Vdm 3d printing

Vascular Deformation Mapping (VDM) of thoracic aortic aneurysm: an application for color 3D printing in aortic disease - Burris

Editorial

Nicholas S. Burris1, Benjamin A. Hoff1,2, Brian D. Ross1,2,3

1Department of Radiology, University of Michigan, Ann Arbor, MI, USA;2Center for Molecular Imaging (CMI), University of Michigan, Ann Arbor, MI, USA;3Department of Biologic Chemistry, University of Michigan, Ann Arbor, MI, USA

Correspondence to: Nicholas S. Burris, MD. Department of Radiology, University of Michigan, 1500 E. Medical Center Drive, TC B1-132, SPC-5030, Ann Arbor, MI 48109-5030, USA. Email: [email protected].

Provenance: This is an invited Editorial commissioned by Section Editor Busheng Zhang, MD, PhD (Department of Cardiac Surgery, Shanghai Chest Hospital, Shanghai Jiao Tong University, Shanghai, China).

Comment on: Burris NS, Hoff BA, Kazerooni EA, et al. Vascular Deformation Mapping (VDM) of Thoracic Aortic Enlargement in Aneurysmal Disease and Dissection. Tomography 2017;3:163-73.

Submitted Dec 04, 2018. Accepted for publication Dec 10, 2018.

doi: 10.21037/atm.2018.12.16

3D printing is a rapidly evolving technology at the forefront of biomedical innovation and cardiovascular 3D printing is one of the most common medical applications (1). Technical advances in biomedical 3D printing have been driven by improved printer technology and image segmentation tools, however, clinical and research applications of cardiovascular are still catching up to such rapid technical advances. While traditionally medical 3D printing has focused on the creation of anatomical models from imaging data [e.g., computed tomography (CT), magnetic resonance imaging (MRI)] using a single material, recent advances in multi-material printing technology have allowed for generation of 3D printed models with variable properties such as flexibility and color. Material flexibility has been shown to be a particularly appealing property for cardiovascular applications in the field of structural heart disease, specifically for procedural planning in transcatheter aortic valve replacement (TAVR) where various valve size and design characteristics can be studied within a flexible, patient-specific model of the aortic root to determine optimal device selection and deployment (2). Additionally, physiologic properties of the diseased valve in aortic stenosis (e.g., pressure gradient, flow acceleration) can be simulated through the use of 3D printed models with tissue-specific elastic properties (3). Recent advances in 3D printing techniques have also allowed for the creation of models containing a full range of color. Full spectrum color 3D printing applications may be particularly useful for biomedical applications. One potential use of color 3D printing in biomedical 3D printing is to depict the relationship of anatomic and functional data using color-coded physiological data, essentially creating a model that fuses “form” and “function”.

Material flexibility has been shown to be a particularly appealing property for cardiovascular applications in the field of structural heart disease, specifically for procedural planning in transcatheter aortic valve replacement (TAVR) where various valve size and design characteristics can be studied within a flexible, patient-specific model of the aortic root to determine optimal device selection and deployment (2). Additionally, physiologic properties of the diseased valve in aortic stenosis (e.g., pressure gradient, flow acceleration) can be simulated through the use of 3D printed models with tissue-specific elastic properties (3). Recent advances in 3D printing techniques have also allowed for the creation of models containing a full range of color. Full spectrum color 3D printing applications may be particularly useful for biomedical applications. One potential use of color 3D printing in biomedical 3D printing is to depict the relationship of anatomic and functional data using color-coded physiological data, essentially creating a model that fuses “form” and “function”.

Our group has recently developed a novel image processing technique, termed Vascular Deformation Mapping (VDM), that yields a 3D assessment of aortic growth in patients with thoracic aortic aneurysm (TAA) (4). In brief, the VDM analysis workflow involves aortic segmentation of two computed tomography angiography (CTA) examinations, followed by image registration and measurement of local aortic wall deformation (i.e., strain) between baseline and follow-up time points using a spatial Jacobian analysis, which is then normalized by the time interval to yield aortic growth rate. The 3D nature of VDM allows for assessment of aortic enlargement along the entire length and circumference of the vessel wall and allows for aortic growth rate measurements to be depicted as a “heat map” that is superimposed on the patient’s aortic anatomy yielding a functionalized model. Given that the output of VDM analysis yields both anatomic and color-coded aortic growth data, the technique is well-suited for color 3D printing. As an example of the potential applicability of color 3D printing to VDM we present the case of a young patient with a rapidly expanding ascending aortic aneurysm who underwent CTA evaluation for the purposes of surgical planning (5). VDM analysis was performed as part of a retrospective institutional review board approved study. Results of VDM analysis were superimposed on a model of the patient’s thoracic aorta and were printed on a color 3D printer using PolyJet method (J750 3D Printer, Stratasys, Ltd.) (Figure 1). This patient’s VDM model clearly demonstrates high intensity growth (red) in the ascending aorta, with lower intensity gradations of growth involving the proximal portions of the aortic arch (yellow) and areas of stability (green) in the distal portions of the aortic arch. The color 3D printed model of this patient’s thoracic aorta was reviewed with the cardiac surgeon who had repaired this patient’s aneurysm and feedback was universally positive. Specifically, the surgeon noted that such models could help plan a surgical resection strategy that maximized removal of growing segments of aortic tissue, while preserving non-growing segments.

As an example of the potential applicability of color 3D printing to VDM we present the case of a young patient with a rapidly expanding ascending aortic aneurysm who underwent CTA evaluation for the purposes of surgical planning (5). VDM analysis was performed as part of a retrospective institutional review board approved study. Results of VDM analysis were superimposed on a model of the patient’s thoracic aorta and were printed on a color 3D printer using PolyJet method (J750 3D Printer, Stratasys, Ltd.) (Figure 1). This patient’s VDM model clearly demonstrates high intensity growth (red) in the ascending aorta, with lower intensity gradations of growth involving the proximal portions of the aortic arch (yellow) and areas of stability (green) in the distal portions of the aortic arch. The color 3D printed model of this patient’s thoracic aorta was reviewed with the cardiac surgeon who had repaired this patient’s aneurysm and feedback was universally positive. Specifically, the surgeon noted that such models could help plan a surgical resection strategy that maximized removal of growing segments of aortic tissue, while preserving non-growing segments. In this case, the coronary arteries were noted by the surgeon to arise from areas of growing proximal ascending aorta, suggesting the need for a surgical approach that requires coronary artery manipulation, thus increasing the technical demands of the surgical repair. An added benefit of 3D printing of VDM results is that surgeons are able to handle the functionalized model of the aorta and understand how the patient’s specific anatomical landmarks relate to the distribution of aortic growth considering that this relationship would have to be thoroughly understood by the surgeon to permit a selective aortic resection strategy in the operating room. Additionally, we believe that color 3D-printed models of VDM results could play an important role in pre-operative patient education. Many patients with aortic disease have a limited understanding of their disease process, creating barriers to optimal care. Additionally, patients are often asked to undertake aggressive pre-operative regimen (e.

In this case, the coronary arteries were noted by the surgeon to arise from areas of growing proximal ascending aorta, suggesting the need for a surgical approach that requires coronary artery manipulation, thus increasing the technical demands of the surgical repair. An added benefit of 3D printing of VDM results is that surgeons are able to handle the functionalized model of the aorta and understand how the patient’s specific anatomical landmarks relate to the distribution of aortic growth considering that this relationship would have to be thoroughly understood by the surgeon to permit a selective aortic resection strategy in the operating room. Additionally, we believe that color 3D-printed models of VDM results could play an important role in pre-operative patient education. Many patients with aortic disease have a limited understanding of their disease process, creating barriers to optimal care. Additionally, patients are often asked to undertake aggressive pre-operative regimen (e. g., dietary or lifestyle medications) to minimize their operative risks and we believe that the availability of a color 3D printed VDM model would allow surgeons to not only more effectively explain the surgical repair strategy, but also to more clearly confer the gravity of the patient’s aortic disease with the goal of increasing patient participation in decision making and engagement in their pre- and post-operative regimens.

g., dietary or lifestyle medications) to minimize their operative risks and we believe that the availability of a color 3D printed VDM model would allow surgeons to not only more effectively explain the surgical repair strategy, but also to more clearly confer the gravity of the patient’s aortic disease with the goal of increasing patient participation in decision making and engagement in their pre- and post-operative regimens.

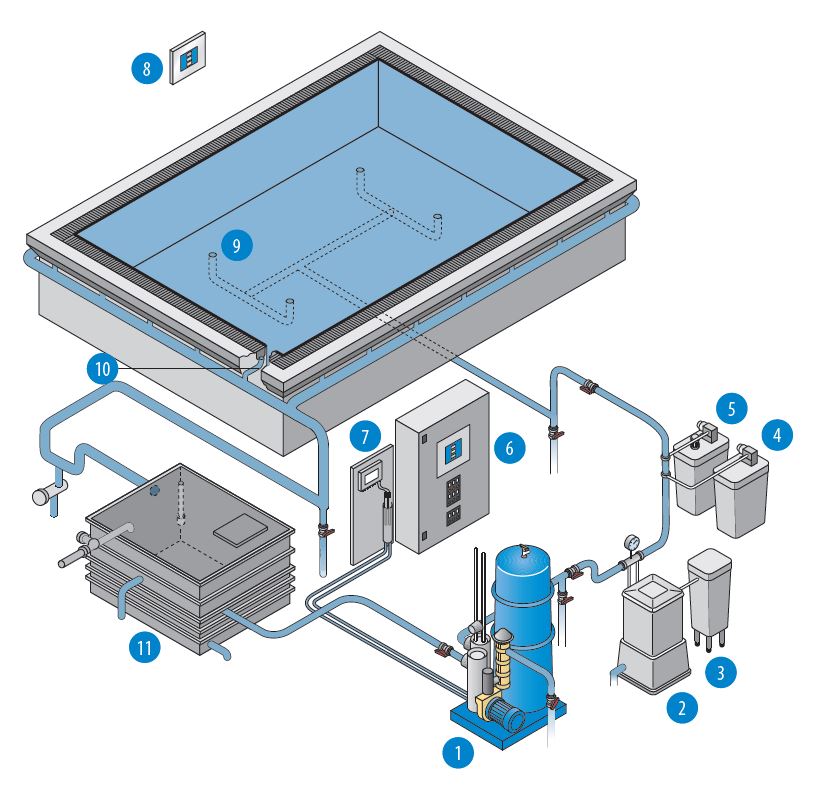

Figure 1 Photograph of a color 3D printed model of the VDM results shown in a left anterior oblique orientation, demonstrating heterogeneous growth in the thoracic aorta. The aorta model was printed using a digital CT image file using PolyJet 3D printing technique, which involves deposition of resin droplets that are cured through exposure to ultra violet light (J750 3D Printer, Stratasys, Ltd.). This process allowed for 3D printing resolution of 14 microns per layer and multi-material model composition in full color scale. Following printing of the aorta model, it was cleaned and clear coated to provide a glossy finish. Color 3D printed models could be valuable for both surgical planning and patient education purposes. VDM, Vascular Deformation Mapping; CT, computed tomography.

Following printing of the aorta model, it was cleaned and clear coated to provide a glossy finish. Color 3D printed models could be valuable for both surgical planning and patient education purposes. VDM, Vascular Deformation Mapping; CT, computed tomography.

Continued advancements in 3D printing technology have allowed for creation of increasingly sophisticated models composed of multiple materials with variable material stiffness and color among other properties. Beyond simply using color to differentiate certain anatomic structures (e.g., arteries vs. veins, left vs. right ventricle) we demonstrate that full spectrum color 3D printing could also be used to display the distribution of color-coded physiologic information on an anatomic model, adding a 4th dimension to a standard 3D model. In our specific application of color 3D printing in VDM, the functionalized model displays a patient specific aneurysm morphology with a color overlay of aortic growth measurements, although many other potentially useful physiologic parameters could be displayed in a similar manner. Examples of cardiovascular applications that could potentially benefit from color 3D printing with fused anatomic-physiologic data include atrial voltage/wall thickness mapping for atrial ablation planning, myocardial tissue characterization (e.g., T1, T2 and delayed enhancement mapping) prior to endomyocardial biopsy or ventricular ablation, and MRI-derived aortic wall shear stress mapping prior to aortic surgery (6-10).

Examples of cardiovascular applications that could potentially benefit from color 3D printing with fused anatomic-physiologic data include atrial voltage/wall thickness mapping for atrial ablation planning, myocardial tissue characterization (e.g., T1, T2 and delayed enhancement mapping) prior to endomyocardial biopsy or ventricular ablation, and MRI-derived aortic wall shear stress mapping prior to aortic surgery (6-10).

In summary, we believe that color 3D printing has many potential clinical and research applications in cardiovascular disease and highlight VDM assessment of aortic growth in TAA as an example of just one new potential application. In future work we hope to further improve our models with the addition of flexible and hollow materials with anatomically correct wall thickness to better simulate realistic aortic properties. As full spectrum color 3D printers become more widely available and affordable we envision many applications in advance surgical/procedural planning, patient education and biomedical research that will advance the understanding and treatment of cardiovascular disease.

Acknowledgements

None.

Footnote

Conflicts of Interest: The authors have no conflicts of interest to declare.

References

- Vukicevic M, Mosadegh B, Min JK, et al. Cardiac 3D Printing and its Future Directions. JACC Cardiovasc Imaging 2017;10:171-84. [Crossref] [PubMed]

- Ripley B, Kelil T, Cheezum MK, et al. 3D printing based on cardiac CT assists anatomic visualization prior to transcatheter aortic valve replacement. J Cardiovasc Comput Tomogr 2016;10:28-36. [Crossref] [PubMed]

- Maragiannis D, Jackson MS, Igo SR, et al. Replicating Patient-Specific Severe Aortic Valve Stenosis With Functional 3D Modeling. Circ Cardiovasc Imaging 2015;8:e003626. [Crossref] [PubMed]

- Burris NS, Hoff BA, Kazerooni EA, et al.

Vascular Deformation Mapping (VDM) of Thoracic Aortic Enlargement in Aneurysmal Disease and Dissection. Tomography 2017;3:163-73. [Crossref] [PubMed]

Vascular Deformation Mapping (VDM) of Thoracic Aortic Enlargement in Aneurysmal Disease and Dissection. Tomography 2017;3:163-73. [Crossref] [PubMed] - Burris NS, Hoff BA, Patel HJ, et al. Three-Dimensional Growth Analysis of Thoracic Aortic Aneurysm With Vascular Deformation Mapping. Circ Cardiovasc Imaging 2018;11:e008045. [Crossref] [PubMed]

- Bollache E, Fedak PW, van Ooij P, et al. Perioperative evaluation of regional aortic wall shear stress patterns in patients undergoing aortic valve and/or proximal thoracic aortic replacement. J Thorac Cardiovasc Surg 2018;155:2277-86.e2. [Crossref] [PubMed]

- Ferreira VM, Piechnik SK, Robson MD, et al. Myocardial tissue characterization by magnetic resonance imaging: novel applications of T1 and T2 mapping. J Thorac Imaging 2014;29:147-54. [Crossref] [PubMed]

- Bishop M, Rajani R, Plank G, et al. Three-dimensional atrial wall thickness maps to inform catheter ablation procedures for atrial fibrillation.

Europace 2016;18:376-83. [Crossref] [PubMed]

Europace 2016;18:376-83. [Crossref] [PubMed] - Rolf S, Hindricks G, Sommer P, et al. Electroanatomical mapping of atrial fibrillation: Review of the current techniques and advances. J Atr Fibrillation 2014;7:1140. [PubMed]

- Dickfeld T, Tian J, Ahmad G, et al. MRI-Guided ventricular tachycardia ablation: integration of late gadolinium-enhanced 3D scar in patients with implantable cardioverter-defibrillators. Circ Arrhythm Electrophysiol 2011;4:172-84. [Crossref] [PubMed]

Cite this article as: Burris NS, Hoff BA, Ross BD. Vascular Deformation Mapping (VDM) of thoracic aortic aneurysm: an application for color 3D printing in aortic disease. Ann Transl Med 2018;6(Suppl 2):S123. doi: 10.21037/atm.2018.12.16

VDM General Advice | ZBrush Docs

Pixologic

General Advice About Alpha 3D and VDM

This section contains assorted information about Alpha 3D and the associated VDM feature. These items are important to consider when you are creating or using such brushes.

These items are important to consider when you are creating or using such brushes.

Creation

- When creating an Alpha 3D, select the Standard Brush or the Chisel3D/Layer brush based on the results that you wish to achieve. The Layer/Chisel Brush will produce results closer to the original model stored in the brush. The Standard Brush will produce a result closer to that of a standard 2D alpha.

- When creating your VDM on a grid, it is advised to work with subdivision levels. Just as with regular sculpting, going up and down in levels during the creation process will bring you more flexibility than trying to work with a fixed resolution.

- The border of the grid defines elevation level 0 for the brush. You can push and pull the mesh during VDM creation to create parts which will cut into or extend out from the surface when using the Alpha 3D.

- Because VDMs store mesh data, avoid using unnecessary subdivision levels. High resolution VDMs may make brush strokes slow.

High resolution VDMs also result in brushes with a large file size.

High resolution VDMs also result in brushes with a large file size. - During the creation process, try to use as much of the grid area as possible. This will give better polygon distribution and avoid the need for too many subdivision levels.

- When sculpting, it can be very easy to accidentally deform the border of the grid. Masking the sculpted parts of the grid model and then using Deformation >> Morph to Grid will adjust the edges to be perfectly square again. However, it can also create steps along the boundary between the sculpted areas and the edges. You may need to smooth and redo the operation multiple times to get a nice transition.

- Instead of fixing the edges after sculpting, you can avoid affecting the edges in the first place by masking the borders of the grid before you begin sculpting. Be sure to clear the mask before subdividing the model and then reapply the mask after – otherwise you will get triangles along the edges of the masked area.

- If you need to delete subdivision levels in order to use functions like the Gizmo 3D Deformers to bend or twist, you will need to reconstruct those levels before you can use Deformations >> Morph to Grid. You can reconstruct the subdivision levels with Tool >> Geometry >> Recontruct Subdiv.

Usage

- When using an Alpha 3D brush, don’t forget that you can use different Stroke settings. For example, if you create a Dragon scale VDM you can combine it with the Stroke >> Dots stroke and a Stroke >> Lazy Mouse >> Lazy Step value close to 1. This would create strips of scales.

- Keep in mind that the VDM will deform the existing topology based on the shape stored in the brush. Depending on your brush radius and the actual stroke that you make, this can widely stretch other details close to your stroke.

- The standard alpha settings found in Alpha >> Modify have no effect on a VDM.

Become an insider

Sign up to access exclusive tools, giveaways & tutorials

Get Access

About right angles and diagonals

Technical

Subscribe to the author

Subscribe

Don't want

31

If you've been 3D printing for more than a day, you've already heard the term 'calibrate the table', and you need to ensure that the table is parallel to the extruder's plane of motion. Calibration is very important so that the first few layers stick to the table and are the same thickness.

Calibration is very important so that the first few layers stick to the table and are the same thickness.

But this opus is not about the calibration of your table. It's about how 'square' your printer's frame is. The planes of all axes should be perpendicular to each other, although this is not only important for the first layer to adhere well, it is more important to get the part printed properly, especially if you are trying to print mechanical elements that need to fit together. friend and have fairly tight tolerances. If you're getting prints that are slanted, or simply distorted, it's most likely your frame is not "square" in shape. Below is an image of the 3 main cases of frame out-of-square, even if the nozzle is level with the table plane. nine0003

The frame warp in these images is very exaggerated to make it easier to see the problem, in fact it is very hard to see by eye, but problems can occur when printing parts that need to be fitted and aligned to work together. I've designed a simple triangle that can be printed out to test the printer for squareness. Actually, you can print any box or anything like that with a flat base, with one side wall and front or back flat walls, I personally like the triangular piece better, I think it looks great! nine0003

I've designed a simple triangle that can be printed out to test the printer for squareness. Actually, you can print any box or anything like that with a flat base, with one side wall and front or back flat walls, I personally like the triangular piece better, I think it looks great! nine0003

Thingiverse -Triangle Square ThingieNow print it (or something). After printing, take a right triangle and check how well built your printer is. Honestly, it's best if possible to leave this part on the table. in this way it is easier to tell in which plane there is a problem and where it needs to be corrected.

After checking, if you determine which of the planes you need to adjust. The setup methodology will be very different depending on the printer model, so I won't get into it, but you can check with the manufacturer or the forums for your specific model. nine0003

But once you have checked and corrected any issues with the printer being "out of square", you will notice not only that the technical parts fit together better, but the "organic" prints should improve in visual quality.

----

P.S.

I do not claim authorship of this article. This is my frivolous translation http://3dprintingexp.blogspot.ru/2016/09/square-is-as-important-as-level.html

trust the cutouts in the frame, even in spite of laser cutting. I did this: assembled a 'breathing' frame, installed eyelets for attaching to the table, remembering that the diagonals of the rectangles are equal to , measuring the distances between the extreme points, brought out the guides, then fixed the eyes and continued the assembly. I suspect that a similar problem can be on steel frames.

Follow author

Subscribe

Don't want

31

Free EMPI VDM 3D file Steering wheel top・Model to download and 3D print・Cults

nine0004 Cap for Gaggia Achille coffee machine

Free

GoPro Hero 3 Black Variable ND Hood 55mm

Free

Best 3D Printer Files in the Miscellaneous Category

MiG I-270 Rocket Fighter

3. 15 €

15 €

10 inch e-drum pad with small 3d printer

Free

Railroad Track Section - Thomas & Friends

Free

Covid 19 Mask - COVID Pandemic Mask by Philippe de Bry

Free

Dinosaur BJD

10.72 €

Toy hair dryer

3.72 €

nine0004 Flexi Tracks : Turret Head Print in Place No Support2,50 €

ICE for OS-Railway - fully 3D-printable railway system!

Free

Bestsellers in Miscellaneous category

Predator-inspired movable mask

6.20 €

MMPR Dragon Dagger

4. 71 €

71 €

Charizard - pokemon with flexible articulation (seal in place, without supports)

3 €

Mickey Christmas night light Litophane

3,50 €

Gremlin rail 640 mm FPV

0,94 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2 €

nine0004 hinged shenron3 €

CHRISTMAS TREE v2

1,50 €

4th planet Fighting pre-Olympic god

12 €

ItsLitho "Creamy" personalized Lithophane Christmas ball

1,90 €

flexible volute

2 €

nine0004 THING - ENVIRONMENT - COMPANION - HD - PRINT €2. -55% 1.30 €  90

90

Chainsaw Man - Denji

€17.88 -fifty% 8.94 €

HAND OF THE ADDAMS FAMILY

5€ -25% 3.75 €

ItsLitho "Drop" personalized lithophane Christmas ball

1,90 €

Wednesday item

€3.81 -twenty% 3.05€

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.