3D printed dnd figures

3d Printed Dnd Mini - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

An artist created 3D models of every D&D monster, and they’re all free

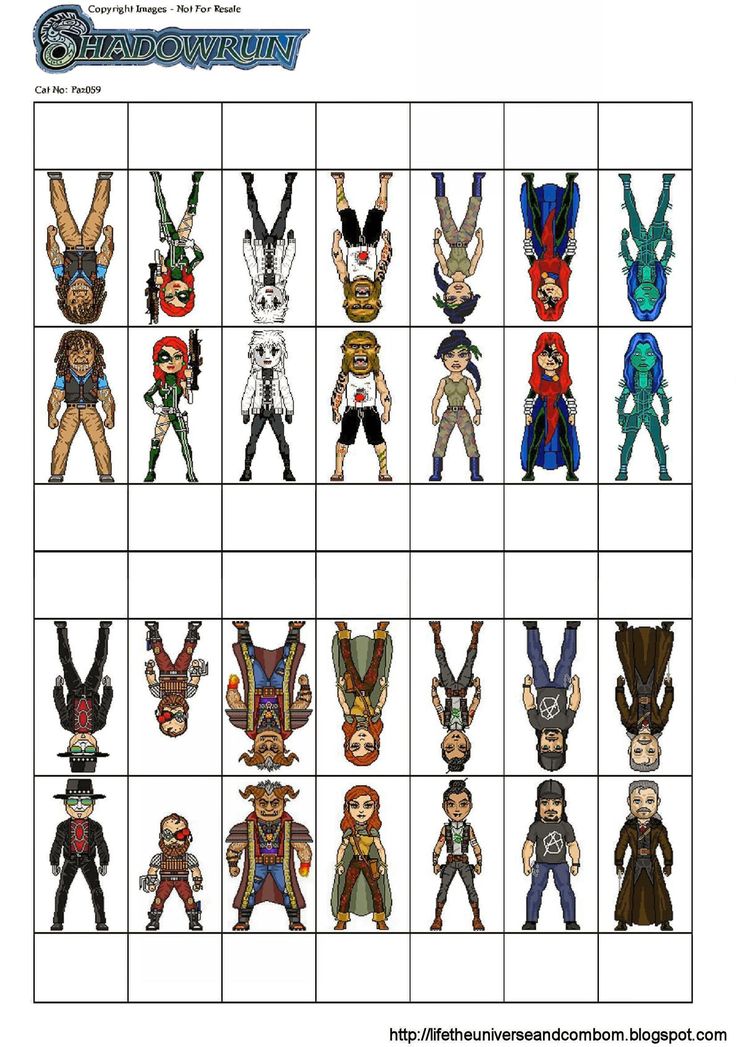

For more than five years, one man has been creating 3D models of every single monster in Dungeons & Dragons’ 5th edition, and giving away those digital files for free, so people with 3D printers can make them at home.

Miguel Zavala’s art project consists of more than 1,900 digital files, and he has nearly 3,000 paying subscribers supporting his work on Patreon. Polygon talked with Zavala about his work, and how (for the most part) he’s been able to avoid the ire of D&D’s publisher, Wizards of the Coast.

Zavala says he studied 3D modeling in college, but after a stint in the advertising industry he left it all behind. That’s until five years ago, when his wife inspired him to make a hobby of creating digital models for his own 3D printer. After getting a good response on Reddit, he started taking commissions for custom figures. Eventually that income became enough to pay the rent, he quit his day job to work at 3D modeling full time.

“I’ve made almost 2,000 models so far” Zavala said, “covering all of the D&D books all the way up to [Mordenkainen’s Tome of Foes]. It’s just been a hell of a ride.”

The income from his Patreon, where Zavala still does loads of custom commissions for his patrons and other D&D-adjacent work, now covers well more than just his rent. He also sells printed models of some of his minis online, but says the income from those is nominal at best.

He also sells printed models of some of his minis online, but says the income from those is nominal at best.

Is the publisher of D&D OK with this? Zavala says it is, now that he’s made some changes to his process.

A demonic alchemist that Zavala designed for one of his patrons.Photo: Miguel ZavalaFive years ago, Zavala says, Wizards actually cracked down on his project. All of his models were pulled offline for a time. That’s because he was using another online platform to host them, and the fine print on that website stated that the platform holder would automatically assume rights to his creations. Wizards didn’t like that, so Zavala switched over to Shapeways, which has different rules for creators, and he was allowed to resume his work.

“I reached out to them,” Zavala said, “and very honestly, it was just like, ‘Hey, I’m not trying to compete with you guys. I’m not trying to do anything like that. It’s just some people don’t have access to game stores, and some folks like to have a little extra creative balance in their games, and I make these things available for free. ’ [...] Once they understood that I wasn’t trying to make an easy buck off of this, they immediately opened up.”

’ [...] Once they understood that I wasn’t trying to make an easy buck off of this, they immediately opened up.”

Portions of D&D content are available to the public through the Open-Gaming License set up by Wizards. The publisher also has a formal policy on fan-created content. Zavala says he’s careful to follow those rules. All of the files themselves are available for free, and certain monsters — like named characters from D&D lore and other items that fall outside of the OGL — are only available as free digital downloads. You can find them all spread out across two different accounts on Shapeways. The first is called The DM Workshop, and the second is his own personal account.

“Wizards has been in contact with Miguel ‘mz4250’ Zavala,” a spokesperson at Wizards confirmed for Polygon. “He does nice sculpts, and we appreciate the creativity he brings to the hobby! As long as he’s following our Fan Policy and our [Open Game License], we don’t take issue with what he’s doing. D&D always encourages storytellers and creators to share what they are making with the community.”

D&D always encourages storytellers and creators to share what they are making with the community.”

Wizards has its own officially licensed lines of pre-painted miniatures, which are sold primarily in collectible blind boxes. There’s also a smaller line of unpainted miniatures, but only about 30 models are currently being produced. While they’re all very durable and high quality, there’s really nothing like the variety that Zavala’s free files can offer.

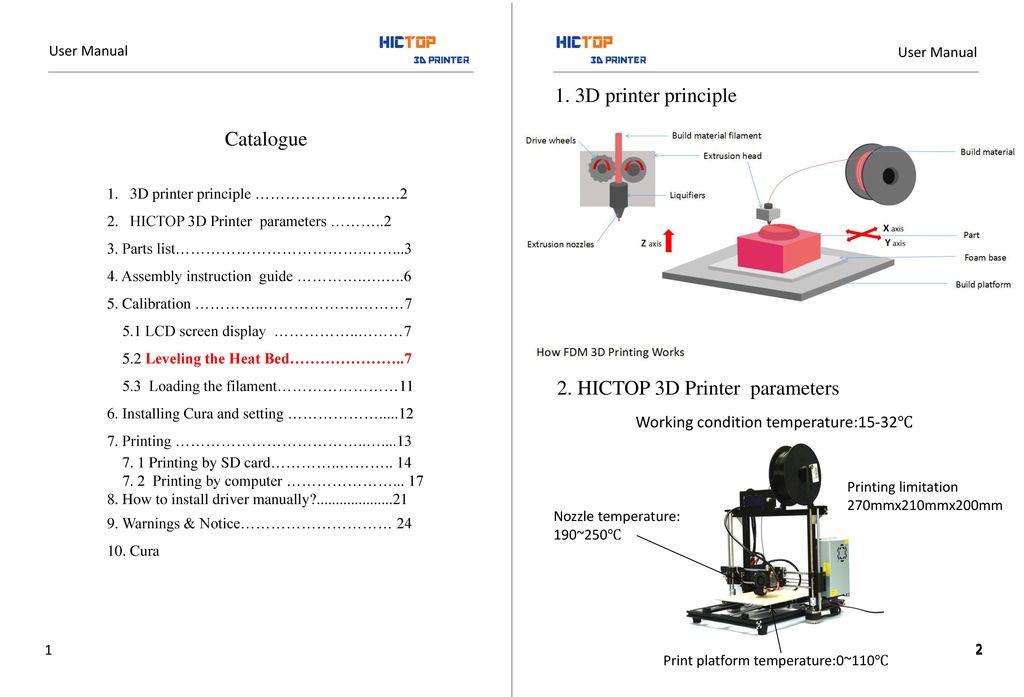

Part of the reason that his work has become so popular is because 3D printers have improved and become cheaper over the last few years. For at-home builds of single miniatures, Zavala recommends something like the Elegoo Mars or the Anycubic Photon, both of which you can find on Amazon for around $250. Zavala isn’t the only one doing work like this either. Other 3D modelers he recommends for D&D minis include Mia Kay and Duncan “Shadow” Luca.

Other 3D modelers he recommends for D&D minis include Mia Kay and Duncan “Shadow” Luca.

“I’m just going to continue improving my skills and, as the technology changes, I’ll adapt with that,” Zavala says. He’s spending lots of time converting his digital library into new file types that will be useful in virtual reality and augmented reality applications to come.

Elegoo Mars 2 3D printer

Prices taken at time of publishing.

- $300 at Amazon

Vox Media has affiliate partnerships. These do not influence editorial content, though Vox Media may earn commissions for products purchased via affiliate links. For more information, see our ethics policy.

free D&D figurine library, 2-phase silicone paste prototyping and 3D printed police jeep

News

In this episode, we'll be covering a huge free collection of Dungeons & Dragons action figure 3D models, an experimental Israeli 3D printed police jeep, and a two-phase silicone paste 3D printing technique.

So many monsters, so little time

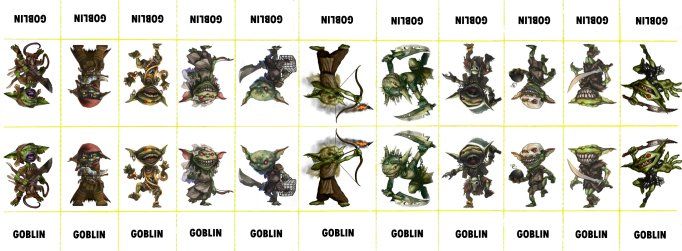

A year and a half ago, a die-hard Dungeons & Dragons fan named Miguel Savala took on a massive project - modeling all the monsters in the Monster Manual, including over three hundred dragons, orcs, trolls and other poisonous, winged and toothy mythical creatures. Now the project is officially completed, and D&D fans have the opportunity to download and print the necessary game figures.

The maker didn't stop with the monster guide alone, adding models from add-ons A and B, which include ordinary animals and various NPCs - bandits, peasants and others. The complete collection of 3D models is published on Shapeways and is available for free download after registration at this link.

The complete collection of 3D models is published on Shapeways and is available for free download after registration at this link.

3D printed police jeep

Visitors to the ISDEF 2017 International Exhibition of National Security and Civil Defense Industry in Tel Aviv were able to see an unusual car - a 3D printed police jeep, somewhat reminiscent of Strati from Local Motors.

Whether Local Motors was involved in the design is not disclosed, but it is known that the prototype with a 3D printed body was stuffed with a number of off-the-shelf components to reduce cost - a steering wheel from a Citroen Berlingo, power steering from a helicopter and an engine from an electric scooter. Interestingly, the license plate is decorated with the numbers "007". As the police explain, this is a tribute to the memory of Roger Moore - one of the performers of the role of James Bond, who died last month. Whether Israeli police or British secret agents will cut through such cars has not yet been specified.

3D Printing with Two Phase Silicone Paste

If you've ever dabbled in building sandcastles on a warm, sunny beach, you've got simple and eco-friendly silicone 3D printing technology right under your nose. The fact is that the adhesion of wet sand is ensured by the formation of water capillary bridges between the grains. The same principle was used by North Carolina State University scientists to develop their own silicone 3D printing technique.

Printing with uncured silicone is problematic due to the difficulty of balancing the fluidity required for extrusion and the viscosity required for shape retention. The scientists decided to test printing with a mixture of already cured silicone microparticles and liquid silicone. Silicone paste can be brought to the required consistency for extrusion by adding water. In this case, liquid silicone is added to the aqueous solution after the solid particles, and after mixing, it envelops them, allowing the particles to stick together, that is, to form the very “capillary bridges”.

After application, most of the weight load is on the solid particles. As a result, the likelihood of spreading of fresh layers is reduced. After printing is completed, the binding liquid material is cured by heating to 85°C, and the output is homogeneous, flexible, porous silicone products. The report of the research team is published at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow author

Follow

Don't want

6

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer.

In the framework of this article, I want to present my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this area, it’s hard to say why…

I probably considered it some kind of “childish pampering”, another hype topic for which there is simply not enough time…

The turning point happened when one of the wheels on my travel suitcase wore out . You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons.

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach . ..

..

As a result, I “upped” it - installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

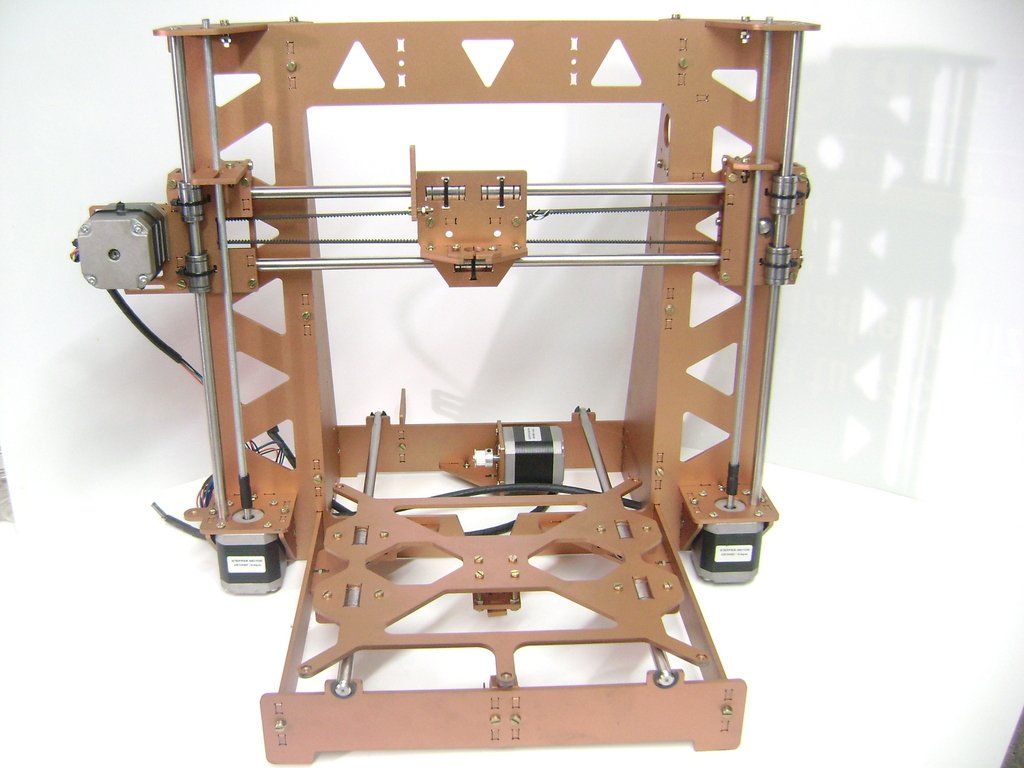

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even, one might say, hypnotizing :-))

And this, in fact, is my delta (if anyone is interested), which went through, let's say, “ultimate up”: all electronics are placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door is made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car ... The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc.

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material.

In my case, as such a material, I used a plastic film.

In my case, as such a material, I used a plastic film. - Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. “Size doesn't matter...” :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a little and I’ll start!!!”

Here you need to take into account one simple point: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you .

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get comfortable with the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

▍ NOTE 3. "What type of printer to get."

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”.

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse.com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so.

"Crutches" of course. But even so.

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties.

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

Just here I wanted to say that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements.

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it flakes, peels off the table, etc..."

With a properly configured printer (in my case, at a print temperature of 205 degrees, a thermal chamber and a desktop temperature of 100 degrees), the use of auxiliary techniques, for example, among which, one can name the so-called ABS juice (which is ABS- plastic dissolved in acetone), you can create wear-resistant and durable things, without any hypothetical problems.

For example, my printer has been printing for many hours at temperatures well below freezing. And this happened more than once, not twice, not three! And the print quality was excellent:

12 hour ABS printing at -4 C

At one time, I wrote a fairly detailed article on this topic and I will try to give the main excerpts from it. The essence of the issue here is as follows: due to the fact that different GOSTs are used for the production of acetone, acetone differs in quality. Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))).

In contrast, there is a much higher quality acetone, which, however, is not found at all in any household stores, even large chain stores, such as Auchan or Leroy Merlin.

This type of acetone is found exclusively in shops that sell varnishes and paints for automotive work - that is, these are highly specialized shops for car workshops:

Acetone, which can be purchased there, is of excellent quality, smells almost like alcohol, quickly disappears,

:-) - this is a joke, of course, don't even try it.

However, its main advantage, compared to household type acetone, is that it perfectly dissolves ABS plastic and does not allow it to precipitate. For me personally, it was a very surprising observation when the same ABS plastic was perfectly dissolved with acetone from an auto shop, and completely precipitated when I tried to use household acetone (I just ran out of good acetone, and I had to use "what is ").

Therefore, if you want your result to be always excellent, then here is the right acetone. It should be labeled "for professional use":

▍ NOTE 7.

What about ABS juice?

What about ABS juice? “ABS juice” is what printers call a mixture of acetone and pieces of ABS plastic dissolved in it. This mixture is smeared on the surface of the desktop before printing and allowed to dry. Thanks to this spread, the model easily sticks to the desktop and does not peel off during the printing process. After printing is completed and the platen has cooled down, the model can be easily separated.

All that needs to be said here is that, after trying different approaches over time, I settled on using flexible metal spatulas, also called “Japanese-style spatulas”:

According to the results of many tests, this method of spreading turned out to be one of the most convenient options, such spatulas can be cleaned very quickly and easily after work. In other words, highly recommended!

▍ NOTE 8. "Yes, nothing sensible can be done on it, I indulged a little and decided to sell it - you can't use it for anything good anyway"

I absolutely disagree with the statement above, which is periodically heard from newcomers to 3D printing. You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost factory quality! Of course, for this, the appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before!

You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost factory quality! Of course, for this, the appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before!

For example, among my homemade products, the following can be listed:

- Heated sole for boots, which is a hose integrated into the insole (and filled with household silicone from a household store), through which water flows, heated with a catalytic type hand warmer. Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater.

The project is currently in progress.

The project is currently in progress.

- Centrifugal water pump, mounted on the shaft of an internal combustion engine, which drives a portable high-pressure air compressor with a pressure of 500 bar. The pump pumps coolant through the casing of the high pressure pump, or rather its second stage. Despite the fact that the pump is 3D printed and runs at over 6000 rpm, nothing “fell apart, fell apart, didn’t break.” As you can see in the photo, the pump is installed instead of the “starter”, that is, the armstarter. The compressor scheme as a whole is as follows: 2 engines. Connected by clutch. One is heavy duty. The second is modified and turned into a high pressure compressor:

Yes, before assembling this, I also did not believe that this was possible. Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

- I printed a number of Rank-Hilsch test tubes, the essence of which I have described in detail in this article.

- Printed mass of parts, more than 100 pieces, to create 10 web-controlled robots. There was also a detailed article about this here.

Well, and a bunch of all sorts of useful and not very crafts. As you can see from my crafts above, I have a special passion for creating some useful things, a utilitarian direction. That is, so that the printout is useful, and does not belong to the type “yyy breathe, Mikola, what am I doing here” :-), and then put it on the shelf and that's it. Although, engineers are also not alien to beauties, and this will be my next fact below.

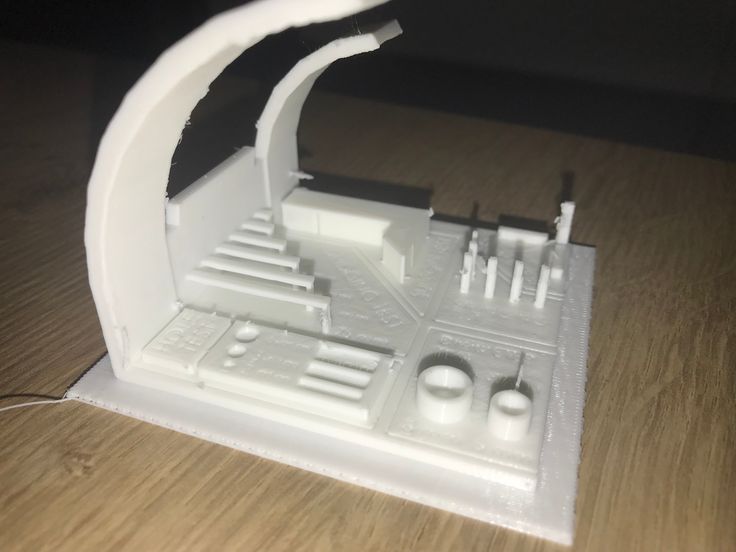

▍ NOTE 9 Proper placement of the model when printing is half the battle

It would seem an obvious fact, but many underestimate it. Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

This allows the layers in the printout to run at an angle of approximately 45-50 degrees to the model. The result of this is that the printed model is almost completely invisible layers and the model looks like it has been post-processed, but at the same time retains a deep matte color, which, to my personal taste, is more like a marble than a glossy result of processing in an acetone bath :

An additional advantage of this method is that the layers going at an angle of 45-50 ° to the model give it additional strength. This is especially true for printing statues, which contain many thin elements that easily break off when the statue is accidentally dropped from a table or shelf (learned from bitter experience, this happened to me many times, and ruined some fairly decent prints).

That is, the layers going across the model, if the model has a large extension in height, does not allow it to maintain sufficient strength. For better understanding, I tried to illustrate this point in the figures below:

▍ NOTE 10.

"Blurring" must be taken into account when printing, especially if the model is made up of separate parts and must be assembled by joining these parts to each other, entering into each other, etc.

"Blurring" must be taken into account when printing, especially if the model is made up of separate parts and must be assembled by joining these parts to each other, entering into each other, etc. I tried to illustrate this point in the figures below. The implication here is that if you're printing a composite model, you need to correct for the amount of bleed on the plastic (I'm not sure what it's called, but at least I tried to convey what I mean). If this is not taken into account, then the model will not fit.

For example, in my case this correction is 0.2 mm per diameter - if I want the model to fit more tightly; if I need a free joint, without excessive density, then 0.3 mm per diameter:

That is, suppose that the blue part has a size of 10x10mm. So it must be modeled in the CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is.

This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

For your specific case, the amendments may be different.

▍ NOTE 11. What if...

In fact, this note complements note number 8. Using a 3D printer allows you to create metal parts using a printed 3D model. For this, the casting method is used according to the lost wax or burnt model. In our case, we will deal mainly with casting metal on a burnt model.

Briefly, it looks like this: printing a 3D model (using PLA plastic) → pouring it with plaster → burning the PLA plastic, simultaneously with burning the mold, in a conventional stove oven → pouring the resulting shape with molten metal (melted in a conventional microwave) .

Image source: 3dtopo.com

I told about a simple method of melting metals in a home microwave oven here.

There was even a good article about casting on Habré.

▍ NOTE 12. Durability?

Despite the fact that ABS plastic is called exposed to ultraviolet radiation and, accordingly, burns out, losing its strength in the sun, in my practice, even printouts that are constantly exposed to the sun have not lost their strength and color at all, continuing to be successfully used and At the moment.

It should also be added here that printouts are constantly exposed not only to the rays of the sun, but also work continuously in damp conditions!

As such printouts, I can give an example of winglets for technical cranes, which I printed out, but, unfortunately, did not photograph this process; as well as fasteners on shoes that I use “both in the snow, and in the heat and in the pouring rain, and in general, always with me”:

▍ NOTE 13. And what about the thread?

Periodically, there is a need to print parts containing a particular thread.