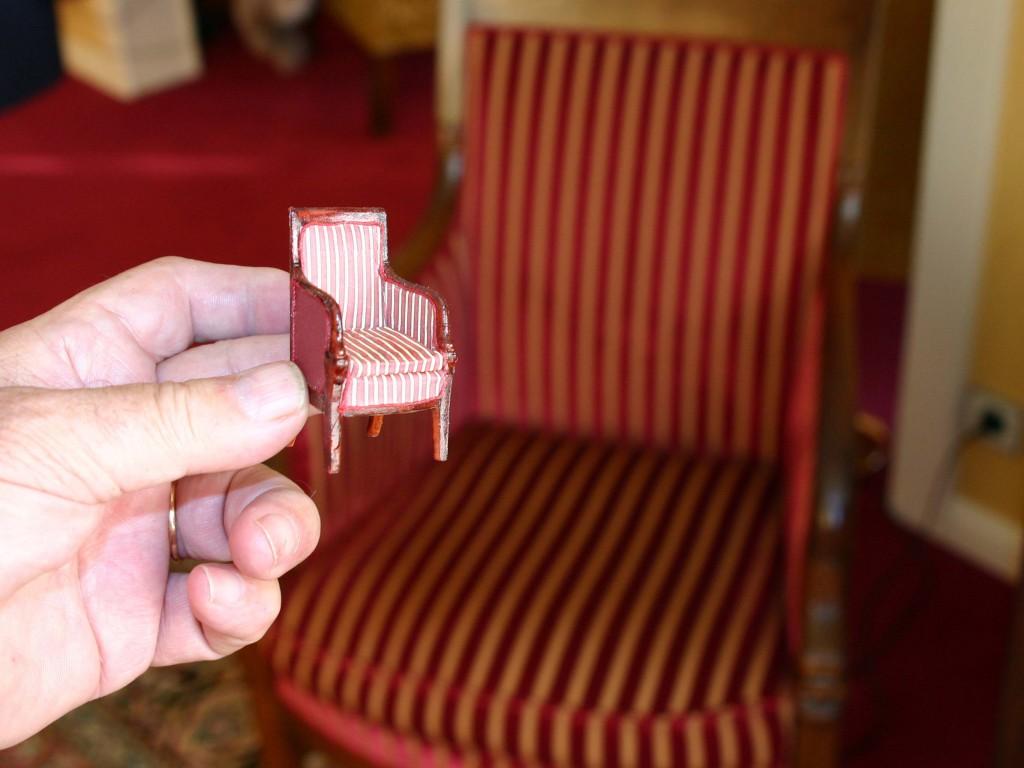

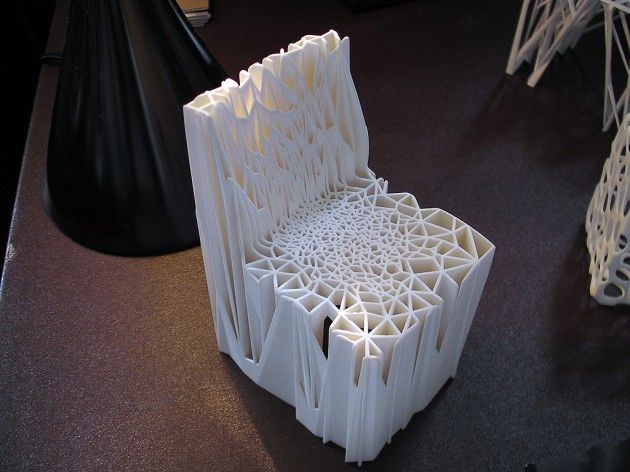

3D printed miniature furniture

Doll Furniture 3d Printing - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(158 relevant results)

Dollhouse 3d - Etsy.

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Furniture on a 3D printer: 3D printing

In this article we talk about making furniture using additive technologies - 3D printing - about the advantages and examples of using this approach in practice and what technique is best to use.

This article was prepared using a publication from the site 3dsourced.com, which was translated and supplemented for you by the Top 3D Group.

You may have once had the idea to use 3D printing in the manufacture of furniture for your home, but you dismissed it, considering this idea too laborious, time consuming or expensive. After all, large industrial 3D printers with a huge print area, like the Farsoon SS403P 3D printer, are usually needed to create large pieces of cabinet furniture, right? nine0003

That used to be true, but now there are ways to use 3D printing in the interior without the need for large-format industrial machines.

Read on - we'll take a look at some of these applications with real examples.

Option 1: Build furniture with the Hangprinter

Designed by Torbjørn Ludwigsen, the Hangprinter is a cable-suspended and movable print unit designed to print large objects as cheaply as possible. The Hangprinter doesn't fit in a case, its print chamber is the entire room. nine0003

The Hangprinter doesn't fit in a case, its print chamber is the entire room. nine0003

Hoping to inspire others to try frameless 3D printing, Thorbjörn has made the software files for this printer open and free for everyone to copy, use and further refine. Most parts of the Hangprinter can be 3D printed, and the cost of building one yourself is estimated to be as low as $250.

Chris Riley Stool

Introduced in mid-2017, Hangprinter printing immediately began to be tested in the creation of large objects. In the video below - one of the very first examples - Chris Riley's bar stool. nine0003

Such videos showed the strengths and weaknesses of Hangprinter, for example - the ability to create really large objects for relatively very little money and the possible delamination due to the lack of a closed camera.

Chris Riley's Stool printed with offset layers and delamination, and it also took two weeks to print because the Hangprinter was so loud it couldn't be used at night and had to be printed only during the day. nine0003

Hangprinter assembly and operation requires familiarity with 3D printers, an understanding of the mechanics of how they work, skills in working with electronics and device debugging, but there are also detailed instructions for beginners, as well as a small but growing community of other Hangprinter users who can be contacted for help.

For those who are willing to put up with the shortcomings described above, or are confident that they can avoid them, Hangprinter remains the most affordable and affordable way to create fully 3D printed furniture. nine0003

Option 2: 3D printed furniture on a large 3D printer

3D printed furniture from the Print Your City project. This model may not fit in your desktop printer.

This model may not fit in your desktop printer.

The second method is to use a stationary 3D printer with a really large print chamber

Print Your City

The “Print Your City” project, for example, uses a 3D printer to print street furniture and other small architectural forms, consisting of a robot and a fenced indoor area equipped with a special printing platform. nine0003

Last but not least, plastic for printing is made from recycled waste.

Despite the simplicity of the idea itself, this method of manufacture is beyond the reach of most people. Large 3D printers not only take up a lot of space, sometimes entire rooms, but are also incredibly expensive. Large industrial 3D printers like the Farsoon HT1001P can still cost hundreds of thousands of dollars.

Because of this, very few furniture projects are carried out by individuals, usually by businesses or very passionate enthusiasts, and the Wilkhahn Printstool stool shown below is an example of both. nine0003

Wilkhahn Printstool One

Designed by Thorsten Frank and manufactured by Wilkhahn, this 3D stool was produced on an industrial 3D printer and is available as part of Wilkhahn's premium office furniture range.

Wilkhahn is a German furniture manufacturer that strives to differentiate itself from its competitors.

“Unlike almost any other office furniture manufacturer, Wilkhahn stands for designs made in Germany all over the world. It offers high-quality office and dynamic conference furniture that sets the benchmark for the entire industry,” the company says. nine0003

Printstool One is one of the few 3D printed pieces of furniture available commercially. It takes several hours to create and assemble, including 3D printing the base and attaching the seat. The base is printed with lignin, an organic biopolymer that decomposes in nature.

The base is printed with lignin, an organic biopolymer that decomposes in nature.

Although the Printstool One is a commercial product, it is not easy to obtain. It is not part of the main Wilkhahn catalog and was released in a limited edition of 500 pieces.

The price for this stool has not been disclosed and probably depends on options, seat material, for example. But given that regular stock stools in this manufacturer's catalog range from $266 to $660, it's safe to assume that the Printstool One costs at least $500, making it quite an expensive plastic stool. However, overpayment for exclusive furniture is a quite common phenomenon. nine0003

In recent years, 3D printing has become more and more accessible. Most likely, this will also affect its large-format sector.

RH Engineering & ManoFigura - furniture for the home

"Magna Patero Ortus" - 3D printed sink RH Engineering & Manofigura .

In mid-2020, this pair of German designers broke into the luxury furniture and interiors segment with their signature Manoveneer finishing technology and large-scale 3D printing. nine0003

Their favorite printer is the BigRep One, large enough to print furniture, with a 1005 mm³ displacement, and costs around $39,000, depending on specifications.

The production process begins with 3D printing of craft furniture based on the client's design, then the ManoVeneer branded coating is applied to the product. What Manoveneer is made of is a company secret, it is only known that the coating is waterproof, can imitate the texture of natural stone and weighs very little.

Option 3: modular printing on a small 3D printer

Large 3D printers will always be a barrier to 3D printing furniture, due to their size and cost, prompting designers to look for ways to stop using them, turning to smaller 3D printers and printing smaller parts for later assembly.

Supermod 3D printed wall

3D printed Supermod wall.

Designed by the founders of Simplus Designs, the Supermod shelving wall consists of individually printed modules that fit together. nine0003

Supermod was created for decoration, visual division of the room into zones and storage of small things in cells. As a modular system, Supermod bypasses the need for large scale 3D printers. While the assembled wall may be taller than most people, each module can be printed on an affordable desktop 3D printer.

The next method involves using 3D printed parts in combination with conventional ones, such as a table top shield or wooden legs, giving the 3D printed components the role of fasteners and framing elements. This is the most accessible way for a wide range of makers to use 3D printing in the creation or repair of furniture. nine0003

Option 4: 3D printed parts as accessories

John Christie “Saul” Dining Table and Chairs

John Christie, who has been designing custom furniture for over 20 years, returned to university at 40.

“During my studies, I became interested in 3D printing and how I could integrate it into the traditional furniture making process. In my projects, I studied how 3D printed parts can be used in the production of furniture.”

John is best known for his Saul Dining Table and Chairs. The table is a handcrafted piece of wood with 3D printed connections.

The author suggested that his connection system would provide "greater customization, reduced production time and waste" when applied to existing pieces of furniture.

This furniture set was exhibited at the Royal Academy of Arts in Edinburgh in 2016. nine0003

This is a craft project to sell products, but similar technology has been used by amateur authors as well.

Alexandre Chappelle Furniture

Designer and YouTuber Alexandre Chappelle has documented the process of making his own wooden table with 3D printed connections. As with John Christie's project, the only 3D printed parts on this table were the articulations, while the rest of the table's parts were made from wood using conventional hand tools. nine0003

The chair is another creation of Alexandre Chappelle.

The author has posted the STL files and instructions on his personal website, where they are available for as little as $5.

This is perhaps the most affordable way to 3D print your own furniture, although the fact that John and Alexander's designs are mostly made of wood begs the question: is using 3D printed fittings 3D printed furniture?

Which technique should be used to 3D print furniture? nine0013

So which of these methods can you use for your own furniture project?

If you are a professional studio or independent designer with the necessary funds, and you have a project that needs to be printed reliably and with high quality, then a large 3D printer will be the best option. 3D printing on a large printer can be ordered from a 3D studio if this is a one-time project and you are not going to purchase a printer. If you need printing all the time, contact Top 3D Shop, and our specialists will help you choose the machine that is most suitable for solving your problems. nine0003

3D printing on a large printer can be ordered from a 3D studio if this is a one-time project and you are not going to purchase a printer. If you need printing all the time, contact Top 3D Shop, and our specialists will help you choose the machine that is most suitable for solving your problems. nine0003

If an industrial 3D printer is not available, then high-quality products can be created using 3D printing on a personal or professional desktop machine, using modular designs or printing connections for parts made using other technologies.

Regardless of the way you choose to use 3D printing in furniture creation, you already know that it can and should be used in this area. And this is what you can do for your own home, workshop or production today. nine0003

And 3D printers that can be purchased at the Top 3D Shop will help you with this - contact us for advice and, with the help of our employees, select the exact 3D printer that you need.

Drawn - furniture printing project from France

3D printed design furniture project

All fantasies that people will someday print furniture have come true! Meet: furniture printing to order.

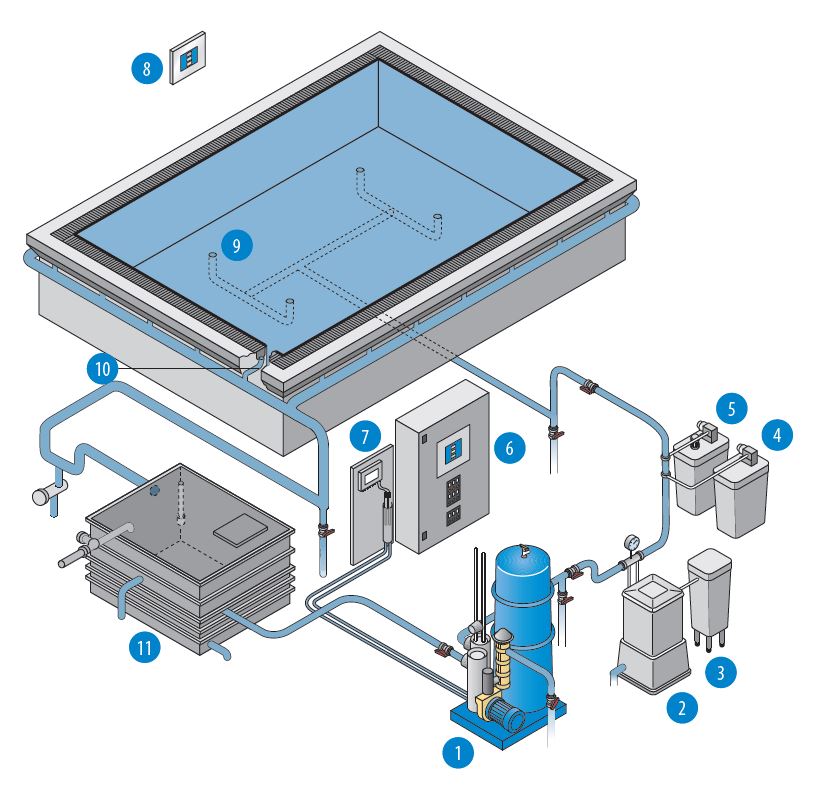

How it works

An industrial manipulator works here as a 3D printer — a robot arm with a plastic extruder attached to it. This extruder consumes plastic pellets and has a very thick nozzle.

You can clearly see the operation of the printer on the first full print test:

It is noteworthy that it is impossible to stop and go to a new extrusion segment, as is usually the case in desktop FDM printers.

Therefore, we see that all products are made of a continuous thread of plastic, which gives them their own special style.

About meeting

Our acquaintance with the Frenchman happened at the Geek Picnic exhibition in August 2014 in St. our stands were opposite). We exhibited a large table printed on a 3D printer and our large 3D printer Tsar, and Sylvain brought several lamps, vases, one mini-chair and one large red chair:

I must say that Sylvain turned out to be a very nice person, and we We were happy to talk about various aspects of 3D printing news, new technologies, the nuances of 3D printing itself, and exchange experiences. He names his 3D printer Galatea, which, in my opinion, finally animates this complex and high-tech machine. By the way, the site says that he speaks 7 languages - a truly extraordinary person. Here it is, on the right in the photo:

He names his 3D printer Galatea, which, in my opinion, finally animates this complex and high-tech machine. By the way, the site says that he speaks 7 languages - a truly extraordinary person. Here it is, on the right in the photo:

Pro lamp

The Frenchman even gave us a 3D printed lamp from his collection! Therefore, let's examine the product in more detail. Outwardly, the lamp looks very cool:

And the first thing that catches your eye is the thick layers of plastic:

The thickness of the layer is almost as much as 5mm!

It immediately becomes clear to the sophisticated reader that this object was printed upside down. Otherwise, it would not be possible to print the upper hanging part. Let's turn it over to the position in which it was printed and see beautiful loops of frozen plastic:

And just a hole is drilled inside and a cartridge is inserted. Everything is simple.

I apologize for such an ugly light bulb and I hope that the author of this masterpiece will not be offended.

And finally, a video of the printing process of this lamp:

In conclusion,

3D printing is being applied in all areas. So far, these are the first experiments, but this cannot but rejoice - as we see in this case, it is possible to print really working furniture. nine0003

Albeit with limitations, though not the same as we are used to, but still furniture. I think this is a breakthrough, because the machine makes a product without human assistance, without waste, but at the same time, each product can be unique without an unrealistic increase in cost!

For me, this French project played a very important role, because I have the same goal - to create decorative objects using the magic of plastic fusing.

After talking with our French colleagues, it was decided to develop my project of a large 3D printer (Tsar 3D printer) in the direction of printing directly from granules.