Who makes 3d printer ink

5 Biggest 3D Printing Companies

DDD, PRLB, and FARO lead the 5 biggest 3D printing companies list

By

Nathan Reiff

Full Bio

Nathan Reiff has been writing expert articles and news about financial topics such as investing and trading, cryptocurrency, ETFs, and alternative investments on Investopedia since 2016.

Learn about our editorial policies

Updated August 01, 2022

Reviewed by

Thomas Brock

Reviewed by Thomas Brock

Full Bio

Thomas J. Brock is a CFA and CPA with more than 20 years of experience in various areas including investing, insurance portfolio management, finance and accounting, personal investment and financial planning advice, and development of educational materials about life insurance and annuities.

Learn about our Financial Review Board

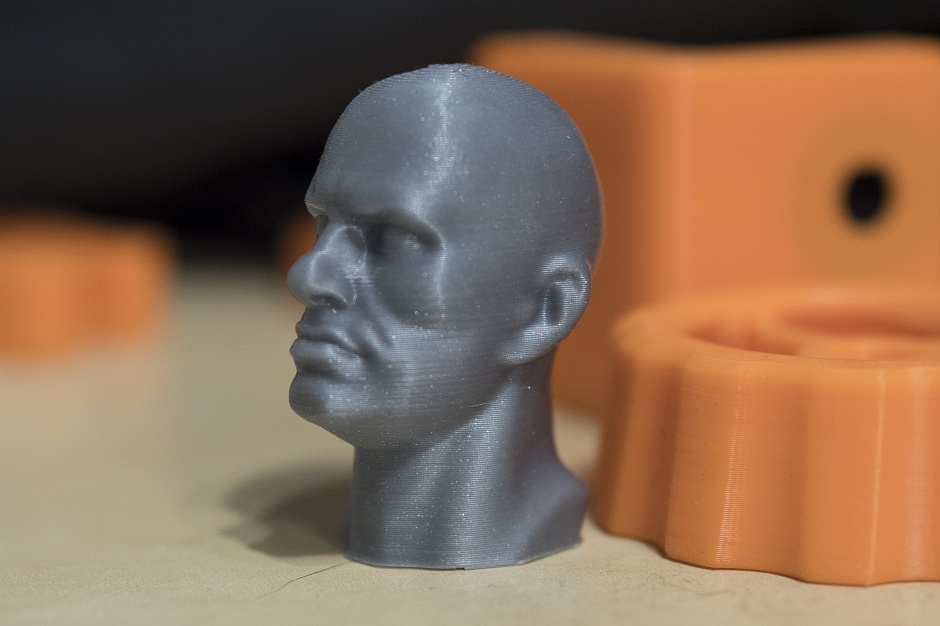

The manufacturing process known as 3D printing is one of the most promising and rapidly developing technologies with applications across a multitude of industries. 3D printing involves the additive layering of thin sheets of material that are fused together to create a physical product from a digital design. While the industry is currently hampered by relatively slow production times, advocates believe that 3D printing ultimately will have the capability to mass produce everything from medical equipment to automotive parts to airline components. Below, we look at the 5 biggest 3D printing companies by 12-month trailing (TTM) revenue. This list is limited to companies that are publicly traded in the U.S. or Canada, either directly or through ADRs. Some foreign companies may report semiannually, and so may have longer lag times. All data are from YCharts as of September 8, 2020.

- Revenue (TTM): $566.6 million

- Net Income (TTM): -$78.4 million

- Market Cap: $632.3 million

- 1-Year Trailing Total Return: -24.6%

- Exchange: New York Stock Exchange

3D Systems invented 3D printing in 1989 with the development and patenting of its stereolithography technology, which uses ultraviolet lasers to help create highly precise parts. DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

DDD built on that by developing new technologies, including selective laser sintering, multi-jet printing, film-transfer imaging, color jet printing, direct metal printing, and plastic jet printing. 3D Systems has three business units: products, materials, and services. The products category offers 3D printers and software and includes small desktop and commercial printers that print in plastics and other materials.

- Revenue (TTM): $451.0 million

- Net Income (TTM): $58.6 million

- Market Cap: $3.9 billion

- 1-Year Trailing Total Return: 58.2%

- Exchange: New York Stock Exchange

Proto Labs was founded in 1999 with a focus on building automated solutions to develop plastic and metal parts used in the manufacturing process. The company expanded to launch an industrial-grade 3D printing service that allowed developers and engineers to move prototypes into the production process. The company's primary business services include injection molding, sheet metal fabrication and 3D printing.

- Revenue (TTM): $334.7 million

- Net Income (TTM): -$79.7 million

- Market Cap: $1.0 billion

- 1-Year Trailing Total Return: 20.6%

- Exchange: NASDAQ

FARO specializes in 3D measurement and other services for the fields of architecture, engineering, and construction. With a 40-year history, FARO' began before the advent of 3D printing. The company's products include coordinate measuring machines, laser trackers and projectors, mappers, scanners, and software. FARO also serves the aerospace, automotive, and power generation industries.

- Revenue (TTM): $205.3 million

- Net Income (TTM): -$2.7 million

- Market Cap: $1.9 billion

- 1-Year Trailing Total Return: 94.8%

- Exchange: NASDAQ

Belgian company Materialise has a 30-year history providing 3D printing solutions and related software. It provides platforms to facilitate the development of 3D printing applications in industries such as healthcare, automotive, aerospace, and art and design. Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

Some of the company's first 3D printing activities included anatomical models in both dental and hearing aid products. Materialise also produces eyewear and automobile products.

- Revenue (TTM): $52.9 million

- Net Income (TTM): -$14.5 million

- Market Cap: $238.2 million

- 1-Year Trailing Total Return: 48.3%

- Exchange: NASDAQ

ExOne specializes in manufacturing 3D printing machines for customers across various industries. It also produces 3D printed products to specification for industrial customers. ExOne 3D printers utilize binder jetting technology, fusing powder particles of materials like metal or sand into molds, cores, and other products.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "YCharts."

3D Systems. "Our Story."

Materialise. "Timeline."

Top 3D Printer Manufacturers and Suppliers in the USA and Canada

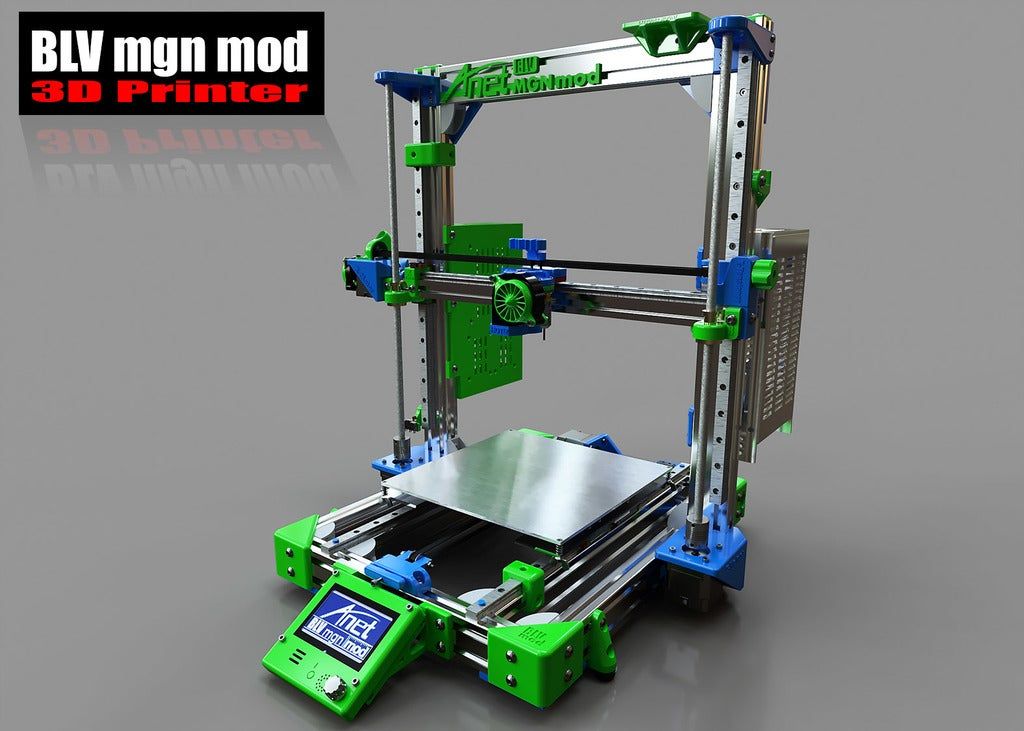

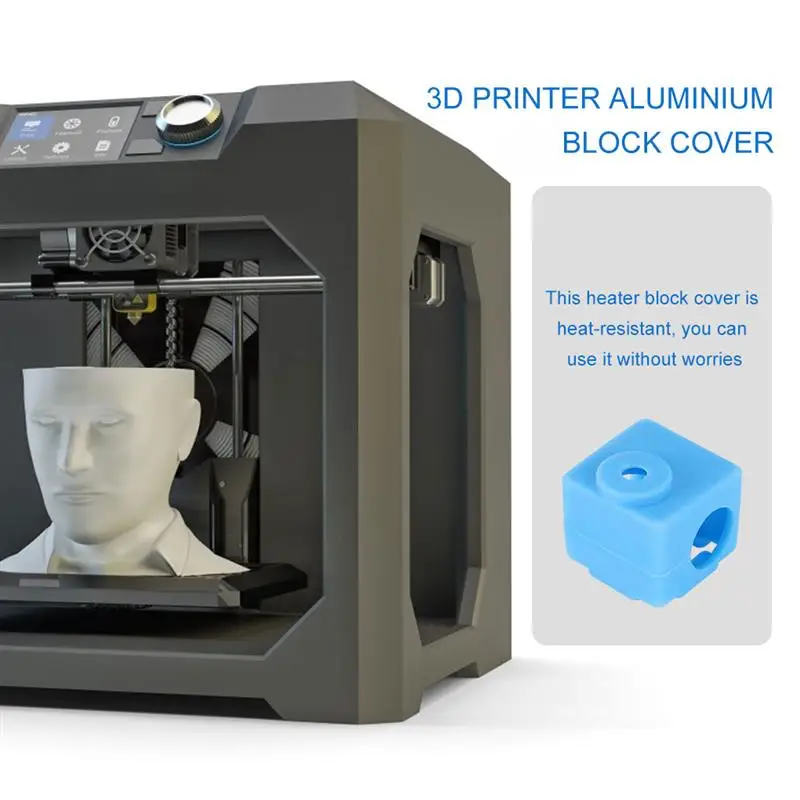

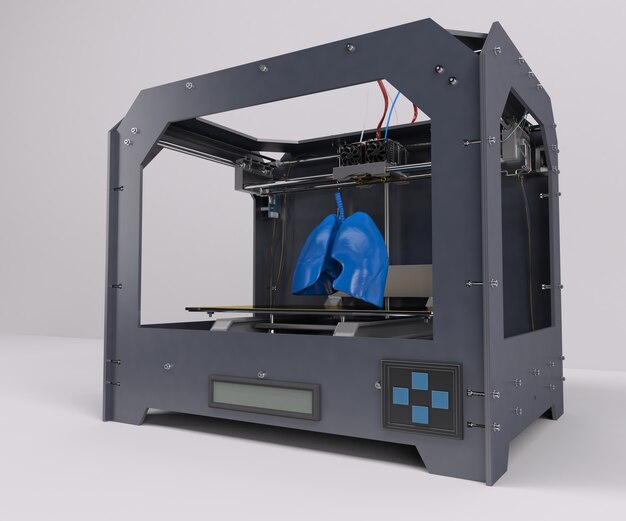

A 3D printer uses CAD to create 3D objects from a variety of materials,like molten plastic or powders

Image credit: Shutterstock/Aumm graphixphoto

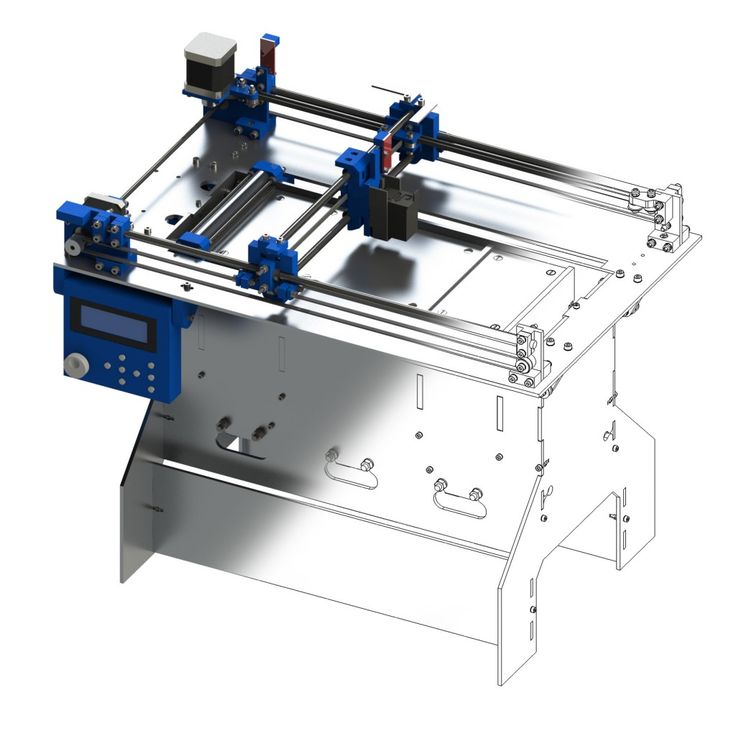

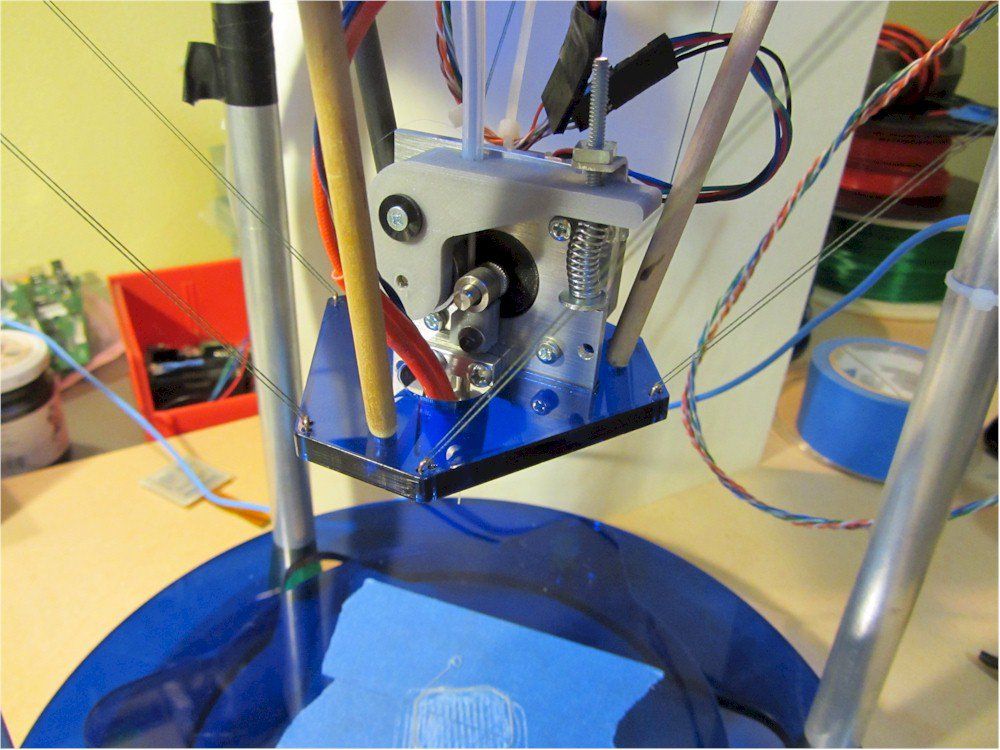

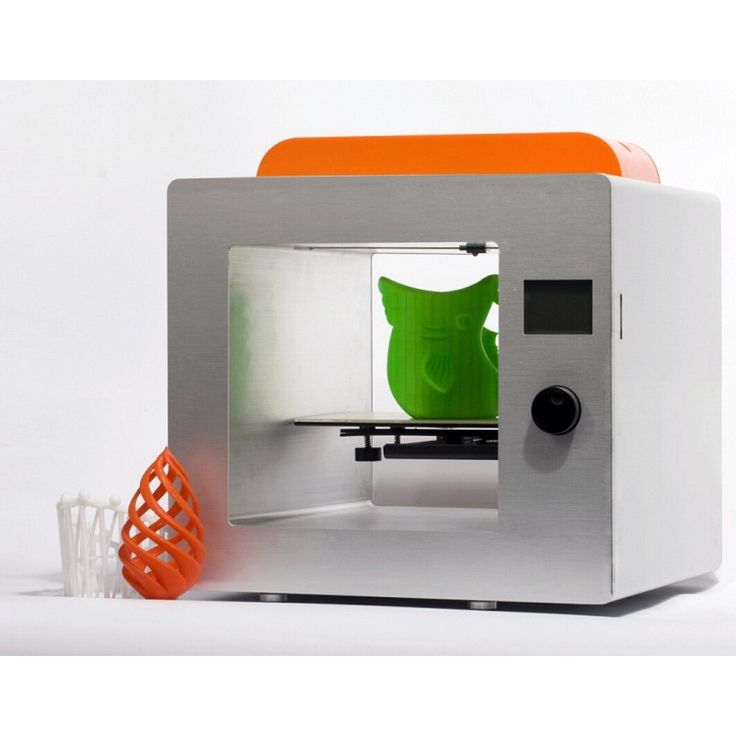

3D printers also called additive manufacturing printers or fabrication printers are a type of material design printer that designs and builds 3D models and products of devices and components using an additive manufacturing process.

3D printers design three-dimensional prototypes and create the end product by directly building them using computer-aided design (CAD) or software-created 3D design diagrams, figures, and patterns.

3D printers utilize additive manufacturing, where the printer designs the object by applying sequential layers of raw material to print a three-dimensional object.

In this article, we'll cover details on the top U.S. providers of 3D printers, along with our featured list of top 3D printer suppliers on Thomasnet.com.

Top Featured U.S. & Canada Suppliers of 3D Printers

Below is a list of featured suppliers of 3D printers from our platform. The company name, year, location, and employee count are also listed in the table.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Revenue |

| 1 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $100 - 249. |

| 2 | AON3D | 2015 | Montreal | QC | h3N1P4 | NA | NA |

| 3 | Nexa3D | NA | Ventura | CA | 93003 | 10-49 | $5 - 9.9 Mil |

| 4 | Terrafilum | 2017 | Cary | IL | 60013 | 1-9 | Under $1 Mil |

| 5 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $10 - 24. |

Company Summaries

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

Located in Montreal, QC, AON3D is an industry-leading manufacturer of high-temperature 3D printers. The company's printers prints with polyetheretherketone (PEEK), polyvinylidene fluoride (PVDF), polyphenylene sulfide (PPS), acrylonitrile butadiene styrene (ABS), thermoplastic elastomer (TPE), thermoplastic polyurethanes (TPU), polyphthalamide (PPA), polypropylene (PP), polyvinyl chloride (PVC), polycarbonate and nylon materials.

Nexa3D specializes in manufacturing 3D printers for engineering, dental, medical and education industries. The company is situated in Ventura, CA.

The company is situated in Ventura, CA.

Headquartered in Cary, IL, Terrafilum manufactures 3D printers since 2017. The company meets the demands of the commercial and educational sectors.

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Top U.S. Suppliers of 3D Printers Based on Sales

Below we have assembled information on the top suppliers of 3D printers in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

| Position | Company Name | Year Established | City | State | Zip | Employee Size | Sales Volume |

| 1 | HP Inc. | 1938 | Palo Alto | CA | 94304 | 500-999 | $118,004,000,000 |

| 2 | Trumpf, Inc. | 1934 | Farmington | CT | 06032 | 1000+ | $2,700,000,000 |

| 3 | Stratasys Ltd. | NA | Eden Prairie | MN | 55344 | 200-499 | $672,458,000 |

| 4 | Sciaky, Inc. | 1939 | Chicago | IL | 60638 | 50-99 | $107,000,000 |

| 5 | 3D Systems - Quickparts Solutions | 1986 | Atlanta | GA | 30346 | 50-99 | $99,999,999 |

| 6 | XYZprinting, Inc. | NA | San Diego | CA | 92121 | 200-499 | $75,000,000 |

| 7 | MakerBot Industries, LLC | 2009 | Brooklyn | NY | 11201 | 100-199 | $74,716,906 |

| 8 | MarkForged | NA | Cambridge | MA | 02138 | 100-199 | $30,000,000 |

| 9 | Mimaki USA | 1999 | Suwanee | GA | 30024 | 50-99 | $26,785,966 |

| 10 | Raise 3D Technologies, Inc. | 2018 | Irvine | CA | 92618 | 10-49 | $24,999,999 |

Company Summaries

With over 80 years of experience, HP Inc. is a manufacturer of 3D printers. The company meets the demands of consumer goods or electronics, orthotics, prosthetics, health care, medical, higher education, transportation, automotive, and aerospace industries.

Located in Farmington, CT, Trumpf, Inc. manufactures laser metal fusion (LMF) and laser metal deposition (LMD) printers for over 20 years. Data communications, electronics, photovoltaics, science, tool or mold making, transport, display, dental, aviation, aerospace, medical technology, jewelry, automotive, construction, and sheet metal processing are some of the industries served by the company.

Stratasys Ltd. manufactures 3D printers serving industries such as consumer products, aerospace, automotive, dental, medical, education, railway, art, fashion, and government. PolyJet, stereolithography (SLA), and fused deposition modeling (FDM) technology 3D printers are offered by the company.

Established in 1939, Sciaky, Inc. specializes in electron beam 3D printers for nuclear, medical, semiconductor, marine, aircraft, power generation, oil & gas sectors. The company uses materials such as titanium, tantalum, tungsten, niobium, aluminum, steel, and Inconel® for printing.

3D Systems - Quickparts Solutions manufactures metal, plastic, and casting 3D printers. The company meets the demands of motorsports, aerospace, defense, automotive, consumer technology, jewelry, semiconductor, truck, bus, rail, and turbomachinery markets.

Founded in 2013, XYZprinting, Inc. specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

specializes in 3D printers including fused filament fabrication (FFF), stereolithography (SLA), and digital light processing (DLP). The company is situated in San Diego, CA.

MakerBot Industries, LLC manufactures 3D printers that print with polymers, composites, and metal materials. Aerospace, automotive, education, and manufacturing are some of the industries served by the company.

MarkForged is a leader in manufacturing 3D printers that prints using materials such as continuous fibers, plastics, stainless steel, tool steel, copper, and Inconel®. The company serves consumer packaged goods, electronics, automotive, aerospace, education, research, energy, defense, federal, energy, and medical markets.

Founded in 1975, Mimaki USA specializes in manufacturing 3D printers. The company is headquartered in Suwanee, GA.

Raise 3D Technologies, Inc. is a leading manufacturer of industrial-grade 3D printers. The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

The company's 3D printers offer HEPA filters and WiFi, LAN, USB port and live camera connectivity.

Summary

With the help of the provided details on the 3D printer suppliers in the United States and Canada in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

You can also look at our Supplier Discovery page, which has information on more than 150 suppliers of 3D printers.

Trademark Notice

Sources

-

3D Printers

Other 3D Printing Articles

- Types of 3D Printing Technologies

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- All About Material Jetting

- All About Multi-Jet Modeling (MJM) 3D Printing

Other Top Suppliers Articles

- Top RFID Antenna Manufacturers USA and Internationally

- Top Thermocouple Manufacturers in the USA - By Revenue, Location and Product Type

- Top Suppliers of Integrated Circuit Design Services in the USA and Globally

- Top Industrial Automation Software Companies in the USA and Globally

- Top Cloud Services Providers and the USA and around the Globe

- Top Battery Enclosure Manufacturers and Suppliers in the US and Globally

- Top Proximity Sensors Suppliers and Manufacturers in the USA and Worldwide

- Top Resistor Suppliers and Manufacturers in the US and Globally

- Top RFID Tag Manufacturers in the USA and Internationally

- Top Temperature Sensors Manufacturers and Suppliers

- Top Cable Assembly Manufacturer Companies in the USA

- RFID Software Companies in the USA and Internationally

- Top Predictive Maintenance Companies in the USA and Globally

- Top Pipe and Tube Bending Companies in the USA

- Top EDM Services Suppliers in the USA

- Top RFID Reader Manufacturers and Suppliers in the USA and Internationally

- Top RFID Inventory Control Software Companies in the USA and Internationally

- Top U.

S. Screw Machining Service Suppliers

S. Screw Machining Service Suppliers - Top Sensors Manufacturers and Suppliers in the USA

- Top Graphene Companies and Manufacturers in the USA

- Top Suppliers of Polyvinyl Chloride (PVC)

Top Laboratory Supply Companies in the USNext Story »

More from Custom Manufacturing & Fabricating

Live ink for 3D printer

created

4684

Bookmark

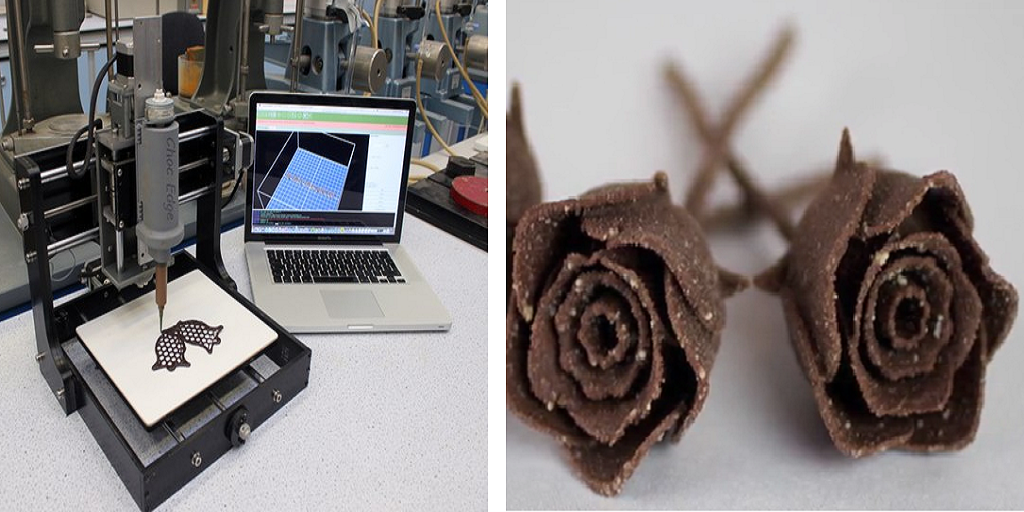

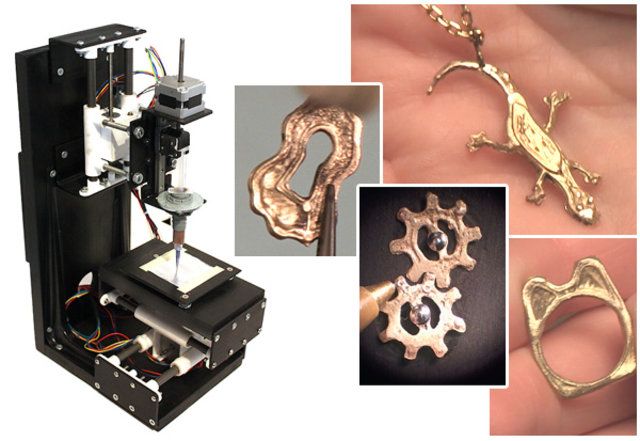

Manuel Schaffner of the Swiss Higher Technical School of Zurich and colleagues from Switzerland and Ireland created a "live" ink for a 3D printer - the ink contains bacteria. This means that 3D printers will now be able to print living materials capable of degrading toxins and facilitating organ transplant. Details of their development scientists outlined in an article published in S science Advances .

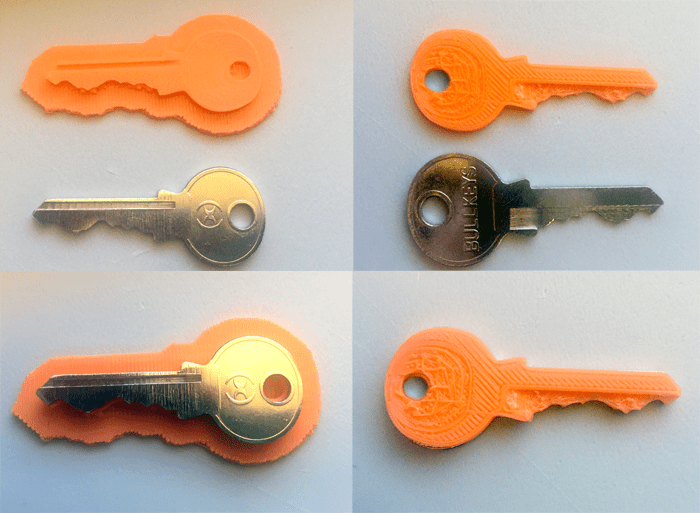

Traditional 3D printers use as ink powdered metals and plastics. They are great for making heavy-duty steel or even artificial bones, but not so good for making biocompatible materials, that require more flexibility, such as skin grafts.

This is where the new functional living ink comes in handy, called Flink. With Flink, researchers can type any amount of materials derived from bacteria, including elastic. Researchers have demonstrated this ability by printing materials with "embedded" bacteria Acetobacter xylinum . This bacterium makes cellulose, which can be used as a matrix for replacing skins and coverings for biomedical devices that help protect patients from organ rejection. Moreover, Flink researchers can print these materials in any 3D shape in one step.

Since any bacteria or combination of bacteria, Flink expands the range of possible applications of 3D printed materials - decomposition of toxins into environment, production of vitamins, generation of chemical energy through photosynthesis - which are impossible with using "lifeless" ink.

3D printing bacteria ink

Information provided by the Information Agency "Scientific Russia". Mass media registration certificate: IA No. ФС77-62580, issued Federal Service for Supervision of Communications, Information Technology and Mass Communications on July 31, 2015.

SCIENCE FOR CHILDREN

The development of scientists from the Perm Polytechnic University will allow the production of efficient industrial filters from ceramics

16:30 / Chemistry

Luminous protein will help assess the amount of calcium in yeast cells

15:30 / Biology

Head of the Ministry of Education and Science V. Falkov: science is now expected not from ratings and indices, but from specific technologies and developments

15 :00 / Science and society, Education

"Prometheus of the laser era". FIAN film dedicated to the 100th anniversary of Academician N. G. Basova

G. Basova

15:00 / Science and Society, Physics

MSU chemists came up with a system for home monitoring of diseases

14:30 / Health, Medicine, Chemistry

MSU geographers created the first detailed soil map of the Smolenskoye Poozerye National Park

13:30 / Geography

Physicists calculated how time crystals appear light

12:30 / Information technology, Physics

An innovative plant for the manufacture of artificial vessels has been developed in Russia

11:30 / Engineering

Chief Oncologist of Siberia. Anniversary of academician E.L. Choinzonova

10:00 / Health, Medicine, Science and Society

How arthropods sounded in the era of dinosaurs

19:00 / Paleontology

In memory of the great scientist. Science in the global world. "Obvious - incredible" broadcast 05/10/2008

03/04/2019

In memory of the great scientist. Nanotechnologies. "Obvious - incredible" broadcast 3. 08.2002

08.2002

03/04/2019

Remembering Sergey Petrovich Kapitsa

02/14/2017

The history of New Year holidays

08/01/2014

5Cellulose based 3D printing ink

3D printing

Researchers at the Swiss Institute for Quality Control and Laboratory Research EMPA have succeeded in developing an environmentally friendly 3D printing ink based on cellulose nanocrystals. This development can be used to produce microstructures with outstanding mechanical properties that will find applications in prosthetics and other medical fields.

To create 3D microstructured materials, EMPA used an additive 3D printing technology called robocasting (Direct Ink Writing, DIW). During this process, a viscous substance, the printing material, enters through the nozzle and immediately takes the desired shape due to pseudoplasticity. Dr. Gilberto Siqueira and Dr. Tanya Zimmerman of the Wood Materials Laboratory, together with Jennifer Lewis of Harvard University and André Studart of ETH Zurich, have succeeded in developing a new sustainable 3D printing material based on cellulose nanocrystals (CNC).

Along with lignin and hemicelluloses, cellulose is the main component of wood. This biopolymer is composed of glucose chains organized into long fibrous structures. In different areas, there is a different degree of ordering of cellulose fibrils. “Sites with a more ordered structure are characterized by a pronounced crystalline form, and it is these areas that we use for our research,” explains Dr. Siqueira. After acid treatment of these areas, the researchers obtain a product in the form of cellulose nanocrystals - rod-like structures 120 nm long and 6.5 nm in diameter. It was these formations that served as the material for creating environmentally friendly "ink" for 3D printing. On their basis, it was possible to obtain "ink" with a CNC content of about 20%, while previous developments contained no more than 2.5% of this biomaterial.

“The main challenge was to achieve a viscous elastic consistency so that the consumable could easily pass through the nozzles of the 3D printer,” says Dr. Siqueira. At the same time, the material had to be dense enough so that the model held its shape before drying or polymerization, without melting immediately after printing. The first "ink" with cellulose was water-based, which made the prototype very fragile. Therefore, the EMPA research team invented another method for manufacturing consumables, already based on a polymer. This method has a significant advantage: after printing and polymerization using UV study, cellulose nanocrystals are “glued together” by polymer blocks, which gives the composite material additional strength.

Siqueira. At the same time, the material had to be dense enough so that the model held its shape before drying or polymerization, without melting immediately after printing. The first "ink" with cellulose was water-based, which made the prototype very fragile. Therefore, the EMPA research team invented another method for manufacturing consumables, already based on a polymer. This method has a significant advantage: after printing and polymerization using UV study, cellulose nanocrystals are “glued together” by polymer blocks, which gives the composite material additional strength.

Despite resistance

Researchers admit that they had to seriously puzzle over the solution of individual problems. “Most polymers are water-repellent or hydrophobic, while cellulose, being hydrophilic, attracts water. As a result, they are incompatible,” laments Dr. Siqueira. To create favorable conditions, the scientists resorted to chemical CNC surface treatment.

After the first attempts at printing and X-ray analysis of the obtained microstructures, the laboratory specialists noticed that the cellulose nanocrystals were almost perfectly aligned in the direction of printing. It turned out that the degree of ordering depends on the force with which the “ink” is forced through the nozzles of the 3D printer. This feature can be used if it is necessary to obtain a model that has a certain rigidity in one direction or another.

It turned out that the degree of ordering depends on the force with which the “ink” is forced through the nozzles of the 3D printer. This feature can be used if it is necessary to obtain a model that has a certain rigidity in one direction or another.

A sea of possibilities

The above advantages of CNC proved to be decisive when compared to other materials such as carbon fibres. In addition, cellulose is a renewable material and the most abundant natural polymer on Earth. It is found not only in trees, but also in other plants and even bacteria. Crystals obtained by isolation from various sources differ from each other only in size, and not in properties.

The automotive and packaging industries can also use this versatile material, which can be chemically modified through 3D printing if needed. However, according to Dr. Siqueira, the most important application of "ink" with cellulose nanocrystals is biomedicine and prosthetics in particular.

The possibilities of new "inks" are currently being studied within the walls of EMPA. At the same time, the development of new environmentally friendly consumables for various areas of 3D printing is being carried out.

At the same time, the development of new environmentally friendly consumables for various areas of 3D printing is being carried out.

You can read about other 3D printing technologies in our review.

Follow the author

Follow

Don't want

2

More interesting articles

16

Subscribe to the author

Subscribe

Don't want

The use of 3D printers in construction is becoming commonplace. This year was no exception, even...

Read more

ten

Subscribe to the author

Subscribe

Don't want

Introduction

So, good day to all! This is my second post.

9 Mil

9 Mil 9 Mil

9 Mil