Anjan contractor 3d food printer

The audacious plan to end hunger with 3-D printed food

Anjan Contractor’s 3D food printer might evoke visions of the “replicator” popularized in Star Trek, from which Captain Picard was constantly interrupting himself to order tea. And indeed Contractor’s company, Systems & Materials Research Corporation, just got a six month, $125,000 grant from NASA to create a prototype of his universal food synthesizer.

But Contractor, a mechanical engineer with a background in 3D printing, envisions a much more mundane—and ultimately more important—use for the technology. He sees a day when every kitchen has a 3D printer, and the earth’s 12 billion people feed themselves customized, nutritionally-appropriate meals synthesized one layer at a time, from cartridges of powder and oils they buy at the corner grocery store. Contractor’s vision would mean the end of food waste, because the powder his system will use is shelf-stable for up to 30 years, so that each cartridge, whether it contains sugars, complex carbohydrates, protein or some other basic building block, would be fully exhausted before being returned to the store.

Advertisement

Ubiquitous food synthesizers would also create new ways of producing the basic calories on which we all rely. Since a powder is a powder, the inputs could be anything that contain the right organic molecules. We already know that eating meat is environmentally unsustainable, so why not get all our protein from insects?

If eating something spat out by the same kind of 3D printers that are currently being used to make everything from jet engine parts to fine art doesn’t sound too appetizing, that’s only because you can currently afford the good stuff, says Contractor. That might not be the case once the world’s population reaches its peak size, probably sometime near the end of this century.

“I think, and many economists think, that current food systems can’t supply 12 billion people sufficiently,” says Contractor. “So we eventually have to change our perception of what we see as food.”

There will be pizza on Mars

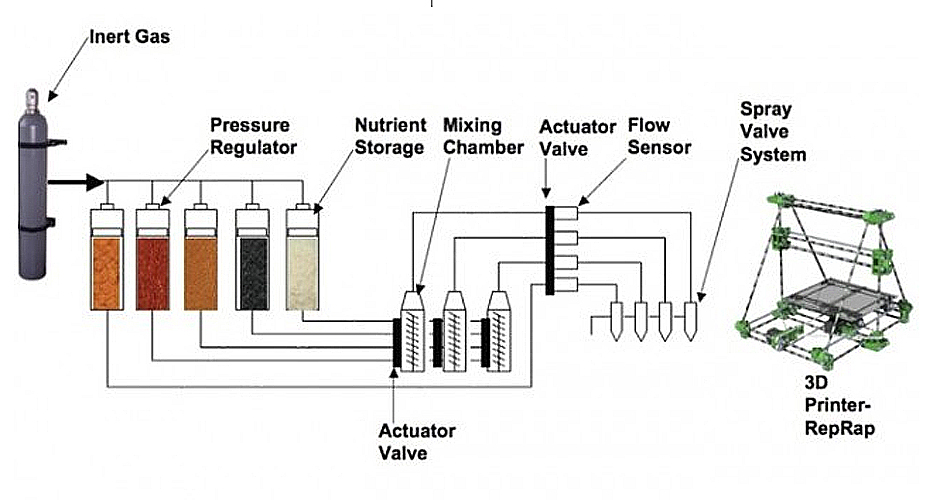

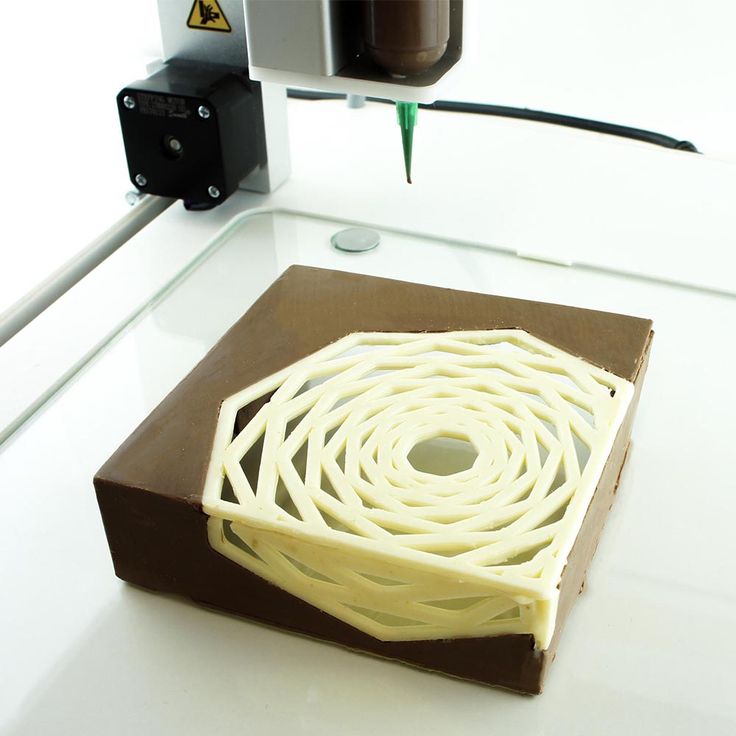

The ultimate in molecular gastronomy. (Schematic of SMRC’s 3D printer for food.)Image: SMRC

(Schematic of SMRC’s 3D printer for food.)Image: SMRC

Advertisement

If Contractor’s utopian-dystopian vision of the future of food ever comes to pass, it will be an argument for why space research isn’t a complete waste of money. His initial grant from NASA, under its Small Business Innovation Research program, is for a system that can print food for astronauts on very long space missions. For example, all the way to Mars.

“Long distance space travel requires 15-plus years of shelf life,” says Contractor. “The way we are working on it is, all the carbs, proteins and macro and micro nutrients are in powder form. We take moisture out, and in that form it will last maybe 30 years.”

Pizza is an obvious candidate for 3D printing because it can be printed in distinct layers, so it only requires the print head to extrude one substance at a time. Contractor’s “pizza printer” is still at the conceptual stage, and he will begin building it within two weeks. It works by first “printing” a layer of dough, which is baked at the same time it’s printed, by a heated plate at the bottom of the printer. Then it lays down a tomato base, “which is also stored in a powdered form, and then mixed with water and oil,” says Contractor.

It works by first “printing” a layer of dough, which is baked at the same time it’s printed, by a heated plate at the bottom of the printer. Then it lays down a tomato base, “which is also stored in a powdered form, and then mixed with water and oil,” says Contractor.

Finally, the pizza is topped with the delicious-sounding “protein layer,” which could come from any source, including animals, milk or plants.

Advertisement

The prototype for Contractor’s pizza printer (captured in a video, above) which helped him earn a grant from NASA, was a simple chocolate printer. It’s not much to look at, nor is it the first of its kind, but at least it’s a proof of concept.

Replacing cookbooks with open-source recipes

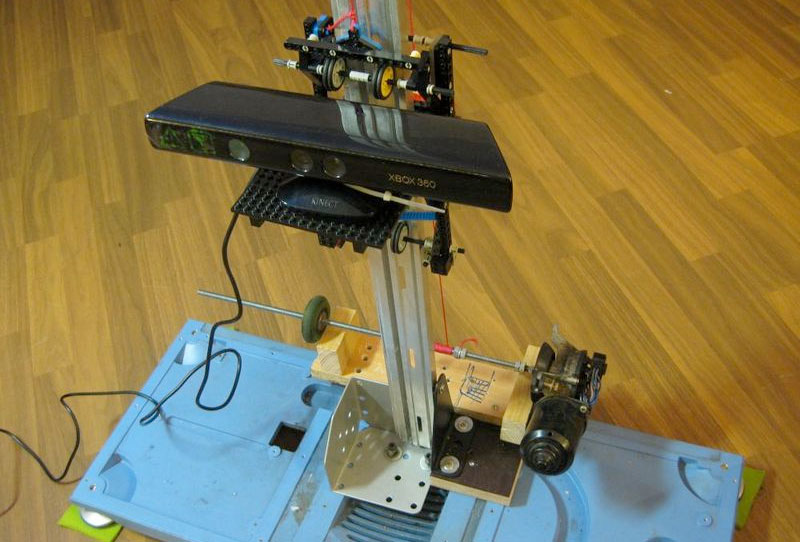

SMRC’s prototype 3D food printer will be based on open-source hardware from the RepRap project.Image: RepRap

Remember grandma’s treasure box of recipes written in pencil on yellowing note cards? In the future, we’ll all be able to trade recipes directly, as software. Each recipe will be a set of instructions that tells the printer which cartridge of powder to mix with which liquids, and at what rate and how it should be sprayed, one layer at time.

Each recipe will be a set of instructions that tells the printer which cartridge of powder to mix with which liquids, and at what rate and how it should be sprayed, one layer at time.

Advertisement

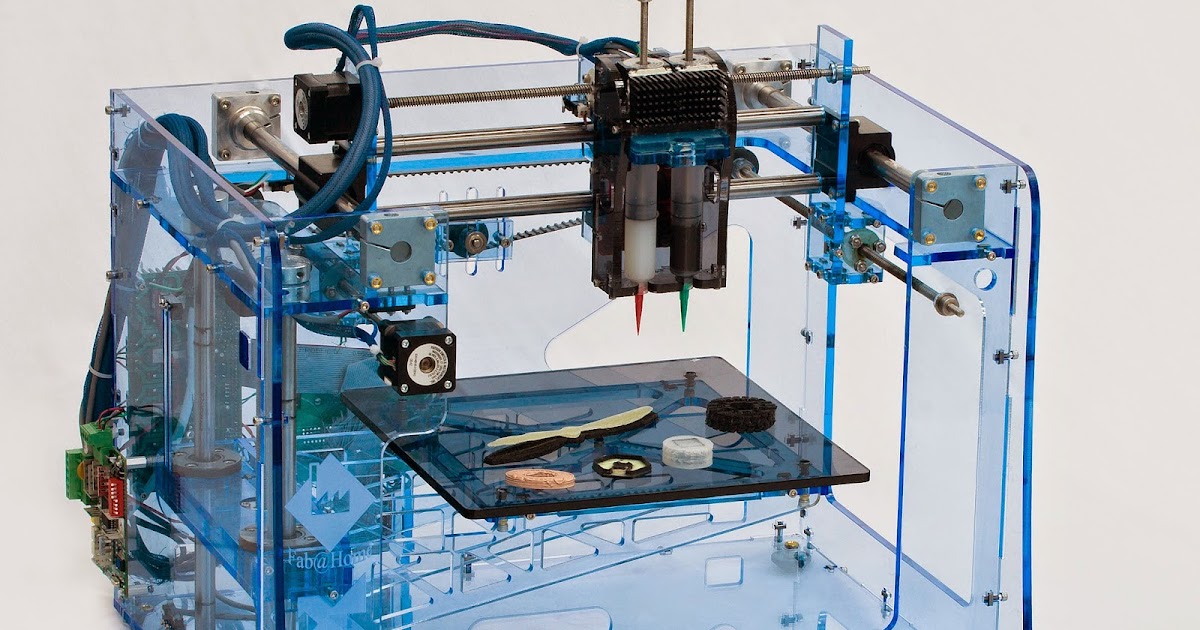

This will be possible because Contractor plans to keep the software portion of his 3D printer entirely open-source, so that anyone can look at its code, take it apart, understand it, and tweak recipes to fit. It would of course be possible for people to trade recipes even if this printer were proprietary—imagine something like an app store, but for recipes—but Contractor believes that by keeping his software open source, it will be even more likely that people will find creative uses for his hardware. His prototype 3D food printer also happens to be based on a piece of open-source hardware, the second-generation RepRap 3D printer.

“One of the major advantage of a 3D printer is that it provides personalized nutrition,” says Contractor. “If you’re male, female, someone is sick—they all have different dietary needs. If you can program your needs into a 3D printer, it can print exactly the nutrients that person requires.”

If you can program your needs into a 3D printer, it can print exactly the nutrients that person requires.”

Replacing farms with sources of environmentally-appropriate calories

2032: Delicious Uncle Sam’s Meal Cubes are laser-sintered from granulated mealworms; part of this healthy breakfast.Image: TNO Research

Contractor is agnostic about the source of the food-based powders his system uses. One vision of how 3D printing could make it possible to turn just about any food-like starting material into an edible meal was outlined by TNO Research, the think tank of TNO, a Dutch holding company that owns a number of technology firms.

Advertisement

In TNO’s vision of a future of 3D printed meals, “alternative ingredients” for food include:

- algae

- duckweed

- grass

- lupine seeds

- beet leafs

- insects

From astronauts to emerging markets

While Contractor and his team are initially focusing on applications for long-distance space travel, his eventual goal is to turn his system for 3D printing food into a design that can be licensed to someone who wants to turn it into a business. His company has been “quite successful in doing that in the past,” and has created both a gadget that uses microwaves to evaluate the structural integrity of aircraft panels and a kind of metal screw that coats itself with protective sealant once it’s drilled into a sheet of metal.

His company has been “quite successful in doing that in the past,” and has created both a gadget that uses microwaves to evaluate the structural integrity of aircraft panels and a kind of metal screw that coats itself with protective sealant once it’s drilled into a sheet of metal.

Since Contractor’s 3D food printer doesn’t even exist in prototype form, it’s too early to address questions of cost or the healthiness (or not) of the food it produces. But let’s hope the algae and cricket pizza turns out to be tastier than it sounds.

BeeHex Revolutionizes Food with 3D Printing and Robotics

BeeHex Revolutionizes Food with 3D Printing and Robotics

The story of BeeHex, a technology startup that makes 3D printers that print food, is likely to make you hungry and guaranteed to make you smile.

BeeHex is creating groundbreaking, advanced robotics equipment for the food industry, but it is pizza printers that first opened doors for founder Anjan Contractor.

It all began in Austin, TX thousands of pizzas ago.

“I was very fortunate to work for a company that was a subcontractor to NASA, the Air Force, and other federal agencies,” Contractor said. He was the principal engineer on a NASA project and invented a 3D printer to re-create food in space from powdered ingredients (much like Tang).

“NASA could provide nutrition through dehydrated food, but for astronauts on deep space missions that wasn’t a viable option since the mission may last five to six years,” Contractor explained. “They wanted to provide textured food, personalized nutrition, and a better eating experience for optimal health and wellness.”

Printing pizza because was a natural fit for 3D printing process—a layer by layer construction of crust, sauce, cheese, and toppings.

Out of that work, Contractor improved on his printer design, accommodating various food consistencies and developed a patent-pending no-drip mechanism for food printing.

He decided to start a company—in Texas. Although a graduate in mechanical engineering from OSU, Contractor says that Ohio wasn’t even on his radar.

The Prototype, the Pivot, and Early Market Validation

Contractor and three other founders poured their resources into buying and building the first equipment, materials, and prototypes. Initially, the company was targeted for confectionary, then the founders pivoted to capitalize on the popularity gained by the NASA’s first “space pizza.”

“We went to trade shows and South by Southwest, hoping to raise some kind of funding,” Contractor said. “When that didn’t happen, we were going back and forth across the country as a catering company with the printable pizza. We would knock down the machine, pack it in a box, and fly from New York to Silicon Valley making from $2500 to $10,000. It was very difficult. Printing 300 pizzas with two people is not an easy task.”

By October of 2015, Contractor thought that it was time to wrap things up.

“Two people going crazy across the country printing pizza was not a sustainable business,” he said. “We set a deadline of six more months. ”

”

“I at least wanted to succeed as a ‘space pizza’ catering company if not as a ‘food robot manufacturing’ company,” Contractor said. BeeHex landed a big project with GE Aviation in Cincinnati to print and serve pizza to 300 people.

“I was extremely busy that day,” Contract said. “We were churning out 300 pizzas one by one–myself, my cofounder, and a pizza robot; it was a messy process. That’s when Jim and Tom Grote, owners of legendary Donato’s pizza, wearing suits and ties came to see us.”

As Contractor tells it, the Grotes took off their ties and coats and jumped in.

“Jim was filling cartridges, filling cheese,” Contractor said. “Here is someone who has 200 restaurants that are so clean and particular about how they make pizzas—when they say something is 100 calories, you know it’s right—and with us, the dough was all over his pants and hands and face. It was a humbling experience.”

Something Jim Grote said, gave Contractor a little lift.

“This is how I started in 1963, he told us,” Contractor said. “He helped us out all day.”

BeeHex Delivers Disruptive Technology to Food GiantsGrote Company, also founded by Jim Grote, manufactures top quality food slicing and assembling equipment.

“At 8 a.m. when I am leaving Cincinnati,” Contractor said, “Jim Grote gave me the news that he wanted to invest in BeeHex.”

Contractor moved BeeHex to Columbus with joy in his heart.

“A lot of people in Austin told us that Columbus was going to be tough for a startup,” Contractor said. “To be honest, Columbus is as good as Austin, especially for food equipment. Columbus is a hidden gem and one of the best places in the world.”

Ohio has a headquarters concentration of food producers, manufacturers, and chains.

“With Jeni’s Splendid Ice Creams, Cheryl’s Cookies, and Graeter’s Ice Cream, and major food chains, from Donato’s, to Wendy’s, White Castle, Charley’s Grilled Subs, Arby’s, Max & Erma’s, and Buffalo Wild Wings, we are in a wonderful place,” Contractor said.

BeeHex is in the advantaged stages of development and prototype testing, preparing to build a pre-production machine.

“The help that we get in this environment is invaluable,” said Contractor. “We have exceptional backing from the Grote company and are working with manufacturers on scaling production and directly with customers. The early adopter market is set. Some customers already have purchased our machines before we have manufactured the first production version.”

When Contractor came back to Ohio, our Backyard Effect different from his previous experience with accelerators in Texas and on the West Coast.

“Rev1 wasn’t charging,” he said, “so I was a little skeptical at first. Rev1 helps on multiple levels, from brushing up our business model to giving me templates to calculate ROI for my customers. That’s how I’ve landed a few customers.”

Contractor likens the surge of startups in Columbus to what he saw in Austin ten years ago.

“OSU is producing talent in engineering, science, art architecture and business,” he said. “The startup culture is growing very fast here. Rev1 and others are helping it grow. Columbus is poised to be the next Austin, even greater.”

3D food printer from Moscow scientists prints chocolate, cakes and even nuggets

A 3D food printer with a system of "smart" recipes that prints food products with specified properties was created by scientists from the Moscow State University of Food Production (MGUPP). The new device consists of 99% domestic components and can be used to design vending machines that print products according to the client's order. The 3D printer already prints with dough and chocolate, and in the future it will be able to produce even meat products - nuggets, for example, have already been successfully obtained.

chocolate chess

One of the goals of developing a 3D food printer was to create food rich in vitamins, micronutrients and antioxidants that would be a healthy alternative to traditional meals.

“Today, many are deficient in nutrients and micronutrients that can be replenished with elements in chemical form, but eating foods fortified with them contributes to better absorption. The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

The main difference between the development of MGUPP scientists and existing 3D printers is the units modified for the tasks of the food industry. The unique technology allows you to take a device for printing with plastic and upgrade it for printing with food raw materials.

“We made one unique extruder (a nozzle through which the raw material exits) of a revolving type. Inside it is a drum into which various raw materials are fed, which allows you to speed up the production process and use fewer parts. This is also our innovation - the use of one powerful drum extruder, into which various raw materials are fed under different pressures and temperatures, ”notes Alexey Kuchumov.

The development of MGUPP scientists allows you to make a 3D printer of any size and for any task, as well as increase the print area to one and a half meters, which is 1.2 meters more than existing analogues.

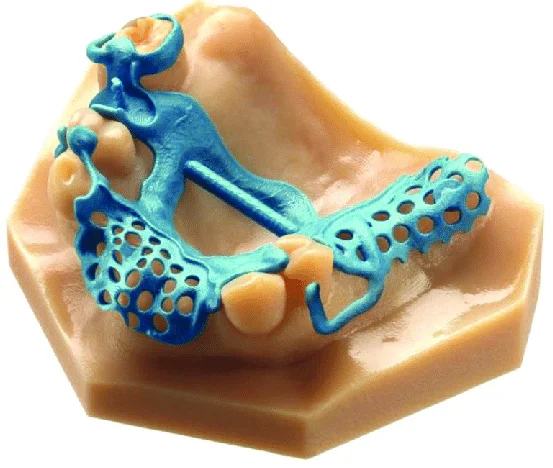

3D printer

In addition, the new device provides the ability to produce artificial meat using bioprinting technology. At the same time, the printer performs the function of a freezer - a refrigerator, and with different setting temperatures. It is designed in such a way that the necessary climatic environment will be formed for each type of raw material: its own temperature, its own humidity, etc. Among other things, a laboratory for the production of “cultured” meat is being opened together with 3D Bioprinting Solutions.

“The bioprinter prints a special plant-based substrate, on which live cells taken painlessly from animals are applied. This device prints according to a given digital model, using special nozzles - devices that allow you to print both cellular material and plant fibers. Such meat can be called “ethical”, and it will be in demand on the market,” comments Alexey Kuchumov.

Such meat can be called “ethical”, and it will be in demand on the market,” comments Alexey Kuchumov.

As 3D Bioprinting Solutions Managing Partner Yousef Hesuani, 3D Bioprinting Solutions Managing Partner, added: “At this stage, it is possible to obtain the structure and organoleptic properties of the product similar to a natural product. The technology of printing with plant fibers followed by the application of a cell culture to the printed fibers has been developed, and special food bioprinters have been developed that allow automating the printing process. For example, the nuggets obtained using this technology were prepared according to a special recipe.”

Today, the MGUPP 3D-farm operates continuously, students and graduate students independently assemble printers and debug printing with food raw materials and living cells. The development is carried out within the framework of the MGUPP strategic project "Additive Technologies and Ingredients of the FoodNet Market" under the program of the Russian Ministry of Education and Science "Priority 2030" within the framework of the national project "Science and Universities".

features, pros and cons of each model

04/07/2021

Content

-

- What is a food 3D printer

- Scope

- used raw materials

- Driving 3D-printer

- Popular

- TOP-10 TOP-10 Top-10 Top-10 Top-10 Most Actual Most Actual Most Actual Most Actual Most Actual Most Actual Most Actual Mounts

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus food 3D printer with cooling chamber 9004

What is a 3D food printer

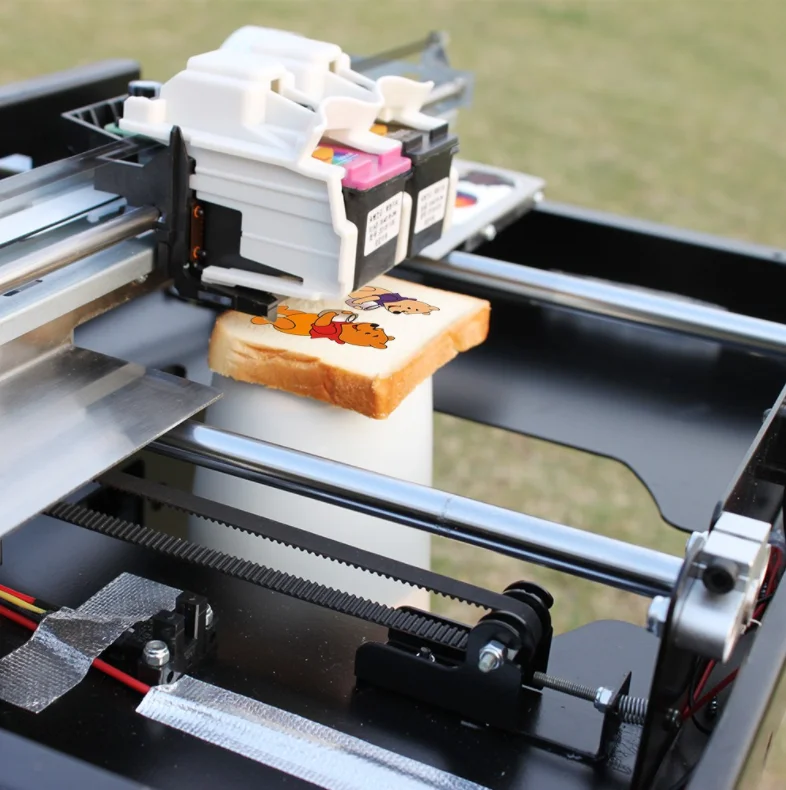

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer.

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with glaze

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products.

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes;

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used.

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database.

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges;

The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; -

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies. Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

-

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake.

There are several types of food 3D printers:

-

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe;

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular manufacturers

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products.

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures. Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

Free Shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Available on credit. To checkout, add the product to the cart and follow the instructions Go

Manufacturer Wiiboox Free Shipping

Add to compare

Product added to compare Go

Manufacturer Choc Edge Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market.

The top is based on ratings and customer reviews.

The top is based on ratings and customer reviews. 1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

-

Ease of operation;

-

A wide range of proposed projects;

-

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment.

Pros:

-

Versatility: the ability to print not only sweet dishes, but also side dishes;

-

Attractive appearance;

-

High build quality;

-

Convenient control by touch panel.

Cons:

-

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate.

Pros of :

-

Attractive appearance;

-

Uninterrupted work;

-

Durability;

-

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D Food Printer with Cooling Chamber

Choc Creator V2.0 Plus 3D Food Printer with Cooling Chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that maintaining the optimal temperature in the room to preserve the integrity of chocolate figures is too problematic: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is slightly higher than a classic one, but the high performance of the final product justifies any costs.

Pros of :

-

Availability of a cooling system for finished products;

-

High printing precision;

-

Long service life;

-

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

-

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

This is a unique technology that helps to unleash the creative potential of the chef. 5.byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients.

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients.

Pros:

-

The ability to create unique flavors;

-

Neat and bright printing;

-

Aesthetic appearance of the device.

Cons:

-

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

-

Practicality;

-

High build quality;

-

Attractive appearance;

-

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision.

Pros:

-

Ease of operation;

-

High build quality;

-

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling.

Pros:

Cons:

-

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing:

-

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

-

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

-

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

-

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Learn more

-

- What is a food 3D printer