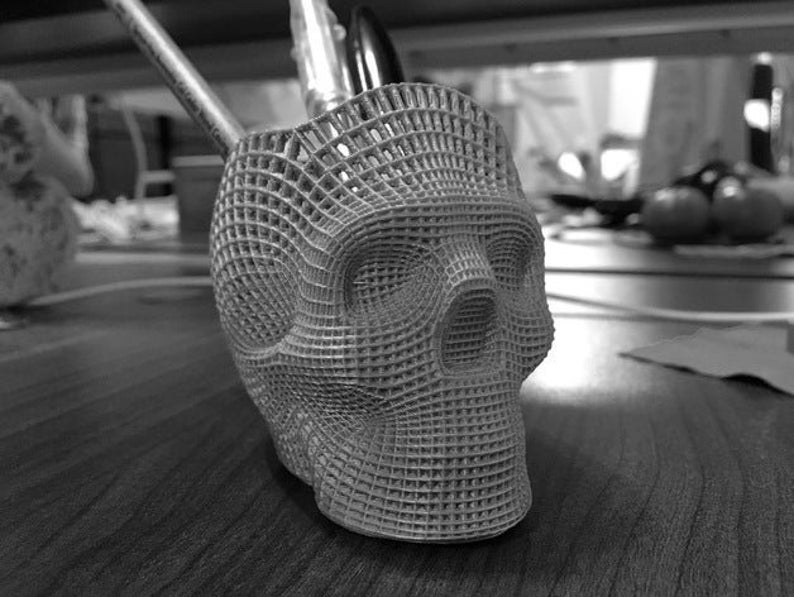

To print bulky items on your home printer?

Mug

Musical instrument

Device model

Figures and toys

Architectural models

To print bulky objects on your home printer?

Capabilities of a 3D printer

Promising directions

Medicine.

3D bioprinting - additive manufacturing of living tissues

OPM is an original equipment manufacturer (OEM) of medical devices that utilize the company's OsteoFab®process, which combines laser sintering additive manufacturing technology and OPM's proprietary OXPEKK® material formulation to 3D print orthopedic and neurological implants.

Food

Printer Painter

Driving 3D Printer

Digital Chocolatier

VIRTUOO MIXER 9000 9000 9000

9000

9000

Creat Printer Printer Printing

clothing

3D printer capabilities

Engineering

Possibly 3D Printer

Technologies of the future

Stages 3D Press

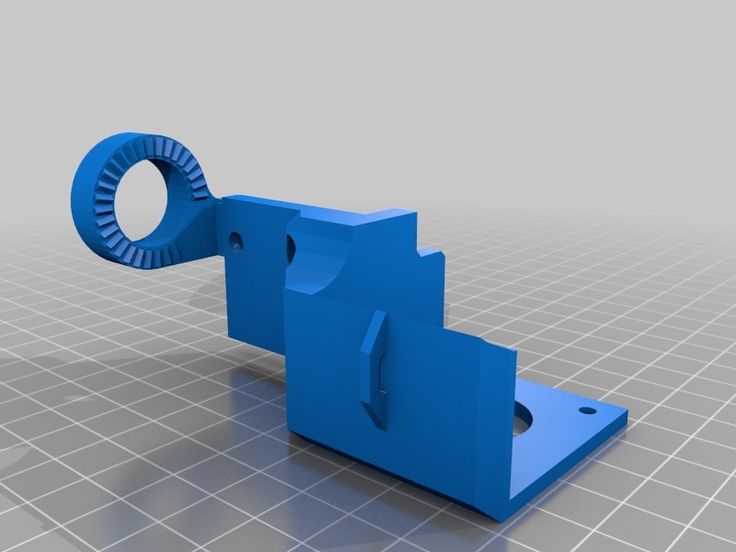

development image of the future object in the 3D editor "3D Studio Max", "AutoCAD", "Compass", "SolidWorks", etc.

FDM technology (Fused Deposition Modeling)

3D printing steps

select "Save As" or "Import/Export" from the menu.

you should specify the degree of detail of the model or the degree of its division into triangles.

, taking into account the requirements for the quality of its outer surface and the power of the computer.

FDM technology (Fused Deposition Modeling)

3D printing steps

Slicer program specifies the sequence of material application during 3D printing

Slicer programs cut the model into thin horizontal plates, set the trajectory of the print head and convert it into a digital G-code.

FDM technology (Fused Deposition Modeling)

3D printing steps

FDM (Fused Deposition Modeling) technology

3D printing steps

The most important elements of a 3D printer are the working platform and the print head.