3D printed differential

Differential best 3D printing files・Cults

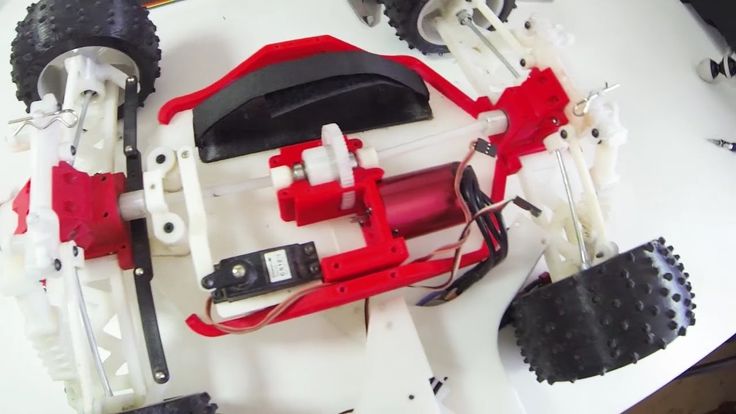

CRAMER Truggy RC 4x4 Full 3D Printed

€7.50

FUNNY CAR Rear End Differential N Brakes

€5.78

One Way Differential for 1:28 WlToys Mini-Z Drift models

Free

Reely New1 rc car differential

€2.91

Cylindrical gear - paired - z100 m2 D204 d30

€0.50

Cylindrical gear - paired - z100 m2 D204 d25

€0.50

Cylindrical gear - paired - z100 m2 D204 d20

€0.50

Cylindrical gear - paired - z99 m2 D202 d30

€0.50

Cylindrical gear - paired - z99 m2 D202 d25

€0. 50

Cylindrical gear - paired - z99 m2 D202 d20

€0.50

Cylindrical gear - paired - z98 m2 D200 d30

€0.50

Cylindrical gear - paired - z98 m2 D200 d25

€0.50

Cylindrical gear - paired - z98 m2 D200 d20

€0.50

Cylindrical gear - paired - z97 m2 D198 d30

€0.50

Cylindrical gear - paired - z97 m2 D198 d25

€0.50

Cylindrical gear - paired - z97 m2 D198 d20

€0.50

Cylindrical gear - paired - z96 m2 D196 d30

€0.50

Cylindrical gear - paired - z96 m2 D196 d25

€0.50

Cylindrical gear - paired - z96 m2 D196 d20

€0. 50

50

Cylindrical gear - paired - z95 m2 D194 d30

€0.50

Cylindrical gear - paired - z95 m2 D194 d25

€0.50

Cylindrical gear - paired - z95 m2 D194 d20

€0.50

Cylindrical gear - paired - z94 m2 D192 d30

€0.50

Cylindrical gear - paired - z94 m2 D192 d25

€0.50

Cylindrical gear - paired - z94 m2 D192 d20

€0.50

Cylindrical gear - paired - z93 m2 D190 d30

€0.50

Cylindrical gear - paired - z93 m2 D190 d25

€0.50

Cylindrical gear - paired - z93 m2 D190 d20

€0.50

Cylindrical gear - paired - z92 m2 D188 d30

€0. 50

50

Cylindrical gear - paired - z92 m2 D188 d25

€0.50

Cylindrical gear - paired - z92 m2 D188 d20

€0.50

Cylindrical gear - paired - z91 m2 D186 d30

€0.50

Cylindrical gear - paired - z91 m2 D186 d25

€0.50

Cylindrical gear - paired - z91 m2 D186 d20

€0.50

Cylindrical gear - paired - z90 m2 D184 d30

€0.50

Cylindrical gear - paired - z90 m2 D184 d25

€0.50

Cylindrical gear - paired - z90 m2 D184 d20

€0.50

Cylindrical gear - paired - z42 89 D182 d30

€0.50

Cylindrical gear - paired - z89 m2 D182 d25

€0. 50

50

Cylindrical gear - paired - z89 m2 D182 d20

€0.50

Cylindrical gear - paired - z88 m2 D180 d30

€0.50

Cylindrical gear - paired - z88 m2 D180 d25

€0.50

Cylindrical gear - paired - z88 m2 D180 d20

€0.50

Cylindrical gear - paired - z87 m2 D178 d30

€0.50

Cylindrical gear - paired - z87 m2 D178 d25

€0.50

Cylindrical gear - paired - z87 m2 D178 d25

€0.50

Cylindrical gear - paired - z87 m2 D178 d20

€0.50

Cylindrical gear - paired - z86 m2 D176 d30

€0.50

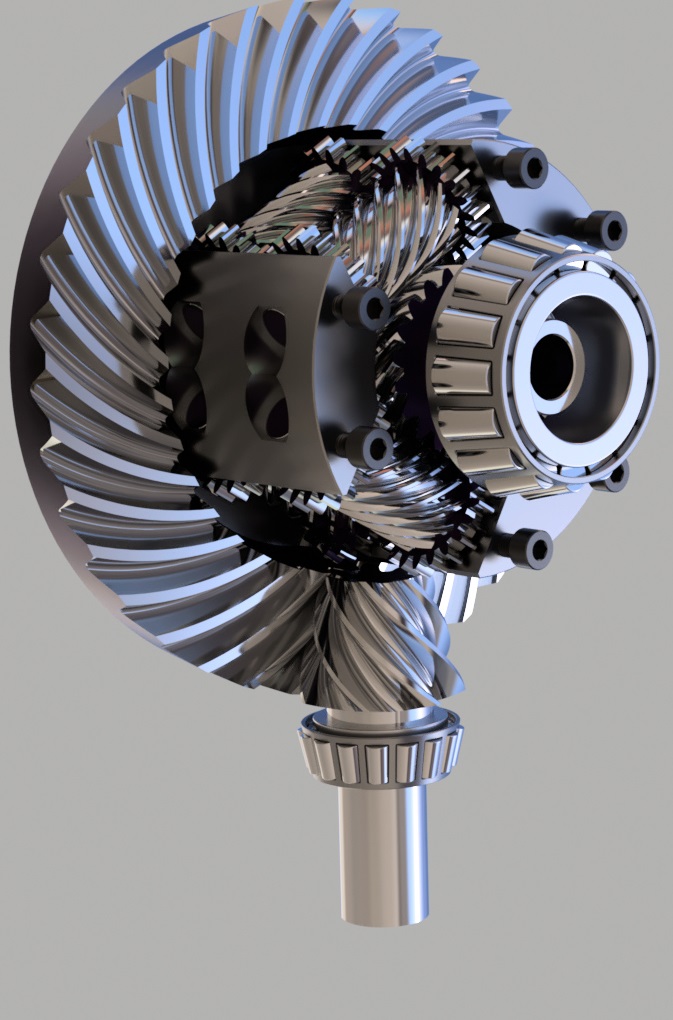

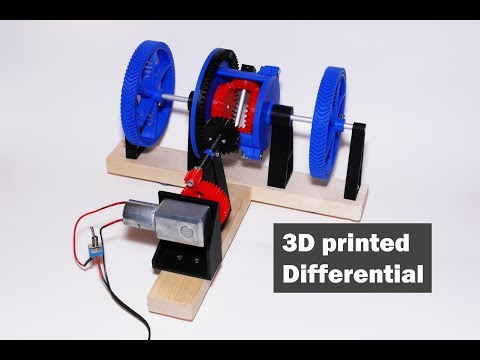

Differential Mechanism 3D Printing Model With Motor

-

Loading

Click to zoom

424 sales |

5 out of 5 stars €58. 90

90

Loading

Low in stock

VAT included (where applicable)

Explore related searches

-

mechanism

Explore more related searches

Listed on Oct 19, 2022

8 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

Differential. 3D printing | Manufacturing Company MG3D

Skip to main content

Differential

Differential

Differential

News

-

Photopolymer printing in various formats is in great demand in the field of high-speed production of various blanks. 3D printing with a photopolymer produces the highest detail of any object. Not only a special computer program helps in this, but also polymer resins applied in thin layers, which harden well under the action of laser beams or UV radiation.

Application of photopolymer printing

For projects that have a 3d model, or are just planned, design engineers will develop the necessary programs and select the right photopolymer.

In practice, SLA or DLP printing is most often used, a feature of which is high accuracy. The presence of layouts, in the form of samples, greatly facilitates the work with objects that have complex geometry.

In practice, SLA or DLP printing is most often used, a feature of which is high accuracy. The presence of layouts, in the form of samples, greatly facilitates the work with objects that have complex geometry. This includes factory-made industrial parts, jewelry and medical products. The order received for work is processed by special programs and editors, carefully checked, and only then they go to work.

Photopolymers are smooth plastic objects. Most often, acrylic is used for their manufacture. Printing with photopolymers occurs using a 3d printer. Each printing device has its own settings in microns (from 16), which create an accurate image. Simultaneously with the application of the thinnest layers of polymers, a support material in the form of a gel is applied.

More

-

3D printers print layers of 3D blanks. 3D printing is made from one or more liquid or solid materials in accordance with specified sizes and shapes (CAD).

During printing, physical or chemical processes of hardening or melting occur. Typical materials used in 3D printers are plastics, resins, ceramics, and metals.

During printing, physical or chemical processes of hardening or melting occur. Typical materials used in 3D printers are plastics, resins, ceramics, and metals. Read more

-

The 3D printing process must go through a series of specific steps, each with a different purpose. Each needs special attention.

Read more

-

The popularity of 3D printers does not fade from the moment this production is launched. Widespread use is explained very simply: you can get exclusive things in a matter of minutes, the most important thing is to create a 3d project. On the printer, you can print goods for children, clothes, interior items, tools and other things from different materials. 3D printing is a manufacturing process in which a 3D printer manages to print a three-dimensional part by applying several layers of a chosen material. For production, a developed 3d model is required. The scope of use is multifaceted: toys for children, home accessories, dishes, door handles, mobile phone cases, shelves and coasters for kitchens are printed on a 3D printer.

Anything can be printed on a 3d printer.

Anything can be printed on a 3d printer. Read more

-

Printing on 3D printers is used for most areas, with its help it is possible to create individual objects for play, education, design. This is a popular service: today printers are used not only in large-scale production, there are also home models.

Read more

-

Processing of 3d products is used to give an attractive appearance to the product, to create a glossy sheen. Different solutions can be used depending on the material from which the product is made. For details, you can not carry out finishing processing, since the appearance of the goods does not play a big role.

The appearance of products printed on a 3D printer directly depends on the technique and processing methods used. The surface of the products can be smooth or ribbed. And if the appearance is practically not important for details, when creating decorative elements, it is necessary that they be perfectly smooth and even.

In order to make products attractive, post-processing is used. Below we describe several types of equipment that are used to process materials, depending on the type of product, textures and their sizes.

In order to make products attractive, post-processing is used. Below we describe several types of equipment that are used to process materials, depending on the type of product, textures and their sizes. Chemical post-processing of 3D models

This is the most popular method for processing plastic products. Due to timely work performed, the product acquires a glossy sheen, and its edges look natural. The most important thing is to choose the right time for processing so as not to spoil the appearance. For cleaning, the following textures are most often used:Read more

-

Laser material processing is a production that is used in various fields. Thanks to the automated operation of the equipment, it is possible to quickly and accurately perform many works with materials of any thermal conductivity.

Thanks to scientific and technological progress, it is possible to improve the processing of various materials.

Today, a laser is used for this, after the touch of which the textures change beyond recognition. There are many reasons why laser processing of various materials is in demand. We will talk about them below.

Today, a laser is used for this, after the touch of which the textures change beyond recognition. There are many reasons why laser processing of various materials is in demand. We will talk about them below. Why laser processing is so popular

Different methods are used to process materials, but the laser deserves special attention. Below we describe why this production has not lost its relevance for several decades.

Fully automated process

In today's 21st century, many people want to move away from manual labor and work on special equipment. And laser processing completely falls under these parameters: the whole process is fully automated, you only need to set the necessary parameters.

Read more

-

Artistic processing of materials is a science that studies the effect of various methods on products in order to improve their appearance or reconstruction. Using different methods, it will be possible to apply beautiful ornaments, memorable dates, more important than inscriptions, to protect them from negative influences.

Read more

-

The company MG3D, whose main specialization is 3D printing, was contacted by a customer who wanted to create a model of the Moscow school No. 1520 named after the Kaptsovs. This is an old educational institution, built at the end of the century before last. The masters of the company took upon themselves the execution of the order for the manufacture of a detailed model of the school.

A separate difficulty of this order was that it was required to complete it in just three days. However, the MG3D masters did an excellent job with the task.

A school with an amazing history deserves professional treatment

Read more

-

MG3D was contacted by a customer whose task surprised even experienced craftsmen who have been busy with their business for more than a year. Namely, we ordered 200 fountain cutters, this is a small-scale production, and 3D printing as a method fit perfectly: cheaper, easier and faster than casting in industrial molds.

The conditions set by the customer required the MG3D team to use all their experience. After all, it was not only about an environmentally friendly, high-quality and durable product.

The conditions set by the customer required the MG3D team to use all their experience. After all, it was not only about an environmentally friendly, high-quality and durable product. What other requirements did the customer have for the product?

Checkout.

Contacts

To place an order, use the form on the left.

Leave your details and, if available, attach a file to explain your order.

Our specialist will contact you as soon as possible.

There are also other ways to contact us:

Moscow, st. Tvardovsky d. 8, building 1, floor 1, office 118

+7 (495) 204-21-30

Mon-Fri 10.00 - 19.00

Printing a car. Beware, there are many beautiful photos!

Creativity

Subscribe to the author

Subscribe

Don't want

43

Hello, dear participants of the portal!

After a long break, I will continue to write about people whose ideas have been successfully translated into reality with the help of 3D printing!

This project started last year, 2015. Then my friend came up to me and asked: 'Is it possible to print a car on a 3D printer?' To which I smiled and replied that you can print anything on a 3D printer, even your own house. However, as our conversation progressed...

Then my friend came up to me and asked: 'Is it possible to print a car on a 3D printer?' To which I smiled and replied that you can print anything on a 3D printer, even your own house. However, as our conversation progressed...

... the questions became more specific and the eyes more round. By the end of the conversation, before I noticed, we already had a work plan drawn up and instead of words, we moved on to actions.

Oh yes, I completely forgot.

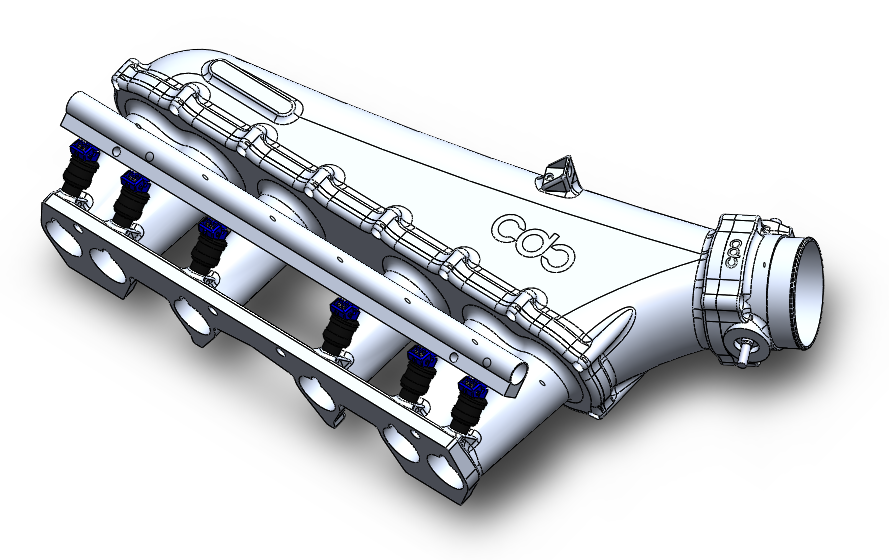

A young man, a student, a year later as an engineer, quite clearly set a goal - by all means, to print a 1:1 scale car transmission for his diploma, designed by him.

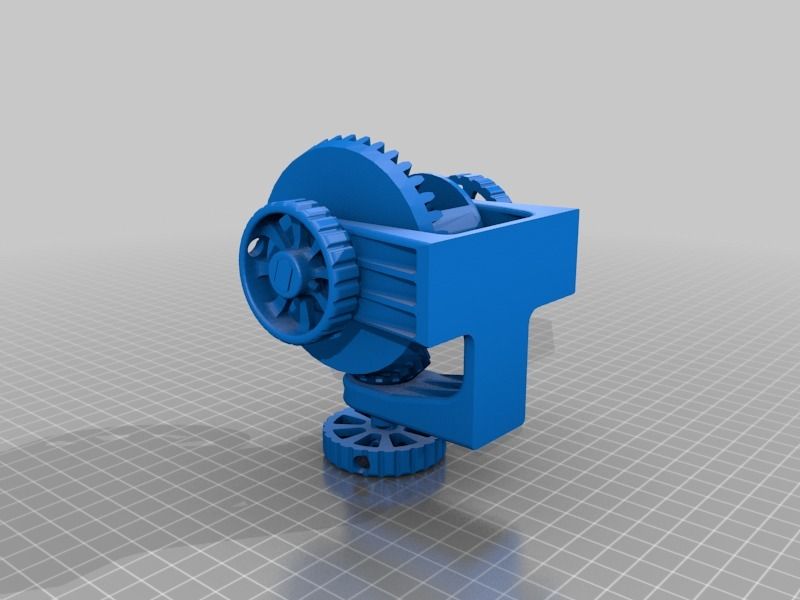

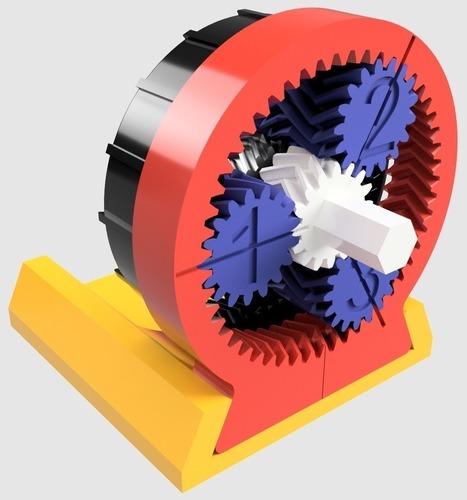

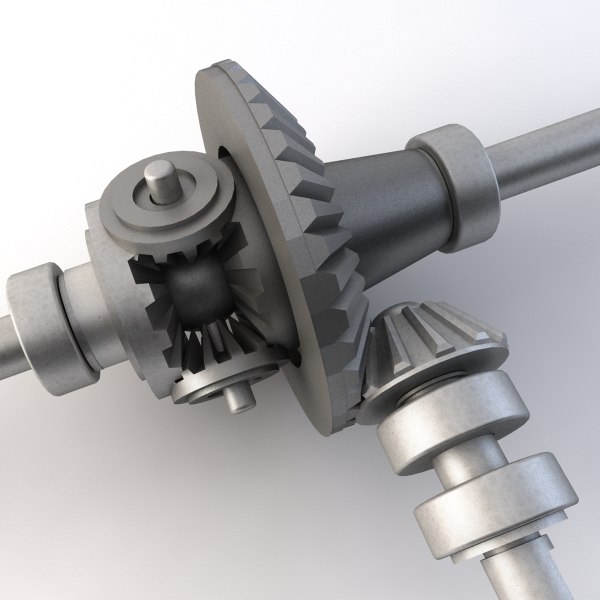

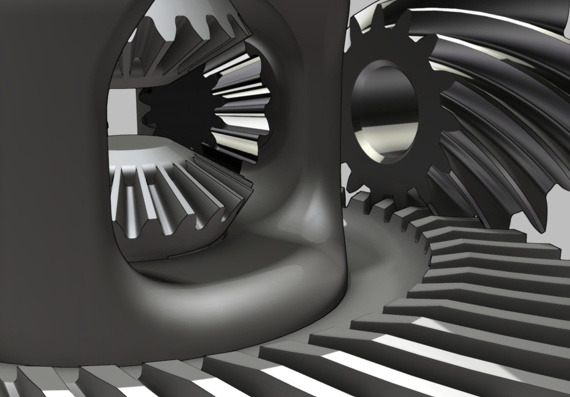

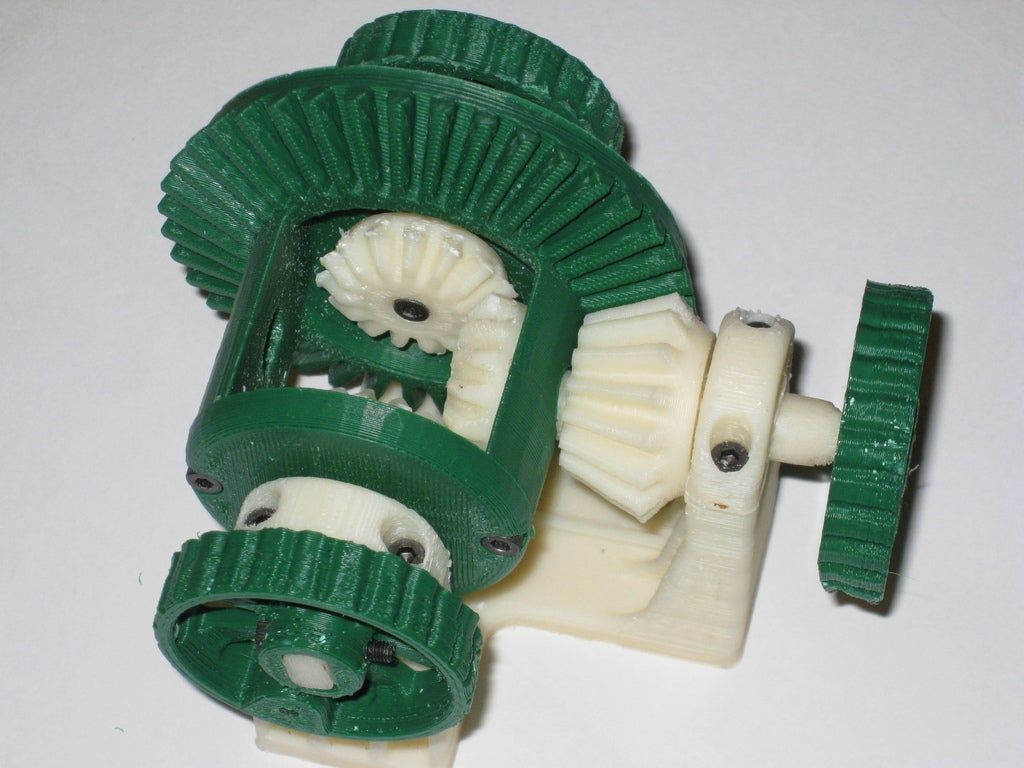

So, from words to deeds, we started small - we decided to print an interwheel self-locking differential.

After months of designing, the first result was obtained:

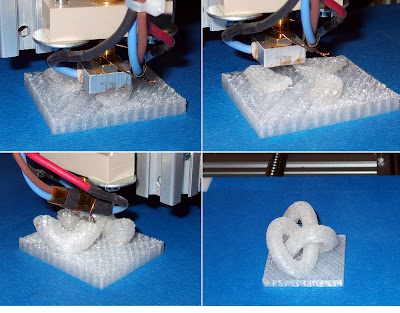

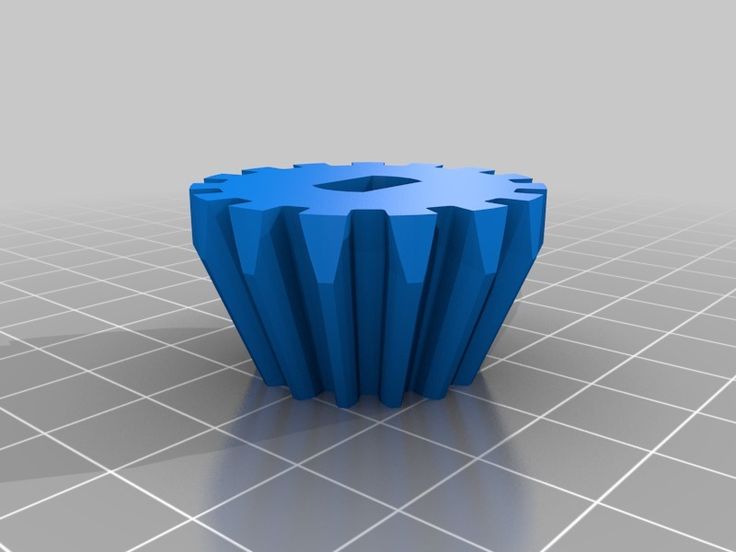

And we started printing. First of all, we decided to check how the driven gear is printed. By the way, one of the design conditions was that the outer diameter should not go beyond the dimensions of the working area of the 3D printer on which we printed: 200x200mm.

First pancake:

Why pancake? Yes, because the inner diameter turned out to be smaller, and the wheel did not sit on the body. This is what we discovered when we printed the corpus:

The corpus took more than four days to print.

By the way, we printed the driven gear and the differential housing on PRO 250, which the guys from Picaso 3D helped us find, as soon as I told about our project.

Many thanks to Picaso 3D!

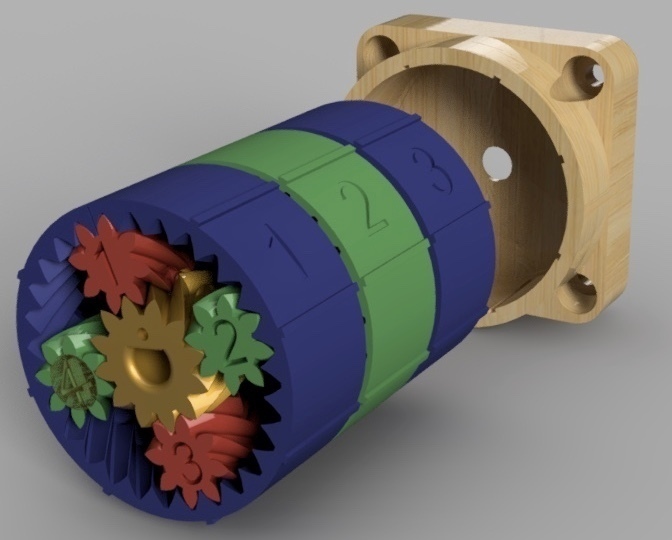

The rest of the parts have already been printed on the single nozzle Designer. Unfortunately, I don't have photos of the build process. I invite you, dear readers, to watch and enjoy the result. Of course, we are proud of what we have achieved:

The stripe on the yellow wheel is the result of gluing, because in the end we reprinted the gear on a simple Designer without supports.

In parallel, mat. differential model , on which we checked how it manifests itself when one wheel hits a site with less grip:

In the end, you always want to say 'And they lived happily ever after'.